$50

John Deere 310SK, 410K Backhoe Loaders With TMC Repair Manual PDF DOWNLOAD

John Deere 310SK, 410K Backhoe Loader With TMC Operation and Test Manual

File Details:

John Deere 310SK, 410K Backhoe Loader With TMC Operation and Test Manual

Language : English

Pages : 1456

Size : 46.4 MB

Downloadable : Yes

Format : PDF

Serial No : TM12487

Image Preview:

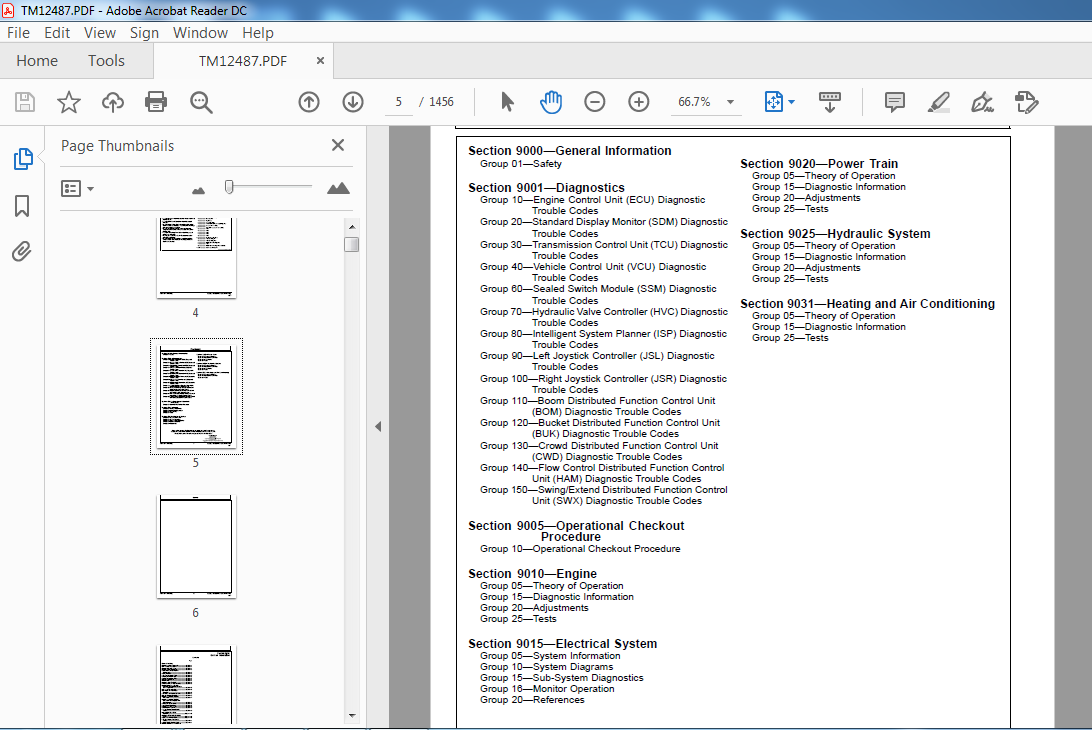

Table of Contents:

John Deere 310SK, 410K Backhoe Loader With TMC Operation and Test Manual

Section 9000—General Information

Group 01—Safety

Section 9001—Diagnostics

Group 10—Engine Control Unit (ECU) Diagnostic

Trouble Codes

Group 20—Standard Display Monitor (SDM) Diagnostic

Trouble Codes

Group 30—Transmission Control Unit (TCU) Diagnostic

Trouble Codes

Group 40—Vehicle Control Unit (VCU) Diagnostic

Trouble Codes

Group 60—Sealed Switch Module (SSM) Diagnostic

Trouble Codes

Group 70—Hydraulic Valve Controller (HVC) Diagnostic

Trouble Codes

Group 80—Intelligent System Planner (ISP) Diagnostic

Trouble Codes

Group 90—Left Joystick Controller (JSL) Diagnostic

Trouble Codes

Group 100—Right Joystick Controller (JSR) Diagnostic

Trouble Codes

Group 110—Boom Distributed Function Control Unit

(BOM) Diagnostic Trouble Codes

Group 120—Bucket Distributed Function Control Unit

(BUK) Diagnostic Trouble Codes

Group 130—Crowd Distributed Function Control Unit

(CWD) Diagnostic Trouble Codes

Group 140—Flow Control Distributed Function Control

Unit (HAM) Diagnostic Trouble Codes

Group 150—Swing/Extend Distributed Function Control

Unit (SWX) Diagnostic Trouble Codes

Section 9005—Operational Checkout

Procedure

Group 10—Operational Checkout Procedure

Section 9010—Engine

Group 05—Theory of Operation

Group 15—Diagnostic Information

Group 20—Adjustments

Group 25—Tests

Section 9015—Electrical System

Group 05—System Information

Group 10—System Diagrams

Group 15—Sub-System Diagnostics

Group 16—Monitor Operation

Group 20—References

Section 9020—Power Train

Group 05—Theory of Operation

Group 15—Diagnostic Information

Group 20—Adjustments

Group 25—Tests

Section 9025—Hydraulic System

Group 05—Theory of Operation

Group 15—Diagnostic Information

Group 20—Adjustments

Group 25—Tests

Section 9031—Heating and Air Conditioning

Group 05—Theory of Operation

Group 15—Diagnostic Information

Group 25—Tests

Recognize Safety Information ………………. 9000-01-1

Follow Safety Instructions…………………….. 9000-01-1

Operate Only If Qualified ……………………… 9000-01-1

Wear Protective Equipment………………….. 9000-01-2

Avoid Unauthorized Machine

Modifications…………………………………… 9000-01-2

Inspect Machine …………………………………. 9000-01-2

Stay Clear of Moving Parts…………………… 9000-01-2

Avoid High-Pressure Oils …………………….. 9000-01-3

Avoid High-Pressure Fluids ………………….. 9000-01-3

Work In Ventilated Area……………………….. 9000-01-4

Prevent Fires ……………………………………… 9000-01-4

Prevent Battery Explosions ………………….. 9000-01-5

Handle Chemical Products Safely………….. 9000-01-5

Decommissioning — Proper

Recycling and Disposal of Fluids

and Components …………………………….. 9000-01-6

Prepare for Emergencies……………………… 9000-01-6

Use Steps and Handholds

Correctly ………………………………………… 9000-01-6

Start Only From Operator’s Seat …………… 9000-01-7

Use and Maintain Seat Belt ………………….. 9000-01-7

Prevent Unintended Machine

Movement………………………………………. 9000-01-7

Prevent Unintended Machine

Movement—If Equipped With

Pilot Controls ………………………………….. 9000-01-7

Avoid Work Site Hazards……………………… 9000-01-8

Keep Riders Off Machine …………………….. 9000-01-8

Avoid Backover Accidents ……………………. 9000-01-9

Avoid Machine Tipover ………………………… 9000-01-9

Add and Operate Attachments

Safely…………………………………………….. 9000-01-9

Use Special Care When

Operating……………………………………… 9000-01-10

Operating or Traveling On Public

Roads ………………………………………….. 9000-01-10

Inspect and Maintain ROPS ……………….. 9000-01-10

Park and Prepare for Service

Safely…………………………………………… 9000-01-11

Service Cooling System Safely …………… 9000-01-11

Remove Paint Before Welding or

Heating ………………………………………… 9000-01-12

Make Welding Repairs Safely …………….. 9000-01-12

Drive Metal Pins Safely ……………………… 9000-01-12

Service Tires Safely…………………………… 9000-01-13

Description:

John Deere 310SK, 410K Backhoe Loader With TMC Operation and Test Manual

- This manual is written for an experienced technician. Essential tools required in performing certain service work are identified in this manual and are recommended for use. Live with safety: Read the safety messages in the introduction of this manual and the cautions presented throughout the text of the manual. This is the safety-alert symbol.

- When this symbol is seen on the machine or in this manual, be alert for the potential of personal injury. Technical manuals are divided in two parts: repair and operation and tests. Repair sections tell how to repair the components.

- Operation and test sections help to quickly identify the majority of routine failures quickly. Information is organized in groups for the various components requiring service instruction. At the beginning of each group are summary listings of all applicable essential tools, service equipment and tools, other materials needed to do the job, service parts kits, specifications, wear tolerances, and torque values.

- Technical manuals are concise guides for specific machines. They are on-the-job guides containing only the vital information needed for diagnosis, analysis, testing, and repair. Fundamental service information is available from other sources covering basic theory of operation, fundamentals of troubleshooting, general maintenance, and basic type of failures and their causes. TM124