Starting from:

$50

Home

John Deere 160GLC Excavator Operation and Tests Technical Manual PDF DOWNLOAD

John Deere 160GLC Excavator Operation and Tests Technical Manual PDF DOWNLOAD

John Deere 160GLC Excavator Operation & Test Technical Manual TM13345X19 – PDF DOWNLOAD

FILE DETAILS:

John Deere 160GLC Excavator Operation & Test Technical Manual TM13345X19 – PDF DOWNLOAD

Language : English

Pages : 1219

Downloadable : Yes

File Type : PDF

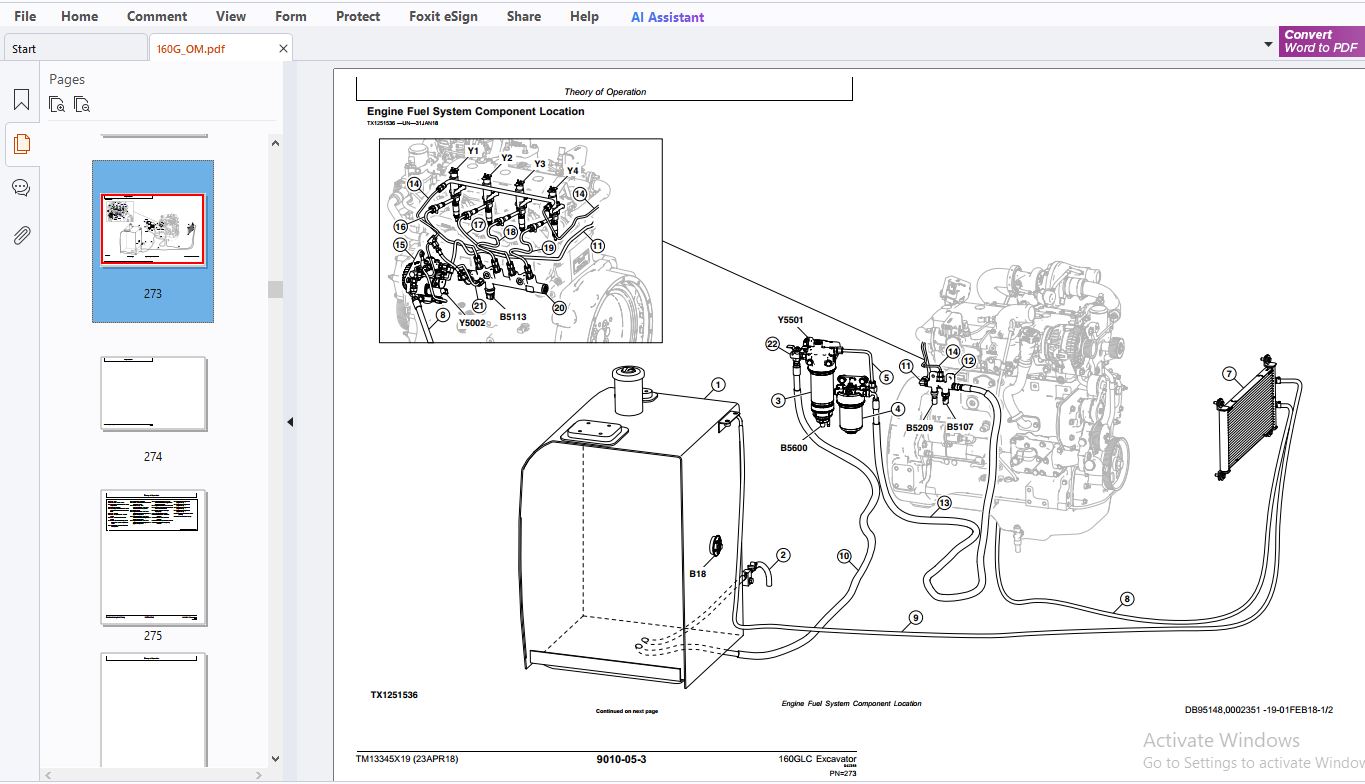

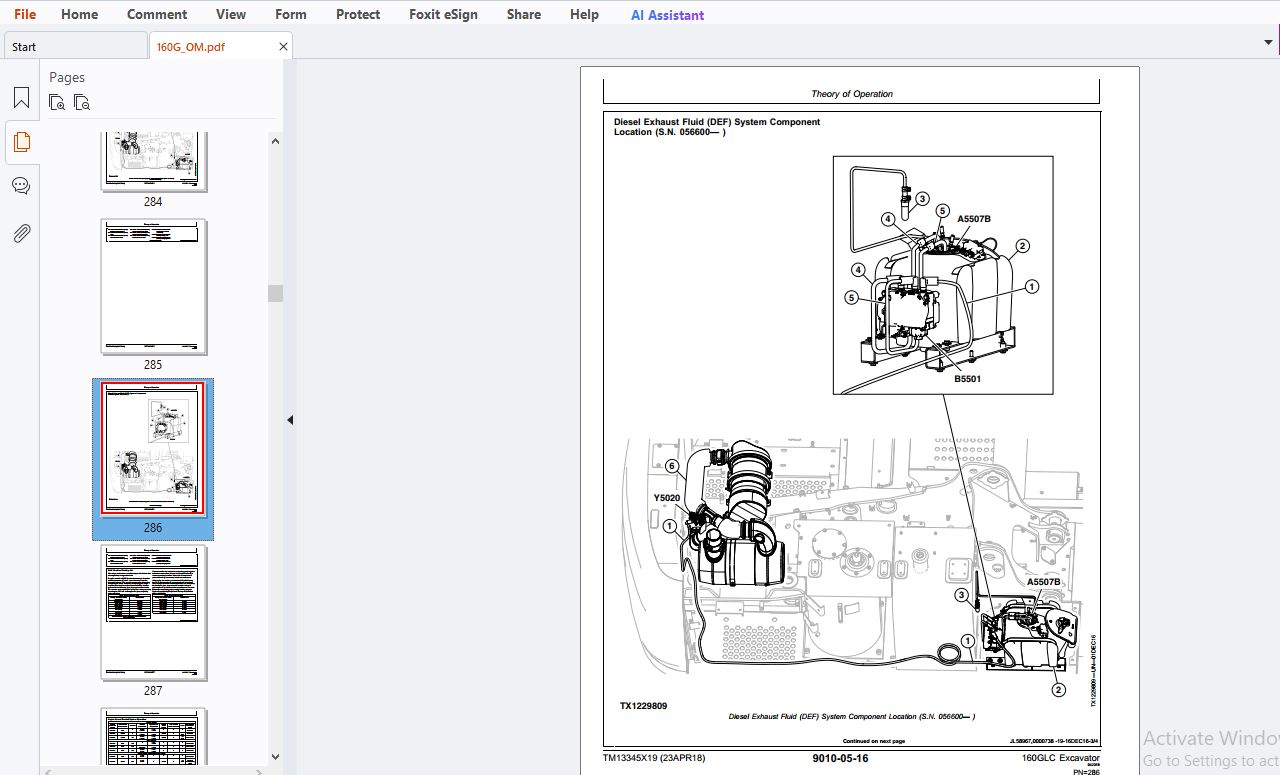

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

John Deere 160GLC Excavator Operation & Test Technical Manual TM13345X19 – PDF DOWNLOAD

- This manual is written for an experienced technician. Essential tools required in performing certain service work are identified in this manual and are recommended for use.

- Live with safety: Read the safety messages in the introduction of this manual and the cautions presented throughout the text of the manual.

- Technical manuals are divided in two parts: repair and operation and tests. Repair sections tell how to repair the components. Operation and test sections help you identify the majority of routine failures quickly.

- Information is organized in groups for the various components requiring service instruction. At the beginning of each group are summary listings of all applicable essential tools, service equipment, service parts, other materials needed to do the job, service parts kits, specifications, wear tolerances, and torque values.

- Technical Manuals are concise guides for specific machines. They are on-the-job guides containing only the vital information needed for diagnosis, analysis, testing, and repair.

- Fundamental service information is available from other sources covering basic theory of operation, fundamentals of troubleshooting, general maintenance, and basic type of failures and their causes.

TABLE OF CONTENTS:

John Deere 160GLC Excavator Operation & Test Technical Manual TM13345X19 – PDF DOWNLOAD