$30.95

Hyundai HR70/110/120/140C-9 (Tier3) Service Manual – PDF DOWNLOAD

Hyundai HR70/110/120/140C-9 (Tier3) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Hyundai HR70/110/120/140C-9 (Tier3) Service Manual – PDF DOWNLOAD

Language : English

Pages :166

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Hyundai HR70/110/120/140C-9 (Tier3) Service Manual – PDF DOWNLOAD

• Chapter 1: Machine designation, manufacturer, serial number and measuring units

• Chapter 2: Technical specifications Compaction rollers

• Chapter 3: Operating elements & displays

• Chapter 4: Options

• Chapter 5: Maintenance

• Chapter 6: Diesel engine and hydraulic system

• Chapter 7: Drum drive and rear axle

• Chapter 8: Antrieb vibration system

• Chapter 9: Electrical system

• Chapter 10: Steering system and articulated pendulum joint

• Chapter 11: Towing

Chapter 1: Machine designation, manufacturer, serial number and measuring units

11 Machine designation, intended use and manufacturer 1-2

111 Manufacturer 1-2

112 HR70C-9: Type plate and serial number 1-3

113 HR110C-9/ HR120C-9/HR140C-9: Type plate and serial number 1-4

114 Legal measuring units 1-5

115 Tightening torques (in Nm) for screws & bolts 1-6

• Chapter 2: Technical specifications Compaction rollers

21 Technical specif ic ations 2-2

211 Operating data 2-2

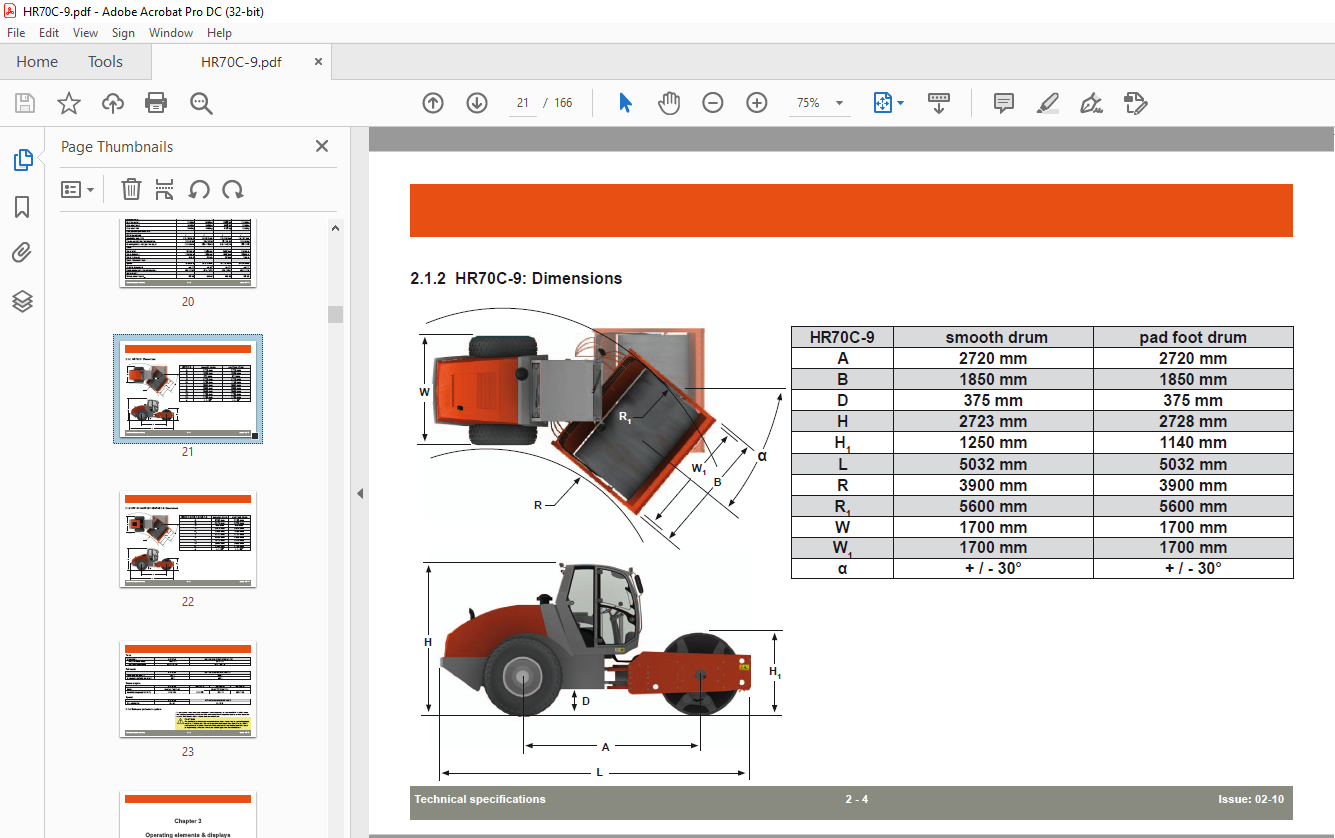

212 HR70C-9: Dimensions 2-4

213 HR110C-9/ HR120C-9/HR140C-9: Dimensions 2-5

214 Roll-over protection system 2-6

• Chapter 3: Operating elements & displays

31 Control elements and displays 3-2

432 Overview: Components of the ECO Speed system 4-15

• Chapter 5: Maintenance

51 Maintenance measures 5-2

511 Safety instructions referring to maintenance work 5-2

512 Safety precautions to be taken prior to maintenance work 5-3

513 HR70C-9: Maintenance overview 5-4

514 HR110C-9HR120C-9/HR140C-9: Maintenance overview 5-5

515 Maintenance instructions referring to the initial operation 5-6

516 Instruction and demonstration at the machine 5-7

517 Check list: 1st inspection after 50 operating hours 5-9

518 Table of lubricants 5-10

52 Maintenance work 5-11

521 Maintenance work related to the Diesel engine 5-11

522 Hydraulic system 5-15

523 Rear axle 5-17

524 HR70C-9: Maintenance work at the drum drive 5-20

525 HR110C-9/HR120C-9/HR140C-9: Maintenance work at the drum drive 5-21

526 Maintenance work at the vibration drive 5-22

527 Maintenance work at the ventilation system 5-23

528 Note regarding maintenance work related to the electrical installation 5-23

529 HR70C-9: Perkins Diesel engine maintenance schedule 5-24

5210 HR110C-9HR120C-9HR140C-9: Deutz Diesel engine maintenance schedule 5-25

53 Tires at the rear axle 5-26

531 Water filling in the tires of the rear axle 5-26

532 Emptying the tires 5-27

533 Filling procedure: Using the “Hanauer Maus” 5-28

534 Checking the tire inflation pressure 5-29

535 Mounting the tires 5-29

• Chapter 6: Diesel engine and hydraulic system

61 Diesel engine 6-2

611 Technical specifications Diesel engine 6-2

612 Maintenance overview Diesel engine 6-2

62 Hydraulic system 6-3

621 Technical specifications hydraulic system 6-3

622 Maintenance work hydraulic system 6-3

623 Hydraulic circuit diagram: Entire hydraulic system HR70C-9 6-4

624 Hydraulic circuit diagram: Entire hydraulic system HR110C-9HR120C-9HR140C-9 6-5

• Chapter 7: Drum drive and rear axle

71 Drum and rear axle 7-2

711 Techncal specifications drum 7- 2

712 Technical specifications rear axle 7- 2

713 Overview: Drum 7- 3

714 Overview Drive Hydraulics Drum HR70C-9HR110C-9HR120C-9HR140C-9 7- 4

715 Overview Drive Hydraulics Rear Axle HR70C-9HR110C-9HR120C-9HR140C-9 7- 5

716 HR70C-9: Drive unit – Sequence of functions 7- 6

717 HR110C-9HR120C-9HR140C-9: Drive unit – Sequence of functions 7- 7

718 Trouble shooting: What to do if the compaction roller does not start 7- 8

719 Speeds, hydraulic measuring and adjustment values for compaction rollers 7-10

7110 Overview: Asdjustments at the oil pressure pump of the drum drive 7-10

7111 Overview: Adjustments at the oil pressure pump of the drum drive 7-11

72 Installing & dismantling the drum

721 Preparing the drum for repair work 7-13

7211 Overview Drum 7-14

722 Removing the drum 7-17

723 Dismantling the drum 7-18

724 Removing the bearing 7-20

725 Installing the bearing 7-21

726 Assembling the drum 7-23

727 Installing the drum 7-27

• Chapter 8: Drive unit of the vibration system

81 Vibration system 8- 2

811 Technical specifications 8- 2

812 Overview: Vibration system 8- 3

813 Overview: Vibration hydraulics 8- 4

814 Sequence of functiosn – Vibration mode 8- 5

815 Trouble shooting: What to do if the vibration does not start 8- 6

82 Engine speeds, hydraulic measuring and default values 8- 7

821 Overview: Measuring points of the vibration hydraulics and required operating conditions 8- 8

822 Overview: Adjustments at the oil pressure pump (vibration) 8- 9

83 Using a sirometer 8-10

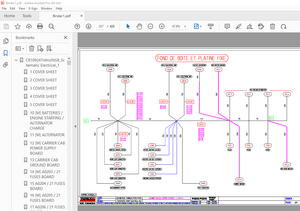

• Chapter 9: Electrical system

91 Electrical system 9- 2

911 Maintenance work referring to the electrical system 9- 2

912 Overview: Electrical system HR70C-9 9- 3

913 Overview: Electrical system HR110C-9HR120C-9HR140C-9 9- 4

914 Printed circuit board, fuses and relays 9- 5

Electric circuit diagrams 9-10

• Chapter 10: Steering system & Articulated pendulum joint

101 Steering system and articulated pendulum joint 10-2

102 Steering system 10-2

1021 Technical specifications 10-2

1022 Overview: Steering hydraulics and components 10-3

103 Articulated pendulum joint 10-4

1031 Installing and dismantling the articulated pendulum joint 10-5

• Kapitel 11: Towing the compaction roller

111 Towing the compaction roller 11- 2

1111 Safety instructions referring to towing the compaction roller 11- 2

1112 Precautionary measures to be taken prior to towing 11- 3

1113 Carrying out the towing process 11- 4

1114 After the towing process 11- 5

IMAGES PREVIEW OF THE MANUAL: