$45

Hitachi AH250-D AH300-D Articulated Dump Truck Service Manual (KM8TE-E-01) PDF DOWNLOAD

Hitachi AH250-D AH300-D Articulated Dump Truck Service Manual

FILE DETAILS:

Hitachi AH250-D AH300-D Articulated Dump Truck Service Manual

Language : English

Pages : 533

Downloadable : YES

Format : PDF

Serial No. 003362 and up

DESCRIPTION:

Hitachi AH250-D AH300-D Articulated Dump Truck Service Manual

INTRODUCTION:

Read this manual carefully for it has been produced to assist you in the correct operation, maintenance and care of your HITACHI machine. Failure to do so could result in personnel injury or equipment damage. Right and left hand sides are determined by facing in the direction of forward travel. Warranty is provided as part of HITACHI support program for customers who operate and maintain their equipment as described in this manual.

- The warranty is explained on the warranty certificate which you should have received from your dealer. Should the equipment be abused, or modified to change its performance beyond the original factory specifications, the warranty will become void and field improvements may be denied. This manual is divided into chapters.

- The information contained in the manual is in logical sequence, with the instructions written in step by step format. Effective maintenance on your HITACHI machine is achieved when personnel fully understand the information contained in this manual. Every effort has been made to ensure that the information contained in this manual was correct at the time of publication.

- HITACHI has a policy of continuous product development, improvement, and design. HITACHI , reserves the right to change, amend and update the design of its product at any time without prior notice. With this policy, changes may have occurred that are not included in this manual.

- Whilst every endeavour has been made to provide accurate and reliable information, HITACHI Co. specifically disclaims any actual or implied warranty and under no circumstances shall be liable for any loss, damage or injury to person or property suffered, whether direct, indirect or consequential, arising from the use of this manual.

- In particular and without detracting from above, the disclaimer also applies in the event of any specification, warning, or representation contained in this manual being inadequate, inaccurate, or unintentionally misleading.

- The user is urged to strictly comply with the instructions and warnings that are given in the interests of general safety. Please do not hesitate to contact your HITACHI Product Support Representative whenever you have a query on your HITACHI product or this manual.

TABLE OF CONTENTS:

Hitachi AH250-D AH300-D Articulated Dump Truck Service Manual

SAFETY 13

SAFETY FEATURES 13

GENERAL SAFETY 14

SAFETY REGULATION 15

SAFETY DECALS 21

CHAPTER 1 OPERATIONAL CHECK-OUT PROCEDURE 47

OPERATIONAL CHECK-OUT 47

OPERATIONAL CHECKS – KEY SWITCH ON, ENGINE OFF 47

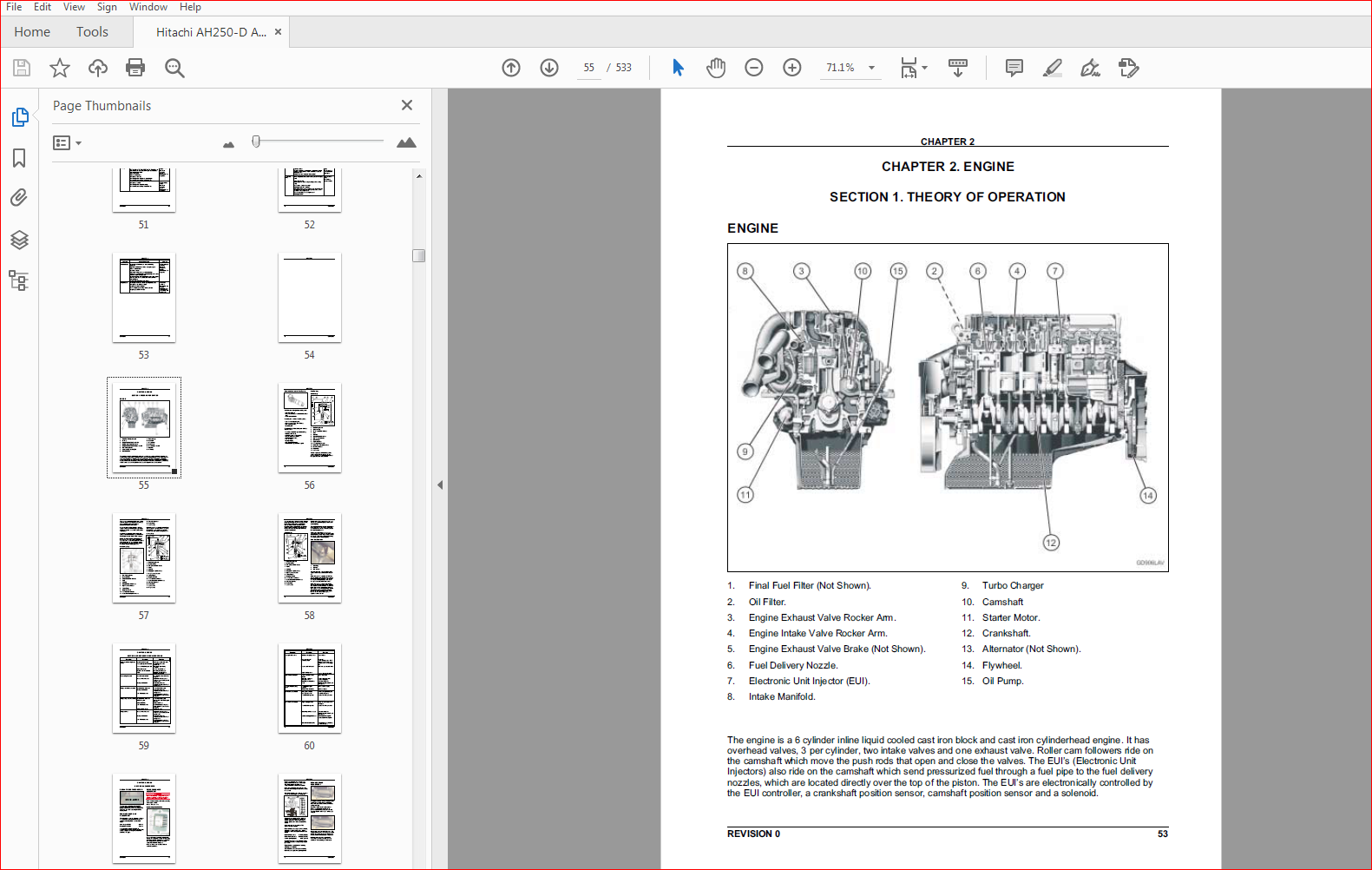

CHAPTER 2 ENGINE 53

SECTION 1 THEORY OF OPERATION 53

ENGINE 53

SECTION 2 DIAGNOSE ENGINE MALFUNCTIONS 57

SECTION 3 ADJUSTMENTS 59

DISPLAY MENU TACHOMETER 59

SLOW AND FAST IDLE ADJUSTMENT 59

VALVE CLEARANCE ADJUSTMENT 59

EXHAUST BRAKE ADJUSTMENT 60

SECTION 4 TESTS 61

CYLINDER COMPRESSION TEST 61

FUEL PUMP PRESSURE TEST 62

FUEL RETURN FLOW QUANTITY AT ENGINE TEST 63

FUEL SYSTEM LOW PRESSURE FUEL CIRCUIT LEAK TEST 65

OIL PUMP PRESSURE TEST 66

CAN BUS J1939 69

WHAT EXACTLY IS A “CAN BUS” 69

CANBUS 71

TESTING THE “CANBUS” 73

CHECKING THE CABLES 73

CHECKING OPENS, SHORTS BETWEEN WIRES AND SHORTS TO GROUND ON THE CAN

HARNESS 74

MAIN “CAN” HARNESS 74

“CAN” SHORT TO GROUND 75

REVISION 0 37

“CAN “OPEN CIRCUIT 76

“CAN” SHORT TO POSITIVE 0 -24 VOLTS 77

CHAPTER 3 ELECTRICAL SYSTEM 79

SECTION 1 SYSTEM INFORMATION 79

ELECTRICAL SCHEMATIC SYMBOLS 79

CHASSIS CONTROL UNIT (CCU & OEU) 80

MDU2 (MONITOR DISPLAY UNIT) 81

MDU2 LAYOUT 82

MDU2 INPUT AND OUTPUTS 83

RELAY 85

START-UP DISPLAY 86

DEFAULT SCREEN 86

DEFAULT SCREEN 86

DEFAULT SCREEN 86

DEFAULT SCREEN 86

DEFAULT SCREEN 87

TO GO TO MAIN MENU FROM DEFAULT SCREEN 87

MAIN MENU 87

EXPLANATION OF WIRE MARKINGS 92

SECTION 2 DESCRIPTION OF CIRCUITS 125

SSM 137

MDU2 WARNING LIGHTS 148

MDU2 GAUGES 152

CCU2 OUTPUT SPECIFICATION 153

OEU OUTPUT SPECIFICATION 157

SECTION 3 REFERENCES 161

PART 1 ENGINE FAULT CODES (ADM) 161

PART 1: ENGINE FAULT CODES (PLD-MR) 166

PART 2 DM1 FAULT CODES 192

Service Code Diagnostics – Electronic Unit Injector (EUI) Controller 209

SECTION 4 TESTS 211

KEY SWITCH TEST 211

RELAYS 211

Diode Test 212

Pneumatic System Solenoids, Pressure Switches, and Sensor Tests 213

TABLE OF CONTENTS

38 REVISION 0

Steering Column Switch Test 218

CHAPTER 4 TRANSMISSION ZF 6 HP 592 C PLUS 231

SECTION 1 THEORY OF OPERATION 231

GENERAL DESCRIPTIONS 231

STALL SPEEDS 238

PLANETARY GEARS AND POWER FLOWS 240

THE BASIC LAWS OF PLANETARY GEAR SETS 241

ECOMAT TRANSMISSION PLANETARY CONFIGURATION 242

TRANSMISSION CLUTCH CONFIGURATION 243

TRANSMISSION CROSS SECTIONAL DIAGRAM 245

POWER FLOW 247

HYDRAULIC SYSTEM 257

VALVE SCHEMATIC 259

VALVE SCHEMATIC 260

HYDRAULIC PRESSURES 261

PRESSURE CHART 262

RETARDER 263

RETARDER LEVER 264

ZF GEAR SHIFT CONTROL LEVER 265

INTERNAL SOLENOIDS 271

REMOVE VALVE BODY 273

RENEWING SENSORS 274

EXTERNSL SOLENOIDS 282

DIAGNOSTIC CODES 283

ELECTRONIC CONTROL SYSTEM 283

WIRING HARNESSES 287

RANGE / SHIFT TESTS 287

DO NOT SHIFT LIGHT 288

SECTION 2 DIAGNOSTIC INFORMATION 289

DIAGNOSTIC PROCEDURE 289

DIAGNOSE POWER TRAIN SYSTEM MALFUNCTIONS 290

CHECK THE TRANSMISSION FLUID LEVEL 302

TRANSMISSION CONTROL UNIT ERROR CODES 303

REVISION 0 39

TABLE OF CONTENTS

TABLE OF ERROR CODES 304

SECTION 3 ADJUSTMENTS AND TESTS 327

TRANSMISSION WARM-UP PROCEDURE 327

CHAPTER 5 PNEUMATIC SYSTEM 331

SECTION 1 THEORY OF OPERATION 331

PNEUMATIC SYSTEM OPERATION 331

PNEUMATIC SYSTEM SCHEMATIC 332

SECTION 2 DIAGNOSTIC INFORMATION 343

DIAGNOSTIC PROCEDURE 343

DIAGNOSE PNEUMATIC SYSTEM MALFUNCTIONS 344

SECTION 3 ADJUSTMENTS AND TESTS 346

PNEUMATIC SYSTEM MAIN PRESSURE TEST AND ADJUSTMENT 346

PARK BRAKE PRESSURE TEST 347

PARK BRAKE ADJUSTMENT 348

GRAMMER SEAT FUNCTIONAL TEST 350

CHAPTER 6 HYDRAULIC SYSTEM 351

SECTION 1 THEORY OF OPERATION 351

ARTICULATED DUMP TRUCK HYDRAULIC SYSTEM OPERATION 351

SECTION 2 DIAGNOSTIC INFORMATION 385

DIAGNOSTIC PROCEDURE 385

DIAGNOSE HYDRAULIC SYSTEM MALFUNCTIONS 386

SECTION 3 TESTS 399

JT05800 DIGITAL THERMOMETER INSTALLATION 399

JT02156A DIGITAL ANALOGUE PRESSURE/TEMPERATURE ANALYSER INSTALLATION 399

HYDRAULIC OIL CLEANUP PROCEDURE USING PORTABLE FILTER CADDY 399

HYDRAULIC SYSTEM WARM-UP PROCEDURE 400

CYCLE TIME TEST 401

MAIN HYDRAULIC PUMP RESIDUAL AND COMPENSATOR VALVES TEST AND ADJUSTMENT

402

SYSTEM RELIEF VALVE AND BIN RAISE CIRCUIT RELIEF VALVE TEST 404

PRIORITY VALVE TEST 405

ACCUMULATOR PRESSURE REDUCING VALVE TEST AND ADJUSTMENT 405

BRAKE ACCUMULATOR CHARGE VALVE TEST AND ADJUSTMENT 406

BRAKE LOW PRESSURE SWITCH AND BRAKE ACCUMULATOR TEST 407

FRONT AND REAR BRAKE ACCUMULATORS PRESSURE TEST AND CHARGE PROCEDURE

408

SERVICE BRAKE VALVE TEST 409

STEERING RELIEF VALVE PRESSURE TEST AND ADJUSTMENT 410

40 REVISION 0

TABLE OF CONTENTS

STEERING CYLINDER LEAKAGE TEST 410

SECONDARY STEERING PUMP RESIDUAL AND COMPENSATOR VALVES TEST AND

ADJUSTMENT 411

BIN LOWER CIRCUIT RELIEF VALVE TEST 412

CHAPTER 7 HEATING AND AIR CONDITIONING 413

SECTION 1 THEORY OF OPERATION 413

AIR CONDITIONING SYSTEM CYCLE OF OPERATION 413

HEATER CORE OPERATION 414

SECTION 2 DIAGNOSTIC INFORMATION 415

DIAGNOSE AIR CONDITIONING SYSTEM MALFUNCTIONS 415

HEATING/AIR CONDITIONING COMPONENT LOCATION 417

SECTION 3 TESTS 419

AIR CONDITIONING OPERATIONAL CHECKS 419

R134A AIR CONDITIONING SYSTEM TEST 420

OPERATING PRESSURE DIAGNOSTIC CHART 421

A/C FREEZE CONTROL SWITCH TEST 423

A/C COMPRESSOR CLUTCH TEST 423

A/C HIGH/LOW PRESSURE SWITCH TEST 423

A/C EXPANSION VALVE TEST 424

EXPANSION VALVE BENCH TEST 425

REFRIGERANT LEAK TEST 426

CHAPTER 8 MAINTENANCE SCHEDULES 429

NOTES: 432

CHAPTER 9 DAILY OR 10 HOURLY SERVICE CHECKS 433

CHAPTER 10 150 HOURS SERVICE AND CHECKS 435

SECTION 1 DRIVE TRAIN 435

INTRODUCTION 435

SERVICE INSTRUCTIONS 435

LOWER AND RAISE THE BELLY PLATE 435

CHAPTER 11 500 HOURS SERVICE AND CHECKS 439

SECTION 1 DRIVE TRAIN 439

INTRODUCTION 439

SERVICE INSTRUCTIONS 439

ENGINE 439

TRANSMISSION 440

BRAKES 443

REVISION 0 41

TABLE OF CONTENTS

TRANSFER CASE 444

SECTION 2 CLEAN, CHECK AND REPLACE BREATHERS 445

GENERAL CHECK DRIVE LINE & SUSPENSION FASTENERS 445

TRANSFER CASE BREATHER (LOCATED UNDER THE HYDRAULIC RESERVOIR) 445

TRANSMISSION BREATHER AND AXLE BREATHERS 445

SECTION 3 CAB AND ELECTRICAL 447

INSPECT, CLEAN AND REPLACE CAB AIR FILTER 447

CHECK BATTERIES, CLEAN AND TIGHTEN TERMINALS 448

CHECK ELECTRICAL CONNECTORS, HARNESSES AND LOOMS 448

CHECK WORK LIGHTS, REVERSE BUZZER AND HORNS 448

RECORD & DELETE FAULT CODES ON THE MDU 448

CHECK THE OPERATOR CONTROLS AND INSTRUMENTS 448

SECTION 4 LUBRICATION 449

GREASE ALL GREASE POINTS 449

HYDRAULICS 450

REPLACE HYDRAULIC RESERVOIR BREATHER 450

CHAPTER 12 1 000 HOURS SERVICE AND CHECKS 453

SECTION 1 DRIVE TRAIN 453

INTRODUCTION 453

SERVICE INSTRUCTIONS 453

Engine 453

SECTION 2 HYDRAULICS AND LUBRICATION 457

REPLACE HYDRAULIC RESERVOIR BREATHER 457

SECTION 4 AXLES AND CHASSIS & SUSPENSION 459

CHECK AXLE OIL LEVEL 459

CHECK FINAL DRIVE OIL LEVELS 459

CHECK BIN SHOCK PAD CLEARANCE 459

CHAPTER 13 2 000 HOURS SERVICE AND CHECKS 461

SECTION 1 DRIVE TRAIN 461

INTRODUCTION 461

SERVICE INSTRUCTIONS 461

ENGINE 461

SECTION 2 HYDRAULICS AND LUBRICATION 467

REPLACE HYDRAULIC OIL RETURN FILTER 467

SECTION 3 CAB, PNEUMATICS AND ELECTRICAL 469

REPLACE PNEUMATIC SYSTEM DRYER FILTER 469

CHAPTER 14 3 000 HOURS SERVICE AND CHECKS 471

42 REVISION 0

TABLE OF CONTENTS

SECTION 1 DRIVE TRAIN 471

INTRODUCTION 471

SERVICE INSTRUCTIONS 471

SECTION 2 HYDRAULICS AND PNEUMATICS 473

CHAPTER 15 4 000 HOURS SERVICE AND CHECKS 475

SECTION 1 DRIVE TRAIN 475

REPLACE FAN BELT 475

SECTION 2 HYDRAULICS AND PNEUMATICS 477

INTRODUCTION 477

SERVICE INSTRUCTIONS 477

CHAPTER 16 AS REQUIRED SERVICE 479

SECTION 1 ENGINE 479

INTRODUCTION 479

SERVICE INSTRUCTIONS 479

SECTION 2 CAB AND LUBRICATION 483

CLEAN AIR CONDITIONING FILTERS 483

GREASE HINGES 483

CHAPTER 17 MISCELLANEOUS SERVICE AND CHECKS 485

SECTION 1 DRIVE TRAIN 485

INTRODUCTION 485

SERVICE INSTRUCTIONS 485

ENGINE 485

WHEELS 485

SECTION 2 ELECTRICAL 487

USING BATTERY CHARGER 487

ADJUST HEADLIGHTS 489

SECTION 3 OPERATIONAL CHECKOUT 493

OPERATIONAL CHECK-OUT 493

CHAPTER 18 TROUBLE SHOOTING 501

SECTION 1 SYMPTOMS AND REMEDIES 501

INTRODUCTION 501

CHAPTER 19 APPENDIX 513

REVISION 0 43

TABLE OF CONTENTS

OBW Functional Description – ADT Mk IV

001-4002-00 513

HYDRAULIC FAN COOLER FUNCTIONAL DESCRIPTION – ADT MK IV

001-4003-02 516

TABLE OF CONTENTS 516

1 INTRODUCTION 516

2 CHASSIS CONTROL UNIT SOFTWARE REQUIREMENTS 516

CCU2 HEADLIGHT LOGIC AND CONTROL

001-4004-00 519

1 INTRODUCTION 519

2 HEADLIGHT LOGIC AND CONTROL 519

CCU2 WIPER CONTROL LOGIC

001-4005-00 521

1 INTRODUCTION 521

2 WIPER CONTROL LOGIC AND TIMING 521

AIR-CONDITIONING CONTROL LOGIC

001-4006-00 523

1 INTRODUCTION 523

2 INPUTS/OUTPUTS 523

BIN CONTROL LOGIC

001-4007-00 525

1 INTRODUCTION 525

2 BIN CONTROL LOGIC 525

PR001_PARK BRAKE FUNCTION 529

INTRODUCTION 529

IMAGES PREVIEW OF THE MANUAL: