$45

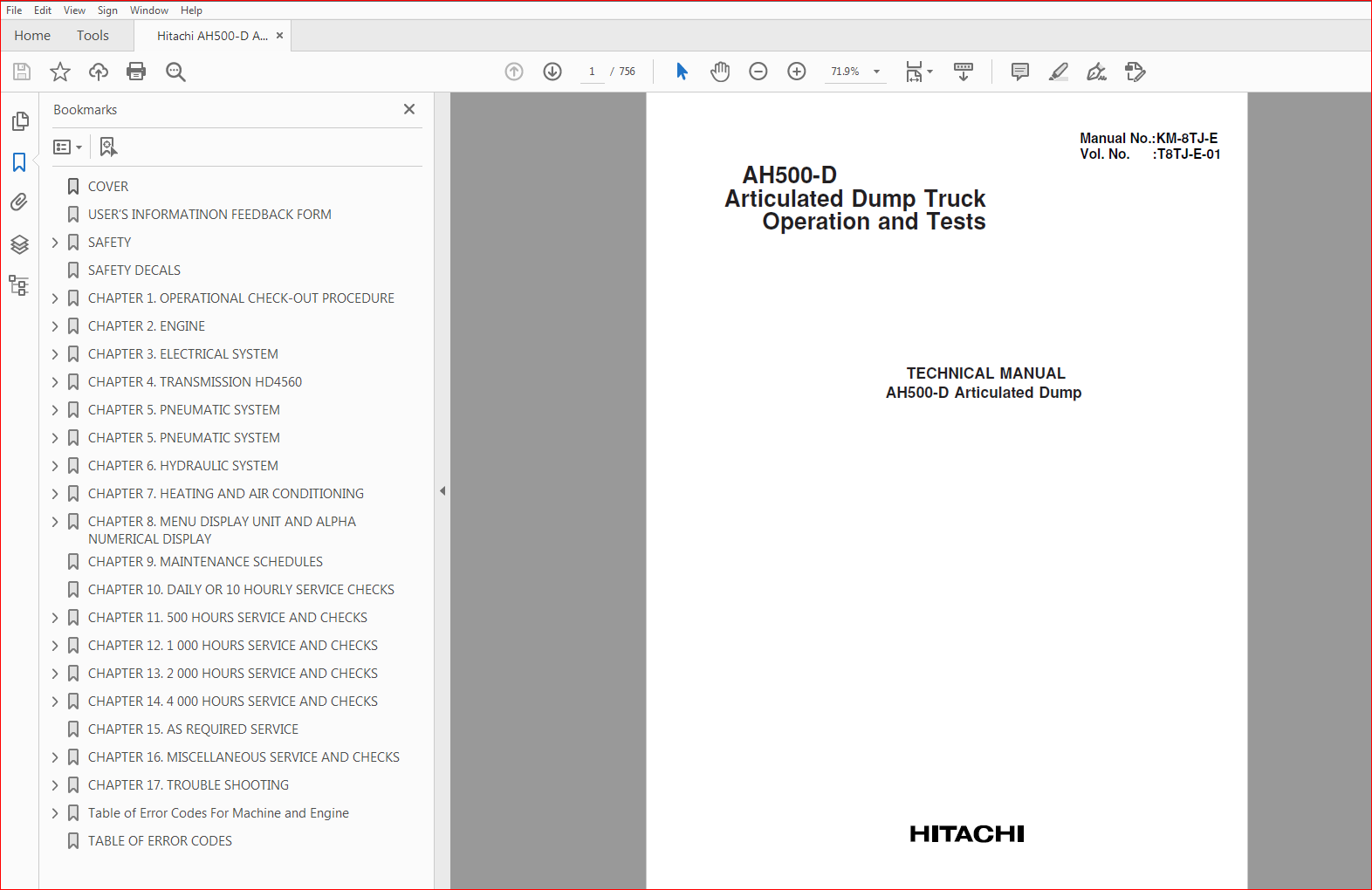

Hitachi AH500-D Articulated Dump Truck Technical Manual (KM-8TJ-E) PDF DOWNLOAD

Hitachi AH500-D Articulated Dump Truck Technical Manual

FILE DETAILS:

Hitachi AH500-D Articulated Dump Truck Technical Manual

Language : English

Pages : 756

Downloadable : YES

Format : PDF

Size : 26.1 MB

Manual No.:KM-8TJ-E

Vol. No. :T8TJ-E-01

DESCRIPTION:

Hitachi AH500-D Articulated Dump Truck Technical Manual

TO THE SERVICE PERSONEL:

Do not operate the machine unless you have read the Operator’s Manual and fully understand how to operate the machine properly. This manual is written for an experienced technician and are on-the-job guides containing only the vital information needed for diagnosis, analyses, testing and repair. Essential tools required in performing certain service works are identified and in this manual and are recommended for use.

- The safe operation of your HITACHI machines very important to prevent any personal injury and/or damage. This manual must be read and fully understood before carrying out any tests on your HITACHI machine. Right and left hand sides are determined by facing in the direction of forward travel. This manual is divided into chapters.

- The information contained in the manual is in logical sequence, with the instructions written in step by step format. information contained in this manual. Every effort has been made to ensure that the information contained in this manual was correct at the time of publication. HITACHI Co. has a policy of continuous product development, improvement, and design.

- HITACHI Co. reserves the right to change, amend and update the design of its product at any time without prior notice. With this policy, changes may have occurred that are not included in this manual.

- Whilst every endeavour has been made to provide accurate and reliable information, HITACHI Co. specifically disclaims any actual or implied warranty and under no circumstances shall be liable for any loss, damage or injury to person or property suffered, whether direct, indirect or consequential, arising from the use of this manual.

- In particular and without detracting from above, the disclaimer also applies in the event of any specification, warning, or representation contained in this manual being inadequate, inaccurate, or unintentionally misleading.

- The user is urged to strictly comply with the instructions and warnings that are given in the interests of general safety. Please do not hesitate to contact your HITACHI Product Support Representative whenever you have a query on your HITACHI product or this manual.

TABLE OF CONTENTS:

Hitachi AH500-D Articulated Dump Truck Technical Manual

USER’S INFORMATINON FEEDBACK FORM 11

SAFETY 19

Specification 19

Safety Features 19

Unauthorised Modifications of the Roll Over Protective Structure (ROPS) and the Falling Objects Protective

Structure (FOPS) 20

Noise Emission Levels 20

General Safety 20

SAFETY DECALS 27

CHAPTER 1. OPERATIONAL CHECK OUT PROCEDURE 37

OPERATIONAL CHECK OUT 37

OPERATIONAL CHECKS KEY SWITCH ON, ENGINE OFF 37

OPERATIONAL CHECKS ENGINE ON 39

CHAPTER 2. ENGINE 45

SECTION 1. THEORY OF OPERATION 45

ENGINE 45

SECTION 2. DIAGNOSE ENGINE MALFUNCTIONS 49

SECTION 3. ADJUSTMENTS 53

DISPLAY MENU TACHOMETER 53

SLOW AND FAST IDLE ADJUSTMENT 53

VALVE CLEARANCE ADJUSTMENT 53

EXHAUST BRAKE ADJUSTMENT 54

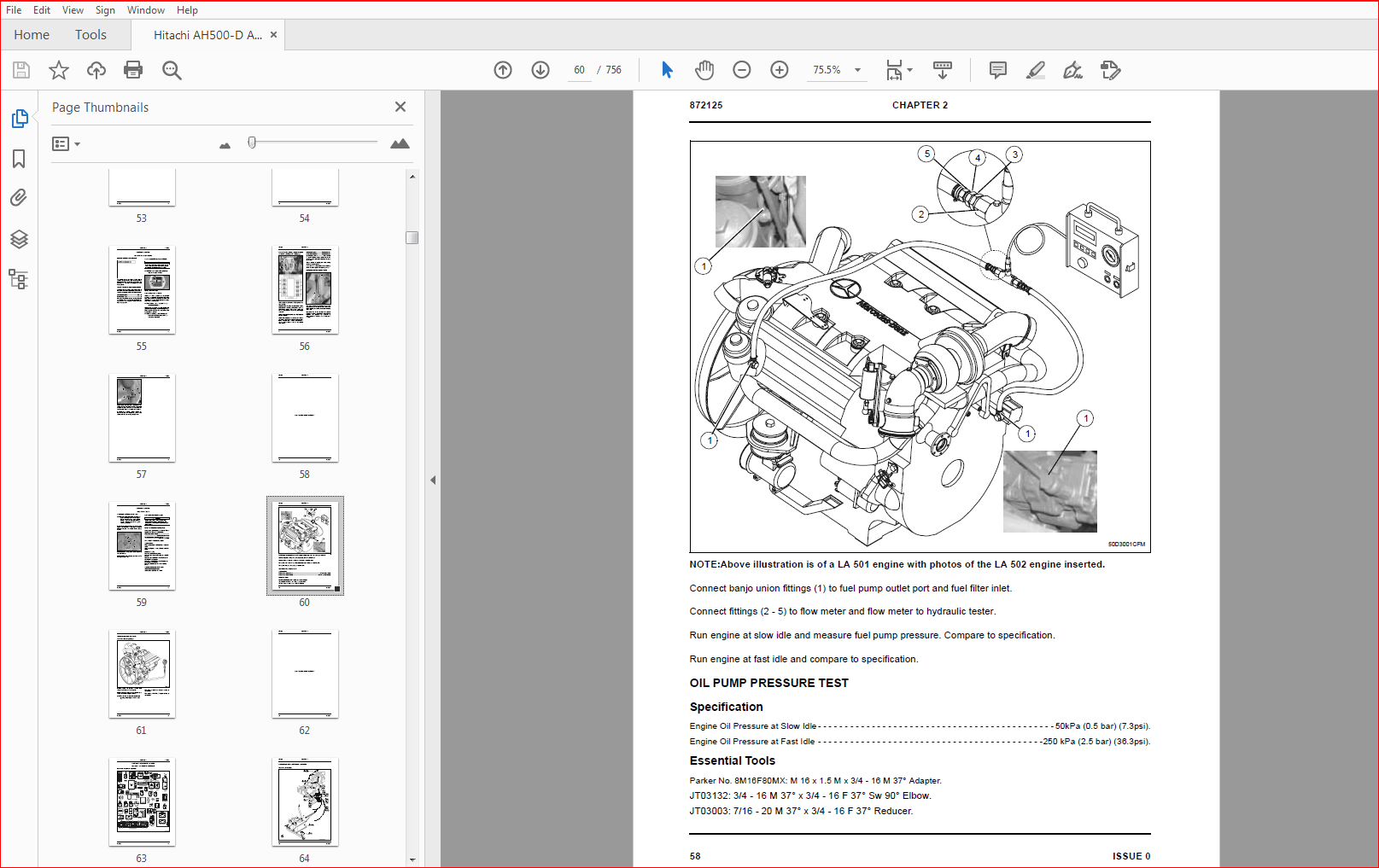

SECTION 4. TESTS 57

CYLINDER COMPRESSION TEST 57

FUEL PUMP PRESSURE TEST 57

CHAPTER 3. ELECTRICAL SYSTEM 61

SECTION 1. SYSTEM INFORMATION 61

HARNESSES AND COMPONENT LOCATION 62

EXPLANATION OF WIRE MARKINGS 92

PLUGS AND CONNECTORS 117

SECTION 2. DESCRIPTION OF CIRCUITS 245

ISOLATOR SWITCH 245

IGNITION SWITCH ON 247

IGNITION SWITCH IN START POSITION 248

MENU D 270

SECTION 3. REFERENCES 273

SERVICE CODE DIAGNOSTICS AFTER MACHINE REPAIR 273

SECTION 4. TESTS 363

KEY SWITCH TEST 363

RELAYS 363

Material Safety Data Sheets (MSDS) 20

TABLE OF CONTENTS

14

CHAPTER 4. TRANSMISSION HD4560 387

SECTION 1. THEORY OF OPERATION 387

GENERAL DESCRIPTIONS 387

TRANSMISSION IDENTIFICATION 388

TORQUE CONVERTER 389

TORQUE CONVERTER OPERATION 390

LOCK UP CLUTCH OPERATION 394

PLANETARY GEARS AND POWER FLOWS 397

THE BASIC LAWS OF PLANETARY GEAR SETS 398

CLUTCHES 398

HD TRANSMISSION PLANETARY CONFIGURATION 399

HD TRANSMISSION CLUTCH CONFIGURATION 400

POWER FLOW 404

HYDRAULIC SYSTEM 413

MAIN PRESSURE CIRCUIT 413

CONTROL MAIN CIRCUIT 415

TORQUE CONVERTER CIRCUIT 415

CONVERTER IN PRESSURE CIRCUIT 416

HYDRAULICS (OPERATION) 417

SOLENOIDS 417

NORMALLY OPEN SOLENOIDS 418

NORMALLY CLOSED SOLENOIDS 419

HYDRAULIC CIRCUITS 421

TORQUE CONVERTER AND LUBE PRESSURE CIRCUITS OVERVIEW 429

CONVERTER FLOW VALVE OPERATION 429

OVERDRIVE KNOCKDOWN VALVE 429

EXHAUST BACKFILL PRESSURE 430

PRESSURE TABLE AND TEST PIONTS 431

RETARDER 433

APPLICATIONS AND CAPACITIES 433

Retarder Control Overview 434

Apply Controls 434

INPUTS AND OUTPUTS 435

RETARDER CONTROL HYDRAULICS 435

TESTING RETARDER CHARGING PRESSURE 436

Retarder Off 436

HD RETARDER HYDRAULIC SCHEMATIC RETARDER OFF 437

HD RETARDER HYDRAULIC SCHEMATIC RETARDER ON 438

ELECTRONIC CONTROL SYSTEM 439

TRANSMISSION CONTROL UNIT

(T C U) 439

PULSE WIDTH MODULATION (P W M) 439

PUSH BUTTON SHIFT SELECTOR 443

AH500 D STALL SPEEDS 396

TABLE OF CONTENTS

15

SPEED SENSORS 444

WIRING HARNESSES 444

RANGE / SHIFT TESTS 445

DO NOT SHIFT LIGHT 446

SECTION 2. DIAGNOSTIC INFORMATION 455

DIAGNOSTIC PROCEDURE 455

DIAGNOSE POWER TRAIN SYSTEM MALFUNTIONS 456

CHAPTER 5. PNEUMATIC SYSTEM 473

SECTION 1. THEORY OF OPERATION 473

PNEUMATIC SYSTEM OPERATION 473

PNEUMATIC SYSTEM SCHEMATIC 474

SECTION 2. DIAGNOSTIC INFORMATION 485

DIAGNOSTIC PROCEDURE 485

DIAGNOSE PNEUMATIC SYSTEM MALFUNCTIONS 486

SECTION 3. TESTS 495

PNEUMATIC SYSTEM MAIN PRESSURE TEST AND ADJUSTMENT 495

PARK BRAKE PRESSURE TEST 496

CHAPTER 6. HYDRAULIC SYSTEM 497

SECTION 1. THEORY OF OPERATION 497

ARTICULATED DUMP TRUCK HYDRAULIC SYSTEM OPERATION 497

SECTION 2. DIAGNOSTIC INFORMATION 535

DIAGNOSTIC PROCEDURE 535

DIAGNOSE HYDRAULIC SYSTEM MALFUNCTIONS 536

HYDRAULIC SYSTEM COMPONENT LOCATION 544

SECTION 3. TESTS 557

JT05800 DIGITAL THERMOMETER INSTALLATION 557

JT02156A DIGITAL ANALOGUE PRESSURE/TEMPERATURE ANALYZER INSTALLATION 557

HYDRAULIC SYSTEM WARM UP PROCEDURE 558

MAIN HYDRAULIC PUMP RESIDUAL AND COMPENSATOR VALVES TEST AND

PRIORITY VALVE TEST 562

ACCUMULATOR PRESSURE REDUCING VALVE TEST AND ADJUSTMENT 562

BRAKE ACCUMULATOR CHARGE VALVE TEST AND ADJUSTMENT 563

BRAKE LOW PRESSURE SWITCH AND BRAKE ACCUMULATOR TEST 564

FRONT AND REAR BRAKE ACCUMULATORS PRESSURE TEST AND CHARGE

SERVICE BRAKE VALVE TEST 565

STEERING RELIEF VALVE PRESSURE TEST AND ADJUSTMENT 566

HYDRAULIC OIL CLEANUP PROCEDURE USING PORTABLE FILTER CADDY 557

ADJUSTMENT 560

CYCLE TIME TEST 559

PROCEDURE 565

SYSTEM RELIEF VALVE AND BIN RAISE CIRCUIT RELIEF VALVE TEST 561

TABLE OF CONTENTS

16

STEERING CYLINDER LEAKAGE TEST 567

SECONDARY STEERING PUMP RESIDUAL AND COMPENSATOR VALVES TEST AND ADJUSTMENT

567

BIN LOWER CIRCUIT RELIEF VALVE TEST 568

FAN DRIVE CONTROLLER TEST AND ADJUSTMENT 569

CHAPTER 7. HEATING AND AIR CONDITIONING 573

SECTION 1. THEORY OF OPERATION 573

AIR CONDITIONING SYSTEM CYCLE OF OPERATION 573

HEATER CORE OPERATION 574

SECTION 2. DIAGNOSTIC INFORMATION 575

DIAGNOSE AIR CONDITIONING SYSTEM MALFUNCTIONS 575

DIAGNOSE HEATER SYSTEM MALFUNCTIONS 577

HEATING/AIR CONDITIONING COMPONENT LOCATION 578

SECTION 3. TESTS 581

AIR CONDITIONING OPERATIONAL CHECKS 581

R134A AIR CONDITIONING SYSTEM TEST 582

OPERATING PRESSURE DIAGNOSTIC CHART 583

A/C FREEZE CONTROL SWITCH TEST 585

A/C COMPRESSOR CLUTCH TEST 585

A/C HIGH/LOW PRESSURE SWITCH TEST 585

A/C EXPANSION VALVE TEST 586

EXPANSION VALVE BENCH TEST 587

REFRIGERANT LEAK TEST 588

CHAPTER 8. MENU DISPLAY UNIT AND ALPHA NUMERICAL DISPLAY 589

START UP DISPLAY 589

DEFAULT SCREEN 590

TO SELECT BETWEEN MENUS 590

CHAPTER 9. MAINTENANCE SCHEDULES 601

CHAPTER 10. DAILY OR 10 HOURLY SERVICE CHECKS 605

CHAPTER 11. 500 HOURS SERVICE AND CHECKS 607

SECTION 1. DRIVE TRAIN 607

INTRODUCTION 607

SERVICE INSTRUCTIONS 607

ENGINE 607

TRANSMISSION 609

BRAKES 610

AXLES 611

TRANFER CASE 612

SECTION 2. CLEAN, CHECK AND REPALCE BREATHERS 613

GENERAL CHECK DRIVELINE & SUSPENSION FASTENERS 613

REPLACE CRANKCASE BREATHER 613

TABLE OF CONTENTS

17

TRANSMISSION BREATHER (LOCATED UNDER CAB) 614

REPLACE FUEL TANK BREATHER 614

TRANSFER CASE BREATHER (LOCATED BEHIND CAB) 614

AXLE BREATHERS 614

SECTION 3. CAB AND ELECTRICAL 616

INSPECT, CLEAN AND REPLACE CAB AIR FILTER 616

CHECK BATTERIES, CLEAN AND TIGHTEN TERMINALS 617

CHECK ELECTRICAL CONNECTORS, HARNESSES AND LOOMS 617

CHECK WORK LIGHTS, REVERSE BUZZER AND HORNS 617

RECORD & DELETE FAULT CODES ON THE MDU. 617

CHECK THE OPERATOR CONTROLS AND INSTUMENTS 617

SECTION 4. LUBRICATION 619

CHECK GREASE LEVEL OF AUTO GREASING SYSTEM 619

REPLACE AUTO GREASING SYSTEM FILTER 619

HYDRAULICS 620

CHAPTER 12. 1 000 HOURS SERVICE AND CHECKS 623

SECTION 1. ENGINE 623

INTRODUCTION 623

SERVICE INSTRUCTIONS 623

REPLACE TRANSMISSION OIL FILTERS 629

Check oil level. (See Chapter 12 Check Transmission Oil Level). 629

CHANGE THE TRANSFER CASE FILTER 629

SECTION 3. HYDRAULICS AND LUBRICATION 631

REPLACE HYDRAULIC RESERVOIR BREATHER 631

SECTION 4. AXLES AND CHASSIS & SUSPENSION 633

CHANGE AXLE OIL 633

CHANGE FINAL DRIVE OIL 634

CHAPTER 13. 2 000 HOURS SERVICE AND CHECKS 635

SECTION 1. DRIVE TRAIN 635

INTRODUCTION 635

SERVICE INSTRUCTIONS 635

SECTION 2. HYDRAULICS AND LUBRICATION 637

REPLACE HYDRAULIC SYSTEM OIL RETURN FILTER 638

SECTION 3. CAB, PNEUMATICS AND ELECTRICAL 641

REPLACE PNEUMATIC SYSTEM DRYER FILTER 641

CHAPTER 14. 4 000 HOURS SERVICE AND CHECKS 643

SECTION 1. HYDRAULICS AND PNEUMATICS 643

INTRODUCTION 643

SERVICE INSTUCTIONS 643

CHAPTER 15. AS REQUIRED SERVICE 645

CHAPTER 16. MISCELLANEOUS SERVICE AND CHECKS 647

SECTION 2. TRANSMISSION AND TRANSFER CASES 629

TABLE OF CONTENTS

18

SECTION 1. ENGINE 647

INTRODUCTION 647

SERVICE INSTRUCTIONS 647

SECTION 2. ELECTRICAL 649

USING BATTERY CHARGER 649

ADJUST HEADLIGHTS 651

SECTION 3. OPERATIONAL CHECKOUT 655

OPERATIONAL CHECK OUT 655

CHAPTER 17. TROUBLE SHOOTING 665

SECTION 1. SYMPTOMS AND REMEDIES 665

INTRODUCTION 665

SECTION 2. FAULT CODES 679

Table of Error Codes For Machine and Engine 679

TRANSMISSION CONTROL UNIT ERROR CODES 693

TABLE OF ERROR CODES 694

IMAGES PREVIEW OF THE MANUAL: