$45

Hitachi AH350 AH400 Articulated Dump Truck Service Manual PDF DOWNLOAD

Hitachi AH350 AH400 Articulated Dump Truck Operator’s Manual – PDF DOWNLOAD

FILE DETAILS:

Hitachi AH350 AH400 Articulated Dump Truck Operator’s Manual – PDF DOWNLOAD

P/N: EM872200B

Language: English

Division: Hitachi

Product Lines: Articulated Dump Trucks

Publication Type: Operator’s Manuals

Associated Models: AH350, AH400

Series: AH SERIES

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Hitachi AH350 AH400 Articulated Dump Truck Operator’s Manual – PDF DOWNLOAD

COVER 1

INTRODUCTION 2

TABLE OF CONENTS 3

SAFETY 5

RECOGNIZE SAFETY INFORMATION 5

UNDERSTAND SIGNAL WORDS 5

FOLLOW SAFETY INSTRUCTIONS 6

PREPARE FOR EMERGENCIES 6

WEAR PROTECTIVE CLOTHING 7

PRETECT AGAINST NOISE 7

INSPECT MACHINE 7

USE HANDHOLDS AND STEPS 8

ADJUST THE OPERATOR’S SEAT 8

FASTEN YOUR SEAT BELT 9

MOVE AND OPERATE MACHINE SAFELY 9

OPERATE ONLY FROM OPERATOR’S SEAT 10

JUMP STARTING 10

KEEP RIDERS OFF MACHINE 10

PROVIDE SIGNALS FOR JOBS INVOLVING MULTIPLE NUMBERS OF MACHINES 11

DRIVE MACHINE SAFELY 11

AVOID INJURY FROM ROLLAWAY ACCIDENTS 12

AVOID ACCIDENTS FROM BACKING UP 13

AVOID POWER LINES 14

UNANTHORISED MODIFICATIONS OF ROPS AND FOPS 14

PROTECT AGAINST FLYING DEBRIS 15

PARK MACHINE SAFELY 15

HANDLE FLUIDS SAFELY – AVOID FIRES 16

TRANSPORT SAFELY 17

PRACTICE SAFE MAINTENANCE 18

WARN OTHERS OF SERVICE WORK 19

SUPPORT MACHINE PROPERLY 19

STAY CLEAR OF MOVING PARTS 19

PREVENT PARTS FROM FLYING 20

STORE ATTACHMENTS SAFELY 20

SUPPORT MAINTENANCE PROPERLY 20

PREVENT BURNS 21

REPLACE RUBBER HOSES PERIODICALLY 21

AVOID HIGH-PRESSURE FLUIDS 22

PREVENT FIRES 23

EVACUATING IN CASE OF FIRE 24

BEWARE OF EXHAUST FUMES 24

AVOID HEATING NEAR PRESSURIZED FLUID LINES 25

AVOID APPLYING HEAT TO LINES CONTAINING FLAMMABLE FLUIDS 25

REMOVE PAINT BEFORE WELDING OR HEATING 25

PREVENT BATTERY EXPLOSIONS 26

SERVICE AIR CONDITIONING SYSTEM SAFELY 26

HANDLE CHEMICAL PRODUCTS SAFELY 27

DISPOSE OF WASTE PROPERLY 27

TYPE PRESSURES 28

NOISE EMISSION LEVELS 28

SAFETY SIGNS 29

ABBREVIATION LIST 37

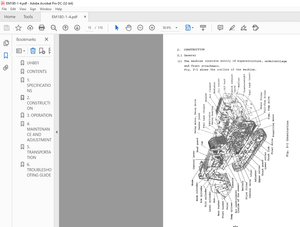

CHAPTER 1 SPECIFICATIONS 39

MACHINE SPECIFICATIONS 39

ENGINE AH400 39

ENGINE AH 350 39

TRANSMISSION 39

TRANSFER CASE (DROP BOX) 39

AXLES 39

BRAKES 39

WHEELS AH400 40

WHEELS AH350 40

SUSPENSION SYSTEM 40

HYDRAULIC SYSTEM 40

STEERING SYSTEM 40

PNEUMATIC SYSTEM 40

ELECTRICAL SYSTEM 40

FRAME AND BODY 41

SERVICE CAPACITIES 41

MACHINE DIMENSIONS 42

RECOMMENDED LUBRICANTS AND COOLANT ADDITIVES 44

RECOMMENDED TORQUE SETTINGS 45

IMPERIAL SIZES- BS GRADES 46

SERIAL NUMBER PLATES 47

CHAPTER 2 OPERATOR’S CONTROLS AND INSTRUMENTS 49

INTRODUCTION 49

CONTROLS AND INSTRUMENTS 54

GAUGES 54

HOUR METER (SMR METER) 54

AIR PRESSURE GAUGE 54

TRANSMISSION TOIL TEMPERATURE GAUGE 54

TACHOMETER AND SPEEDOMETER 55

ENGINE COOLANT TEMPERATURE GAUGE 55

FUEL GAUGE 55

ENGINE OIL PRESSURE GAUGE 56

HYDRAULIC TANK PRESSURE GAUGE 56

WARMING INDICATORS 56

ENGINE TEMPERATURE WARMING INDICATOR 56

PARK BRAKE WARMING INDICATOR 56

BRAKE OVERSTROKE WARMING INDICATOR 57

TRANSMISSION OIL TEMPERATURE WARMING INDICATOR 57

LONGITUDINAL DIFFERENTIAL LOCK WARMING INDICATOR 57

BATTERY CHARGE WARMING INDICATOR 57

ENGINE OIL PRESSURE WARMING INDICATOR 57

LOW COOLANT LEVEL WARMING INDICATOR 58

ENGINE OVERSPEED WARMING INDICATOR 58

EMERGENCY STEERING WARMING INDICATOR 58

DO NOT SHIFT WARMING INDICATOR 58

BIN UP WARMING INDICATOR 59

COLD START WARMING INDICATOR 59

TURN INDICATOR 59

MAIN BEAM INDICATOR 59

ROTATING BEACON INDICATOR (IF FITTED) 59

TRANSIMISSION RETARDER INDICATOR (IF FITTED) 60

LOW RANGE INDICATOR (IF FITTED) 60

SWITCHES 60

WINDSCREEN WIPER/WASHER SWITCH 60

HEADLIGHT SWITCH 60

INTERIOR LIGHT SWITCH 60

HAZARD LIGHT SWITCH 61

LOW RANGE SELECTOR SWITCH (IF FITTED) 61

ROTATING BEACON SELECTOR SWITCH (IF FITTED) 61

TRANSMISSION RETARDER SWITCH LEVER (IF FITTED) 61

IGNITION SWITCH AND START BUTTON 62

BATTERY DISCONNECT SWITCH 62

BATTERY BOX CIRCUIT BEAKERS 63

MACHINE NOT FITTED WITH RETARDER FUNCTION 63

CONTROLLED TRACTION DIFFERENTIAL(CTD) SWITCH 63

CONTROLS 64

STEERNG WHEEL 64

INDICATORS AND HEADLIGHT CONTROL 64

INTER AXLE DIFFERENTIAL LOCK CONTROL 64

PARK/EMERGENCY BRAKE CONTROL VALVE 65

ACCELERATOR AND BRAKE PEDALS 65

PUSH BUTTON SHIFT SELECTOR AND RANGE HOLD SWITCH 66

TIP CONTROL LEVER 66

OPERATOR’S SEAT 67

BACK REST ANGLE ADJUSTMENT 67

SQUAB HEIGHT ADJUSTMENT 67

BACKWARDS AND FORWARDS ADJUSTMENT 68

ARM REST ADJUSTMENT 68

SEAT BELT 68

TRAINER SEAT 69

CLIMATE CONTROL 69

VENTS 69

AIR CONDITIONER CONTROL PANEL 69

LIGHTS 70

FRONT LIGHTS 70

REAR LIGHTS 70

REVERSE LIGHTS 70

INTERIOR LIGHT 70

RELAY/CIRCUIT BREAKER BOX 71

MISCELLANEOUS 71

BONNET CATCH RELEASE LEVRE 71

ASHTRAY 71

STORAGE COMPARTMENT 72

12V UTILITY SOCKET/CIGARETTE LIGHTER 72

DRINKS HOLDER 72

WHEEL SPANNER AND BRACE 72

WINDSCREEN WASHER WATER BOTTLE 72

WINDSCREEN WIPER AND WASHER NOZZLE 73

HORN 73

REVERSE WARMING BUZZER 73

CHAPTER 3 PROCEDURES BEFPRE STARTING 75

SAFETY INSTRUCTIONS 75

RUNNING IN INSTRUCTIONS 75

PROCEDURES BRFORE STARTING 75

DAILY WALK ROUND CHECK 75

CHAPTER 4 OPERATING INSTRUCTIONS 77

SAFETY RULES 77

STARTING THE ENGINE 77

BEFORE STARTING THE ENGINE 77

DRIVING 78

GEAR SHIFTING 79

RETARDERS 79

SERVICE BRAKES AND PARK BRAKES 79

OPERATING WITH INTER -AXLE DIFFERENTIAL LOCKS 80

OPERATING WITH CONTROLLED TRACTION DIFFERENTIAL (CTD) LOCK 81

LOADING THE MACHINE 81

RAISING THE BIN 81

LOWING TEH BIN 81

STEERING 82

OPERATING INDOORS 82

OVERNIGHT PARKING 82

CHAPTER 5 OPERATING TECHNIQUES 83

SAFETY RULES 83

GEAR PRE- SELECTION 85

TRANSPORT OPERATION 85

UPHILL OPERATION 85

GEAR HUNTING 85

DOWNHILL OPERATION 85

USING THE ENGINE TO SLOW THE MACHINE 86

OFF-ROAD OPERATION 86

LOADING 86

UNLOADING 87

STUCK MACHINE 87

CHAPTER 6 RECOVERY AND TRANSPORTATION 89

TOWING 89

MACHINE LIFTING POINTS 91

MACHINE TIE -DOWN POINTS 93

TRANSPORTING 93

CHAPTER 7 PRE-SERVICE INSTRUCTIONS 95

SERVICE POSITION 95

INSTALL THE BIN PROP 96

INSTALL ARTICULATION SAFETY LOCK BAR 96

LOWER AND RAISE THE BELLY PLATE 96

TILT AND LOWER THE CAB 97

RULES WHEN SERVICING 99

GENERAL 99

CONTAMINATED OILS AND FLUIDS 100

MEASURES TO PREVENT FIRES 100

REFRIGERANT R134a 101

WORKING ON PAINTED SURFACES 101

WORKING WITH POLYMER MATERIAL 101

CHAPTER 8 MAINTENANCE SCHEDULES 103

CHAPTER 9 DAILY OI 10 HOURLY SERVICE CHECKS 107

INTRODUCTION 107

SERVICE INSTRUCTIONS 107

ENGINE 107

TRANSMISSION 108

HYDRAULICS 110

CAB AND ELECTRICAL 111

LUBRICATION, GREASE POINTS 111

CHAPTER 10 FIRST 100 HOURS SERVICE 115

INTRODUCTION 115

SERVICE INSTRUCTIONS 115

ENGINE 115

TRANSFER CASE (DROP BOX) 116

HYDRAULICS 117

AXLES AND CHASSIS 117

CHECK THE WHEEL NUTS 118

CHAPTER 11 250 HOURS SERVICE 119

INTRODUCTION 119

SERVICE INSTRUCTIONS 119

ENGINE 119

TRANSFER CASE 120

AXLES AND CHASSIS 121

ELECTRICAL 121

CHAPTER 12 500 HOURS SERVICE 123

INTRODUCTION 123

SERVICE INSTRUCTIONS 123

ENGINE 123

AXLES AND CHASSIS 123

LUBRICATION 123

CHAPTER 13 1000 HOURS SERVICE 125

INTRUCTION 125

SERVICE INSTRUCTION 125

ENGINE 125

TRANSIMISSION 126

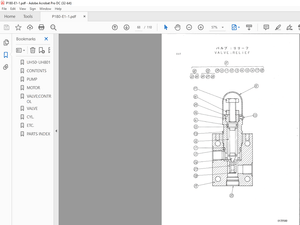

HYDRAULICS 127

PNEUMATICS 127

GREASE THE HINGES 128

CHAPTER 14 2000 HOURS SERVICE 129

INTRODUCTION 129

SERVICE INSTRUCTIONS 129

ENGINE 129

AXLES AND CHASSIS 131

LUBRICATION 131

CHAPTER 15 3000 HOURS SERVICE 133

INTRODUCTION 133

ENGINE 133

SERVICE INJECTORS 133

HYDRAULIC 133

CHAPTER 16 AS REQUIRED SERVICE 135

INTRODUCTION 135

SERVICE INJECTORS 135

ENGINE 135

TRANSFER CASE (DROP BOX) 139

HYDRAULICS 140

CHAPTER 17 TROUBLSHOOTING 141

INTRODUCTION 141

ENGINE 141

TRANSMISSION 144

AXLES 144

WHEELS 145

TYPES 145

BRAKES 146

HYDRAULICS 147

ELECTRICS 147

REAR FRAME AND CAB TROUBLE SHOOTING 149

ALPHABETICAL INDEX 151