$40

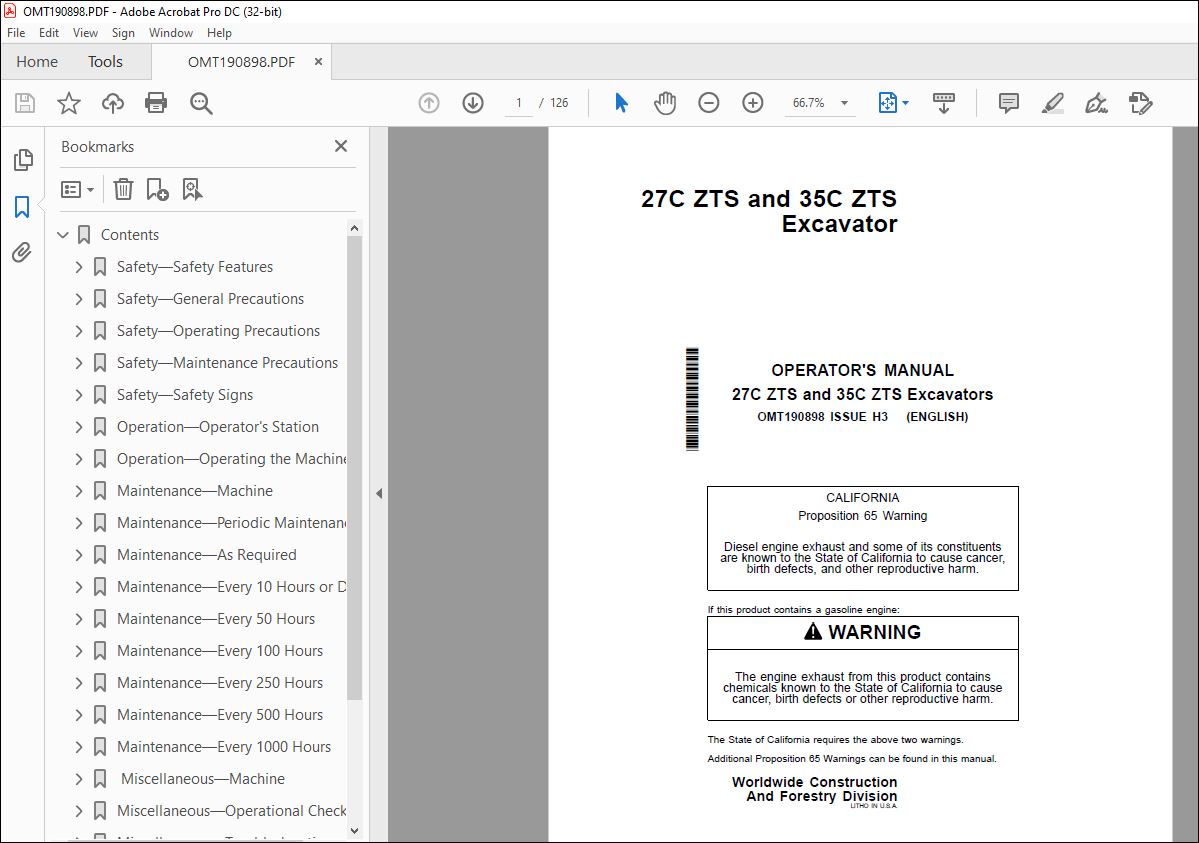

JOHN DEERE 27C 35C ZTS EXCAVATOR REPAIR SERVICE MANUAL PDF DOWNLOAD

John Deere 27C ZTS & 35C ZTS Excavator Operator’s Manual – PDF DOWNLOAD

FILE DETAILS:

John Deere 27C ZTS & 35C ZTS Excavator Operator’s Manual – PDF DOWNLOAD

P/N: OMT190898_UT

Language: English

Division: Construction

Product Lines: Excavators

Publication Type: Operator’s Manuals

Associated Models: 27CZTS, 35CZTS

Series: C SERIES

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

John Deere 27C ZTS & 35C ZTS Excavator Operator’s Manual – PDF DOWNLOAD

Contents 5

Safety—Safety Features 9

Safety and Operator Convenience Features 9

Safety—General Precautions 10

Recognize Safety Information 10

Follow Safety Instructions 10

Operate Only If Qualified 10

Wear Protective Equipment 10

Avoid Unauthorized Machine Modifications 11

Add Cab Guarding for Special Uses 11

Inspect Machine 11

Stay Clear of Moving Parts 11

Avoid High-Pressure Fluids 12

Beware of Exhaust Fumes 12

Prevent Fires 12

Prevent Battery Explosions 13

Handle Chemical Products Safely 13

Dispose of Waste Properly 13

Prepare for Emergencies 14

Safety—Operating Precautions 15

Use Steps and Handholds Correctly 15

Start Only From Operator’s Seat 15

Use and Maintain Seat Belt 15

Prevent Unintended Machine Movement 15

Avoid Work Site Hazards 15

Keep Riders Off Machine 16

Avoid Backover Accidents 16

Avoid Machine Tip Over 17

Use Special Care When Lifting Objects 17

Add and Operate Attachments Safely 18

Safety—Maintenance Precautions 19

Park and Prepare for Service Safely 19

Service Cooling System Safely 19

Remove Paint Before Welding or Heating 19

Make Welding Repairs Safely 20

Drive Metal Pins Safely 20

Safety—Safety Signs 21

Safety Signs 21

Operation—Operator’s Station 23

Pedals and Levers 23

Monitor Panel 23

Monitor Panel Functions 23

Horn Switch 24

Engine Speed Control Lever 24

Pilot Control Shut-Off Lever 24

Windshield Washer and Wiper Switch 25

Travel Alarm and Travel Alarm Cancel Switch 25

Cab Heater—If Equipped 25

Cab Door Release Lever 26

Secondary Exit Tool 26

Opening Front (Secondary Exit) Window 27

Closing Front Window 27

Opening Rear Window 28

Opening Right Side Window 28

Adjusting Operator Seat 29

Tool Box and Operator’s Manual Compartment 29

Operation—Operating the Machine 30

Before Starting Work 30

Operator’s Daily Machine Check Before Starting 30

Starting the Engine 30

Starting the Engine In Cold Weather 31

Check Instruments After Starting 32

Using Booster Batteries—12 Volt System 32

Cold Weather Warm-Up 33

Travel Pedals and Levers 33

Fast Speed Travel Pedal 34

Control Lever Pattern Operation 34

Control Lever Pattern Conversion 35

Boom-Swing Pedal 36

Optional Pedal 37

Positioning Auxiliary Line Selector Valve 37

Operating Backfill Blade 38

Operating Tips—Backfill Blade 39

Operating In Water and Mud 39

Select Correct Track Shoes 40

Driving Up a Steep or Slippery Slope 40

Lifting 40

Lower Boom With Engine Stopped 40

Parking 41

Loading and Unloading for Transport 42

Transporting Machine With Rubber Tracks 42

Towing Machine a Short Distance 43

Lifting Machine 43

Maintenance—Machine 45

Diesel Fuel 45

Biodiesel Fuel 45

Testing Diesel Fuel 47

Handling and Storing Diesel Fuel 47

Alternative and Synthetic Lubricants 47

Engine Break-In Oil 48

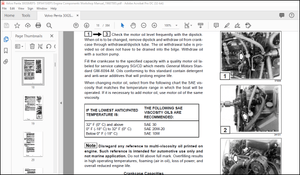

Diesel Engine Oil 48

Hydraulic Oil 49

Travel Gear Case Oil 49

Track Adjuster, Working Tool Pivot, Swing Bearing, and Swing Bearing Gear Grease 50

Maintenance—Periodic Maintenance 51

Service Machine at Specified Intervals 51

Check the Hour Meter Regularly 51

Prepare Machine for Maintenance 51

Open Hood and Access Cover 51

Fuel Tank 52

Hydraulic Breaker and Crusher Attachments 52

Maintenance and Repair Record Keeping System 52

Fluid Analysis Program Test Kits and 3-Way Coolant Test Kit 53

Periodic Maintenance Record Keeping System 53

Maintenance—As Required 56

Clean Radiator Core 56

Clean Air Cleaner Element 56

Maintenance—Every 10 Hours or Daily 57

Check Engine Oil Level 57

Check Hydraulic Oil Tank Level 57

Drain Fuel Tank Sump 58

Drain Water Separator 58

Check Recovery Tank Coolant Level 58

Check Bucket Teeth 59

Check Track Sag—Rubber Track 59

Check Track Sag—Steel Track, If Equipped 60

Adjusting Track Sag 61

Rubber Track Care 61

Removing Rubber Track 62

Installing Rubber Track 63

Converting The Track 64

Seat Belt 64

Maintenance—Every 50 Hours 66

Inspect Fan Belt, Check and Adjust Tension 66

Maintenance—Every 100 Hours 67

Grease Bucket and Link Pins 67

Maintenance—Every 250 Hours 68

Grease Swing Bearing 68

Check Travel Gear Case Oil Level 68

Drain Hydraulic Oil Tank Sump 69

Replace Hydraulic Oil Tank Filter 69

Maintenance—Every 500 Hours 71

Change Engine Oil and Replace Filter 71

Grease Front Joint Pins 71

Grease Swing Bearing Gear 73

Grease Control Lever Universal Joint 73

Replace Final Fuel Filter 74

Replace Air Cleaner Element 74

Drain Cooling System 75

Heavy Duty Diesel Engine Coolant 76

Cooling System Fill and Deaeration 77

Maintenance—Every 1000 Hours 78

Change Travel Gear Case Oil 78

Replace Pilot System Oil Filter 78

Check and Adjust Engine Valve Lash (Clearance) 79

Check Starter and Alternator 79

Change Hydraulic Tank Oil, Clean Suction Screen 79

Miscellaneous—Machine 83

Do Not Service or Adjust Injection Nozzles or High Pressure Fuel Pump 83

Do Not Service Control Valves, Cylinders, Pumps, or Motors 83

Precautions for Alternator and Regulator 83

Handling, Checking, and Servicing Batteries Carefully 83

Using Battery Charger 84

Replacing Batteries 85

Welding On Machine 85

Clean Machine Regularly 85

Electrical Socket 85

Replacing Fuses 86

Installing Bucket With Quick Coupler 87

Track Sag General Information 89

Check Track Shoe Hardware 89

Unified Inch Bolt and Screw Torque Values 89

Metric Bolt and Screw Torque Values 90

Miscellaneous—Operational Checkout 92

Operational Checkout 92

Operator Station Checks—Key Switch On, Engine Off 92

Operator Station Checks—Engine On 92

Miscellaneous Checks 101

Miscellaneous—Troubleshooting 103

Using Troubleshooting Charts 103

Engine 103

Electrical System 106

Hydraulic System 108

Miscellaneous—Storage 111

Prepare Machine for Storage 111

Miscellaneous—Serial Numbers 112

Record Product Identification Number (PIN) 112

Record Engine Serial Number 112

Keep Proof of Ownership 112

Keep Machines Secure 112

Miscellaneous—Specifications 114

27C ZTS and 35C ZTS Engine Specifications 114

27C ZTS and 35C ZTS Drain and Refill Capacities 114

27C ZTS Machine Specifications 114

27C ZTS Working Ranges 115

27C ZTS Excavator Lift Capacity—KG (LB) (Blade Off the Ground With Standard Boom and Rubber Track) 116

27C ZTS Excavator Lift Capacity—KG (LB) (Blade On the Ground With Standard Boom and Rubber Track) 117

35C ZTS Machine Specifications 117

35C ZTS Working Ranges 118

35C ZTS Excavator Lift Capacity—KG (LB) (Blade Off the Ground With Standard Boom and Rubber Track) 119

35C ZTS Excavator Lift Capacity—KG (LB) (Blade On the Ground With Standard Boom and Rubber Track) 120

Page Number 5

Section 1-1 9

Section 1-2 10

Section 1-3 15

Section 1-4 19

Section 1-5 21

Section 2-1 23

Section 2-2 30

Section 3-1 45

Section 3-2 51

Section 3-3 56

Section 3-4 57

Section 3-5 66

Section 3-6 67

Section 3-7 68

Section 3-8 71

Section 3-9 78

Section 4-1 83

Section 4-2 92

Section 4-3 103

Section 4-4 111

Section 4-5 112

Section 4-6 114

John Deere 27C ZTS & 35C ZTS Excavator Operator’s Manual – PDF DOWNLOAD

FILE DETAILS:

John Deere 27C ZTS & 35C ZTS Excavator Operator’s Manual – PDF DOWNLOAD

P/N: OMT190898_UT

Language: English

Division: Construction

Product Lines: Excavators

Publication Type: Operator’s Manuals

Associated Models: 27CZTS, 35CZTS

Series: C SERIES

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

John Deere 27C ZTS & 35C ZTS Excavator Operator’s Manual – PDF DOWNLOAD

Contents 5

Safety—Safety Features 9

Safety and Operator Convenience Features 9

Safety—General Precautions 10

Recognize Safety Information 10

Follow Safety Instructions 10

Operate Only If Qualified 10

Wear Protective Equipment 10

Avoid Unauthorized Machine Modifications 11

Add Cab Guarding for Special Uses 11

Inspect Machine 11

Stay Clear of Moving Parts 11

Avoid High-Pressure Fluids 12

Beware of Exhaust Fumes 12

Prevent Fires 12

Prevent Battery Explosions 13

Handle Chemical Products Safely 13

Dispose of Waste Properly 13

Prepare for Emergencies 14

Safety—Operating Precautions 15

Use Steps and Handholds Correctly 15

Start Only From Operator’s Seat 15

Use and Maintain Seat Belt 15

Prevent Unintended Machine Movement 15

Avoid Work Site Hazards 15

Keep Riders Off Machine 16

Avoid Backover Accidents 16

Avoid Machine Tip Over 17

Use Special Care When Lifting Objects 17

Add and Operate Attachments Safely 18

Safety—Maintenance Precautions 19

Park and Prepare for Service Safely 19

Service Cooling System Safely 19

Remove Paint Before Welding or Heating 19

Make Welding Repairs Safely 20

Drive Metal Pins Safely 20

Safety—Safety Signs 21

Safety Signs 21

Operation—Operator’s Station 23

Pedals and Levers 23

Monitor Panel 23

Monitor Panel Functions 23

Horn Switch 24

Engine Speed Control Lever 24

Pilot Control Shut-Off Lever 24

Windshield Washer and Wiper Switch 25

Travel Alarm and Travel Alarm Cancel Switch 25

Cab Heater—If Equipped 25

Cab Door Release Lever 26

Secondary Exit Tool 26

Opening Front (Secondary Exit) Window 27

Closing Front Window 27

Opening Rear Window 28

Opening Right Side Window 28

Adjusting Operator Seat 29

Tool Box and Operator’s Manual Compartment 29

Operation—Operating the Machine 30

Before Starting Work 30

Operator’s Daily Machine Check Before Starting 30

Starting the Engine 30

Starting the Engine In Cold Weather 31

Check Instruments After Starting 32

Using Booster Batteries—12 Volt System 32

Cold Weather Warm-Up 33

Travel Pedals and Levers 33

Fast Speed Travel Pedal 34

Control Lever Pattern Operation 34

Control Lever Pattern Conversion 35

Boom-Swing Pedal 36

Optional Pedal 37

Positioning Auxiliary Line Selector Valve 37

Operating Backfill Blade 38

Operating Tips—Backfill Blade 39

Operating In Water and Mud 39

Select Correct Track Shoes 40

Driving Up a Steep or Slippery Slope 40

Lifting 40

Lower Boom With Engine Stopped 40

Parking 41

Loading and Unloading for Transport 42

Transporting Machine With Rubber Tracks 42

Towing Machine a Short Distance 43

Lifting Machine 43

Maintenance—Machine 45

Diesel Fuel 45

Biodiesel Fuel 45

Testing Diesel Fuel 47

Handling and Storing Diesel Fuel 47

Alternative and Synthetic Lubricants 47

Engine Break-In Oil 48

Diesel Engine Oil 48

Hydraulic Oil 49

Travel Gear Case Oil 49

Track Adjuster, Working Tool Pivot, Swing Bearing, and Swing Bearing Gear Grease 50

Maintenance—Periodic Maintenance 51

Service Machine at Specified Intervals 51

Check the Hour Meter Regularly 51

Prepare Machine for Maintenance 51

Open Hood and Access Cover 51

Fuel Tank 52

Hydraulic Breaker and Crusher Attachments 52

Maintenance and Repair Record Keeping System 52

Fluid Analysis Program Test Kits and 3-Way Coolant Test Kit 53

Periodic Maintenance Record Keeping System 53

Maintenance—As Required 56

Clean Radiator Core 56

Clean Air Cleaner Element 56

Maintenance—Every 10 Hours or Daily 57

Check Engine Oil Level 57

Check Hydraulic Oil Tank Level 57

Drain Fuel Tank Sump 58

Drain Water Separator 58

Check Recovery Tank Coolant Level 58

Check Bucket Teeth 59

Check Track Sag—Rubber Track 59

Check Track Sag—Steel Track, If Equipped 60

Adjusting Track Sag 61

Rubber Track Care 61

Removing Rubber Track 62

Installing Rubber Track 63

Converting The Track 64

Seat Belt 64

Maintenance—Every 50 Hours 66

Inspect Fan Belt, Check and Adjust Tension 66

Maintenance—Every 100 Hours 67

Grease Bucket and Link Pins 67

Maintenance—Every 250 Hours 68

Grease Swing Bearing 68

Check Travel Gear Case Oil Level 68

Drain Hydraulic Oil Tank Sump 69

Replace Hydraulic Oil Tank Filter 69

Maintenance—Every 500 Hours 71

Change Engine Oil and Replace Filter 71

Grease Front Joint Pins 71

Grease Swing Bearing Gear 73

Grease Control Lever Universal Joint 73

Replace Final Fuel Filter 74

Replace Air Cleaner Element 74

Drain Cooling System 75

Heavy Duty Diesel Engine Coolant 76

Cooling System Fill and Deaeration 77

Maintenance—Every 1000 Hours 78

Change Travel Gear Case Oil 78

Replace Pilot System Oil Filter 78

Check and Adjust Engine Valve Lash (Clearance) 79

Check Starter and Alternator 79

Change Hydraulic Tank Oil, Clean Suction Screen 79

Miscellaneous—Machine 83

Do Not Service or Adjust Injection Nozzles or High Pressure Fuel Pump 83

Do Not Service Control Valves, Cylinders, Pumps, or Motors 83

Precautions for Alternator and Regulator 83

Handling, Checking, and Servicing Batteries Carefully 83

Using Battery Charger 84

Replacing Batteries 85

Welding On Machine 85

Clean Machine Regularly 85

Electrical Socket 85

Replacing Fuses 86

Installing Bucket With Quick Coupler 87

Track Sag General Information 89

Check Track Shoe Hardware 89

Unified Inch Bolt and Screw Torque Values 89

Metric Bolt and Screw Torque Values 90

Miscellaneous—Operational Checkout 92

Operational Checkout 92

Operator Station Checks—Key Switch On, Engine Off 92

Operator Station Checks—Engine On 92

Miscellaneous Checks 101

Miscellaneous—Troubleshooting 103

Using Troubleshooting Charts 103

Engine 103

Electrical System 106

Hydraulic System 108

Miscellaneous—Storage 111

Prepare Machine for Storage 111

Miscellaneous—Serial Numbers 112

Record Product Identification Number (PIN) 112

Record Engine Serial Number 112

Keep Proof of Ownership 112

Keep Machines Secure 112

Miscellaneous—Specifications 114

27C ZTS and 35C ZTS Engine Specifications 114

27C ZTS and 35C ZTS Drain and Refill Capacities 114

27C ZTS Machine Specifications 114

27C ZTS Working Ranges 115

27C ZTS Excavator Lift Capacity—KG (LB) (Blade Off the Ground With Standard Boom and Rubber Track) 116

27C ZTS Excavator Lift Capacity—KG (LB) (Blade On the Ground With Standard Boom and Rubber Track) 117

35C ZTS Machine Specifications 117

35C ZTS Working Ranges 118

35C ZTS Excavator Lift Capacity—KG (LB) (Blade Off the Ground With Standard Boom and Rubber Track) 119

35C ZTS Excavator Lift Capacity—KG (LB) (Blade On the Ground With Standard Boom and Rubber Track) 120

Page Number 5

Section 1-1 9

Section 1-2 10

Section 1-3 15

Section 1-4 19

Section 1-5 21

Section 2-1 23

Section 2-2 30

Section 3-1 45

Section 3-2 51

Section 3-3 56

Section 3-4 57

Section 3-5 66

Section 3-6 67

Section 3-7 68

Section 3-8 71

Section 3-9 78

Section 4-1 83

Section 4-2 92

Section 4-3 103

Section 4-4 111

Section 4-5 112

Section 4-6 114