$40

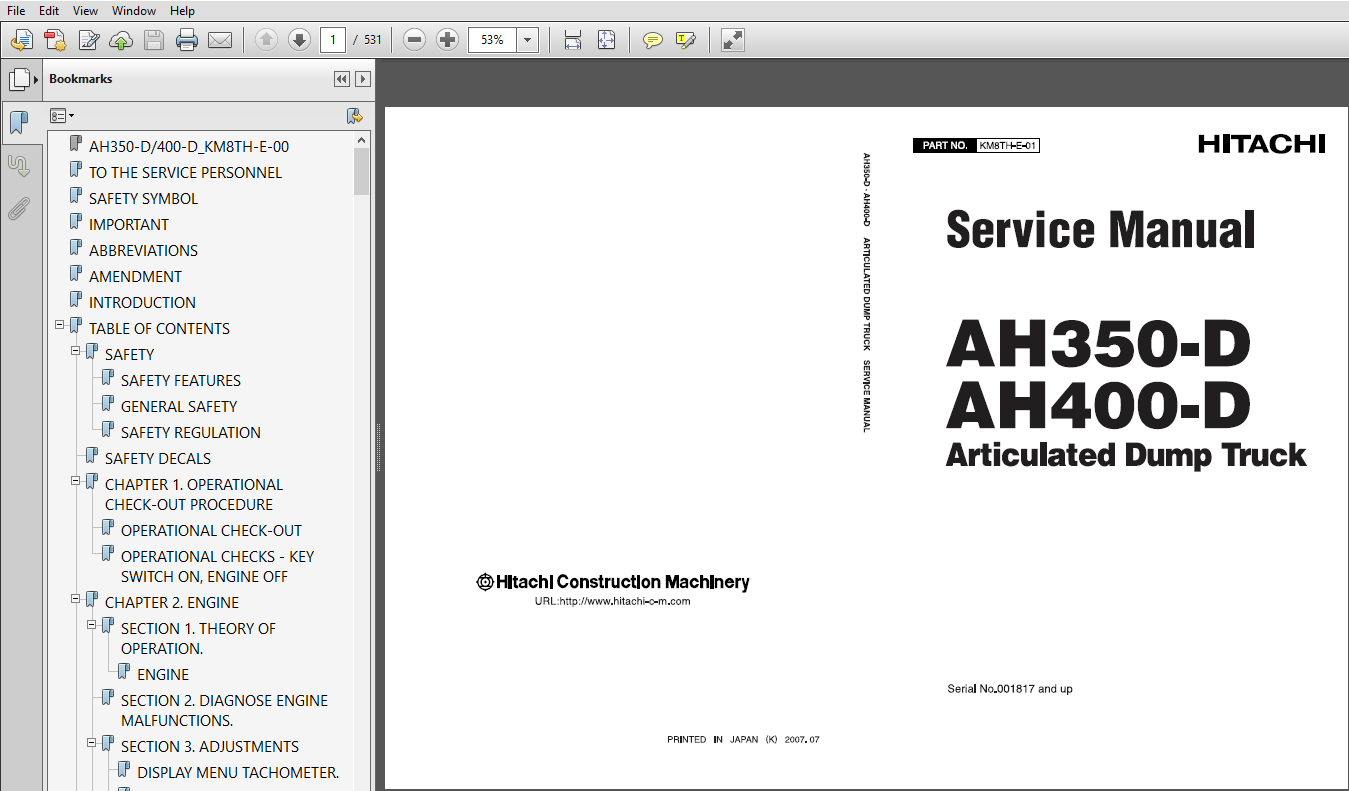

Hitachi AH350-D AH400-D Articulated Dump Truck Service Manual (KM8TH-E-01)PDF DOWNLOAD

Hitachi AH350-D AH400-D Articulated Dump Truck Service + Technical + Workshop Manual

FILE DETAILS:

Hitachi AH350-D AH400-D Articulated Dump Truck Service + Technical + Workshop Manual

This Manual Includes:

- Hitachi AH350-D AH400-D Articulated Dump Truck Service Manual (KM8TH-E-01)

- Hitachi AH350-D AH400-D Articulated Dump Truck Technical Manual (K8TG-E-02)

- Hitachi AH350-D AH400-D Articulated Dump Truck Workshop Manual (KM-3540DE)

SCREENSHOTS OF THE MANUAL:

DESCRIPTION:

Hitachi AH350-D AH400-D Articulated Dump Truck Service + Technical + Workshop Manual

- This manual is written for an experienced technician and are on-the-job guides containing only the vital information needed for diagnosis, analyses, testing and repair. Essential tools required in performing certain service works are identified and in this manual and are recommended for use.

- The safe operation of your HITACHI machines very important to prevent any personal injury and/ or damage.

- This manual must be read and fully understood before carrying out any tests on your HITACHI machine. Right and left hand sides are determined by facing in the direction of forward travel. This manual is divided into chapters.

- The information contained in the manual is in logical sequence, with the instructions written in step by step format. Effective maintenance on your HITACHI machine is achieved when personnel fully understand the information contained in this manual.

- Every effort has been made to ensure that the information contained in this manual was correct at the time of publication.

- HITACHI . has a policy of continuous product development, improvement, and design. HITACHI . reserves the right to change, amend and update the design of its product at any time without prior notice. With this policy, changes may have occurred that are not included in this manual.

- This manual is written for an experienced technician. Essential tools required in performing certain service work are identified in this manual and are recommended for use. Live with safety: Read the safety messages in the introduction of this manual and the cautions presented throughout the text of the manual. This is the safety-alert symbol.

- When you see this symbol on the machine or in this manual, be alert to the potential for personal injury. Service manuals are divided in two parts: Technical and Workshop.

- Workshop sections tell how to repair the components. Technical sections help you identify the majority of routine failures quickly. Information is organized in groups for the various components requiring service instruction.

- At the beginning of each group are summary listings of all applicable essential tools, service equipment and tools, other materials needed to do the job, service parts kits, specifications, wear tolerances, and torque values. Service Manuals are concise guides for specific machines.

- They are on-the-job guides containing only the vital information needed for diagnosis, analysis, testing, and repair. Fundamental service information is available from other sources covering basic theory of operation, fundamentals of troubleshooting, general maintenance, and basic type of failures and their causes.

TABLE OF CONTENTS:

Hitachi AH350-D AH400-D Articulated Dump Truck Service Manual (KM8TH-E-01)

AH350-D/400-D_KM8TH-E-00………………………………………………………….. 1

TO THE SERVICE PERSONNEL………………………………………………………….. 5

SAFETY SYMBOL……………………………………………………………………. 6

IMPORTANT……………………………………………………………………….. 8

ABBREVIATIONS……………………………………………………………………. 9

AMENDMENT……………………………………………………………………….. 11

INTRODUCTION…………………………………………………………………….. 13

TABLE OF CONTENTS………………………………………………………………… 37

SAFETY………………………………………………………………………. 15

SAFETY FEATURES…………………………………………………………… 15

GENERAL SAFETY……………………………………………………………. 16

SAFETY REGULATION…………………………………………………………. 17

SAFETY DECALS………………………………………………………………… 23

CHAPTER 1. OPERATIONAL CHECK-OUT PROCEDURE………………………………………. 47

OPERATIONAL CHECK-OUT……………………………………………………… 47

OPERATIONAL CHECKS – KEY SWITCH ON, ENGINE OFF……………………………….. 47

CHAPTER 2. ENGINE…………………………………………………………….. 53

SECTION 1. THEORY OF OPERATION……………………………………………… 53

ENGINE……………………………………………………………….. 53

SECTION 2. DIAGNOSE ENGINE MALFUNCTIONS……………………………………… 57

SECTION 3. ADJUSTMENTS…………………………………………………….. 59

DISPLAY MENU TACHOMETER………………………………………………… 59

SLOW AND FAST IDLE ADJUSTMENT…………………………………………… 59

VALVE CLEARANCE ADJUSTMENT……………………………………………… 59

EXHAUST BRAKE ADJUSTMENT……………………………………………….. 60

SECTION 4. TESTS………………………………………………………….. 63

CYLINDER COMPRESSION TEST………………………………………………. 63

FUEL PUMP PRESSURE TEST………………………………………………… 63

OIL PUMP PRESSURE TEST…………………………………………………. 65

CAN BUS J1939…………………………………………………………. 69

WHAT EXACTLY IS A “CAN BUS”…………………………………………….. 69

CANBUS……………………………………………………………….. 71

TESTING THE “CANBUS”…………………………………………………… 73

CHECKING THE CABLES……………………………………………………. 73

CHECKING OPENS, SHORTS BETWEEN WIRES AND SHORTS TO GROUND ON THE CAN HARNESS…. 73

MAIN “CAN” HARNESS…………………………………………………….. 74

“CAN” SHORT TO GROUND………………………………………………….. 75

“CAN “OPEN CIRCUIT…………………………………………………….. 76

“CAN” SHORT TO POSITIVE 0 -24 VOLTS……………………………………… 77

CHAPTER 3. ELECTRICAL SYSTEM…………………………………………………… 79

SECTION 1. SYSTEM INFORMATION………………………………………………. 79

ELECTRICAL SCHEMATIC SYMBOLS……………………………………………. 79

CHASSIS CONTROL UNIT (CCU & OEU)………………………………………… 80

MDU2 (MONITOR DISPLAY UNIT)…………………………………………….. 81

MDU2 LAYOUT…………………………………………………………… 82

MDU2 INPUT AND OUTPUTS…………………………………………………. 83

RELAY………………………………………………………………… 85

START-UP DISPLAY………………………………………………………. 86

DEFAULT SCREEN………………………………………………………… 86

DEFAULT SCREEN………………………………………………………… 86

DEFAULT SCREEN………………………………………………………… 86

DEFAULT SCREEN………………………………………………………… 86

DEFAULT SCREEN………………………………………………………… 87

TO GO TO MAIN MENU FROM DEFAULT SCREEN…………………………………… 87

MAIN MENU…………………………………………………………….. 87

EXPLANATION OF WIRE MARKINGS……………………………………………. 92

SECTION 2. DESCRIPTION OF CIRCUITS…………………………………………..125

SSM…………………………………………………………………..137

MDU2 WARNING LIGHTS…………………………………………………….148

MDU2 GAUGES……………………………………………………………152

CCU2 OUTPUT SPECIFICATION……………………………………………….153

OEU OUTPUT SPECIFICATION………………………………………………..157

SECTION 3. REFERENCES………………………………………………………161

ENGINE FAULT CODES (ADM)………………………………………………..161

ENGINE FAULT CODES (PLD-MR)……………………………………………..166

SSM FAULT CODES………………………………………………………..192

PART 2. DM1 FAULT CODES…………………………………………………193

SECTION 4. TESTS…………………………………………………………..211

KEY SWITCH TEST………………………………………………………..211

RELAYS………………………………………………………………..211

Diode Test…………………………………………………………….212

Pneumatic System Solenoids, Pressure Switches, and Sensor Tests……………..213

Steering Column Switch Test……………………………………………..218

CHAPTER 4. TRANSMISSION HD4560………………………………………………….231

SECTION 1. THEORY OF OPERATION………………………………………………231

GENERAL DESCRIPTIONS……………………………………………………231

STALL SPEEDS…………………………………………………………..238

PLANETARY GEARS AND POWER FLOWS………………………………………….240

THE BASIC LAWS OF PLANETARY GEAR SETS…………………………………….241

HD TRANSMISSION PLANETARY CONFIGURATION…………………………………..242

HD TRANSMISSION CLUTCH CONFIGURATION……………………………………..243

TRANSMISSION CROSS SECTIONAL DIAGRAM……………………………………..245

POWER FLOW…………………………………………………………….247

HYDRAULIC SYSTEM……………………………………………………….257

SOLENOIDS……………………………………………………………..261

HYDRAULIC CIRCUITS……………………………………………………..263

TORQUE CONVERTER AND LUBE PRESSURE CIRCUITS – OVERVIEW……………………..271

EXHAUST BACKFILL PRESSURE……………………………………………….272

PRESSURE TABLE AND TEST POINTS…………………………………………..277

RETARDER………………………………………………………………278

APPLICATIONS AND CAPACITIES……………………………………………..278

INPUTS AND OUTPUTS……………………………………………………..280

RETARDER CONTROL HYDRAULICS……………………………………………..280

TESTING RETARDER CHARGING PRESSURE……………………………………….281

HD RETARDER HYDRAULIC SCHEMATIC RETARDER OFF………………………………282

HD RETARDER HYDRAULIC SCHEMATIC RETARDER ON……………………………….283

ELECTRONIC CONTROL SYSTEM……………………………………………….284

PUSH BUTTON SHIFT SELECTOR………………………………………………288

SPEED SENSORS………………………………………………………….289

WIRING HARNESSES……………………………………………………….289

RANGE / SHIFT TESTS…………………………………………………….290

DO NOT SHIFT LIGHT……………………………………………………..291

SECTION 2. DIAGNOSTIC INFORMATION……………………………………………293

DIAGNOSTIC PROCEDURE……………………………………………………293

DIAGNOSE POWER TRAIN SYSTEM MALFUNCTIONS………………………………….294

CHECK THE TRANSMISSION FLUID LEVEL……………………………………….306

TRANSMISSION CONTROL UNIT ERROR CODES…………………………………….309

Service Code Diagnostics – How To Use Listing For Transmission Codes…………310

TABLE OF ERROR CODES……………………………………………………….311

ALLISON HD 4560R ELECTRONIC CONTROL WTEC III………………………………317

SECTION 3. ADJUSTMENTS AND TESTS…………………………………………….319

TRANSMISSION WARM-UP PROCEDURE…………………………………………..319

TRANSMISSION OIL COOLER RESTRICTION TEST………………………………….328

CHAPTER 5. PNEUMATIC SYSTEM…………………………………………………….329

SECTION 1. THEORY OF OPERATION………………………………………………329

PNEUMATIC SYSTEM OPERATION………………………………………………329

PNEUMATIC SYSTEM SCHEMATIC………………………………………………330

SECTION 2. DIAGNOSTIC INFORMATION……………………………………………341

DIAGNOSTIC PROCEDURE……………………………………………………341

DIAGNOSE PNEUMATIC SYSTEM MALFUNCTIONS……………………………………342

SECTION 3. ADJUSTMENTS AND TESTS…………………………………………….344

PNEUMATIC SYSTEM MAIN PRESSURE TEST AND ADJUSTMENT…………………………344

PARK BRAKE PRESSURE TEST………………………………………………..345

PARK BRAKE ADJUSTMENT…………………………………………………..346

GRAMMER SEAT FUNCTIONAL TEST…………………………………………….348

CHAPTER 6. HYDRAULIC SYSTEM…………………………………………………….349

SECTION 1. THEORY OF OPERATION………………………………………………….349

ARTICULATED DUMP TRUCK HYDRAULIC SYSTEM OPERATION……………………………..349

SECTION 2. DIAGNOSTIC INFORMATION……………………………………………….383

DIAGNOSTIC PROCEDURE……………………………………………………….383

DIAGNOSE HYDRAULIC SYSTEM MALFUNCTIONS……………………………………….384

SECTION 3. TESTS………………………………………………………………397

JT05800 DIGITAL THERMOMETER INSTALLATION……………………………………..397

JT02156A DIGITAL ANALOGUE PRESSURE/TEMPERATURE ANALYSER INSTALLATION…………….397

HYDRAULIC OIL CLEANUP PROCEDURE USING PORTABLE FILTER CADDY…………………….397

HYDRAULIC SYSTEM WARM-UP PROCEDURE…………………………………………..398

CYCLE TIME TEST……………………………………………………………399

MAIN HYDRAULIC PUMP RESIDUAL AND COMPENSATOR VALVES TEST AND ADJUSTMENT………….400

SYSTEM RELIEF VALVE AND BIN RAISE CIRCUIT RELIEF VALVE TEST…………………….402

PRIORITY VALVE TEST………………………………………………………..403

ACCUMULATOR PRESSURE REDUCING VALVE TEST AND ADJUSTMENT………………………..403

BRAKE ACCUMULATOR CHARGE VALVE TEST AND ADJUSTMENT…………………………….404

BRAKE LOW PRESSURE SWITCH AND BRAKE ACCUMULATOR TEST…………………………..405

FRONT AND REAR BRAKE ACCUMULATORS PRESSURE TEST AND CHARGE PROCEDURE…………….406

SERVICE BRAKE VALVE TEST……………………………………………………407

STEERING RELIEF VALVE PRESSURE TEST AND ADJUSTMENT…………………………….408

STEERING CYLINDER LEAKAGE TEST………………………………………………408

SECONDARY STEERING PUMP RESIDUAL AND COMPENSATOR VALVES TEST AND ADJUSTMENT………409

BIN LOWER CIRCUIT RELIEF VALVE TEST………………………………………….410

FAN DRIVE CIRCUIT PRESSURES…………………………………………………411

CHAPTER 7. HEATING AND AIR CONDITIONING………………………………………….413

SECTION 1. THEORY OF OPERATION………………………………………………413

AIR CONDITIONING SYSTEM CYCLE OF OPERATION………………………………..413

HEATER CORE OPERATION…………………………………………………..414

SECTION 2. DIAGNOSTIC INFORMATION……………………………………………415

DIAGNOSE AIR CONDITIONING SYSTEM MALFUNCTIONS……………………………..415

HEATING/AIR CONDITIONING COMPONENT LOCATION……………………………….417

SECTION 3. TESTS…………………………………………………………..419

AIR CONDITIONING OPERATIONAL CHECKS………………………………………419

R134A AIR CONDITIONING SYSTEM TEST……………………………………….420

OPERATING PRESSURE DIAGNOSTIC CHART………………………………………421

A/C FREEZE CONTROL SWITCH TEST…………………………………………..423

A/C COMPRESSOR CLUTCH TEST………………………………………………423

A/C HIGH/LOW PRESSURE SWITCH TEST………………………………………..423

A/C EXPANSION VALVE TEST………………………………………………..424

EXPANSION VALVE BENCH TEST………………………………………………425

REFRIGERANT LEAK TEST…………………………………………………..426

CHAPTER 8. MAINTENANCE SCHEDULES………………………………………………..429

NOTES:……………………………………………………………………432

CHAPTER 9. DAILY OR 10 HOURLY SERVICE CHECKS……………………………………..433

CHAPTER 10. 150 HOURS SERVICE AND CHECKS…………………………………………435

SECTION 1. DRIVE TRAIN……………………………………………………..435

INTRODUCTION…………………………………………………………..435

SERVICE INSTRUCTIONS……………………………………………………435

LOWER AND RAISE THE BELLY PLATE………………………………………….435

CHAPTER 11. 500 HOURS SERVICE AND CHECKS…………………………………………439

SECTION 1. DRIVE TRAIN……………………………………………………..439

INTRODUCTION…………………………………………………………..439

SERVICE INSTRUCTIONS……………………………………………………439

ENGINE………………………………………………………………..439

TRANSMISSION…………………………………………………………..440

BRAKES………………………………………………………………..443

TRANSFER CASE………………………………………………………….444

SECTION 2. CLEAN, CHECK AND REPLACE BREATHERS…………………………………445

GENERAL CHECK DRIVE LINE & SUSPENSION FASTENERS……………………………445

TRANSFER CASE BREATHER (LOCATED UNDER THE HYDRAULIC RESERVOIR)………………445

TRANSMISSION BREATHER AND AXLE BREATHERS………………………………….445

SECTION 3. CAB AND ELECTRICAL……………………………………………….447

INSPECT, CLEAN AND REPLACE CAB AIR FILTER…………………………………447

CHECK BATTERIES, CLEAN AND TIGHTEN TERMINALS………………………………448

CHECK ELECTRICAL CONNECTORS, HARNESSES AND LOOMS…………………………..448

CHECK WORK LIGHTS, REVERSE BUZZER AND HORNS……………………………….448

RECORD & DELETE FAULT CODES ON THE MDU……………………………………448

CHECK THE OPERATOR CONTROLS AND INSTRUMENTS……………………………….448

SECTION 4. LUBRICATION……………………………………………………..449

GREASE ALL GREASE POINTS………………………………………………..449

HYDRAULICS…………………………………………………………….450

REPLACE HYDRAULIC RESERVOIR BREATHER……………………………………..450

WET DISC BRAKE COOLING OIL RESERVOIR (AH400-D) ONLY (ON TOP OF RESERVOIR)…….451

CHAPTER 12. 1 000 HOURS SERVICE AND CHECKS……………………………………….453

SECTION 1. DRIVE TRAIN……………………………………………………..453

INTRODUCTION…………………………………………………………..453

SERVICE INSTRUCTIONS……………………………………………………453

Engine………………………………………………………………..453

SECTION 2. HYDRAULICS AND LUBRICATION………………………………………..457

REPLACE HYDRAULIC RESERVOIR BREATHER……………………………………..457

SECTION 4. AXLES AND CHASSIS & SUSPENSION…………………………………….459

CHECK AXLE OIL LEVEL……………………………………………………459

CHECK FINAL DRIVE OIL LEVELS…………………………………………….459

CHANGE AXLE OIL (AH350-D With Hitachi Wet Brakes)………………………….459

CHECK BIN SHOCK PAD CLEARANCE……………………………………………460

CHAPTER 13. 2 000 HOURS SERVICE AND CHECKS……………………………………….463

SECTION 1. DRIVE TRAIN……………………………………………………..463

INTRODUCTION…………………………………………………………..463

SERVICE INSTRUCTIONS……………………………………………………463

ENGINE………………………………………………………………..463

SECTION 2. HYDRAULICS AND LUBRICATION………………………………………..467

REPLACE WET DISC BRAKE COOLER OIL AND FILTER………………………………467

SECTION 3. CAB, PNEUMATICS AND ELECTRICAL…………………………………….469

REPLACE PNEUMATIC SYSTEM DRYER FILTER…………………………………….469

CHAPTER 14. 3 000 HOURS SERVICE AND CHECKS……………………………………….471

SECTION 1. DRIVE TRAIN……………………………………………………..471

INTRODUCTION…………………………………………………………..471

SERVICE INSTRUCTIONS……………………………………………………471

SECTION 2. HYDRAULICS AND PNEUMATICS…………………………………………473

CHAPTER 15. 4 000 HOURS SERVICE AND CHECKS……………………………………….475

SECTION 1. DRIVE TRAIN……………………………………………………..475

REPLACE FAN BELT……………………………………………………….475

SECTION 2. HYDRAULICS AND PNEUMATICS…………………………………………477

INTRODUCTION…………………………………………………………..477

SERVICE INSTRUCTIONS……………………………………………………477

CHAPTER 16. AS REQUIRED SERVICE…………………………………………………479

SECTION 1. ENGINE………………………………………………………….479

INTRODUCTION…………………………………………………………..479

SERVICE INSTRUCTIONS……………………………………………………479

SECTION 2. CAB AND LUBRICATION………………………………………………483

CLEAN AIR CONDITIONING FILTERS…………………………………………..483

GREASE HINGES………………………………………………………….483

CHAPTER 17. MISCELLANEOUS SERVICE AND CHECKS……………………………………..485

SECTION 1. DRIVE TRAIN……………………………………………………..485

INTRODUCTION…………………………………………………………..485

SERVICE INSTRUCTIONS……………………………………………………485

ENGINE………………………………………………………………..485

WHEELS………………………………………………………………..485

SECTION 2. ELECTRICAL………………………………………………………487

USING BATTERY CHARGER…………………………………………………..487

ADJUST HEADLIGHTS………………………………………………………489

SECTION 3. OPERATIONAL CHECKOUT……………………………………………..493

OPERATIONAL CHECK-OUT…………………………………………………..493

CHAPTER 18. TROUBLE SHOOTING……………………………………………………501

SECTION 1. SYMPTOMS AND REMEDIES…………………………………………….501

INTRODUCTION…………………………………………………………..501

CHAPTER 19. APPENDIX…………………………………………………………..513

OBW Functional Description ADT Mk IV 001-4002-00 ……………………………..513

HYDRAULIC FAN COOLER FUNCTIONAL DESCRIPTION . ADT MK IV 001-4003-02……………..516

TABLE OF CONTENTS………………………………………………………516

1. INTRODUCTION………………………………………………………..516

2. CHASSIS CONTROL UNIT SOFTWARE REQUIREMENTS……………………………..516

CCU2 HEADLIGHT LOGIC AND CONTROL 001-4004-00………………………………….519

1. INTRODUCTION………………………………………………………..519

2. HEADLIGHT LOGIC AND CONTROL…………………………………………..519

CCU2 WIPER CONTROL LOGIC 001-4005-00…………………………………………521

1. INTRODUCTION………………………………………………………..521

2. WIPER CONTROL LOGIC AND TIMING………………………………………..521

AIR-CONDITIONING CONTROL LOGIC 001-4006-00……………………………………523

1. INTRODUCTION………………………………………………………..523

2. INPUTS/OUTPUTS………………………………………………………523

BIN CONTROL LOGIC 001-4007-00……………………………………………….525

1. INTRODUCTION………………………………………………………..525

2. BIN CONTROL LOGIC……………………………………………………525

PR001_PARK BRAKE FUNCTION…………………………………………………..529

INTRODUCTION…………………………………………………………..529

SERVICE MANUAL REVISION REQUEST FORM………………………………………………..531

Hitachi AH350-D AH400-D Articulated Dump Truck Technical Manual (K8TG-E-02)

TECHNICALMANUAL……………………………………………………………………………. 1

Introduction…………………………………………………………………………… 3

Contents………………………………………………………………………………. 5

General Information…………………………………………………………………. 7

Safety…………………………………………………………………………. 9

Recognize Safety Information………………………………………………….. 9

Follow Safety Instructions……………………………………………………. 9

Operate Only If Qualified…………………………………………………….. 9

Wear Protective Equipment…………………………………………………….. 10

Avoid Unauthorized Machine Modifications……………………………………….. 10

Inspect Machine……………………………………………………………… 10

Stay Clear Of Moving Parts……………………………………………………. 11

Avoid High-Pressure Fluids……………………………………………………. 11

Beware Of Exhaust Fumes………………………………………………………. 11

Prevent Fires……………………………………………………………….. 12

Prevent Battery Explosions……………………………………………………. 12

Handle Chemical Products Safely……………………………………………….. 13

Dispose of Waste Properly…………………………………………………….. 13

Prepare for Emergencies………………………………………………………. 13

Use Steps And Handholds Correctly……………………………………………… 14

Start Only From Operator’s Seat……………………………………………….. 14

Use And Maintain Seat Belt……………………………………………………. 14

Prevent Unintended Machine Movement……………………………………………. 15

Avoid Work Site Hazards………………………………………………………. 15

Keep Riders Off Machine………………………………………………………. 16

Avoid Backover Accidents……………………………………………………… 16

Avoid Machine Tip Over……………………………………………………….. 17

Operating on Slopes………………………………………………………….. 17

Operating Or Traveling On Public Roads…………………………………………. 18

Inspect and Maintain ROPS…………………………………………………….. 18

Add And Operate Attachments Safely…………………………………………….. 18

Park And Prepare For Service Safely……………………………………………. 19

Service Tires Safely…………………………………………………………. 20

Service Cooling System Safely…………………………………………………. 20

Remove Paint Before Welding or Heating…………………………………………. 21

Make Welding Repairs Safely…………………………………………………… 21

Drive Metal Pins Safely………………………………………………………. 21

Operational Checkout Procedure……………………………………………………….. 23

Operational Checkout Procedure……………………………………………………. 25

Specifications……………………………………………………………………… 33

SPECIFICATIONS………………………………………………………………….. 35

Engine…………………………………………………………………………….. 39

Theory of Operation……………………………………………………………… 41

350D and 400D (OM 501) Engine Sectional View……………………………………. 41

Engine Operation…………………………………………………………….. 43

Electronic Unit Injector Fuel System…………………………………………… 43

Fuel Delivery……………………………………………………………….. 44

Cold Start Operation…………………………………………………………. 48

Diagnose Engine Malfunctions……………………………………………………… 49

Diagnose Engine Malfunctions………………………………………………….. 49

Adjustments…………………………………………………………………….. 53

Display Monitor Tachometer……………………………………………………. 53

Slow and Fast Idle Adjustment…………………………………………………. 53

Valve Clearance Adjustment……………………………………………………. 54

Exhaust Brake Adjustment……………………………………………………… 56

Tests………………………………………………………………………….. 57

Cylinder Compression Test…………………………………………………….. 57

Fuel Pump Pressure Test………………………………………………………. 58

Oil Pump Pressure Test……………………………………………………….. 60

Electrical System…………………………………………………………………… 63

System Information………………………………………………………………. 66

Electrical Diagram Information………………………………………………… 66

CAN BUS J1939…………………………………………………………………… 73

WHAT EXACTLY IS A “CAN BUS”…………………………………………………… 73

TESTING THE “CANBUS”…………………………………………………………. 75

CHECKING THE CABLES………………………………………………………….. 76

CHECKING OPENS, SHORTS BETWEEN WIRES AND SHORTS TO GROUND ON THE CAN

HARNESS………. 77

MAIN “CAN” HARNESS…………………………………………………………… 77

“CAN” SHORT TO GROUND………………………………………………………… 78

“CAN” OPEN CIRCUIT…………………………………………………………… 79

“CAN” SHORT TO POSITIVE 0 -24 VOLTS……………………………………………. 80

CCU WITH THE THREE CONNECTORS…………………………………………………. 82

CHASSIS CONTROL UNIT (CCU)……………………………………………………. 81

CCU CONNECTOR X5 (J3)………………………………………………………… 83

CCU CONNECTOR X6A (J1A)………………………………………………………. 84

CCU CONNECTOR X6B (J1L)………………………………………………………. 85

THE FOLLOWING DESCRIBES THE INPUTS AND OUTPUTS OF THE CCU………………………… 86

PLUG X5 (J3)………………………………………………………………… 86

PLUG X6A (J1A)………………………………………………………………. 88

PLUG X6B (J1L)………………………………………………………………. 90

MDU (MONITOR DISPLAY UNIT)……………………………………………………. 93

MDU LAYOUT………………………………………………………………….. 94

MDU INPUT AND OUTPUTS………………………………………………………… 95

THE FOLLOWING DESCRIBES THE INPUTS AND OUTPUTS OF THE MDU………………………… 96

PLUG X37……………………………………………………………………. 96

PLUG X38……………………………………………………………………. 97

MDU MENU STRUCTURE…………………………………………………………… 98

DEFAULT OPTIONS AVAILABLE FOR THE LARGE ADT’S ARE AS FOLLOWS……………………… 99

LARGE ADT, MDU MENU A…………………………………………………………107

LARGE ADT, MDU MENU B…………………………………………………………108

ENGINE VALUES………………………………………………………………..109

TRANSMISSION VALUES…………………………………………………………..110

VEHICLE VALUES……………………………………………………………….111

LARGE ADT, MDU MENU C…………………………………………………………113

CCU INPUTS…………………………………………………………………..115

CCU ANALOG…………………………………………………………………..118

CCU OUTPUTS………………………………………………………………….120

LARGE ADT, MDU MENU D…………………………………………………………123

MENU D CONT………………………………………………………………….125

LARGE ADT, MDU MENU E…………………………………………………………129

ON BOARD WEIGHING…………………………………………………………….134

OBW MODULE…………………………………………………………………..134

X161 CONNECTOR 12 Way Deutch…………………………………………………..134

Calibration of the OBW System………………………………………………….136

MENU C………………………………………………………………………136

MENU D………………………………………………………………………138

Auto Zero……………………………………………………………………139

“Hopper site”………………………………………………………………..139

“OBW Function”……………………………………………………………….139

ELECTRICAL SCHEMATICS…………………………………………………………140

SCHEMATIC SYMBOLS…………………………………………………………….140

EARTH POINTS…………………………………………………………………141

System Diagrams………………………………………………………………….143

Explanation of Wire Markings…………………………………………………..143

Fuse Specifications…………………………………………………………..144

Functional Schematic and Component Location Legend……………………………….146

Functional Schematic………………………………………………………….154

Section Legend……………………………………………………………154

Electrical System Functional Schematic………………………………………….155

Main Power Harness (W6)……………………………………………………….156

Wiring Diagram……………………………………………………………156

Component Location………………………………………………………..158

Front Frame/Engine Harness (W7)………………………………………………..160

Wiring Diagram……………………………………………………………160

Component Location………………………………………………………..162

Engine Main Harness (W8)………………………………………………………164

Wiring Diagram……………………………………………………………164

Component Location………………………………………………………..166

Cab Power Harness (W9)………………………………………………………..167

Wiring Diagram……………………………………………………………167

Component Location………………………………………………………..168

Cab Main Harness (W10)………………………………………………………..170

Wiring Diagram……………………………………………………………170

Component Location………………………………………………………..181

Controller Area Network (CAN) Harness (W11)……………………………………..188

Wiring Diagram……………………………………………………………188

Component Location………………………………………………………..190

Transmission Control Harness (W12)……………………………………………..192

Wiring Diagram……………………………………………………………192

Component Location………………………………………………………..194

Transmission Harness (W13)…………………………………………………….196

Wiring Diagram……………………………………………………………196

Component Location………………………………………………………..198

Hydraulic Harness (W14)……………………………………………………….200

Wiring Diagram……………………………………………………………200

Component Location………………………………………………………..202

Rear Fame Harness (W15)……………………………………………………….204

Wiring Diagram……………………………………………………………204

Component Location………………………………………………………..206

Work Light Harness (W16)………………………………………………………207

Wiring Diagram……………………………………………………………207

Component Location………………………………………………………..208

Air Conditioning Actuator Harness (W18)…………………………………………210

Wiring Diagram……………………………………………………………210

Component Location………………………………………………………..212

Sub-System Diagnostics……………………………………………………………214

Starting and Charging Circuit………………………………………………….214

Theory of Operation……………………………………………………….214

Cold Start Circuit……………………………………………………………218

Theory of Operation……………………………………………………….218

Electronic Unit Injector Controller Circuit……………………………………..220

Theory of Operation……………………………………………………….220

Engine Control Unit Circuit……………………………………………………224

Theory of Operation……………………………………………………….224

Transmission Control Unit Circuit………………………………………………226

Theory of Operation……………………………………………………….226

Chassis Control Unit Circuit…………………………………………………..232

Theory of Operation……………………………………………………….232

Dump Body Control, Fan Drive, and Range Hold Circuit Theory of Operation……………238

Park Brake and Exhaust Brake Circuit……………………………………………242

Theory of Operation……………………………………………………….242

Monitor Display Unit Circuit…………………………………………………..246

Theory of Operation……………………………………………………….246

Turn Signal and 4-Way Flasher Circuit…………………………………………..252

Theory of Operation……………………………………………………….252

Stop Light Circuit……………………………………………………………256

Theory of Operation……………………………………………………….256

Backup Alarm and Backup Light Circuit…………………………………………..258

Theory of Operation……………………………………………………….258

Wiper/Washer Circuit………………………………………………………….260

Theory of Operation……………………………………………………….260

Battery Balancer and 12-Volt Accessory Circuit Theory of Operation…………………264

Air Conditioning Circuit………………………………………………………266

Theory of Operation……………………………………………………….266

Electric Mirror Circuit……………………………………………………….270

Theory of Operation……………………………………………………….270

Unloader Valve Circuit ……………………………………………………….272

Theory of Operation……………………………………………………….272

References………………………………………………………………………273

Service Code Diagnostics………………………………………………………273

After Machine Repair………………………………………………………273

How Codes Are Displayed On Monitor Display Unit………………………………275

How To Use Listing For Transmission Codes……………………………………276

Engine Control Unit……………………………………………………….277

Electronic Unit Injector (EUI) Controller……………………………………285

Chassis Control Unit………………………………………………………302

Transmission Control Unit (TCU)…………………………………………….305

D-Series Articulated Dump Trucks 350D and 400D Service ADVISOR™ Computer Connection….415

Circuit Check Using Monitor Display Unit (MDU) or Service ADVISOR………………….418

Two-Wire Sensor…………………………………………………………..418

Three-Wire Sensor…………………………………………………………419

Key Switch Test………………………………………………………………420

Relay Test…………………………………………………………………..420

Diode Test…………………………………………………………………..421

Pneumatic System Solenoids, Pressure Switches, and Sensor Tests……………………422

Hydraulic Pressure Switches Test……………………………………………….427

Hydraulic Temperature Sensors Test……………………………………………..428

Body Position Sensor Test……………………………………………………..429

Steering Column Switch Test……………………………………………………432

Retarder Voltage Regulator Test………………………………………………..433

Transmission Speed Sensors Test………………………………………………..436

Transmission Solenoids Test……………………………………………………437

Electronic Unit Injector (EUI) Controller……………………………………….438

Remove and Install………………………………………………………..438

Engine Control Unit…………………………………………………………..438

Remove and Install………………………………………………………..438

Cold Start Module…………………………………………………………….440

Remove and Install………………………………………………………..440

Chassis Control Unit………………………………………………………….441

Remove and Install………………………………………………………..441

Transmission Control Unit …………………………………………………….442

Remove and Install………………………………………………………..442

Battery Balancer……………………………………………………………..443

Remove and Install………………………………………………………..443

Monitor Display Unit………………………………………………………….444

Remove and Install………………………………………………………..444

Replace Monitor Display Unit Bulbs……………………………………………..445

Remove, Install, and Calibrate Accelerator Pedal Position Sensor…………………..447

Replace DEUTSCH™ Rectangular or Triangular Connectors…………………………….448

Replace DEUTSCH™ Connectors……………………………………………………449

Install DEUTSCH™ Contact………………………………………………………450

Replace WEATHER PACK™Connector…………………………………………………451

Install WEATHER PACK™Contact…………………………………………………..452

Replace (Pull Type) Metri-Pack™ Connectors………………………………………454

Replace (Push Type) Metri-Pack™ Connectors………………………………………455

Remove Connector Body from Blade Terminals………………………………………455

Power Train…………………………………………………………………………457

Theory of Operation………………………………………………………………459

Transmission External Components……………………………………………….459

Transmission…………………………………………………………………461

Control System……………………………………………………………461

Cross Sectional Diagram……………………………………………………464

TORQUE CONVERTER………………………………………………………….466

Operational Overview………………………………………………………466

TORQUE CONVERTER OPERATION…………………………………………………467

Stator One-way Clutch Operation…………………………………………….468

Vortex Flow………………………………………………………………469

Rotary Flow………………………………………………………………470

LOCK-UP CLUTCH OPERATION…………………………………………………..471

Stall Testing…………………………………………………………….471

Stall Test Procedure………………………………………………………471

AH400-D/AH350-D STALL SPEEDS……………………………………………….473

Analysing Stall Test Results……………………………………………….473

Trouble Shooting A Freewheeling Stator………………………………………473

Troubleshooting A Stuck Stator……………………………………………..473

Stall Torque Ratio………………………………………………………..473

Clutch Engagement…………………………………………………………474

PLANETARY GEARS AND POWER FLOWS…………………………………………….513

THE BASIC LAWS OF PLANETARY GEAR SETS……………………………………….514

CLUTCHES…………………………………………………………………514

HD TRANSMISSION PLANETARY CONFIGURATION……………………………………..515

Transmission Cross

Sectional Diagram……………………………………….518

POWER FLOW……………………………………………………………….520

Neutral Power Flow………………………………………………………..521

1st Range Power Flow………………………………………………………522

2nd Range Power Flow………………………………………………………523

3rd Range Power Flow………………………………………………………524

4th Range Power Flow………………………………………………………525

5th Range Power Flow………………………………………………………526

6th Range Power Flow………………………………………………………527

Reverse Range Power Flow…………………………………………………..528

Retarder Operation………………………………………………………..529

Transmission Thermal Valve Operation……………………………………………533

Differential Lock Operation……………………………………………………534

Inter-Axle Lock Operation……………………………………………………..534

Diagnostic Information……………………………………………………………535

Diagnostic Procedure………………………………………………………….535

Power Train Systems…………………………………………………………..536

Diagnose Malfunctions……………………………………………………..536

Power Train………………………………………………………………….550

Component Location Diagram…………………………………………………550

Tests…………………………………………………………………………..553

Transmission…………………………………………………………………553

Warm Up Procedure…………………………………………………………553

Transmission Pressure Test…………………………………………………….554

Clutch Enable Test with Service ADVISER™………………………………………..562

Transmission Clutch Drag Test………………………………………………….567

Torque Converter Stall Test—350D……………………………………………….569

Torque Converter Stall Test—400D……………………………………………….571

Torque Converter Stator Tests………………………………………………….573

Torque Converter Lockup Test…………………………………………………..575

Transmission Thermal Valve Test………………………………………………..576

Transmission Oil Cooler Restriction Test………………………………………..577

RETARDER…………………………………………………………………….578

Retarder Operation……………………………………………………………578

APPLICATIONS AND CAPACITIES……………………………………………………578

Retarder Control – Overview……………………………………………………579

Apply Controls……………………………………………………………….579

INPUTS AND OUTPUTS……………………………………………………………580

RETARDER CONTROL HYDRAULICS……………………………………………………580

TESTING RETARDER CHARGING PRESSURE……………………………………………..581

HD RETARDER HYDRAULIC SCHEMATIC RETARDER OFF…………………………………….582

HD RETARDER HYDRAULIC SCHEMATIC RETARDER ON……………………………………..583

ELECTRONIC CONTROL SYSTEM……………………………………………………..584

SYSTEM COMPONENTS…………………………………………………………….584

TRANSMISSION CONTROL UNIT (TCU)………………………………………………..584

PULSE WIDTH MODULATION (PWM)…………………………………………………..584

Pulse Width Modulation Waveforms(Solenoid Duty Cycle)…………………………….585

UPSHIFT CLUTCH CONTROL………………………………………………………..585

PUSH BUTTON SELECTORS…………………………………………………………588

Mode………………………………………………………………………..588

Hold Upshift Shift Schedule Or Range Hold……………………………………….588

Pre-select Downshift Shift Schedule…………………………………………….588

Speed Sensor Locations………………………………………………………..589

WIRING HARNESSES……………………………………………………………..589

External Wiring Harness……………………………………………………….589

Internal Wiring Harness……………………………………………………….590

RANGE / SHIFT TESTS…………………………………………………………..590

Range Verification……………………………………………………………590

Off-going Ratio Test………………………………………………………….590

Oncoming Ratio Test…………………………………………………………..591

DO NOT SHIFT LIGHT……………………………………………………………591

Backfill Pressure…………………………………………………………….593

Accumulator Relay Valve……………………………………………………….595

Front Suspension Strut Leakage Check……………………………………………596

Park Brake Test………………………………………………………………596

Park Brake Pad Thickness Check…………………………………………………597

Park Brake Adjustment…………………………………………………………598

Checking Controlled Traction Clutch (Differential Lock) Condition………………….601

Pneumatic System…………………………………………………………………….603

Theory of Operation………………………………………………………………606

Pneumatic System Schematic…………………………………………………….606

Pneumatic System Operation…………………………………………………….607

Air Pressure Supply Circuit Operation…………………………………………..608

Air Dryer and Unloader Valve…………………………………………………..610

Pneumatic Manifold……………………………………………………………612

Pneumatic Circuit…………………………………………………………….618

Diagnostic Information……………………………………………………………623

Diagnostic Procedure………………………………………………………….623

Diagnose Pneumatic System Malfunctions………………………………………….624

Pneumatic System Component Location Diagram……………………………………..628

Tests…………………………………………………………………………..631

Pneumatic System Main Pressure Test and Adjustment……………………………….631

Park Brake Pressure Test………………………………………………………632

Hydraulic System…………………………………………………………………….635

Theory of Operation………………………………………………………………637

Articulated Dump Truck Hydraulic System Operation………………………………..637

Main Hydraulic Pump Operation………………………………………………….640

Main Hydraulic Pump Load Sense Operation………………………………………..642

Service Brake System Operation…………………………………………………646

Steering and Secondary Steering System Operation…………………………………650

Steering Valve Operation………………………………………………………654

Secondary Steering Pump Operation………………………………………………656

Hydraulic System Manifold Operation…………………………………………….658

Fan Drive System Operation…………………………………………………….666

Dump Body Control Valve Operation………………………………………………668

Hydraulic System Circuit Symbols……………………………………………….670

Hydraulic System Schematic—350D………………………………………………..672

Hydraulic System Schematic—400D………………………………………………..674

Diagnostic Information……………………………………………………………677

Diagnostic Procedure………………………………………………………….677

Diagnose Hydraulic System Malfunctions………………………………………….678

Diagnose Service Brake System Malfunctions………………………………………683

Diagnose Steering System Malfunctions…………………………………………..686

Hydraulic System Component Location…………………………………………….690

Tests…………………………………………………………………………..699

JT05800 Digital Thermometer Installation………………………………………..699

JT02156A Digital Pressure/Temperature Analyzer Installation……………………….699

Hydraulic Oil Cleanup Procedure Using Portable Filter Caddy……………………….700

Hydraulic System Warm-Up Procedure……………………………………………..701

Cycle Time Test………………………………………………………………702

Main Hydraulic Pump Residual and Compensator Valves Test and Adjustment…………….703

System Relief Valve and Dump Body Raise Circuit Relief Valve Test………………….706

Priority Valve Test…………………………………………………………..707

Accumulator Pressure Reducing Valve Test and Adjustment…………………………..708

Brake Accumulator Charge Valve Test and Adjustment……………………………….710

Brake Low Pressure Switch and Brake Accumulator Test……………………………..712

Front and Rear Brake Accumulators Pressure Test and Charge Procedure……………….714

Service Brake Valve Test………………………………………………………715

Steering Relief Valve Pressure Test and Adjustment……………………………….716

Steering Cylinder Leakage Test…………………………………………………718

Secondary Steering Pump Residual and Compensator Valves Test and Adjustment…………719

Dump Body Lower Circuit Relief Valve Test……………………………………….721

Fan Drive Controller Test and Adjustment………………………………………..722

Wet Disk Brake Thermal Valve Test………………………………………………724

Wet Disk Brake Cooling System Bypass Check Valve Test…………………………….725

Wet Disk Brake Cooler Restriction Test………………………………………….726

Wet Disk Brake Cooling Oil Filter Restriction Test……………………………….728

Heating and Air Conditioning………………………………………………………….731

Theory of Operation………………………………………………………………733

Air Conditioning System Cycle of Operation………………………………………733

Heater Core Operation…………………………………………………………734

Diagnostic Information……………………………………………………………735

Diagnose Air Conditioning System Malfunctions……………………………………735

Diagnose Heater System Malfunctions…………………………………………….737

Heating/Air Conditioning Component Location……………………………………..738

Tests…………………………………………………………………………..741

Air Conditioning Operational Checks…………………………………………….741

R134a Air Conditioning System Test……………………………………………..743

Operating Pressure Diagnostic Chart…………………………………………….745

A/C Freeze Control Switch Test…………………………………………………747

A/C Compressor Clutch Test…………………………………………………….748

A/C High/Low Pressure Switch Test………………………………………………748

A/C Expansion Valve Test………………………………………………………751

Expansion Valve Bench Test…………………………………………………….753

Refrigerant Leak Test…………………………………………………………754

Index………………………………………………………………………………755

REVISION REQUEST FORM………………………………………………………………..761

Hitachi AH350-D AH400-D Articulated Dump Truck Workshop Manual (KM-3540DE)

TECHNICALMANUAL……………………………………………………………………………. 1

Contents………………………………………………………………………………. 3

General Information…………………………………………………………………. 4

Safety…………………………………………………………………………. 6

Recognize Safety Information………………………………………………….. 6

Follow Safety Instructions……………………………………………………. 6

Operate Only If Qualified…………………………………………………….. 6

Wear Protective Equipment…………………………………………………….. 7

Avoid Unauthorized Machine Modifications……………………………………….. 7

Inspect Machine……………………………………………………………… 7

Stay Clear Of Moving Parts……………………………………………………. 8

Avoid High-Pressure Fluids……………………………………………………. 8

Beware Of Exhaust Fumes………………………………………………………. 8

Prevent Fires……………………………………………………………….. 9

Prevent Battery Explosions……………………………………………………. 9

Handle Chemical Products Safely……………………………………………….. 10

Dispose of Waste Properly…………………………………………………….. 10

Prepare for Emergencies………………………………………………………. 10

Use Steps And Handholds Correctly……………………………………………… 11

Start Only From Operator’s Seat……………………………………………….. 11

Use And Maintain Seat Belt……………………………………………………. 11

Prevent Unintended Machine Movement……………………………………………. 12

Avoid Work Site Hazards………………………………………………………. 12

Keep Riders Off Machine………………………………………………………. 13

Avoid Backover Accidents……………………………………………………… 13

Avoid Machine Tip Over……………………………………………………….. 14

Operating on Slopes………………………………………………………….. 14

Operating Or Traveling On Public Roads…………………………………………. 15

Inspect and Maintain ROPS…………………………………………………….. 15

Add And Operate Attachments Safely…………………………………………….. 15

Park And Prepare For Service Safely……………………………………………. 16

Service Tires Safely…………………………………………………………. 17

Service Cooling System Safely…………………………………………………. 17

Remove Paint Before Welding or Heating…………………………………………. 18

Make Welding Repairs Safely…………………………………………………… 18

Drive Metal Pins Safely………………………………………………………. 18

Operational Checkout Procedure……………………………………………………….. 20

Operational Checkout Procedure……………………………………………………. 22

Engine…………………………………………………………………………….. 30

Theory of Operation……………………………………………………………… 32

350D and 400D (OM 501) Engine Sectional View……………………………………. 32

Engine Operation…………………………………………………………….. 34

Electronic Unit Injector Fuel System…………………………………………… 34

Fuel Delivery……………………………………………………………….. 35

Cold Start Operation…………………………………………………………. 39

Diagnose Engine Malfunctions……………………………………………………… 40

Diagnose Engine Malfunctions………………………………………………….. 40

Adjustments…………………………………………………………………….. 44

Display Monitor Tachometer……………………………………………………. 44

Slow and Fast Idle Adjustment…………………………………………………. 44

Valve Clearance Adjustment……………………………………………………. 45

Exhaust Brake Adjustment……………………………………………………… 47

Tests………………………………………………………………………….. 48

Cylinder Compression Test…………………………………………………….. 48

Fuel Pump Pressure Test………………………………………………………. 49

Oil Pump Pressure Test……………………………………………………….. 51

Electrical System…………………………………………………………………… 54

System Information………………………………………………………………. 57

Electrical Diagram Information………………………………………………… 57

System Diagrams…………………………………………………………………. 64

Explanation of Wire Markings………………………………………………….. 64

Fuse Specifications………………………………………………………….. 65

Functional Schematic and Component Location Legend………………………………. 67

Functional Schematic…………………………………………………………. 75

Section Legend…………………………………………………………… 75

Electrical System Functional Schematic…………………………………………. 76

Main Power Harness (W6)………………………………………………………. 77

Wiring Diagram…………………………………………………………… 77

Component Location……………………………………………………….. 79

Front Frame/Engine Harness (W7)……………………………………………….. 81

Wiring Diagram…………………………………………………………… 81

Component Location……………………………………………………….. 83

Engine Main Harness (W8)……………………………………………………… 85

Wiring Diagram…………………………………………………………… 85

Component Location……………………………………………………….. 87

Cab Power Harness (W9)……………………………………………………….. 88

Wiring Diagram…………………………………………………………… 88

Component Location……………………………………………………….. 89

Cab Main Harness (W10)……………………………………………………….. 91

Wiring Diagram…………………………………………………………… 91

Component Location……………………………………………………….. 102

Controller Area Network (CAN) Harness (W11)…………………………………….. 109

Wiring Diagram…………………………………………………………… 109

Component Location……………………………………………………….. 111

Transmission Control Harness (W12)…………………………………………….. 113

Wiring Diagram…………………………………………………………… 113

Component Location……………………………………………………….. 115

Transmission Harness (W13)……………………………………………………. 117

Wiring Diagram…………………………………………………………… 117

Component Location……………………………………………………….. 119

Hydraulic Harness (W14)………………………………………………………. 121

Wiring Diagram…………………………………………………………… 121

Component Location……………………………………………………….. 123

Rear Fame Harness (W15)………………………………………………………. 125

Wiring Diagram…………………………………………………………… 125

Component Location……………………………………………………….. 127

Work Light Harness (W16)……………………………………………………… 128

Wiring Diagram…………………………………………………………… 128

Component Location……………………………………………………….. 129

Air Conditioning Actuator Harness (W18)………………………………………… 131

Wiring Diagram…………………………………………………………… 131

Component Location……………………………………………………….. 133

Sub-System Diagnostics…………………………………………………………… 135

Starting and Charging Circuit…………………………………………………. 135

Theory of Operation………………………………………………………. 135

Cold Start Circuit…………………………………………………………… 139

Theory of Operation………………………………………………………. 139

Electronic Unit Injector Controller Circuit…………………………………….. 141

Theory of Operation………………………………………………………. 141

Engine Control Unit Circuit…………………………………………………… 145

Theory of Operation………………………………………………………. 145

Transmission Control Unit Circuit……………………………………………… 147

Theory of Operation………………………………………………………. 147

Chassis Control Unit Circuit………………………………………………….. 153

Theory of Operation………………………………………………………. 153

Dump Body Control, Fan Drive, and Range Hold Circuit Theory of Operation…………… 159

Park Brake and Exhaust Brake Circuit…………………………………………… 163

Theory of Operation………………………………………………………. 163

Monitor Display Unit Circuit………………………………………………….. 167

Theory of Operation………………………………………………………. 167

Turn Signal and 4-Way Flasher Circuit………………………………………….. 173

Theory of Operation………………………………………………………. 173

Stop Light Circuit…………………………………………………………… 177

Theory of Operation………………………………………………………. 177

Backup Alarm and Backup Light Circuit………………………………………….. 179

Theory of Operation………………………………………………………. 179

Wiper/Washer Circuit…………………………………………………………. 181

Theory of Operation………………………………………………………. 181

Battery Balancer and 12-Volt Accessory Circuit Theory of Operation………………… 185

Air Conditioning Circuit……………………………………………………… 187

Theory of Operation………………………………………………………. 187

Electric Mirror Circuit………………………………………………………. 191

Theory of Operation………………………………………………………. 191

Unloader Valve Circuit ………………………………………………………. 193

Theory of Operation………………………………………………………. 193

References……………………………………………………………………… 194

Service Code Diagnostics……………………………………………………… 194

After Machine Repair……………………………………………………… 194

How Codes Are Displayed On Monitor Display Unit……………………………… 196

How To Use Listing For Transmission Codes…………………………………… 197

Engine Control Unit………………………………………………………. 198

Electronic Unit Injector (EUI) Controller…………………………………… 206

Chassis Control Unit……………………………………………………… 223

Transmission Control Unit (TCU)……………………………………………. 226

D-Series Articulated Dump Trucks 350D and 400D Service ADVISOR™ Computer Connection…. 336

Circuit Check Using Monitor Display Unit (MDU) or Service ADVISOR…………………. 339

Two-Wire Sensor………………………………………………………….. 339

Three-Wire Sensor………………………………………………………… 340

Key Switch Test……………………………………………………………… 341

Relay Test………………………………………………………………….. 341

Diode Test………………………………………………………………….. 342

Pneumatic System Solenoids, Pressure Switches, and Sensor Tests…………………… 343

Hydraulic Pressure Switches Test………………………………………………. 348

Hydraulic Temperature Sensors Test…………………………………………….. 349

Body Position Sensor Test…………………………………………………….. 350

Steering Column Switch Test…………………………………………………… 353

Retarder Voltage Regulator Test……………………………………………….. 354

Transmission Speed Sensors Test……………………………………………….. 357

Transmission Solenoids Test…………………………………………………… 358

Electronic Unit Injector (EUI) Controller………………………………………. 359

Remove and Install……………………………………………………….. 359

Engine Control Unit………………………………………………………….. 359

Remove and Install……………………………………………………….. 359

Cold Start Module……………………………………………………………. 361

Remove and Install……………………………………………………….. 361

Chassis Control Unit…………………………………………………………. 362

Remove and Install……………………………………………………….. 362

Transmission Control Unit ……………………………………………………. 363

Remove and Install……………………………………………………….. 363

Battery Balancer…………………………………………………………….. 364

Remove and Install……………………………………………………….. 364

Monitor Display Unit…………………………………………………………. 365

Remove and Install……………………………………………………….. 365

Replace Monitor Display Unit Bulbs…………………………………………….. 366

Remove, Install, and Calibrate Accelerator Pedal Position Sensor………………….. 368

Replace DEUTSCH™ Rectangular or Triangular Connectors……………………………. 369

Replace DEUTSCH™ Connectors…………………………………………………… 370

Install DEUTSCH™ Contact……………………………………………………… 371

Replace WEATHER PACK™Connector………………………………………………… 372

Install WEATHER PACK™Contact………………………………………………….. 373

Replace (Pull Type) Metri-Pack™ Connectors……………………………………… 375

Replace (Push Type) Metri-Pack™ Connectors……………………………………… 376

Remove Connector Body from Blade Terminals……………………………………… 376

Power Train………………………………………………………………………… 378

Theory of Operation……………………………………………………………… 380

Transmission External Components………………………………………………. 380

Transmission………………………………………………………………… 382

Control System…………………………………………………………… 382

Cross Sectional Diagram…………………………………………………… 385

Torque Converter…………………………………………………………….. 387

Operation……………………………………………………………….. 387

Transmission………………………………………………………………… 389

Clutch Engagement………………………………………………………… 389

Retarder Operation……………………………………………………….. 428

Transmission Thermal Valve Operation…………………………………………… 432

Differential Lock Operation…………………………………………………… 433

Inter-Axle Lock Operation…………………………………………………….. 433

Diagnostic Information…………………………………………………………… 434

Diagnostic Procedure…………………………………………………………. 434

Power Train Systems………………………………………………………….. 435

Diagnose Malfunctions…………………………………………………….. 435

Power Train…………………………………………………………………. 449

Component Location Diagram………………………………………………… 449

Tests………………………………………………………………………….. 452

Transmission………………………………………………………………… 452

Warm Up Procedure………………………………………………………… 452

Transmission Pressure Test……………………………………………………. 453

Clutch Enable Test with Service ADVISER™……………………………………….. 461

Transmission Clutch Drag Test…………………………………………………. 466

Torque Converter Stall Test—350D………………………………………………. 468

Torque Converter Stall Test—400D………………………………………………. 470

Torque Converter Stator Tests…………………………………………………. 472

Torque Converter Lockup Test………………………………………………….. 474

Transmission Thermal Valve Test……………………………………………….. 475

Transmission Oil Cooler Restriction Test……………………………………….. 476

Front Suspension Strut Leakage Check…………………………………………… 477

Park Brake Test……………………………………………………………… 477

Park Brake Pad Thickness Check………………………………………………… 478

Park Brake Adjustment………………………………………………………… 479

Checking Controlled Traction Clutch (Differential Lock) Condition…………………. 482

Pneumatic System……………………………………………………………………. 484

Theory of Operation……………………………………………………………… 487

Pneumatic System Schematic……………………………………………………. 487

Pneumatic System Operation……………………………………………………. 488

Air Pressure Supply Circuit Operation………………………………………….. 489

Air Dryer and Unloader Valve………………………………………………….. 491

Pneumatic Manifold…………………………………………………………… 493

Pneumatic Circuit……………………………………………………………. 499

Diagnostic Information…………………………………………………………… 504

Diagnostic Procedure…………………………………………………………. 504

Diagnose Pneumatic System Malfunctions…………………………………………. 505

Pneumatic System Component Location Diagram…………………………………….. 509

Tests………………………………………………………………………….. 512

Pneumatic System Main Pressure Test and Adjustment………………………………. 512

Park Brake Pressure Test……………………………………………………… 513

Hydraulic System……………………………………………………………………. 516

Theory of Operation……………………………………………………………… 518

Articulated Dump Truck Hydraulic System Operation……………………………….. 518

Main Hydraulic Pump Operation…………………………………………………. 521

Main Hydraulic Pump Load Sense Operation……………………………………….. 523

Service Brake System Operation………………………………………………… 527

Steering and Secondary Steering System Operation………………………………… 531

Steering Valve Operation……………………………………………………… 535

Secondary Steering Pump Operation……………………………………………… 537

Hydraulic System Manifold Operation……………………………………………. 539

Fan Drive System Operation……………………………………………………. 547

Dump Body Control Valve Operation……………………………………………… 549

Hydraulic System Circuit Symbols………………………………………………. 551

Hydraulic System Schematic—350D……………………………………………….. 553

Hydraulic System Schematic—400D……………………………………………….. 555

Diagnostic Information…………………………………………………………… 558

Diagnostic Procedure…………………………………………………………. 558

Diagnose Hydraulic System Malfunctions…………………………………………. 559

Diagnose Service Brake System Malfunctions……………………………………… 564

Diagnose Steering System Malfunctions………………………………………….. 567

Hydraulic System Component Location……………………………………………. 571

Tests………………………………………………………………………….. 580

JT05800 Digital Thermometer Installation……………………………………….. 580

JT02156A Digital Pressure/Temperature Analyzer Installation………………………. 580

Hydraulic Oil Cleanup Procedure Using Portable Filter Caddy………………………. 581

Hydraulic System Warm-Up Procedure…………………………………………….. 582

Cycle Time Test……………………………………………………………… 583

Main Hydraulic Pump Residual and Compensator Valves Test and Adjustment……………. 584

System Relief Valve and Dump Body Raise Circuit Relief Valve Test…………………. 587

Priority Valve Test………………………………………………………….. 588

Accumulator Pressure Reducing Valve Test and Adjustment………………………….. 589

Brake Accumulator Charge Valve Test and Adjustment………………………………. 591

Brake Low Pressure Switch and Brake Accumulator Test…………………………….. 593

Front and Rear Brake Accumulators Pressure Test and Charge Procedure………………. 595

Service Brake Valve Test……………………………………………………… 596

Steering Relief Valve Pressure Test and Adjustment………………………………. 597

Steering Cylinder Leakage Test………………………………………………… 599

Secondary Steering Pump Residual and Compensator Valves Test and Adjustment………… 600

Dump Body Lower Circuit Relief Valve Test………………………………………. 602

Fan Drive Controller Test and Adjustment……………………………………….. 603

Wet Disk Brake Thermal Valve Test……………………………………………… 605

Wet Disk Brake Cooling System Bypass Check Valve Test……………………………. 606

Wet Disk Brake Cooler Restriction Test…………………………………………. 607

Wet Disk Brake Cooling Oil Filter Restriction Test………………………………. 609

Heating and Air Conditioning…………………………………………………………. 612

Theory of Operation……………………………………………………………… 614

Air Conditioning System Cycle of Operation……………………………………… 614

Heater Core Operation………………………………………………………… 615

Diagnostic Information…………………………………………………………… 616

Diagnose Air Conditioning System Malfunctions…………………………………… 616

Diagnose Heater System Malfunctions……………………………………………. 618

Heating/Air Conditioning Component Location…………………………………….. 619

Tests………………………………………………………………………….. 622

Air Conditioning Operational Checks……………………………………………. 622

R134a Air Conditioning System Test…………………………………………….. 624

Operating Pressure Diagnostic Chart……………………………………………. 626

A/C Freeze Control Switch Test………………………………………………… 628

A/C Compressor Clutch Test……………………………………………………. 629

A/C High/Low Pressure Switch Test……………………………………………… 629

A/C Expansion Valve Test……………………………………………………… 632

Expansion Valve Bench Test……………………………………………………. 634

Refrigerant Leak Test………………………………………………………… 635

WORKSHOP MANUAL……………………………………………………………………………. 642

Contents………………………………………………………………………………. 644

General Information…………………………………………………………………. 648

Safety…………………………………………………………………………. 650

Recognize Safety Information………………………………………………….. 650

Follow Safety Instructions……………………………………………………. 650

Operate Only If Qualified…………………………………………………….. 650

Wear Protective Equipment…………………………………………………….. 651

Avoid Unauthorized Machine Modifications……………………………………….. 651

Inspect Machine……………………………………………………………… 651

Stay Clear Of Moving Parts……………………………………………………. 652

Avoid High-Pressure Fluids……………………………………………………. 652

Beware Of Exhaust Fumes………………………………………………………. 652

Prevent Fires……………………………………………………………….. 653

Prevent Battery Explosions……………………………………………………. 653

Handle Chemical Products Safely……………………………………………….. 654

Dispose of Waste Properly…………………………………………………….. 654

Prepare for Emergencies………………………………………………………. 654

Use Steps And Handholds Correctly……………………………………………… 655

Start Only From Operator’s Seat……………………………………………….. 655

Use And Maintain Seat Belt……………………………………………………. 655

Prevent Unintended Machine Movement……………………………………………. 656

Avoid Work Site Hazards………………………………………………………. 656

Keep Riders Off Machine………………………………………………………. 657

Avoid Backover Accidents……………………………………………………… 657

Avoid Machine Tip Over……………………………………………………….. 658

Operating on Slopes………………………………………………………….. 658

Operating Or Traveling On Public Roads…………………………………………. 659

Inspect and Maintain ROPS…………………………………………………….. 659

Add And Operate Attachments Safely…………………………………………….. 659

Park And Prepare For Service Safely……………………………………………. 660

Service Tires Safely…………………………………………………………. 661

Service Cooling System Safely…………………………………………………. 661

Remove Paint Before Welding or Heating…………………………………………. 662

Make Welding Repairs Safely…………………………………………………… 662

Drive Metal Pins Safely………………………………………………………. 662

Wheels…………………………………………………………………………….. 664

Removal and Installation…………………………………………………………. 666

Remove and Install Wheel……………………………………………………… 666

Remove and Install Tire………………………………………………………. 668

Axles and Suspension Systems…………………………………………………………. 670

Removal and Installation…………………………………………………………. 672

Axles………………………………………………………………………. 672

Differential or Bevel Drive………………………………………………………. 676

Axle Differential……………………………………………………………. 676

Input Drive Shafts and U-Joints…………………………………………………… 700

Drive Shafts………………………………………………………………… 700

Axle Mounting Parts……………………………………………………………… 708

Axle Links, Stabilizers, and Struts……………………………………………. 708

Front Axle Pivot…………………………………………………………….. 720

Middle and Rear Axle Walking Beams…………………………………………….. 721

Axle Shaft, Bearings, and Reduction Gears………………………………………….. 726

Axle Outboard Planetaries…………………………………………………….. 726

Axle Shafts…………………………………………………………………. 729

Axle Hubs…………………………………………………………………… 729

Transmission……………………………………………………………………….. 738

Removal and Installation…………………………………………………………. 740

Remove and Install Transmission……………………………………………….. 740

Input Drive Shafts and U-Joints…………………………………………………… 742

Remove and Install Transmission-to-Transfer Case Drive Shaft……………………… 742

Gear, Shafts, and Power Shift Clutches…………………………………………….. 744

Disassemble Transmission……………………………………………………… 744

Disassemble and Assemble Torque Converter………………………………………. 751

Disassemble and Assemble Torque Converter Housing……………………………….. 758

Disassemble and Assemble Retarder and P3 Planetary………………………………. 759

Disassemble and Assemble Main Shaft……………………………………………. 769

Disassemble and Assemble P2 Planetary………………………………………….. 770

P1 Planetary………………………………………………………………… 773

Disassemble and Assemble………………………………………………….. 773

Disassemble and Assemble Front Support and Charging Oil Pump……………………… 777

C1/C2 Clutch………………………………………………………………… 783

Disassemble and Assemble………………………………………………….. 783

C3/C4 Clutch and Main Housing…………………………………………………. 793

Disassemble and Assemble………………………………………………….. 793

Disassemble and Assemble Control Valve…………………………………………. 798

Assemble Transmission………………………………………………………… 809

Hydraulic System………………………………………………………………… 820

Remove and Install Transmission Oil Cooler……………………………………… 820

Engine…………………………………………………………………………….. 822

Removal and Installation…………………………………………………………. 824

Engine……………………………………………………………………… 824

Crankshaft, Main Bearings, and Flywheel……………………………………………. 834

Crankshaft and Main Bearing…………………………………………………… 834

Failure Analysis…………………………………………………………. 834

Crankshaft Oil Seals…………………………………………………………. 834

Flywheel……………………………………………………………………. 839

Remove and Install Timing Case Cover…………………………………………… 841

Remove and Install Timing Case………………………………………………… 843

Crankshaft………………………………………………………………….. 846

Bleed Engine Oil Circuit after Major Overhaul…………………………………… 861

Camshaft and Timing Gear Train……………………………………………………. 862

Camshaft……………………………………………………………………. 862

Cylinder Block, Liners, Pistons and Rods…………………………………………… 870

Liner, Piston, and Rod……………………………………………………….. 870

Preliminary Checks……………………………………………………….. 870

Pistons and Connecting Rods…………………………………………………… 871

Cylinder Liners……………………………………………………………… 883

Engine Rotation……………………………………………………………… 892

Check for Excessive Tightness……………………………………………… 892

Lubrication System………………………………………………………………. 894

Remove and Install Oil Filter Housing………………………………………….. 894

Remove, Inspect, and Install Engine Oil Cooler………………………………….. 896

Remove and Install Oil Pan……………………………………………………. 896

Piston Cooling Orifices………………………………………………………. 898

Remove, Inspect and Install……………………………………………….. 898

Engine Oil Pump……………………………………………………………… 899

Remove and Install……………………………………………………….. 899

Oil Pressure Relief Valve…………………………………………………….. 900

Remove and Install……………………………………………………….. 900

Cylinder Head and Valves…………………………………………………………. 902

Cylinder Head and Valves Failure Analysis………………………………………. 902

Remove and Install Valve Cover………………………………………………… 903

Rocker Arms and Shaft………………………………………………………… 903

Clean and Inspect Push Rods…………………………………………………… 906

Cylinder Head……………………………………………………………….. 907

Remove and Install Engine Exhaust Valve Brake…………………………………… 911

Intake and Exhaust Valves…………………………………………………….. 911

Valves……………………………………………………………………… 914

Cylinder Head……………………………………………………………….. 916

Exhaust System………………………………………………………………….. 924

Exhaust Manifold…………………………………………………………….. 924

Remove and Install……………………………………………………….. 924

Fuel Injection System……………………………………………………………. 926

Remove and Install Hand Primer Pump……………………………………………. 926

Remove and Install Fuel Supply Pump……………………………………………. 926

Remove and Install Electronic Unit Injector (EUI)……………………………….. 927

Remove and Install Fuel Delivery Nozzle………………………………………… 928

Air Intake Manifold System……………………………………………………….. 930

Remove and Install Air Intake Manifold…………………………………………. 930

Turbocharger……………………………………………………………………. 932

Turbocharger………………………………………………………………… 932

Remove and Install……………………………………………………….. 932

Turbocharger Seven-Step Inspection…………………………………………….. 935

Cooling System………………………………………………………………….. 942

Water Pump………………………………………………………………….. 942

Thermostats, Housing and Water Piping……………………………………………… 950

Remove and Install Thermostats and Housing……………………………………… 950

Engine Auxiliary System……………………………………………………………… 952

Cooling System………………………………………………………………….. 954

Fan Belt……………………………………………………………………. 954

Remove and Install Radiator…………………………………………………… 954

Intake System…………………………………………………………………… 956

Air Intake System Leakage Check……………………………………………….. 956

Remove and Install Charge Air Aftercooler………………………………………. 956

External Exhaust Systems…………………………………………………………. 960

Remove and Install Muffler and Exhaust Pipes……………………………………. 960

Remove and Install Exhaust Brake Valve Flapper………………………………….. 964

Body Heater Pipes……………………………………………………………. 965

Engine Mounting…………………………………………………………………. 968

Remove and Install Engine and Transmission Rubber Mounts…………………………. 968

External Fuel Supply Systems……………………………………………………… 970

Remove and Install Hand Primer Pump……………………………………………. 970

Remove and Install Primary Fuel Filter (Water Separator)…………………………. 971

Remove and Install Fuel Tank………………………………………………….. 971

Connector Drive (Flexplate)………………………………………………………….. 976

Elements……………………………………………………………………….. 978

Remove and Install Connector Drive (Flexplate)………………………………….. 978

Transfer Drive……………………………………………………………………… 980

Removal and Installation…………………………………………………………. 982

Remove and Install Transfer Case………………………………………………. 982

Gear Shafts and Bearings…………………………………………………………. 992

Transfer Case……………………………………………………………….. 992

Steering System……………………………………………………………………..1018

Secondary Steering……………………………………………………………….1020

Secondary Steering Pump……………………………………………………….1020

Hydraulic System…………………………………………………………………1026

Steering Valve……………………………………………………………….1026

Steering Cylinder…………………………………………………………….1028

Service Brakes………………………………………………………………………1034

Active Elements………………………………………………………………….1036

Service Brakes—350D…………………………………………………………..1036

Service Brakes—400D…………………………………………………………..1043

Hydraulic System…………………………………………………………………1054

Bleed Service Brake Hydraulic System……………………………………………1054

Brake Accumulators……………………………………………………………1055

Brake Valve………………………………………………………………….1056

Wet Disk Brake Thermal Valve…………………………………………………..1059

Wet Disk Brake Cooling Oil Pumps……………………………………………….1061

Wet Disk Brake Cooling Oil Reservoir……………………………………………1062

Wet Disk Brake Cooling Oil Cooler………………………………………………1063

Park Brake………………………………………………………………………….1066

Active Elements………………………………………………………………….1068

Park Brake…………………………………………………………………..1068

Frame and Supporting Structure………………………………………………………..1074

Frame Installation……………………………………………………………….1076

Welding on Machine……………………………………………………………1076

Separate Front and Rear Frames…………………………………………………1076

Articulation Frame……………………………………………………………1081

Oscillation Joint…………………………………………………………….1088

Operator’s Station…………………………………………………………………..1092

Operator Enclosure……………………………………………………………….1094

Remove and Install Cab Mounts………………………………………………….1094

Remove and Install Cab Tilt Pump and Cylinder……………………………………1095

Disassemble and Assemble Cab Tilt Cylinder………………………………………1096

Seat and Seat Belt……………………………………………………………….1098

Operator’s Seat………………………………………………………………1098

Heating and Air Conditioning………………………………………………………1100

Refrigerant Cautions and Proper Handling………………………………………..1100

R134a Refrigerant Oil Information………………………………………………1102

R134a Refrigerant Recovery/Recycling and Charging Station Installation Procedure…….1104

Recover R134a Refrigerant……………………………………………………..1105

Flush and Purge Air Conditioner System………………………………………….1106

Evacuate R134a System…………………………………………………………1109

Charge R134a System…………………………………………………………..1110

Remove and Install Air Conditioner Compressor……………………………………1110

Disassemble and Assemble Compressor Clutch………………………………………1111

Inspect Compressor Manifold……………………………………………………1114

Remove and Install Condenser…………………………………………………..1114

Remove and Install High/Low Pressure Switch……………………………………..1115

Remove and Install Receiver-Dryer………………………………………………1116

Remove and Install Expansion Valve……………………………………………..1117

Remove and Install Heater Core and Evaporator Core……………………………….1119

Remove and Install Freeze Control Switch………………………………………..1121

Sheet Metal and Styling………………………………………………………………1124

Hood or Engine Enclosure………………………………………………………….1126

Hood………………………………………………………………………..1126

Main Hydraulic System………………………………………………………………..1132

Hydraulic System…………………………………………………………………1134

Main Hydraulic Pump…………………………………………………………..1134

Hydraulic Pump Drive Shaft…………………………………………………….1139

Hydraulic Reservoir…………………………………………………………..1143

Suction Strainer……………………………………………………………..1145

Hydraulic System Manifold Assembly……………………………………………..1145

Hydraulic Fan Motor…………………………………………………………..1154

Fan Drive Controller………………………………………………………….1158

Pneumatic Systems……………………………………………………………………1160

Pumps and Drives…………………………………………………………………1162

Remove and Install Air Compressor………………………………………………1162

Control Valves…………………………………………………………………..1182

Remove and Install Pneumatic Manifold…………………………………………..1182

Remove and Install Park Brake Control Valve……………………………………..1186

Remove and Install Body Tip Control Valve……………………………………….1187

Remove and Install Seat Control Valve…………………………………………..1188

Differential Lock Actuator…………………………………………………….1189

Remove and Install Park Brake Actuator………………………………………….1199

Reservoir, Filter, and Trap……………………………………………………….1202

Air Unloader Valve with Integral Air Dryer………………………………………1202

Remove and Install Regeneration Air Reservoir……………………………………1204

Remove and Install Air Reservoir……………………………………………….1205

Cylinders……………………………………………………………………….1206

Remove and Install Exhaust Brake Air Cylinder……………………………………1206

Haulage Device………………………………………………………………………1208

Frames………………………………………………………………………….1210

Body………………………………………………………………………..1210

Hydraulic System…………………………………………………………………1214

Body Lift Cylinder……………………………………………………………1214

Dealer Fabricated Tools………………………………………………………………1218

Dealer Fabricated Tools…………………………………………………………..1220

DF1002 Rolling Drag Torque Bar…………………………………………………1220

DFT1132 Removal and Installation Tool…………………………………………..1221

DFT1178 Lifting Tool………………………………………………………….1222

DFT1181 Bushing Driver………………………………………………………..1222

DFT1185 Supports……………………………………………………………..1223

DFT1186 Bushing Driver………………………………………………………..1224

DFT1187 Bearing Driver………………………………………………………..1224

DFT1188 Bearing Driver………………………………………………………..1225

DFT1189 Spanner Wrench………………………………………………………..1226

DFT1194 Bearing Puller………………………………………………………..1227

DFT1195 Planetary Alignment Stud……………………………………………….1227

DFT1196 Bushing Driver………………………………………………………..1229

DFT1199 Bushing Pusher………………………………………………………..1230

DFT1200 Bushing Driver………………………………………………………..1231

DFT1222 Wet Disk Brake Piston Seal Installer…………………………………….1232

DFT1223 Transfer Case Mounting Bracket………………………………………….1233

DFT1224 Engine Mounting Adapter………………………………………………..1234

SERVICE MANUAL REVISION REQUEST FORM………………………………………………………….1246