$35

Heli G2-Series 1.5-2T Three-Wheel Stand-on Battery Forklift Truck Operation & Service Manual – PDF

Heli G2-Series 1.5-2T Three-Wheel Stand-on Battery Forklift Truck Operation & Service Manual – PDF DOWNLOAD

FILE DETAILS:

Heli G2-Series 1.5-2T Three-Wheel Stand-on Battery Forklift Truck Operation & Service Manual – PDF DOWNLOAD

Language : English,

Pages :126

Downloadable : Yes

File Type : PDF

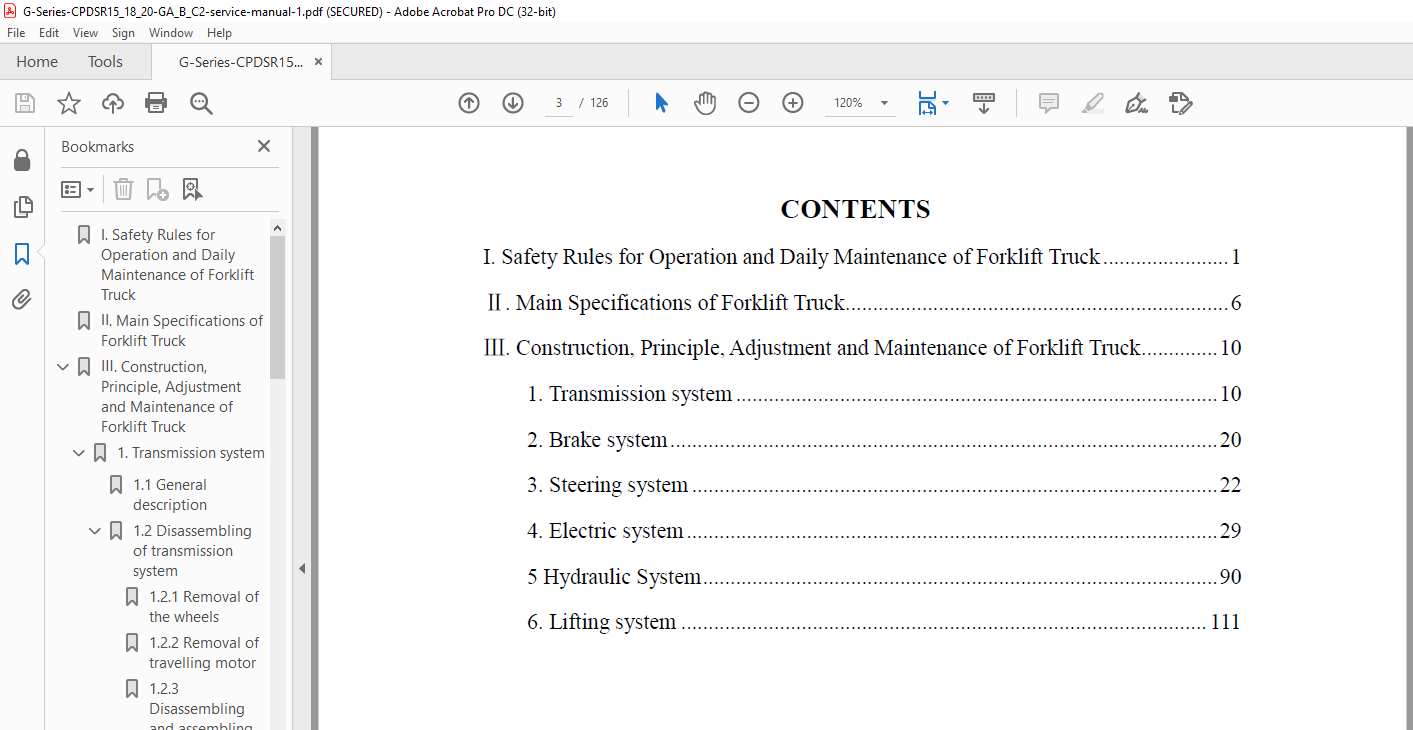

TABLE OF CONTENTS:

Heli G2-Series 1.5-2T Three-Wheel Stand-on Battery Forklift Truck Operation & Service Manual – PDF DOWNLOAD

Ι Safety Rules for Operation and Daily Maintenance of Forklift Truck 4

Ⅱ Main Specifications of Forklift Truck 9

Ⅲ Construction, Principle, Adjustment and Maintenance of Forklift Truck 13

1 Transmission system 13

11 General description 13

12 Disassembling of transmission system 13

121 Removal of the wheels 13

122 Removal of travelling motor 14

123 Disassembling and assembling of transmission box 15

124 Removal of electromagnetic brake 15

125 Disassembly and assembly of gearbox 17

13 Assembling of transmission system 20

131 Assembling of travelling motor 20

132 Mounting the transmission unit to the truck frame 21

133 Assembling of wheels 21

14 Replenishing with Transmission Fluid 21

2 Brake system 23

21 General description 23

211 Service brake 23

212 Parking brake 23

3 Steering system 25

31 General description 25

32 Working principle 25

33 Composition of steering system 26

331 Steering operation mechanism 26

332 Steering sensor 26

34 Steering axle 26

35 Adjustment steps for preload of the steering wheel bearings 30

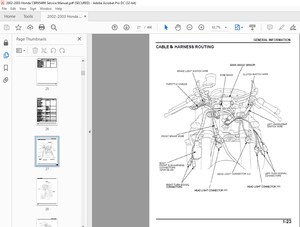

4 Electric system 32

41 General description 32

42 Electrical system specification 34

421 CAN BUS technique 34

422 Instrument 34

423 Controller system 38

424 Motor 42

425 Battery 42

426 Integrated control handle 47

427 Proximity switch 48

43 Failure diagnosis 48

431 General Description 48

432 Common fault of traction system (the instrument shows TR nodes) 49

433 Common fault of pump control system (instrument display PU node) 61

434 Common fault for steering system (instrument displays EM ES nodes) 74

435 Common failures of the instrument (instrument displays DI nodes) 86

436 Valve controller common faults (the instrument displays HY nodes) 88

437 Scheduled maintenance 92

5 Hydraulic System 93

51 General Description 93

511 Oil pump 93

512 Control Valve 95

513 Lift cylinder 98

514 Pipeline explosion-proof valve 99

515 Flow regulator valve100

516 Tilt cylinder101

517 Oil tank102

518 Hydraulic oil circuit102

52 Maintenance, failure analysis and troubleshooting methods104

521 Maintenance104

522 Maintenance of lift pump104

523 Problems analysis and troubleshooting methods111

6 Lifting system114

61 Normal type lifting system general description114

62 Inner mast and outer mast114

63 Fork arm carrier115

64 Roller adjusting method116

65 Repair117

651 Lifting cylinder adjusting117

652 Adjust lift bracket’s height118

653 Replacing rollers of the lift bracket119

654 Replacing rollers of masts120

66 Overview of three-stage full free lifting system120

661 Inner, middle and outer masts120

662 Integral side shifter122

663 Roller arrangement and adjustment method123

664 Maintenance124

IMAGES PREVIEW OF THE MANUAL: