$42

Isuzu Diesel Engine 4JJ1 Troubleshooting Manual ITE-3230 – PDF DOWNLOAD

Isuzu Diesel Engine 4JJ1 Troubleshooting Manual ITE-3230 – PDF DOWNLOAD

DESCRIPTION:

Isuzu Diesel Engine 4JJ1 Troubleshooting Manual ITE-3230 – PDF DOWNLOAD

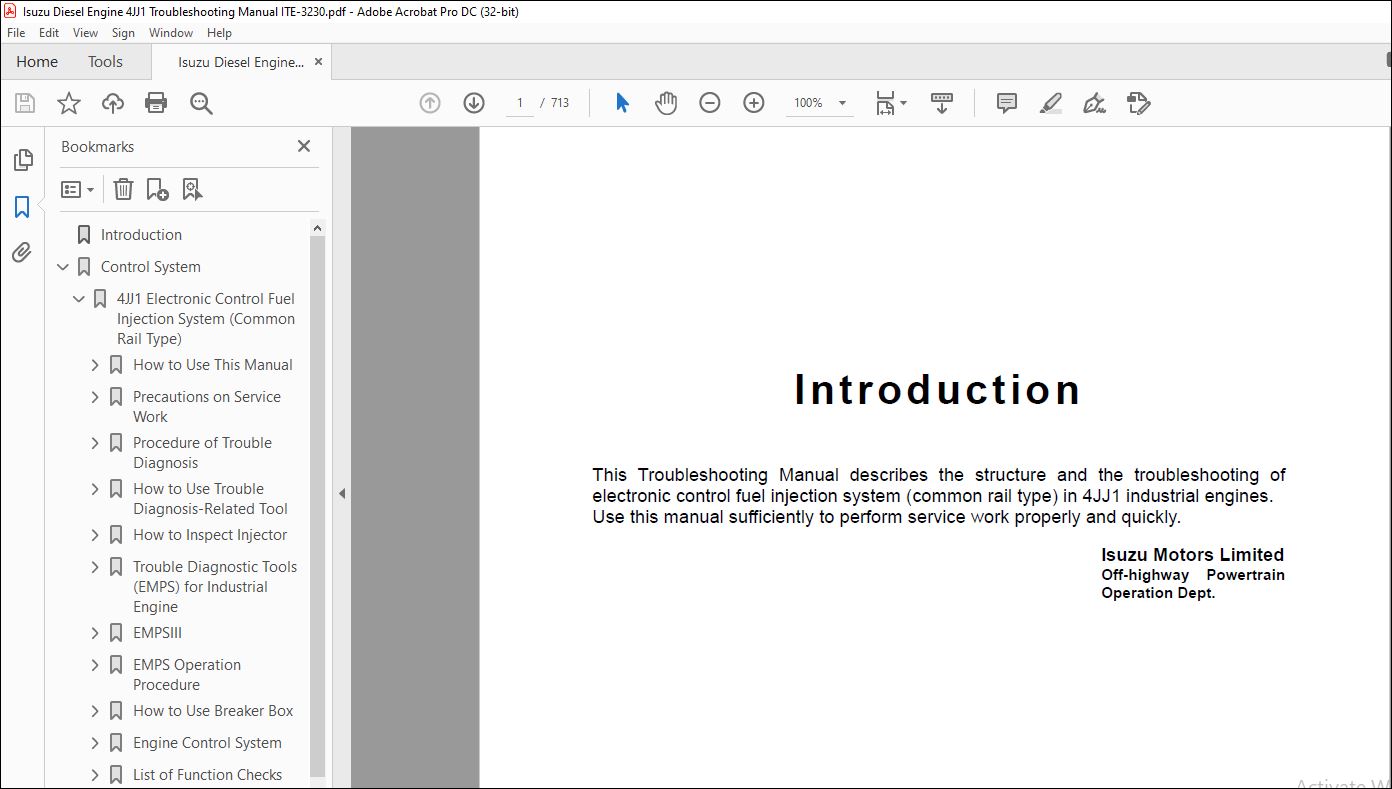

Introduction

This Troubleshooting Manual describes the structure and the troubleshooting of

electronic control fuel injection system (common rail type) in 4JJ1 industrial engines.

Use this manual sufficiently to perform service work properly and quickly.

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Isuzu Diesel Engine 4JJ1 Troubleshooting Manual ITE-3230 – PDF DOWNLOAD

Introduction…………………………………………………………………………………………………………………….. 1

Control System…………………………………………………………………………………………………………………… 3

4JJ1 Electronic Control Fuel Injection System (Common Rail Type)…………………………………………………………………… 3

How to Use This Manual…………………………………………………………………………………………………….. 6

How to use this manual…………………………………………………………………………………………………. 6

Table of abbreviation………………………………………………………………………………………………….. 7

Conversion formula…………………………………………………………………………………………………….. 8

About colors of wirings………………………………………………………………………………………………… 9

About wiring diagrams………………………………………………………………………………………………….. 10

How to read trouble diagnosis section……………………………………………………………………………………. 11

Precautions on Service Work………………………………………………………………………………………………… 13

Electrical system……………………………………………………………………………………………………… 13

Fuel injection system………………………………………………………………………………………………….. 13

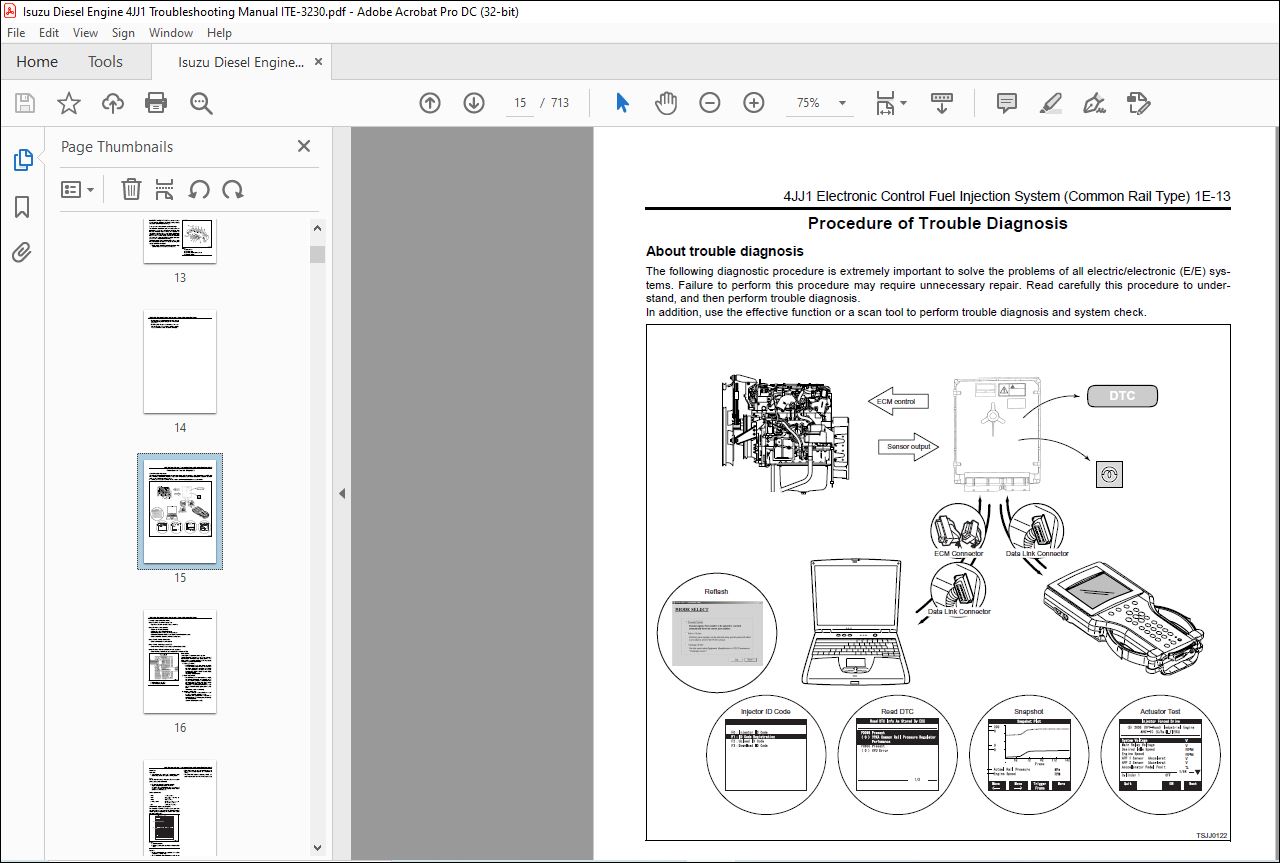

Procedure of Trouble Diagnosis……………………………………………………………………………………………… 15

About trouble diagnosis………………………………………………………………………………………………… 15

Trouble diagnostic procedure……………………………………………………………………………………………. 16

Interview…………………………………………………………………………………………………………….. 17

Pre-inspection………………………………………………………………………………………………………… 19

Trouble diagnosis……………………………………………………………………………………………………… 19

How to read DTC……………………………………………………………………………………………………….. 20

Confirmation after repair………………………………………………………………………………………………. 22

List of final check items………………………………………………………………………………………………. 22

How to clear DTC………………………………………………………………………………………………………. 23

Trouble diagnosis with scan tool………………………………………………………………………………………… 24

How to Use Trouble Diagnosis-Related Tool……………………………………………………………………………………. 29

Function of service tools………………………………………………………………………………………………. 29

Tech2………………………………………………………………………………………………………………… 29

Tech2 data reference value……………………………………………………………………………………………… 52

Rewriting of Q adjust correction data by Tech2……………………………………………………………………………. 65

Injector ID code (No. 1 cylinder – No. 6 cylinder or No. 4 cylinder) registration setting using Tech2…………………………… 72

ID code upload (Tech2)…………………………………………………………………………………………………. 80

ID code download (ECM)…………………………………………………………………………………………………. 84

TIS2000………………………………………………………………………………………………………………. 90

How to Inspect Injector…………………………………………………………………………………………………….100

Injector balance test (Tech2, EMPSIII)……………………………………………………………………………………100

Trouble Diagnostic Tools (EMPS) for Industrial Engine………………………………………………………………………….101

Introduction…………………………………………………………………………………………………………..101

List of functions of EMPS……………………………………………………………………………………………….101

Cautions………………………………………………………………………………………………………………102

EMPS Component Parts……………………………………………………………………………………………………104

ECM (hardware) compatibility…………………………………………………………………………………………….105

ECM Variation………………………………………………………………………………………………………….105

System Requirements for EMPS Software (Recommended)………………………………………………………………………..105

EMPS (software) Setup Procedure………………………………………………………………………………………….106

EMPSIII…………………………………………………………………………………………………………………..109

EMPSIII connection……………………………………………………………………………………………………..109

EMPSIII screen display………………………………………………………………………………………………….112

EMPS Operation Procedure……………………………………………………………………………………………………115

1. Preparation…………………………………………………………………………………………………………115

2. ECM Reflash…………………………………………………………………………………………………………118

3. Injector Replacement…………………………………………………………………………………………………137

4. Replace ECM (Same Model)……………………………………………………………………………………………..151

5. Factory Setting……………………………………………………………………………………………………..176

6. Recover Point……………………………………………………………………………………………………….187

7. Error Messages………………………………………………………………………………………………………189

8. Error Code List……………………………………………………………………………………………………..196

How to Use Breaker Box……………………………………………………………………………………………………..206

Breaker box inspection procedure…………………………………………………………………………………………206

Engine Control System………………………………………………………………………………………………………209

Description of function and operation for engine control (common rail) system…………………………………………………209

Engine control module (ECM)……………………………………………………………………………………………..224

Engine component location diagram………………………………………………………………………………………..226

Wiring diagram of engine control module (ECM)……………………………………………………………………………..239

Pin arrangement of engine control module (ECM)…………………………………………………………………………….244

Circuit diagram………………………………………………………………………………………………………..258

Engine harness location…………………………………………………………………………………………………272

Connector list…………………………………………………………………………………………………………276

List of Function Checks…………………………………………………………………………………………………….279

List of function checks…………………………………………………………………………………………………279

OBD system check……………………………………………………………………………………………………….280

Diagnosis lamp illumination circuit system check…………………………………………………………………………..282

Diagnosis lamp blinking circuit system check………………………………………………………………………………284

Scan tool power supply circuit system check (Tech2)………………………………………………………………………..287

Scan tool power supply circuit system check (EMPSIII)………………………………………………………………………289

Scan tool communication circuit system check………………………………………………………………………………291

Starting circuit system check……………………………………………………………………………………………294

Starting system check…………………………………………………………………………………………………..299

Fuel system check………………………………………………………………………………………………………302

Intake system check…………………………………………………………………………………………………….306

Exhaust system check……………………………………………………………………………………………………306

EGR control system check………………………………………………………………………………………………..307

QOS system check……………………………………………………………………………………………………….310

List of Diagnostic Trouble Codes…………………………………………………………………………………………….315

List of diagnostic trouble codes…………………………………………………………………………………………315

DTC: P0087 (Flash code 227) Common rail low pressure fault (No pressure feed in supply pump)……………………………………334

DTC: P0088 (Flash code 118) Common rail pressure is abnormally high (1st or 2nd stage)…………………………………………344

DTC: P0089 (Flash code 151) Common rail pressure fault (Excessive pressure feed in supply pump)…………………………………350

DTC: P0090 (Flash code 247) SCV drive system open circuit, +B short or ground short……………………………………………355

DTC: P0107 (Flash code 71) Barometric pressure sensor circuit input is low (open circuit or ground short)………………………..361

DTC: P0108 (Flash code 71) Barometric pressure sensor circuit input is high (+5V short)………………………………………..367

DTC: P0112 (Flash code 22) Intake air temperature sensor fault (low voltage fault, GND short, short circuit)……………………..373

DTC: P0113 (Flash code 22) Intake air temperature sensor fault (high voltage fault, open circuit or short to power supply circuit)….379

DTC: P0117 (Flash code 23) Engine coolant temperature sensor fault (low voltage fault, GND short, short circuit)………………….386

DTC: P0118 (Flash code 23) Engine coolant temperature sensor input is high (open circuit or short to power supply)………………..392

DTC: P0182 (Flash code 211) Fuel temperature sensor fault (low voltage fault, GND short)……………………………………….400

DTC: P0183 (Flash code 211) Fuel temperature sensor fault (high voltage fault, open circuit or short to power supply circuit)………406

DTC: P0192 (Flash code 245) Common rail pressure sensor fault (low voltage fault, short circuit)………………………………..414

DTC: P0193 (Flash code 245) Common rail pressure sensor fault (high voltage fault)…………………………………………….420

DTC: P0201 (Flash code 271) Open circuit in injection nozzle #1 drive system………………………………………………….426

DTC: P0202 (Flash code 272) Open circuit in injection nozzle #2 drive system………………………………………………….431

DTC: P0203 (Flash code 273) Open circuit in injection nozzle #3 drive system………………………………………………….436

DTC: P0204 (Flash code 274) Open circuit in injection nozzle #4 drive system………………………………………………….441

DTC: P0219 (Flash code 543) Overrun………………………………………………………………………………………446

DTC: P0237 (Flash code 32) Boost pressure sensor fault (low voltage fault, open circuit)……………………………………….448

DTC: P0238 (Flash code 32) Boost pressure sensor fault (high voltage fault, short to power supply circuit, ground open circuit)…….455

DTC: P0335 (Flash code 15) Crank sensor fault (no signal)…………………………………………………………………..462

DTC: P0336 (Flash code 15) Crank sensor fault (signal fault)………………………………………………………………..469

DTC: P0340 (Flash code 14) Cam sensor fault (no signal)…………………………………………………………………….475

DTC: P0341 (Flash code 14) Cam sensor fault (signal fault)………………………………………………………………….482

DTC: P0380 (Flash code 66) Glow relay circuit fault………………………………………………………………………..488

DTC: P0381 (Flash code 67) Glow plug lamp circuit fault…………………………………………………………………….493

DTC: P0487 (Flash code 44) EGR position sensor fault……………………………………………………………………….498

DTC: P0488 (Flash code 45) EGR valve control fault…………………………………………………………………………504

DTC: P0522 (Flash code 294) Engine oil pressure sensor fault (low voltage fault, open circuit, ground short)……………………..510

DTC: P0523 (Flash code 294) Engine oil pressure sensor fault (high voltage fault, short to power supply, ground short)…………….516

DTC: P0601 (Flash code 53) ROM fault……………………………………………………………………………………..524

DTC: P0603 (Flash code 54) EEPROM fault…………………………………………………………………………………..526

DTC: P0606 (Flash code 51) CPU fault……………………………………………………………………………………..528

DTC: P0606 (Flash code 52) CPU monitoring IC fault…………………………………………………………………………530

DTC: P0611 (Flash code 34) Charge circuit fault (bank 1)……………………………………………………………………532

DTC: P0612 (Flash code 34) Charge circuit fault (bank 2)……………………………………………………………………535

DTC: P0615 (Flash code 19) Starter cut relay circuit fault………………………………………………………………….538

DTC: P0650 (Flash code 77) Diagnosis lamp circuit fault…………………………………………………………………….543

DTC: P1093 (Flash code 227) No pump pressure feed………………………………………………………………………….548

DTC: P1095 (Flash code 225) Pressure limiter open………………………………………………………………………….559

DTC: P1112 (Flash code 295) Boost temperature sensor fault (low voltage fault, ground short)……………………………………570

DTC: P1113 (Flash code 295) Boost temperature sensor fault (high voltage fault, open circuit, short to power supply circuit)……….577

DTC: P1173 (Flash code 542) Overheat……………………………………………………………………………………..584

DTC: P1225 (Flash code 31) Idle UP/DOWN switch fault……………………………………………………………………….589

DTC: P1261 (Flash code 158) Injection nozzle common 1 drive system fault……………………………………………………..593

DTC: P1262 (Flash code 159) Injection nozzle common 2 drive system fault……………………………………………………..600

DTC: P1271 (Flash code 24) Accelerator sensor 1-2 comparison fault…………………………………………………………..607

DTC: P1277 (Flash code 24) Accelerator sensor 1 fault (low voltage fault)…………………………………………………….613

DTC: P1278 (Flash code 24) Accelerator sensor 1 fault (high voltage fault)……………………………………………………618

DTC: P1282 (Flash code 24) Accelerator sensor 2 fault (low voltage fault)…………………………………………………….623

DTC: P1283 (Flash code 24) Accelerator sensor 2 fault (high voltage fault)……………………………………………………628

DTC: P1345 (Flash code 16) Cam sensor out of phase…………………………………………………………………………633

DTC: P1625 (Flash code 416) Main relay fault………………………………………………………………………………638

DTC: P1630 (Flash code 36) A/D conversion fault……………………………………………………………………………644

DTC: P1631 (Flash code 55) Voltage fault in 5V power supply 1……………………………………………………………….646

DTC: P1632 (Flash code 55) Voltage fault in 5V power supply 2……………………………………………………………….650

DTC: P1633 (Flash code 55) Voltage fault in 5V power supply 3……………………………………………………………….654

DTC: P1634 (Flash code 55) Voltage fault in 5V power supply 4……………………………………………………………….658

DTC: P1635 (Flash code 55) Voltage fault in 5V power supply 5……………………………………………………………….662

DTC: U2104 (Flash code 84) CAN Bus fault………………………………………………………………………………….666

DTC: U2106 (Flash code 85) CAN timeout fault………………………………………………………………………………671

List of Trouble Symptom…………………………………………………………………………………………………….676

List of trouble symptom…………………………………………………………………………………………………676

Engine start failure……………………………………………………………………………………………………677

Engine stall…………………………………………………………………………………………………………..685

Engine hunting, rough idling…………………………………………………………………………………………….690

Engine output shortage………………………………………………………………………………………………….695

Exhaust gas contains a lot of white smoke…………………………………………………………………………………699

Exhaust gas contains a lot of black smoke…………………………………………………………………………………702

Noise…………………………………………………………………………………………………………………705

Fuel consumption deteriorates……………………………………………………………………………………………707

Oil consumption deteriorates…………………………………………………………………………………………….710

Special Tool………………………………………………………………………………………………………………712

List of special tool……………………………………………………………………………………………………712