$45

Hitachi AH250-D AH300-D Articulated Dump Truck Technical Manual PDF DOWNLOAD

Hitachi AH250-D AH300-D Articulated Dump Truck Technical Manual

FILE DETAILS:

Hitachi AH250-D AH300-D Articulated Dump Truck Technical Manual

Language : English

Pages : 314

Downloadable : YES

Format : PDF

Vol No.: T8TDE-00

DESCRIPTION:

Hitachi AH250-D AH300-D Articulated Dump Truck Technical Manual

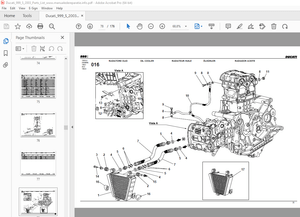

SAMPLE PAGES FROM THE MANUAL:

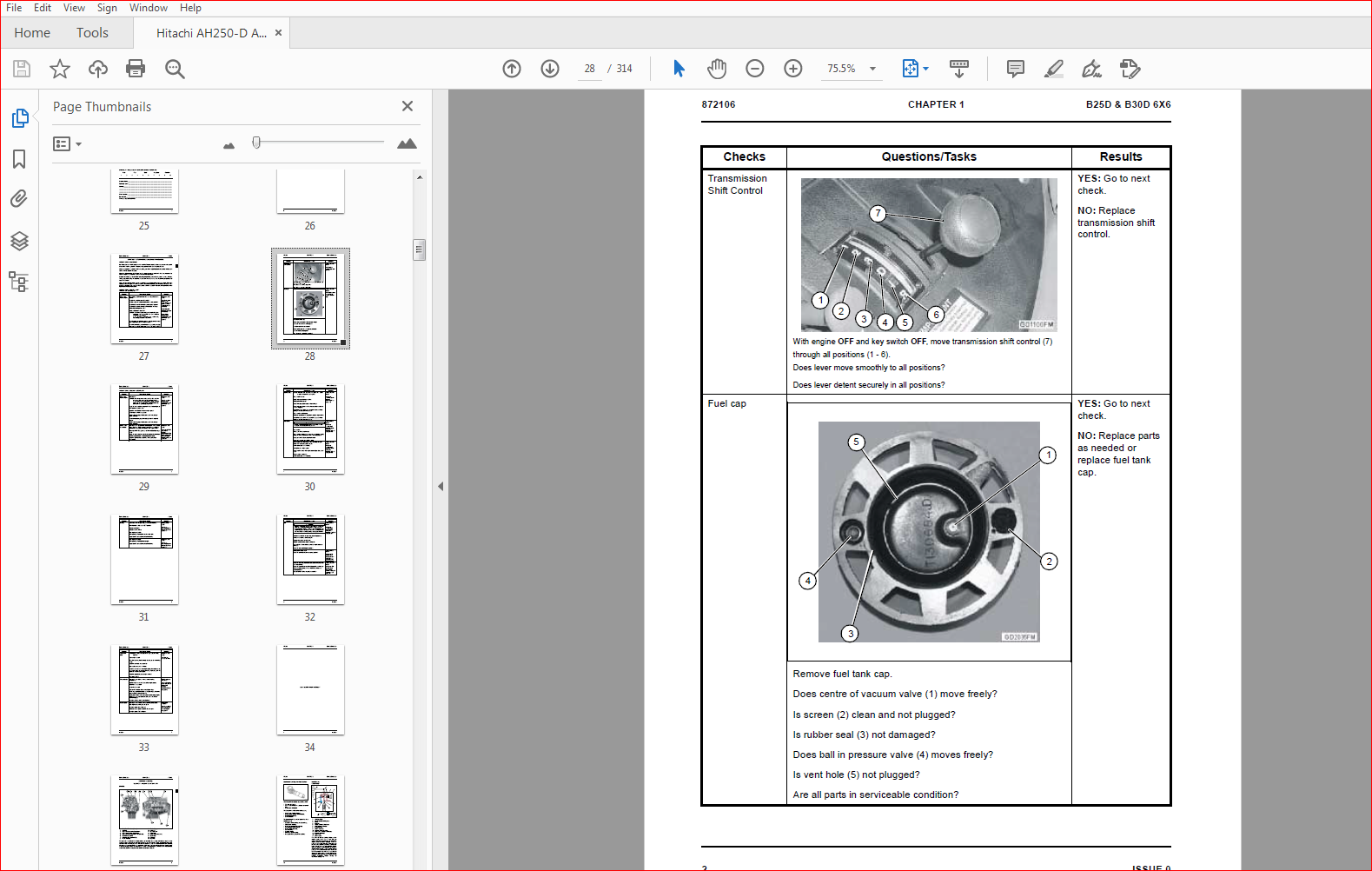

OPERATIONAL CHECK-OUT:

Use this procedure to check operation of the machine. This procedure is designed so you can make a quick check of the machine operation while performing specific checks from the operator’s seat. Should you experience a problem with the machine, you will find helpful diagnostic information in this checkout that will help pinpoint the cause.

- A location will be required which is level and has adequate space to perform the check-out procedure. No tools or equipment are required to perform the check-out procedure.

- Compete the necessary visual checks (oil levels, oil condition, external leaks, loose hardware, linkages, wiring, etc.) prior to doing the operational check-out. The machine must be at operating temperature for many of the checks. Start at the top of the left column and read completely down column before performing check.

- Follow this sequence from left to right. In the far right column, if no problem is found, you will be instructed to go to next check. If a problem is indicated, you will be referred to either a chapter in this manual for specific test or the repair manual for repair procedure.

TABLE OF CONTENTS:

Hitachi AH250-D AH300-D Articulated Dump Truck Technical Manual

SAFETY I

Specification I

Safety Features I

Material Safety Data Sheets (MSDS) II

Unauthorised Modifications of the Roll Over Protective Structure (ROPS) and the Falling Objects Protective

Structure (FOPS) II

Noise Emission Levels II

General Safety II

Safety Regulation II

Mounting and Dismounting the Machine II

AvoidWork Site Hazards III

Keep Riders Off the Machine III

Prepare for Emergencies III

Avoid Backing Over Accidents III

Handle Chemical Products And Flammable Fluids Safety III

Clean the Machine Regularly IV

Prevent Battery Explosions and Acid Burns IV

Wear Protective Equipment V

Use the Seat Belt V

Avoid High Pressure Fluids V

Stay Clear Of Moving Parts V

Beware of Toxic Fumes V

Dispose of Waste Properly VI

Start Only From Operator’s Seat VI

Operating The Machine VI

Welding Repairs VI

Tyre Information VII

Inspect and Maintain ROPS VII

Drive Metal Pins VII

USER’S INFORMATINON FEEDBACK FORM i

CHAPTER 1. OPERATIONAL CHECK OUT PROCEDURE 1

OPERATIONALCHECK OUT 1

OPERATIONAL CHECKS KEY SWITCH ON, ENGINE OFF 1

OPERATIONAL CHECKS ENGINE ON 3

CHAPTER 2. ENGINE 9

SECTION 1. THEORY OF OPERATION 9

ENGINE 9

Electronic Unit Injector Fuel System 10

Cold Start Option 12

SECTION 2. DIAGNOSE ENGINE MALFUNCTIONS 13

TABLE OF CONTENTS

b

SECTION 3. ADJUSTMENTS 17

DISPLAY MENU TACHOMETER 17

SLOWAND FAST IDLE ADJUSTMENT 17

VALVE CLEARANCE ADJUSTMENT 17

EXHAUST BRAKE ADJUSTMENT 18

SECTION 4. TESTS 19

CYLINDER COMPRESSION TEST 19

FUEL PUMP PRESSURE TEST DOWNSTREAM OF FUEL FILTER 20

Specification 20

Essential Tools 20

Service Equipment And Tools 20

Specification 21

Special Tools 21

Specification 22

Special Tools 22

Specification 23

OIL PUMP PRESSURE TEST 24

Specification 24

Essential Tools 24

Service Equipment And Tools 24

CHAPTER 3. ELECTRICAL SYSTEM 25

SECTION 1. SYSTEM INFORMATION 25

Electrical Schematic Symbols 25

HARNESSES AND COMPONENT LOCATION 26

EXPLANATION OF WIRE MARKINGS 52

Wire Colour 52

MultipleWire Colours 52

Circuit Breakers 52

SECTION 2. SYSTEMS AND SUB SYSTEMDIAGRAMS 55

SECTION 2. SYSTEMS AND SUB SYSTEM THEORY OF OPERATION AND DIAGNOSTICS

69

STARTING AND CHARGING CIRCUIT THEORY OF OPERATION 69

Starting Circuit 69

Charging Circuit 69

Flame Start Theory Of Operation 70

Electronic Unit Injector Controller Circuit Theory Of Operation 70

Temperature Sensors 71

Pressure Sensors 72

Engine Control Unit Circuit Theory Of Operation 72

Transmission Control Unit And Retarder Circuit Theory Of Operation 73

TABLE OF CONTENTS

c

Chassis Control Unit Circuit Theory Of Operation 77

Bin Control And Range Hold Circuit Theory Of Operation 79

Range Hold Circuit 80

Park Brake And Exhaust Brake Circuit Theory Of Operation 81

Turn Signal and 4 Way Flasher 85

Unloader Valve Heater Circuit Theory of Operation 91

SECTION 3. REFERENCES 93

SERVICE CODE DIAGNOSTICS AFTER MACHINE REPAIR 93

Service Code Diagnostics How Codes Are Displayed On Menu Display Unit 93

Service Code Diagnostics Engine Control Unit 94

Key Switch Test 123

Relay Test 123

Diode Test 124

Hydraulic Pressure Switches Test 127

Hydraulic Temperature Sensors Test 128

Bin Position Sensor Test 129

Retarder Voltage Regulator Test 131

Transmission Solenoids, Speed Sensors, Sump Temperature Sensor, and Retarder Resistor

Tests 132

Retarder Proportional Solenoid Test 133

Retarder Temperature Sensor Test 133

Transmission Shift Control Test 133

Remove and Install Engine Control Unit 135

Remove and Install Cold Start Module 136

Remove and Install Chassis Control Unit 136

Disconnect harness connectors (4 and 5). 136

Remove and Install Transmission Control Unit 137

Remove and Install Battery Balancer 137

Remove and Install Menu Display Unit 138

Replace Menu Display Unit Bulbs 138

Remove, Install, and Calibrate Accelerator Pedal Position Sensor 140

Replace DEUTSCH™ Rectangular or Triangular Connectors 140

Replace DEUTSCH™ Connectors 141

Install DEUTSCH™Contact 142

Replace WEATHER PACK™ Connector 143

InstallWEATHER PACK™Contact 143

Replace (Pull Type) Metri Pack™ Connectors 144

Replace (Push Type) Metri Pack™ Connectors 145

Remove Connector Body from Blade Terminals 145

CHAPTER 4. POWER TRAIN 147

SECTION 1. THEORY OF OPERATION 147

TRANSMISSION EXTERNAL COMPONENTS 147

TABLE OF CONTENTS

d

TRANSMISSION CONTROL SYSTEM 148

Retarder Operation 156

SECTION 2. DIAGNOSTIC INFORMATION 159

DIAGNOSTIC PROCEDURE 159

Know The System 159

Ask The Operator 159

Inspect The Machine 159

Perform Operational Check out. 159

Perform Troubleshooting 159

Trace And Cause 159

DIAGNOSE POWER TRAIN SYSTEM MALFUNTIONS 160

SECTION 3. TESTS 171

TRANSMISSION WARM UP PROCEDURE 171

Transmission Pressure Test 171

Torque Converter Stall Test 173

Torque Converter Stator Test 174

Transmission Oil to Air Cooler Restriction Test 174

Transmission Oil to Water Cooler Restriction Test 175

Front Suspension Strut Leakage Check 175

Park brake Test 175

Park Brake Pad Thickness Check 176

Park Brake Adjustment 176

CHAPTER 5. PNEUMATIC SYSTEM 179

SECTION 1. THEORY OF OPERATION 179

PNEUMATIC SYSTEM OPERATION 179

All pneumatic functions are supplied pressurized air by the engine driven compressor. 179

PNEUMATIC SYSTEM SCHEMATIC 180

Air Pressure Supply Circuit Operation 182

Air Dryer and Unloader Valve 183

Pneumatic Manifold 184

Pneumatic Circuit 190

CHAPTER 5. PNEUMATIC SYSTEM 193

SECTION 2. DIAGNOSTIC INFORMATION 193

DIAGNOSTIC PROCEDURE 193

DIAGNOSE PNEUMATIC SYSTEM MALFUNCTIONS 194

SECTION 3. TESTS 199

PNEUMATIC SYSTEM MAIN PRESSURE TEST AND ADJUSTMENT 199

Pneumatic System Main Specification 199

Essential Tools 199

TABLE OF CONTENTS

e

Service Equipment and Tools 199

PARK BRAKE PRESSURE TEST 200

Park Brake Pressure Specifications 200

Essential Tools 200

Service Equipment and Tools 200

CHAPTER 6. HYDRAULIC SYSTEM 201

SECTION 1. THEORY OF OPERATION 201

ARTICULATED DUMP TRUCK HYDRAULIC SYSTEM OPERATION 201

SECTION 2. DIAGNOSTIC INFORMATION 237

DIAGNOSTIC PROCEDURE 237

Know the system. 237

Ask the operator. 237

Inspect themachine. 237

Perform Operational Check out. 237

Perform troubleshooting. 237

Trace a cause. 237

DIAGNOSE HYDRAULIC SYSTEM MALFUNCTIONS 238

Hydraulic System Malfunctions 238

Service Brake System Malfuntion 242

Steering System Malfunctions 243

HYDRAULIC SYSTEM COMPONENT LOCATION 246

SECTION 3. TESTS 252

JT05800 DIGITAL THERMOMETER INSTALLATION 252

JT02156A DIGITAL PRESSURE/TEMPERATURE ANALYZER INSTALLATION 252

HYDRAULIC OIL CLEANUP PROCEDURE USING PORTABLE FILTER CADDY 252

Specifications 252

Service Equipment And Tools 252

Specification 253

HYDRAULIC SYSTEM WARM UP PROCEDURE 253

Service Equipment And Tools 253

CYCLE TIME TEST 254

Specifications 254

Service Equipment And Tools 254

MAIN HYDRAULIC PUMP RESIDUAL AND COMPENSATOR VALVES TEST AND ADJUSTMENT

255

Specifications Residual Valve 255

Compensator Valve 255

Essential Tools 255

Service Equipment And Tools 255

Residual Valve Pressure Setting 255

Compensator Valve Pressure Setting 256

TABLE OF CONTENTS

f

SYSTEM RELIEF VALVE AND BIN RAISE CIRCUIT RELIEF VALVE TEST 256

Specifications 256

Essential Tools 256

Service Equipment And Tools 256

PRIORITY VALVE TEST 257

Specifications 257

Essential Tools 257

Service Equipment And Tools 257

ACCUMULATOR PRESSURE REDUCING VALVE TEST AND ADJUSTMENT 257

Specifications 257

Essential Tools 257

Service Equipment And Tools 257

BRAKE ACCUMULATOR CHARGE VALVE TEST AND ADJUSTMENT 258

Specifications 258

Essential Tools 258

Service Equipment And Tools 258

BRAKE LOW PRESSURE SWITCH AND BRAKE ACCUMULATOR TEST 259

Specifications 259

Essential Tools 259

Service Equipment And Tools 259

FRONT AND REAR BRAKE ACCUMULATORS PRESSURE TEST AND CHARGE PROCEDURE

260

Specifications 260

Essential Tools 260

SERVICE BRAKE VALVE TEST 260

Specifications 260

Essential Tools 260

Service Equipment And Tools 260

STEERING RELIEF VALVE PRESSURE TEST AND ADJUSTMENT 261

Specifications 261

Essential Tools 261

Service Equipment And Tools 261

STEERING CYLINDER LEAKAGE TEST 262

Specifications 262

SECONDARY STEERING PUMP RESIDUAL AND COMPENSATOR VALVES TEST AND ADJUSTMENT

262

Specifications 262

Essential Tools 262

Service Equipment And Tools 262

Residual Valve Adjustment 263

Compensator Valve Adjustment 263

BIN LOWER CIRCUIT RELIEF VALVE TEST 264

Specifications 264

TABLE OF CONTENTS

g

Essential Tools 264

Service Equipment And Tools 264

CHAPTER 7. HEATING AND AIR CONDITIONING 265

SECTION 1. THEORY OF OPERATION 265

AIR CONDITIONING SYSTEM CYCLE OF OPERATION 265

HEATER CORE OPERATION 266

SECTION 2. DIAGNOSTIC INFORMATION 267

DIAGNOSE AIR CONDITIONING SYSTEM MALFUNCTIONS 267

DIAGNOSE HEATER SYSTEM MALFUNCTIONS 269

HEATING/AIR CONDITIONING COMPONENT LOCATION 270

SECTION 3. TESTS 273

AIR CONDITIONING OPERATIONAL CHECKS 273

Visual Inspection of Components 273

R134A AIR CONDITIONING SYSTEM TEST 274

Specifications 274

Service Equipment And Tools 274

OPERATING PRESSURE DIAGNOSTIC CHART 275

A/C FREEZE CONTROL SWITCH TEST 277

Specifications 277

A/C COMPRESSOR CLUTCH TEST 277

A/C HIGH/LOWPRESSURE SWITCH TEST 277

Specifications 277

Service Equipment And Tools 277

A/C EXPANSION VALVE TEST 278

Specifications 278

Essential Tools 278

Service Equipment And Tools 278

EXPANSION VALVE BENCH TEST 279

Specifications 279

Essential Tools 279

Service Equipment And Tools 279

REFRIGERANT LEAK TEST 280

Specifications 280

IMAGES PREVIEW OF THE MANUAL: