$45

Heidenhain iTNC 530 Technical Manual 2013 -PDF DOWNLOAD

Heidenhain iTNC 530 Technical Manual 2013 -PDF DOWNLOAD

FILE DETAILS:

Heidenhain iTNC 530 Technical Manual 2013 -PDF DOWNLOAD

Language :English

Pages :1966

Downloadable : Yes

File Type : PDF

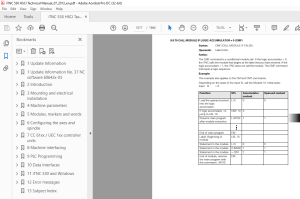

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Heidenhain iTNC 530 Technical Manual 2013 -PDF DOWNLOAD

1 Update Information

1.1 General information

- Update Information for the iTNC 530 HSCI appears at irregular intervals, often as part of a new software version. This is preliminary information in PDF format, containing brief descriptions of new software functions as well as new hardware components. After the Update Information has been published, the new items are included in the iTNC 530 HSCI Technical Manual.

- The Technical Manual and each Update Information are saved in the HEIDENHAIN HESIS-Web including Filebase on the Internet, where registered users can access them at Registered users of the HEIDENHAIN HESIS-Web including Filebase on the Internet receive an e-mail notification when a new Update Information appears.

- This version of the Technical Manual includes all Update Information documents of the iTNC 530 up to and including number 37, meaning that the contents of this Technical Manual for the iTNC 530 HSCI correspond to the scope of functions of software version 60642x-03.

TABLE OF CONTENTS:

Heidenhain iTNC 530 Technical Manual 2013 -PDF DOWNLOAD

1 Update Information 19

11 General information 19

1 Update Information No 37 NC software 60642x-03 21

11 Overview 21

111 Released service packs 21

12 Important notes 22

13 New software options 23

14 New machine parameters 24

15 New functions 29

16 Software option 144-Motion Adaptive Control (MAC) 41

17 DHCP server 43

18 VNC settings 49

19 PLC functions 53

2 Introduction 71

21 Meaning of the symbols used in this manual 71

22 Proper and intended operation 71

23 Trained personnel 71

24 General information 72

241 HSCI interface 75

25 Overview of components 76

251 MC 6xxx main computer, HDR or SSDR hard disk and SIK 76

252 CC 61xx controller unit 84

253 UEC 11x, UMC 11x controller unit with integrated inverter and PLC 86

254 PL 6xxx PLC input/output systems with HSCI interface 89

255 SPI expansion modules 93

256 PSL 13x low-voltage power supply unit 94

257 TE 6xx keyboard units 96

258 BF 2xx visual display units 101

259 MB 6xx machine operating panel 103

2510 HSCI adapter for PLB 6001 OEM-specific machine operating panel 105

2511 HR 4xx(FS), HR 5xx(FS) handwheels 106

2512 Industrial PC with Windows 7 113

2513 Key symbols 114

2514 Touch probes 119

2515 MS 110 / MS 111 installation kit 122

2516 Other accessories 123

2517 Documentation 126

26 Brief description 127

27 Software 139

271 Designation of the software 139

272 PLC software 140

273 Additional control loops or software options 140

274 Upgrade functions (feature content level) 150

275 NC software exchange on the iTNC 530 152

276 Availability of software versions, software options and FCL 164

277 Installing a service pack 167

278 Special features of the software 169

279 HEROS 5 operating system 172

2710 Functional safety (FS) 174

2711 Monitoring hardware changes 174

2712 SELinux 175

2713 Data backup 179

28 Released NC software 180

3 Mounting and electrical installation 181

31 General information 181

311 Safety precautions 181

312 Degrees of protection 182

313 Electromagnetic compatibility 182

314 ESD protection 183

32 Environmental conditions 185

321 Storage and operating temperatures 185

322 Heat generation and cooling 187

323 Limit values for ambient conditions 188

324 Installation elevation 188

325 Mounting attitude MC 6xxx, CC 61xx, UV xxx, UM xxx, UE 2xx B 189

326 Mounting attitude of UMC 111 (FS) 190

327 Mounting attitude of UEC 11x (FS) 191

328 Mounting attitude of MC 6222, MC 7222 192

329 Mounting attitude of CC 6106, UV xxx, UM xxx, UE 2xx B(D) 193

3210 Mounting attitude of PLB 6xxx 194

33 Handling the HDR hard disk 195

34 Mounting the Solid State Disk (SSD) 196

35 Overview of components 197

36 HSCI 204

361 Introduction 204

362 Topology 207

363 HSCI interface 208

37 iTNC 530 HSCI connection overview 209

371 MC 6241 209

372 MC 6242 210

373 MC 6222 211

374 MC 7222 212

375 MC 6341 213

376 IPC 6341 214

377 CC 6106 215

378 CC 6108 216

379 CC 6110 217

3710 UMC 111FS 218

3711 UMC 111 219

3712 UEC 11x 220

3713 PLB 62xx 221

3714 PLB 62xx FS 221

3715 PLB 61xx 222

3716 I/O modules PLD-H and PLA-H 223

38 Supply voltages in the HSCI system 226

381 Overview: Power supply for the iTNC 228

382 Current consumption of the HSCI components 229

383 X90: +24 V NC output of the UxC 11x (FS) 230

384 X101: NC power supply 231

385 Power supply of the CC 61xx 232

386 PSL 13x low-voltage power supply unit 237

39 MS 110 / MS 111 installation kit for double-row configuration 247

391 General information 247

392 Double-row configuration 248

393 Connection overview 250

310 UxC 11x (FS): Power supply and motor connection 254

3101 UMC 111 (FS) 254

3102 UEC 11x (FS) 257

311 UxC 11x (FS): Meaning of the LEDs 263

312 Power supply for PLC outputs 265

313 Power supply for PLB 6xxx (FS) 267

314 Meaning of the LED on PLB 6xxx 268

315 Power supply for control-is-ready signal 268

316 Digital PLC inputs/outputs 269

3161 UxC 11x (FS): Digital PLC inputs/outputs 278

317 Analog PLC inputs/outputs 285

318 PROFIBUS connection 288

319 PROFINET connection 289

320 Configuring the PLC inputs/outputs with IOconfig 291

321 Buffer battery 294

322 Encoder connections 296

3221 General information 296

3222 Position encoder input 297

3223 Speed encoder input 300

323 Adapters for encoder signals 304

324 Connecting the motor power modules (only CC 61xx) 307

325 Analog nominal value output 308

3251 CMA-H 04-04-00-Pin layout 310

326 Touch probes 313

327 MB 620 machine operating panel 317

328 Data interfaces 325

3281 USB interface (USB 20) 328

3282 HDL interface 329

329 MB 720 (FS) machine operating panel 330

330 HSCI adapter for PLB 6001 (FS) OEM-specific machine operating panel 341

331 TE 620 keyboard unit 355

332 TE 630 keyboard unit 356

333 TE 635Q (FS) keyboard unit 359

334 TE 645Q (FS) keyboard unit 360

335 TE 730, TE 720 keyboard unit 364

336 TE 735 (FS) keyboard unit 367

337 TE 740 keyboard unit 370

338 TE 745 (FS) keyboard unit 373

339 BF 250 15-inch TFT screen 377

340 BF 260 19-inch TFT display unit 379

341 Handwheel input 383

3411 HR 4xx (FS) or HR 5xx (FS) portable handwheel 383

3412 HR 520FS, HR 410FS safety-oriented electronic handwheels 387

3413 HR 550 handwheel with wireless transmission 393

3414 HR 410 portable handwheel 411

3415 HR 130 panel-mounted handwheel 413

3416 HRA 110 handwheel adapter 414

342 CML 110 capacitor module 416

343 Connecting cables: Specifications 418

344 Dimensions 419

3441 MC 6241 420

3442 MC 6341, MC 6x51, IPC 6341 421

3443 MC 6242 422

3444 MC 6222 423

3445 MC 7222 424

3446 MB 720 (FS) 425

3447 TE 635Q (FS) 426

3448 TE 645Q (FS) 427

3449 TE 720 428

34410 TE 730 429

34411 TE 735 (FS) 430

34412 TE 630 431

34413 TE 620 432

34414 TE 740 433

34415 TE 745 434

34416 BF 250 435

34417 BF 750 436

34418 BF 260 437

34419 BF 760 439

34420 CC 6106 440

34421 CC 6108 / CC 6110 441

34422 UMC 111 (FS) 442

34423 UEC 11x (FS) 443

34424 PL 6xxx (FS) 444

34425 PLB 6001(FS) 445

34426 PSL 130 446

34427 PSL 135 447

34428 MS 11x 448

34429 Adapter block for the data interface 449

34430 USB hub 450

34431 Line-drop compensator 451

34432 Handwheels 451

34433 Touch probes 457

34434 CML 110 464

34435 USB hub for operating panel 464

345 iTNC 530 HSCI grounding diagram with modular HEIDENHAIN inverter system-External PSL 13x 465

346 iTNC 530 HSCI grounding diagram with modular HEIDENHAIN inverter system-Power supply unit integrated in UV(R) 466

347 iTNC 530 HSCI basic circuit diagram 467

348 iTNC 530 HSCI cable overview-Basic configuration, MC in electrical cabinet 469

349 iTNC 530 HSCI cable overview-Basic configuration, MC in operating panel 470

350 iTNC 530 HSCI cable overview-Basic configuration, MC in electrical cabinet, UEC 1xx 471

351 iTNC 530 HSCI cable overview-Basic configuration, MC in operating panel, UEC 1xx 472

352 Cable overview for iTNC 530 HSCI with HEIDENHAIN inverter systems 473

353 iTNC 530 HSCI cable overview-Accessories 474

4 Machine parameters 475

41 What is a Machine Parameter? 475

42 The Machine Parameter Programming mode of operation 477

43 Input and output of machine parameters 478

431 Input format 478

432 Activating the machine parameter list 480

433 Changing the input values 480

44 List of machine parameters 494

441 Encoders and machines 494

442 Positioning 502

443 Operation with velocity feedforward control 510

444 Servo control with following error 511

445 Integrated speed and current control 512

446 Spindle 526

447 Integrated PLC 530

448 Configuration of the data interface 533

449 3-D touch probe 535

4410 Tool measurement with TT 537

4411 Tapping 542

4412 Display and operation 543

4413 Colors 553

4414 Machining and program run 557

4415 Hardware 566

4416 Second spindle 582

5 Modules, markers and words 583

51 Overview of modules 583

52 Overview of markers and words 591

6 Configuring the axes and spindle 603

61 Control loops 603

611 Selecting the axes 603

612 Axis designation 604

613 Encoders 606

614 Assignment for axes 614

615 Assignment for spindles 616

616 Specifications of the controller unit: 618

617 Reading axis information 621

618 Traverse ranges 623

619 Lubrication pulse 629

62 PLC axes 630

621 Coupling function for PLC axes or auxiliary axes 635

63 PLC positioning 640

64 Axis-error compensation 647

641 Backlash compensation 647

642 Linear axis error compensation 651

643 Nonlinear axis error compensation 652

644 Compensation of thermal expansion 659

645 Compensation of reversal spikes during circular traverse 661

646 Compensation of stick-slip friction 661

647 Compensation of sliding friction (only for digital axes) 662

648 Torsion compensation 663

649 KinematicsComp 664

6410 Software option 141-Cross Talk Compensation (CTC) 688

6411 Software option 142-Position Adaptive Control (PAC) 693

6412 Software option 143-Load Adaptive Control (LAC) 694

6413 Software option 144-Motion Adaptive Control (MAC) 697

6414 Software option 145-Active Chatter Control (ACC) 699

65 Tilting and swivel axes 701

651 Determining the mechanical offset 701

652 Description of the kinematics configuration 714

653 Temperature compensation with tilting axes 741

654 Changing the milling heads 745

655 KinematicsOpt 746

656 “Tilt working plane” feature 761

657 Automatic compensation of offset for tilting axes 770

658 Virtual tool axis 776

659 Tilting functions with open-loop rotary axes 776

6510 Cylindrical surface 777

66 Gantry/synchronized axes 778

661 Gantry axes 778

662 Master-slave torque control 782

663 Brake test for synchronized axes 792

67 Reference marks 796

671 Definition 796

672 Traversing the reference marks 797

68 The control loop 810

681 Relation between jerk, acceleration, velocity and distance 812

682 Interpolator 814

683 Position controller 832

684 Speed controller 848

685 Switching drives on and off 858

686 Current controller 866

687 Braking the drives for an emergency stop and a power failure 870

688 Power and torque limiting 873

689 Weakened field operation 880

69 Offset adjustment 890

691 Offset adjustment with integral factor 890

692 Offset adjustment by code number 890

610 Contouring behavior 891

6101 Radial acceleration 891

6102 Contour velocity at corners 892

611 Monitoring functions 894

6111 Position monitoring 896

6112 Nominal speed value monitoring 898

6113 Movement monitoring 899

6114 Standstill monitoring 900

6115 Positioning window 900

6116 Monitoring of the power supply unit 902

6117 Temperature monitoring 904

6118 Internal power supply and housing fan 907

6119 I2t monitoring 908

61110 Momentary utilization of drive motors 918

61111 Determining the current torque of a drive 920

61112 Status of HEIDENHAIN power modules 922

61113 Controlling the motor brakes 925

61114 Emergency stop monitoring 930

61115 EN 13849-1 on the iTNC 530 HSCI without functional safety (FS) 943

612 Spindle 944

6121 Position encoder of the spindle 945

6122 Speed encoder of the spindle 950

6123 Analog and digital closed-loop spindle control 952

6124 Coded output of spindle speed 965

6125 Volts-per-hertz control mode 967

6126 Oriented spindle stop 968

6127 Tapping with floating tap holder and nominal speed output 974

6128 Tapping with floating tap holder and coded spindle-speed output 976

6129 Rigid tapping 977

61210 Switching the modes of operation 980

61211 Operating a second spindle 985

61212 C-axis operation 987

61213 Software option 96-Advanced spindle interpolation 991

613 Integrated oscilloscope 992

614 Commissioning1004

6141 Tables for power modules, supply modules and motors1004

6142 Field orientation1019

6143 Preparation1020

6144 Commissioning digital control loops with TNCopt1023

6145 Commissioning of digital axes1026

6146 Commissioning the digital spindle1055

6147 Commissioning an analog axis1060

6148 Commissioning the analog spindle1064

615 Block diagram for iTNC 530 with CC 61xx1065

7 CC 61xx / UEC 1xx controller units1067

71 Specifications1067

72 Connecting the encoders1069

721 General information1069

722 Position encoders1069

723 Speed encoders1070

73 Relationship between speed input, position input and PWM output1071

74 Single-speed, double-speed, PWM frequency1072

741 General information1072

742 Single-speed and double-speed (software option 49)1074

743 Combination of several CC 61xx controller units1078

744 PWM frequency1082

75 PLC cycle time1087

76 Monitoring functions1087

77 Special functions1088

771 Multifunction filter1088

772 Filter order for separate low-pass filter in the speed controller1093

773 Dynamic determination of load1093

774 LIFTOFF function1098

775 TRC - Torque Ripple Compensation1101

776 Peculiarities in weakened-field operation1103

777 Crossover Position Filter (CPF)1104

78 Stick-slip friction compensation at quadrant transitions1106

79 Field orientation1108

791 Possibilities for determining the field angle1110

792 Determination of the field angle without motor motion (MP2254x = 0)1113

793 Determination of the field angle with motor motion (MP2254x = 2/3)1115

794 Reading or setting the field angle via the PLC1118

795 Saving the determined field angle1120

796 Definition of the field angle1121

710 Adjustment of linear and torque motors1122

7101 General information1122

7102 Safety precautions for linear and torque motors1126

711 Commissioning linear and torque motors1128

7111 Machine parameters for linear motors1128

7112 Machine parameters for torque motors1129

7113 Adjustment of the current controller1130

7114 Adjustment of the speed controller1133

712 Determining entries for motor tables1140

7121 Determining data for linear motors1140

7122 Determining data for torque motors1143

8 Machine interfacing1147

81 Display and operation1147

811 Position and status display1147

812 Operating modes1165

813 Operating times1169

814 Error messages1176

815 Service files1185

816 Help1189

817 PLC pop-up window1192

818 TNCguide - context-sensitive help system for the iTNC 530 (user documentation)1195

819 Machine datum1205

8110 NC program1210

8111 Adaptive feed control (AFC)1218

8112 Global program settings (PGM)1236

8113 Cycles1241

8114 End of program run1244

8115 Returning to the contour1244

8116 M functions1251

8117 Powering up and shutting down the control1260

8118 Arc end-point tolerance1263

8119 Limit-switch tolerance for M140 / M1501263

8120 Radius compensation1264

8121 User parameters1264

8122 Code numbers1265

8123 Programming station mode1267

8124 Color settings1267

8125 Graphic display1275

8126 Special characters1277

8127 iTNC character set1278

8128 Conversational language1283

8129 Logs1286

8130 Diagnostic functions1298

8131 BUS diagnosis1320

8132 Expanded PLC module interface for 18 axes1329

8133 Window manager1332

8134 Software option 133-Remote Desktop Manager1338

82 PLC window1354

821 Small PLC window1354

822 Large PLC window1358

83 PLC soft keys1372

831 Soft-key project file for screen1372

832 Soft-key project file for HR 420, HR 5xx1385

833 Soft-key rows1389

84 Keystroke simulation1392

841 iTNC control panel1392

842 Machine operating panel1404

843 Touchpad on USB port1405

85 Files1406

851 Datum tables (*D)1409

852 Freely definable tables1409

853 PLC files1419

86 DCM - Dynamic Collision Monitoring1424

861 DCM - monitoring the working space for collisions1424

862 Fixture monitoring with DCM1453

863 Tool carrier kinematics and DCM1477

864 KinematicsDesign1488

87 Pallet management1490

88 Electronic handwheel1502

881 HR 130 panel-mounted handwheel1510

882 HR 410 portable handwheel1510

883 HR 420 portable handwheel1513

884 HR 520 portable handwheel1516

885 HR 550FS wireless handwheel1518

886 HR 150 panel-mounted handwheels with HRA 110 handwheel adapter1524

89 PLC inputs/outputs1526

891 24 V- switching input/outputs1526

892 Analog inputs1529

893 Analog outputs1529

810 Incremental jog positioning1530

811 Hirth coupling1532

812 Datum shift1534

813 Touch probe1535

8131 Using the touch probes1536

8132 Touch probe cycles1539

8133 Measurement log in manual touch probe cycles1546

8134 Measurement log in the touch probe cycles for probing from the NC program1549

8135 Tool measurement1552

814 Special functions for laser cutting machines1561

8141 Analog voltage output1561

8142 Graphic simulation (without TOOL CALL)1563

8143 Program stop for M functions and TOOL CALL S1564

815 Tool changer1565

8151 Tool and pocket table1565

8152 Tool-usage test1597

8153 Automatic calculation of cutting data1601

8154 Automatic tool recognition1603

8155 Controlling the tool changer1603

8156 PLC programming example1629

8157 Extended tool management1641

9 PLC Programming1661

91 PLC Functions1661

911 Selecting the PLC mode1667

912 PLC main menu1667

913 File management1670

914 The WATCH LIST function1671

915 The I/O-FORCE LIST1674

916 The TABLE function1676

917 The TRACE function1678

918 The logic diagram1680

919 The COMPILE function1682

9110 ADVANCED SETUP1683

92 Conditional Compilation1684

93 Hard-Disk Organization1689

931 Encrypted PLC partition (PLCE:)1690

94 System Files1701

941 OEMSYS1701

942 NCMACROSYS1709

943 MGROUPSSYS1712

944 MSPLITSYS1712

945 PLCSOFTKSYS1712

946 CYCLESYS1712

947 TNCSYS1712

95 Data Transfer NC > PLC, PLC > NC1713

951 Data transfer NC program > PLC (FN19: PLC =)1713

952 Data transfer PLC > NC program (Q-parameters)1714

953 Data transfer NC program > NC (FN17: SYSWRITE)1716

954 Data transfer NC > NC program (FN18: SYSREAD)1725

955 Data transfer of machine parameters > PLC1737

956 Interrogate PLC operands in the NC program (FN20: WAIT FOR)1740

957 Data transfer PLC operand <=> NC program1741

96 Operands1744

961 Overview of operands1744

962 Operand addressing (byte, word and double word)1747

963 Timers1748

964 Counters1751

965 Fast PLC inputs1753

97 Program Creation1754

971 ASCII editor1755

972 Program format1755

973 Program structure1756

974 Logical names for files1757

98 Command Set1758

981 Overview1758

982 LOAD (L)1761

983 LOAD NOT (LN)1763

984 LOAD TWO’S COMPLEMENT (L-)1765

985 LOAD BYTE (LB)1766

986 LOAD WORD (LW)1766

987 LOAD DOUBLE WORD (LD)1767

988 ASSIGN (=)1767

989 ASSIGN BYTE (B=)1768

9810 ASSIGN WORD (W=)1769

9811 ASSIGN DOUBLE WORD (D=)1769

9812 ASSIGN NOT (=N)1770

9813 ASSIGN TWO’S COMPLEMENT (=-)1770

9814 SET (S)1771

9815 RESET (R)1772

9816 SET NOT (SN)1773

9817 RESET NOT (RN)1774

9818 AND (A)1775

9819 AND NOT (AN)1777

9820 OR (O)1779

9821 OR NOT (ON)1781

9822 EXCLUSIVE OR (XO)1783

9823 EXCLUSIVE OR NOT (XON)1785

9824 ADDITION (+)1787

9825 SUBTRACTION (-)1788

9826 MULTIPLICATION (X)1789

9827 DIVISION (/)1790

9828 REMAINDER (MOD)1791

9829 INCREMENT (INC)1792

9830 DECREMENT (DEC)1792

9831 EQUAL TO (==)1793

9832 LESS THAN (<)1794

9833 GREATER THAN (>)1795

9834 LESS THAN OR EQUAL TO (<=)1796

9835 GREATER THAN OR EQUAL TO (>=)1797

9836 NOT EQUAL (<>)1798

9837 AND [ ] (A[ ])1799

9838 AND NOT [ ] (AN[ ])1801

9839 OR [ ] (O[ ])1801

9840 OR NOT [ ] (ON[ ])1801

9841 EXCLUSIVE OR [ ] (XO[ ])1801

9842 EXCLUSIVE OR NOT [ ] (XON[ ])1801

9843 ADDITION [ ] (+[ ])1802

9844 SUBTRACT [ ] (-[ ])1803

9845 MULTIPLY [ ] (x[ ])1803

9846 DIVIDE [ ] (/[ ])1803

9847 REMAINDER [ ] (MOD[ ])1803

9848 EQUAL TO [ ] (==[ ])1804

9849 LESS THAN [ ] (<[ ])1805

9850 GREATER THAN [ ] (>[ ])1805

9851 LESS THAN OR EQUAL TO [ ] (<=[ ])1805

9852 GREATER THAN OR EQUAL TO [ ] (>=[ ])1805

9853 NOT EQUAL [ ] (<>[ ])1805

9854 SHIFT LEFT (<<)1806

9855 SHIFT RIGHT (>>)1807

9856 BIT SET (BS)1808

9857 BIT CLEAR (BC)1809

9858 BIT TEST (BT)1810

9859 PUSH DATA ONTO THE DATA STACK (PS)1811

9860 PULL DATA FROM THE DATA STACK (PL)1812

9861 PUSH LOGIC ACCUMULATOR ONTO THE DATA STACK (PSL)1812

9862 PUSH WORD ACCUMULATOR ONTO THE DATA STACK (PSW)1813

9863 PULL LOGIC ACCUMULATOR FROM THE DATA STACK (PLL)1813

9864 PULL WORD ACCUMULATOR FROM THE DATA STACK (PLW)1814

9865 UNCONDITIONAL JUMP (JP)1814

9866 JUMP IF LOGIC ACCUMULATOR = 1 (JPT)1815

9867 JUMP IF LOGIC ACCUMULATOR = 0 (JPF)1815

9868 CALL MODULE (CM)1816

9869 CALL MODULE IF LOGIC ACCUMULATOR = 1 (CMT)1816

9870 CALL MODULE IF LOGIC ACCUMULATOR = 0 (CMF)1817

9871 END OF MODULE, END OF PROGRAM (EM)1818

9872 END OF MODULE IF LOGIC ACCUMULATOR = 1 (EMT)1818

9873 END OF MODULE IF LOGIC ACCUMULATOR = 0 (EMF)1818

9874 LABEL (LBL)1818

99 INDEX register (X register)1819

910 Commands for String Processing1821

9101 LOAD String (L)1823

9102 ADD String (+)1823

9103 STORE String (=)1823

9104 OVERWRITE String (OVWR)1824

9105 EQUAL TO Command for String Processing (==)1825

9106 LESS THAN Command for String Processing (<)1825

9107 GREATER THAN Command for String Processing (>)1825

9108 LESS THAN OR EQUAL TO Command for String Processing (<=)1826

9109 GREATER THAN OR EQUAL TO Command for String Processing (>=)1826

91010 NOT EQUAL Command for String Processing (<>)1827

91011 Modules for string processing1828

911 Submit Programs1831

9111 Calling the submit program (SUBM)1832

9112 Interrogating the status of a submit program (RPLY)1832

9113 Canceling a submit program (CAN)1833

912 Cooperative multitasking1835

9121 Starting a parallel process (SPAWN)1835

9122 Control of events1836

913 Constants field (KF)1841

914 Program Structures1842

9141 IF ELSE ENDI structure1843

9142 REPEAT UNTIL structure1843

9143 WHILE ENDW structure1844

9144 CASE branch1844

915 Linking Files1846

9151 USES Statement (USES)1847

9152 GLOBAL statement (GLOBAL)1848

9153 EXTERN Statement (EXTERN)1848

916 PLC Modules1849

9161 Markers, bytes, words, and double words1849

9162 Number conversion1852

917 Python1856

10 Data Interfaces1857

101 Introduction1857

1011 Principles of data transfer1858

1012 Data transfer check: Handshaking1862

102 The Ethernet Interface of the iTNC1863

103 Connecting the iTNC to the Network1864

1031 Settings at the iTNC1864

104 Protection Against Data Tampering1893

105 The USB Interface of the iTNC1894

106 iTNC Serial Data Interfaces1899

1061 General information1899

1062 RS-232-C/V24 interface1899

107 Configuration of Interfaces1902

1071 Control characters1902

1072 Selection of interfaces and operating modes1903

1073 Configuration of interfaces1903

108 Data Transmission Protocols1907

1081 Selection of transmission protocols1907

1082 Standard communications protocol1908

1083 Communications protocol with block check character1910

1084 LSV2 transmission protocol1913

109 Saving and Loading Files1914

1010 Data Transfer by PLC1916

10101 Settings1916

10102 PLC modules1917

1011 External Programming1929

11 iTNC 530 and Windows1931

111 General information and important notes1931

112 IPC 6341-Industrial PC with Windows 71931

12 Error messages1943

121 DSP/NC error messages1943

122 iTNC Error Messages during Data Transfer1944

123 Error messages of the file system1945

13 Subject Index1947

S.M 8/3/2025