$38

Komatsu 102 Series Diesel Engine Shop Manual YEBM200101 – PDF DOWNLOAD

Komatsu 102 Series Diesel Engine Shop Manual YEBM200101 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 102 Series Diesel Engine Shop Manual YEBM200101 – PDF DOWNLOAD

Language : English

Pages : 806

Downloadable : Yes

File Type : PDF

Size: 40.2 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 102 Series Diesel Engine Shop Manual YEBM200101 – PDF DOWNLOAD

The Komatsu 102 Series Diesel Engine Shop Manual YEBM200101 is a digital PDF version of the comprehensive guide that provides detailed information on the maintenance, repair, and overhaul of Komatsu 102 series diesel engines. It is a convenient and portable option for individuals who prefer to have the manual available on their electronic devices.

- The PDF version of the manual is organized into the same sections as the print version, including an overview of the engine and its components, engine inspection and measurement procedures, engine disassembly and assembly procedures, engine testing and adjusting procedures, engine maintenance procedures, and engine troubleshooting and diagnosis procedures.

- One of the advantages of the PDF version of the manual is that it is searchable, making it easy to quickly find the information you need. Additionally, the PDF version includes hyperlinks to make navigation even easier, allowing the user to quickly jump to specific sections or subsections of the manual.

- Another advantage of the PDF version is that it is easily printable, allowing the user to create hard copies of specific sections or the entire manual for easy reference in the workshop or field.

- The digital PDF version of the Komatsu 102 Series Diesel Engine Shop Manual YEBM200101 can be downloaded from various websites, including the Komatsu website, for a fee. It is essential to ensure that the source of the PDF download is reputable to avoid any potential issues with the manual’s quality or accuracy.

- Overall, the Komatsu 102 Series Diesel Engine Shop Manual YEBM200101 in PDF format is an excellent resource for anyone working on or maintaining Komatsu 102 series diesel engines. It provides detailed information in a convenient and portable format, making it an essential tool for any mechanic or technician.

TABLE OF CONTENTS:

Komatsu 102 Series Diesel Engine Shop Manual YEBM200101 – PDF DOWNLOAD

COVER……………………………………………………………………………………… 1

SUB-COVER………………………………………………………………………………. 2

CONTENTS ………………………………………………………………………………. 3

SAFETY…………………………………………………………………………………. 4

SAFETY NOTICE……………………………………………………………………….. 4

FOREWORD ………………………………………………………………………………. 6

GENERAL ………………………………………………………………………….. 6

HOW TO READ THE SHOP MANUAL …………………………………………………………. 7

HOISTING INSTRUCTIONS………………………………………………………………… 8

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER ……………………………… 9

COATING MATERIALS……………………………………………………………………. 11

STANDARD TIGHTENING TORQUE ………………………………………………………….. 13

ELECTRIC WIRE CODE …………………………………………………………………. 16

UNITS………………………………………………………………………………. 17

CAPSCREW MARKINGS AND TORQUE VALUES …………………………………………………… 18

PIPE PLUG TORQUE VALUES………………………………………………………………. 21

SYMBOLS…………………………………………………………………………….. 22

ILLUSTRATIONS……………………………………………………………………….. 23

01 GENERAL ……………………………………………………………………………. 24

APPLICABLE MACHINE…………………………………………………………………… 25

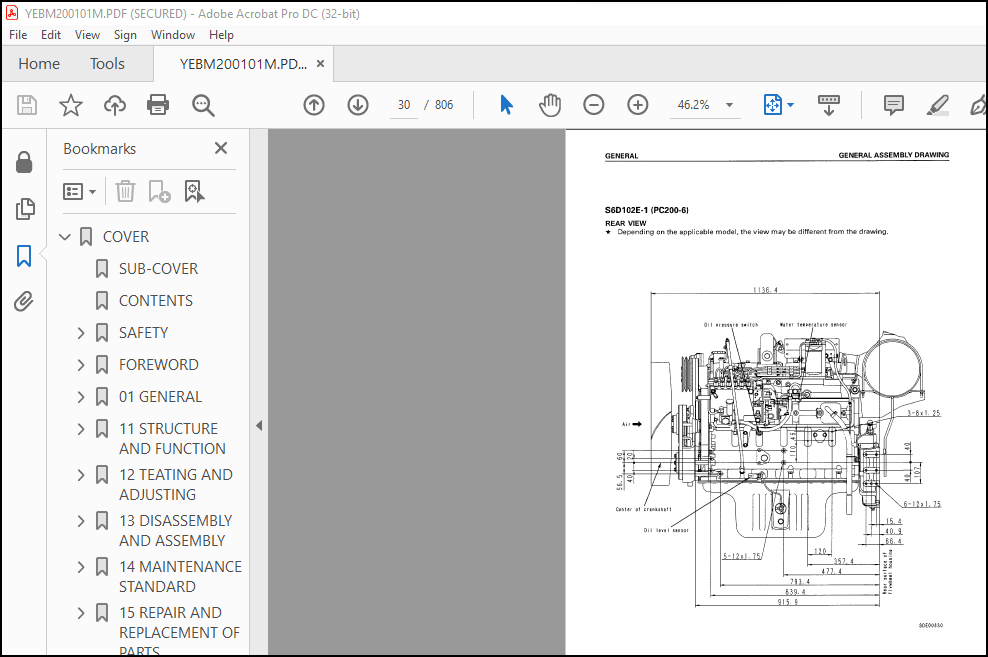

GENERAL ASSEMBLY DRAWING……………………………………………………………… 29

S6D102E-1(PC200-6)FRONT VIEW………………………………………………………. 29

S6D102E-1(PC200-6)REAR VIEW……………………………………………………….. 30

S6D102E-1(PC200-6)LEFT-HAND VIEW…………………………………………………… 31

S6D102E-1(PC200-6)RIGHT-HAND VIEW………………………………………………….. 32

SAA6D102E-2(PC200/210-7)FRONT VIEW…………………………………………………. 33

SAA6D102E-2(PC200/210-7)REAR VIEW………………………………………………….. 34

SAA6D102E-2(PC200/210-7)LEFT-HAND VIEW……………………………………………… 35

SAA6D102E-2(PC200/210-7)RIGHT-HAND VIEW…………………………………………….. 36

SAA6D102E-2(PC220-7)FRONT VIEW…………………………………………………….. 37

SAA6D102E-2(PC220-7)REAR VIEW……………………………………………………… 38

SAA6D102E-2(PC220-7)LEFT-HAND VIEW…………………………………………………. 39

SAA6D102E-2(PC220-7)RIGHT-HAND VIEW………………………………………………… 40

ENGINE PERFORMANCE CURVE……………………………………………………………… 43

S6D102E-1(PC200,200LC-6,PC200,200LC-6 HYPER GX))…………………………………….. 44

S6D102E-1(PC200LC-6 EXCEL, PC200-6 CUSTOM)………………………………………….. 45

SA6D102E-1(PC220, 220LC-6)………………………………………………………… 46

SA6D102E-1(PC220,200LC-6 EXCEL)……………………………………………………. 47

SAA6D102E-2(PC200-7,PC200LC-7,PC210-7,PC210LC-7)…………………………………….. 48

WEIGHT TABLE………………………………………………………………………… 50

11 STRUCTURE AND FUNCTION ………………………………………………………………. 52

OUTLINE OF AIR INTAKE AND EXHAUST SYSTEMS………………………………………………. 53

INTAKE AND EXHAUST DEVICES……………………………………………………………. 54

(S)6D102E-1(INTAKE DEVICE)………………………………………………………… 54

(EXHAUST DEVICE)…………………………………………………………………. 55

SA6D102E-1(INTKAE DEVICE)…………………………………………………………. 56

(EXHAUST DEVICE)…………………………………………………………………. 57

AIR CLEANER…………………………………………………………………………. 58

FRG TYPE(RADIAL SEAL TYPE)………………………………………………………… 58

FTG TYPE(CYCLOPACK TYPE)………………………………………………………….. 58

TURBOCHARGER………………………………………………………………………… 59

S(A)6D102E-1…………………………………………………………………….. 59

SAA6D102E-2……………………………………………………………………… 60

OUTLINE OF WASTE GATE VALVE……………………………………………………….. 61

LUBRICATION OF TURBOCHARGER(ENGINE WITH TURBOCHARGER)………………………………… 62

CYLINDER HEAD……………………………………………………………………….. 63

(S)6D102E-1, SA6D102E-1…………………………………………………………… 63

SAA6D102E-2……………………………………………………………………… 65

CYLINDER BLOCK………………………………………………………………………. 68

(S)6D102E-1, SA6D102E-1 SAA6D102E-2………………………………………………… 68

MAIN MOVING PARTS……………………………………………………………………. 71

(S)6D102E-1, SA6D102E-1 SAA6D102E-2………………………………………………… 71

CRANKSHAFT AND MAIN BEARING……………………………………………………….. 73

PISTON CONNECTING ROD…………………………………………………………….. 73

TIMING GEAR PORTION………………………………………………………………….. 76

FRONT GEAR COVER…………………………………………………………………….. 77

CAMSHAFT TIMING PIN………………………………………………………………….. 78

VALVE MECHANISM……………………………………………………………………… 79

(S)6D102E-1, SA6D102E-1 SAA6D102E-2……………………………………………….. 79

(S)6D102E-1, SA6D102E-1 SAA6D102E-2……………………………………………….. 82

FLYWHEEL, FLYWHEEL HOUSING……………………………………………………………. 83

LUBRICATION SYSTEM DIAGRAM……………………………………………………………. 85

FLOW OF LUBRICAING OIL …………………………………………………………… 86

LUBRICATION OF OUTPUT POWER RELATED EQUIPMENT……………………………………….. 88

OIL PUMP …………………………………………………………………………. 90

OIL FILTER, OIL COOLER……………………………………………………………….. 91

REGULATOR VALVE, SAFETY VALVE…………………………………………………………. 92

FUEL SYSTEM DIAGRAM………………………………………………………………….. 95

(S)6D102E-1, SA6D102E-1…………………………………………………………… 95

SAA6D102E-2……………………………………………………………………… 98

FUEL INJECTION PUMP………………………………………………………………….. 99

TIMING LOCK PIN FOR FUEL INJECTION PUMP…………………………………………………101

FUEL FILTER………………………………………………………………………….102

FUEL INJECTION NOZZLE…………………………………………………………………103

FUEL CUT SOLENOID…………………………………………………………………….104

COOLING SYSTEM DIAGRAM………………………………………………………………..105

(S)6D102E-1 SAA6D102E-2…………………………………………………………..105

SA6D102E-1……………………………………………………………………….106

WATER PUMP…………………………………………………………………………..108

THERMOSTAT…………………………………………………………………………..109

FAN DRIVE……………………………………………………………………………110

OUTSIDE DIAMETER OF PULLEY…………………………………………………………111

AIR COMPRESSOR……………………………………………………………………….113

FLOW DIAGRAMS-COMPRESSED AIR SYSTEM…………………………………………………….115

ALTERNATOR…………………………………………………………………………..117

ALTERNATOR(OPTIONAL)………………………………………………………………….118

STARTING MOTOR……………………………………………………………………….119

STARTING MOTOR……………………………………………………………………….120

STARTING MOTOR(OPTIONAL)………………………………………………………………121

STARTING AID…………………………………………………………………………122

12 TEATING AND ADJUSTING ………………………………………………………………..124

SPECIAL TOOL LIST…………………………………………………………………….126

SPECIAL TOOLS FOR INTAKE AND EXHAUST SYSTEM………………………………………….126

SPECIAL TOOLS FOR ENGINE…………………………………………………………..127

SPECIAL TOOLS FOR FUEL SYSTEM………………………………………………………129

SPECIAL TOOLS FOR COMPONENTS……………………………………………………….130

SPECIAL TOOLS FOR ELECTRICAL COMPONENTS……………………………………………..131

SPECIAL TOOLS FOR ENGINE PERFORMANCE TEST……………………………………………132

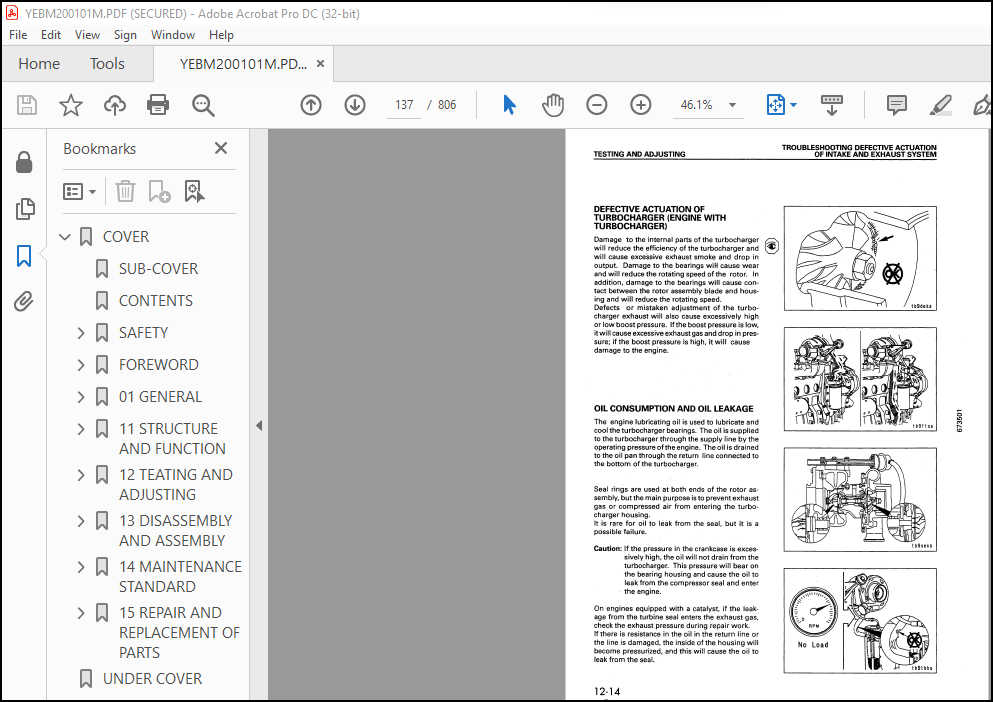

TROUBLESHOOTIN DEFECTIVE ACTUATION OF INTAKE AND EXHAUST SYSTEM……………………………134

CLEAN AIR………………………………………………………………………..134

TESTING INTAKE RESISTANCE………………………………………………………….134

DAMAGE CAUSED BY UNFILTERED AIR…………………………………………………….135

LEAKAGE OF INTAKE AIR(ENGINE WITH TURBOCHARGER)………………………………………135

LEAKAGE OF EXHAUST AIR (EINGINE WITH TURBOCHARGER)……………………………………136

MEASURING PRESSURE OF TURBOCHARGED AIR(EINGINE WITH TURBOCHARGER)………………………136

DEFECTIVE ACTUATION OF TURBOCHARGER (ENGINE WITH TURBOCHARGER)…………………………137

OIL CONSUMPTION AND OIL LEAKAGE…………………………………………………….137

NOISE FROM TURBOCHARGER (ENGINE WITH TURBOCHARGER)……………………………………138

MEASURING PLAY OF TURBOCHARGER ROTOR IN AXIAL AND RADIAL DIRECTION(ENGINE WITH TURBOCHARGER)….139

TESTING TURBOCHARGER WESTGATE VALVE(ENGINE WITH TURBOCHARGER)……………………………..140

TESTING TURBOCHARGER WESTGATE CAPSULE (ENGINE WITH TURBOCHARGER)…………………………..141

TESTING ACTUATION OF TURBOCHARGER WESTGATE (ENGINE WITH TURBOCHARGER )……………………..141

REPLACING TURBOCHARGER WESTGATE ACTUATOR BOOST CAPSULE(ENGINE WITH TURBOCHARGER)…………….142

ADJUSTING TURBOCHARGER WESTGATE ACTUATOR(ENGINE WITH TURBOCHARGER)…………………………144

MEASURING EXHAUST RESISTANCE…………………………………………………………..145

REPLACING TURBOCHARGER(ENGINE WITH TURBOCHARGER)…………………………………………145

TROUBLESHOOTING DEFECTIVE ACTUATION OF ENGINE……………………………………………146

VALVE MECHANISM AND CYLINDER HEAD…………………………………………………..146

TEATING AIR SYSTEM AND FUEL SYSTEM………………………………………………….146

TESTING VALVE CLEARANCE……………………………………………………………147

TEATING COMPRESSION……………………………………………………………….147

PISTON RING SEALING PERFORMANCE…………………………………………………….147

VALVE SEALING PERFORMANCE………………………………………………………….148

HEAD GASKET SEALING PERFORMANCE…………………………………………………….148

VALVE SEAL WEAR…………………………………………………………………..149

PROTRUDING PORTION OF FUEL INJECTION NOZZLE………………………………………….150

FRONT GEAR HOUSING AND GEAR TRAIN…………………………………………………..151

VIBRATION DAMPER………………………………………………………………….151

ROCKER LEVER, VALVE STEM, PUSH ROD, TAPPET, AND CAMSHAFT………………………………152

PISTON AND CONNECTING ROD………………………………………………………….153

CRANDSHAFT AND MAIN BEARING………………………………………………………..155

CYLINDER BLOCK……………………………………………………………………156

FLYWHEEL HOUSING AND FLYWHEEL………………………………………………………157

ADJUSTING VALVE CLEARANCE……………………………………………………………..158

ADJUSTING 4-CYLINDER ENGINE………………………………………………………..159

ADJUSTIN 6-CYLINDER ENGINE…………………………………………………………160

TROUBLESHOOTING DEFECTIVE ACTUATION OF LUBRICATING SYSTEM…………………………………161

OUTLINE………………………………………………………………………….161

HIGH PRESSURE…………………………………………………………………….161

REGULATOR VALVE…………………………………………………………………..161

LOW PRESSURE……………………………………………………………………..161

OIL LEVEL………………………………………………………………………..162

OIL FILTER……………………………………………………………………….162

OIL PRESSURE GAUGE………………………………………………………………..162

OIL PAN SUCTION TUBE ……………………………………………………………..163

BEARING AND OIL PUMP ……………………………………………………………..163

UNSUITABLE OIL PUMP……………………………………………………………….163

DILUTION OF OIL ………………………………………………………………….163

COOLING WATER IN OIL ……………………………………………………………..164

FUEL IN OIL ……………………………………………………………………..165

OIL LEAKAGE………………………………………………………………………168

FUEL INJECTION PUMP CALIBRATION DATA……………………………………………………171

RUNNING IN STANDARD…………………………………………………………………..180

PERFORMANCE TEST CRITERIA……………………………………………………………..181

TROUBLESHOOTING DEFECTIVE ACTUATION OF FEED PUMP(DIAPHRAGM TYPE)…………………………..183

TEST1: TESTING OUTPUT PRESSURE……………………………………………………..183

TEST2: TESTING FLOW……………………………………………………………….184

TROUBLESHOOTING DEFECTIVE ACTUATION OF FEED PUMP(PISTON TYPE)……………………………..185

TEST1: TESTING OUTPUT PRESSURE……………………………………………………..186

TEST2: TESTING FLOW……………………………………………………………….187

TESING AIR INSIDE FUEL SYSTEM………………………………………………………….190

TESING WATER SEPARATOR FUEL FILTER……………………………………………………..191

TROUBLESHOOTING FAILURE OF FUEL INJECTION PUMP(BOSCH VE, LUCAS CAV)………………………..193

DEFECTIVE ACTUATION OF GOVERNOR…………………………………………………….194

STROKE OF FUEL CONTROL LEVER AND ADJUSTMENT………………………………………….194

LUCAS CAV ADJUSTIMENT SCREW………………………………………………………..194

BOSCH VE ADJUSTMENT SCREW………………………………………………………….195

MANUAL SHUT-OFF LEVER……………………………………………………………..195

TIMING PROPULSION ANGLE MECHANISM…………………………………………………..196

ELECTRICAL SHUT-OFF VALVE………………………………………………………….196

DELIVERY VALVE(LUCAS CAV)………………………………………………………….198

TESTING HIGH-PRESSURE FUEL PIPING………………………………………………………199

TESING FUEL INJECTION NOZZLE…………………………………………………………..200

TESING FUEL DRAIN PIPING ……………………………………………………………..202

BLEEDING AIR FROM FUEL SYSTEM………………………………………………………….202

BLEEDING AIR FROM LOW PRESSURE CIRCUIT AND FUEL FILTER………………………………..203

BLEEDING AIR FROM FUEL INJECTION PUMP……………………………………………….203

BLEEDING AIR FROM HIGH-PRESSURE CIRCUIT……………………………………………..204

ADJUSTING FUEL INJECTION TIMING………………………………………………………..204

ADJUSTING FUEL INJECTION TIMING FOR BOSCH VE…………………………………………207

ADJUSTING FUEL INJECTION TIMING FOR LUCAS CAV………………………………………..208

ADJUSTING LOW IDLING SPEED (BOSCH VE, LUCAS CAV)…………………………………………209

REPLACING FUEL INJECTION NOZZLE………………………………………………………..209

TROUBLESHOOTING DEFECTIVE ACTUATION OF COOLING SYSTEM…………………………………….213

TROUBLESHOOTING…………………………………………………………………..213

RADIATOR CAP……………………………………………………………………..215

WATER PUMP……………………………………………………………………….216

RADIATOR, FAN AND RADIATOR SHUTTER………………………………………………….217

THERMOSTAT……………………………………………………………………….219

WATER TEMPERATURE GAUGE, FUEL GAUGE, OOVERLOAD……………………………………….220

TESTING CARBON DEPOSIT IN AIR COMPRESSOR………………………………………………..221

TESING AIR LEAKAGE FROM AIR COMPRESSOR………………………………………………….222

TESING AIR GOVERNOR, UNLOADER VALVE…………………………………………………….223

TESING AIR GOVERNOR…………………………………………………………………..224

TESING BATTERY……………………………………………………………………….226

TESING BATTERY TERMINAL CONNCTIONS …………………………………………………….227

TESTING STARTING CIRCUIT ……………………………………………………………..227

TESTING BATTERY RELAY……………………………………………………………..227

TESING STARTING SWITCH…………………………………………………………….229

TESING STARTING MOTOR AND MAGNETIC SWITCH……………………………………………230

STARTING MOTOR……………………………………………………………………231

TESTING DROP IN CRANKING SPEED……………………………………………………..232

TESING ALTERNATOR…………………………………………………………………….233

ABNORMAL DISPLAY OF CHARGE LAMP…………………………………………………….234

ABNORMAL ACTUATION OF CHARGING SYSTEM……………………………………………….235

TESING OIL PRESSURE SWITCH AND WATER TEMPERATURE SENSOR…………………………………..236

TESTING OIL PRESSURE SWITCH………………………………………………………..236

TESTING WATER TEMPERATURE SENSOR……………………………………………………237

TESING WHITE SMOKE……………………………………………………………………238

NORMAL ACTUATION OF INTAKE HEATER SYSTEM…………………………………………….238

TESING INTAKE HEATER………………………………………………………………….239

TESTING PREHEATING CYCLE…………………………………………………………..240

SIDE VIEW OF ENGINE…………………………………………………………………..241

OUTLINE OF ENGINE PERFORMANCE TEST……………………………………………………..243

BLOW-BY MEASUREMENT AND REPLACEMENT TABLE……………………………………………….244

ENGINE DYNAMOMETER …………………………………………………………………..245

INSTALLING ENGINE…………………………………………………………………245

PROCEDURE FOR RUNNING IN ENGINE…………………………………………………….252

ENGINE PERFORMANCE TEST……………………………………………………………255

ENGINE PAINWORK………………………………………………………………………257

TROUBLESHOOTING………………………………………………………………………260

STANDARD VALUE TABLE FOR TESTING, ADJUSTING, AND TROUBLESHOOTING……………………….261

TROUBLESHOOTING OF ENGINE (S MODE)………………………………………………….264

METHOD OF USING TROUBLESHOOTING CHARTS…………………………………………..265

S-1 STRATING PERFORMANCE IS POOR (STARING ALWAYS TAKES TIME)……………………….269

S-2 ENGINE DOES NOE START………………………………………………………271

(1)ENGINE DOES NOT TURN…………………………………………………….271

(2)ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT (FUEL IS NOT BEING INJECTED)………272

(3)EXHAUST SMOKE COMES OUT BUT ENGINE DOES NOT START(FUEL IS BEING INJECTED)……..273

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)……………………….274

S-4 ENGINE STOPS DURING OPERTIONS……………………………………………275

S-5 ENGINE DOES NOT ROTATE SMOOOTHLY (HUNTING)………………………………..276

S-6 ENGINE LACKS OUTPUT(OR LACKS POWER……………………………………….277

S-7 EXHAUST SMOKE IS BLACK(INCOMPLETE COMBUSTION)……………………………..278

S-8 OIL CONSUMPTION IS EXCESSIVE(OR EXHAUST SMOKE IS BLUE)……………………..279

S-9 OIL BECOMES CONTAMINATED QUICKLY…………………………………………280

S-10 FUEL CONSUMPTION IS EXCESSIVE…………………………………………..281

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN……..282

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP(DROP IN OIL PRESSURE)………………….283

S-13 OIL LEVEL RISES(WATER, FUEL IN OIL) …………………………………….284

S-14 WATER TEMPERATURE BECOMES TOO HIGH(OVERHEATING)…………………………..285

S-15 ABNORMAL NOISE IS MADE…………………………………………………286

S-16 VIBRATION IS EXCESSIVE…………………………………………………287

13 DISASSEMBLY AND ASSEMBLY……………………………………………………………….288

SPECIAL TOOL LIST…………………………………………………………………….293

SPECIAL TOOLS FOR DISASSEMBLY AND ASSEMBLY…………………………………………..293

SPECIAL TOOLS FOR ENGINE…………………………………………………………..295

SPECIAL TOOLS FOR FUEL SYSTEM………………………………………………………297

OUTLINE OF DISASSEMBLY AND ASSEMBLY OF ENGINE……………………………………………299

OUTLINE………………………………………………………………………….299

DISASSEMBLY…………………………………………………………………..299

ASSEMBLY ……………………………………………………………………299

DISASSEMBLY OF ENGINE…………………………………………………………………300

STEAM CLEANING OF ENGINE…………………………………………………………..300

REMOVAL OF STARTING MOTOR………………………………………………………….300

WEIGHT OF ENGINE(REFERENCE VALUE NOT INCLUDING AUXILIARIES SUCH AS MUFFLER)……………..300

INSTALLATION TO ENGINE STAND……………………………………………………….300

DRAINING OIL……………………………………………………………………..301

REMOVAL OF REAR LIFTING BRACKET…………………………………………………….301

REMOVAL OF BELT…………………………………………………………………..301

REMOVAL OF FAN PULLEY……………………………………………………………..302

REMOVAL OF VIBRATION DAMPER, CRANKSHAFT PULLEY……………………………………….302

REMOVAL OF BELT TENSIONER………………………………………………………….302

REMOVAL OF FAN HUB………………………………………………………………..303

REMOVAL OF ALTERNATOR……………………………………………………………..303

REMOVAL OF THERMOSTAT……………………………………………………………..304

REMOVAL OF TURBOCHARGER(ENGINE WITH TURBOCHARGER)…………………………………….304

REMOVAL OF EXHAUST MANIFOLD………………………………………………………..306

REMOVAL OF FUEL FILTER…………………………………………………………….306

REMOVAL OF FUEL FILTER HEAD ……………………………………………………….307

REMOVAL OF FUEL PIPING…………………………………………………………….307

REMOVAL OF DIPSTICK……………………………………………………………….309

REMOVAL OF INTAKE MANIFOLD COVER……………………………………………………309

REMOVAL OF AFTERCOOLER(ENGINE WITH AFTERCOOLER)………………………………………310

REMOVAL OF CYLINDER HEAD COVER……………………………………………………..310

REMOVAL OF FUEL INJECTION NOZZLE……………………………………………………310

REMOVAL OF ROCKER LEVER……………………………………………………………311

REMOVAL OF PUSH ROD……………………………………………………………….312

REMOVAL OF CYLINDER HEAD…………………………………………………………..312

REMOVAL OF FRONT COVER…………………………………………………………….312

REMOVAL OF WATER PUMP……………………………………………………………..313

REMOVAL OF FLYWHEEL……………………………………………………………….313

REMOVAL OF FLYWHEEL HOUSING………………………………………………………..314

REMOVAL OF COMPONENTS(COMPRESSOR, HYDRAULIC PUMP, ETC.)……………………………….314

REMOVAL OF FUEL INJECTION PUMP(BOSCH A, ZEXEL A)……………………………………..314

REMOVAL OF FEED PUMP(ENGINE MOUNT TYPE)……………………………………………..317

REMOVAL OF TAPPET COVER……………………………………………………………317

REMOVAL OF OIL FILLER……………………………………………………………..317

REMOVAL OF OIL COOLER……………………………………………………………..317

REMOVAL OF WATER INLET…………………………………………………………….318

REMOVAL OF OIL PAN………………………………………………………………..318

REMOVAL OF OIL PAN SUCTION TUBE…………………………………………………….318

REMOVAL OF REAR SEAL COVER…………………………………………………………319

REMOVAL OF CAMSHAFT……………………………………………………………….319

REMOVAL OF TAPPET…………………………………………………………………321

REMOVAL OF OIL PUMP……………………………………………………………….321

REMOVAL OF TIMING PIN HOUSING………………………………………………………322

REMOVAL OF GEAR HOUSING……………………………………………………………322

REMOVAL OF BALANCER(WHEN BALANCER IS INSTALLED)………………………………………323

REMOVAL OF PISTON CONNECTING ROD……………………………………………………325

REMOVAL OF CRANKSHAFT……………………………………………………………..327

REMOVAL OF TURBOCHARGER LUBRICATION DRAIN TUBE……………………………………….329

REMOVAL OF CYLINDER BLOCK FROM ENGINE STAND………………………………………….329

ASSEMBLY OF ENGINE……………………………………………………………………330

PREPARATION FOR ASSEMBLY OF CYLINDER BLOCK…………………………………………..330

INSTALLATION OF TAPPET…………………………………………………………….330

INSTALLATION OF CRANKSHAFT…………………………………………………………331

INSTALLATION OF PISTION AND CONNECTING ROD ASSEMBLIES…………………………………335

INSTALLATION OF PISTION AND CONNECTING ROD ASSEMBLY…………………………………..335

INSTALLATION OF GEAR HOUSING……………………………………………………….339

INSTALLATION OF OIL PUMP…………………………………………………………..340

INSTALLATION OF CAMSHAFT…………………………………………………………..341

INSTALLATION OF TIMING PIN…………………………………………………………344

INSTALLATION OF BALANCER…………………………………………………………..347

INSTALLATION OF REAR OIL SEAL………………………………………………………351

INSTALLATION OF OIL PAN SUCTION TUBE………………………………………………..352

INSTALLATION OF OIL PAN……………………………………………………………353

INSTALLATION OF OIL COOLER…………………………………………………………354

INSTALLATION OF OIL FILLER PORT…………………………………………………….354

INSTALLATION OF FEED PUMP………………………………………………………….355

INSTALLATION OF TAPPET COVER……………………………………………………….355

INSTALLATION OF FUEL INJECTION PUMP (BOSCH A, ZEXEL A)………………………………..357

INSTALLATION OF COMPONENTS(COMPRESSOR, HYDRAULIC PUMP, ETC.)…………………………..362

INSTALLATION OF FLYWHEEL HOUSING……………………………………………………362

INSTALLATION OF FLYWHEEL…………………………………………………………..363

INSTALLATION OF WATER PUMP…………………………………………………………364

INSTALLATION OF FRONT COVER………………………………………………………..364

INSTALLATION OF CYLINDER HEAD………………………………………………………366

INSTALLATION OF PUSH ROD…………………………………………………………..367

INSTALLATION OF ROCKER LEVER……………………………………………………….367

TIGHTENING OF CYLINDER HEAD………………………………………………………..369

ADJUSTING VALVE CLEARANCE………………………………………………………….371

INSTALLATION OF FUEL INJECTION NOZZLE……………………………………………….373

INSTALLATION OF CYLINDER HEAD COVER…………………………………………………374

INSTALLATION OF INTAKE MAINIFOLD COVER………………………………………………374

INSTALLATION OF FUEL FILTER HEAD……………………………………………………376

INSTALLATION OF EXHAUST MANIFOLD……………………………………………………377

INSTALLATION OF TURBOCHARGER(ENGINE WITH TURBOCHARGER)………………………………..378

INSTALLATION OF THERMOSTAT…………………………………………………………381

INSTALLATION OF CRANKSHAFT PULLEY, VIBRATION DAMPER…………………………………..382

INSTALLATION OF FAN HUB……………………………………………………………382

INSTALLATION OF BELT TENSIONER……………………………………………………..382

INSTALLATION OF WATER INLET………………………………………………………..383

INSTALLATION OF ALTERNATOR…………………………………………………………383

INSTALLATION OF BELT………………………………………………………………384

INSTALLATION OF OIL FILTER…………………………………………………………385

REMOVAL OF ENGINE FROM ENGINE STAND…………………………………………………385

INSTALLATION OF STARTING MOTOR……………………………………………………..385

INTAKE GROUP…………………………………………………………………………386

DISASSEMBLY AND ASSEMBLY DRAWING……………………………………………………386

OUTLINE………………………………………………………………………….388

REPLACEMENT OF TURBOCHARGER(ENGINE WITH TURBOCHARGER)…………………………………….389

REMOVAL………………………………………………………………………….389

INSTALLATION……………………………………………………………………..390

CLEANING AND INSPECTION……………………………………………………………392

REPLACEMENT OF AFTERCOOLER, GASKET(ENGINE WITH AFTERCOOLER)……………………………….394

REMOVAL………………………………………………………………………….394

CLEANING ……………………………………………………………………….394

INSTALLATION……………………………………………………………………..395

CLEANING AND INSPECTION……………………………………………………………396

ASSEMBLY ……………………………………………………………………….396

REPLACEMENT OF INTAKE CONNECTOR………………………………………………………..397

REMOVAL AND INSTALLATION…………………………………………………………..397

AIR CONNECTOR………………………………………………………………………..397

CLEANING ……………………………………………………………………….397

INSPECTION ……………………………………………………………………..397

REPLACEMENT OF INTAKE MANIFOLD COVER, GASKET…………………………………………….397

REMOVAL………………………………………………………………………….398

CLEANING ……………………………………………………………………….398

INSTALLATION……………………………………………………………………..398

AIR CROSSOVER TUBE……………………………………………………………………399

CLEANING ……………………………………………………………………….399

INSPECTION ………………………………………………………………………399

EXHAUST GROUP………………………………………………………………………..400

DISASSEMBLY AND ASSEMBLY DRAWING……………………………………………………400

OUTLINE OF EXHAUST MANIFOLD………………………………………………………..401

REPLACEMENT OF EXHAUST MANIFOLD, GASKET ………………………………………………..402

REPLACEMENT OF EXHAUST MANIFOLD, GASKET …………………………………………….402

REMOVAL………………………………………………………………………402

CLEANING AND INSPECTION………………………………………………………..402

INSTALLATION………………………………………………………………….402

REPLACEMENT OF EXHAUST MANIFOLD…………………………………………………….403

REMOVAL………………………………………………………………………403

CLEANING ……………………………………………………………………403

INSTALLATION………………………………………………………………….404

INSPECTION……………………………………………………………………404

REPLACEMENT OF TURBOCHARGER……………………………………………………………405

REMOVAL………………………………………………………………………….405

INSTALLATION……………………………………………………………………..406

TURBOCHARGER MOUNTING STUD(ENGINE WITH TURBOCHARGER)……………………………………..409

REPLACEMENT………………………………………………………………………409

CYLINDER BLOCK GROUP………………………………………………………………….410

DISASSEMBLY AND ASSEMBLY DRAWING……………………………………………………410

OUTLINE OF CYLINDER BLOCK GROUP…………………………………………………….413

OUTLINE OF CAMSHAFT……………………………………………………………413

OUTLINE OF CRANKSHAFT………………………………………………………….413

OUTLINE OF CYLINDER BLOCK………………………………………………………413

OUTLINE OF OIL SEAL……………………………………………………………413

REPLACEMENT OF FRONT OIL SEAL………………………………………………………414

REMOVAL………………………………………………………………………414

CLEANING AND INSPECTION………………………………………………………..415

INSTALLATION………………………………………………………………….415

REPLACEMENT OF REAR OIL SEAL……………………………………………………417

OUTLINE OF PISTION…………………………………………………………….419

OUTLINE OF VIBRATION DAMPER…………………………………………………….419

CHECK LIST FOR CYLINDER BLOCK GROUP……………………………………………..420

CYLINDER BLOCK……………………………………………………………………….421

CYLINDER BLOCK……………………………………………………………………421

INSPECTION BEFORE DISASSEMBLY…………………………………………………..421

DISASSEMBLY OF CYLINDER BLOCK…………………………………………………..421

CLEANING OF CYLINDER BLOCK……………………………………………………..423

INSPECTION OF CYLINDER BLOCK……………………………………………………….426

REMOVAL OF GLAZE FROM CYLINDER BORE…………………………………………………428

DISASSEMBLY…………………………………………………………………..428

INSPECTION……………………………………………………………………429

REMOVAL OF GLAZE………………………………………………………………429

CLEANING ……………………………………………………………………432

ASSEMBLY …………………………………………………………………….433

REMOVAL OF GLAZE FROM CYLINDER BLOCK…………………………………………….434

REPLACEMENT OF PLUG……………………………………………………………….437

REMOVAL………………………………………………………………………437

CLEANING AND INSPECTION………………………………………………………..437

INSTALLATION………………………………………………………………….438

REPLACEMENT OF CAP………………………………………………………………..438

REMOVAL …………………………………………………………………….438

CLEANING ……………………………………………………………………439

INSTALLATION ………………………………………………………………..439

INSTALLATION OF CUP PLUG……………………………………………………….440

INSTALLATION OF CAP AND PLUG……………………………………………………….442

INSTALLATION OF CAMSHAFT CUP……………………………………………………444

INSTALLATION OF CAMSHAFT BUSHING………………………………………………..445

REPLACEMENT OF DIPSTICK TUBE……………………………………………………446

STORING CYLINDER BLOCK…………………………………………………………447

CRANKSHAFT…………………………………………………………………………..447

REPLACEMENT OF MAIN BEARING………………………………………………………..448

CLEANING OF CRANKSHAFT…………………………………………………………….455

INSTALLATION OF CRANKSHAFT…………………………………………………………455

REPLACEMENT OF CRANKSHAFT GEAR……………………………………………………..456

REPLACEMENT OF CAMSHAFT AND TAPPET………………………………………………….458

REMOVAL OF CAMSHAFT……………………………………………………………458

REMOVAL OF TAPPET……………………………………………………………..459

INSPECTION OF TAPPET…………………………………………………………..461

STANDARDS FOR PITTING WHEN REUSING………………………………………………463

STANDARD FOR DETERIORATION……………………………………………………..464

INSPECTION OF CAMSHAFT BORE…………………………………………………….467

REPLACEMENT OF CAMSHAFT BUSHING…………………………………………………….467

INSTALLATION OF TAPPET…………………………………………………………468

INSTALLATION OF CAMSHAFT……………………………………………………….471

CLEANING OF CAMSHAFT………………………………………………………………473

INSPECTION OF CAMSHAFT, GEAR……………………………………………………474

REPLACEMENT OF CAMSHAFT,GEAR……………………………………………………….476

REMOVAL………………………………………………………………………476

CLEANING AND INSPECTION………………………………………………………..477

INSTALLATION………………………………………………………………….478

REPLACEMENT OF TIMEING PIN…………………………………………………………….480

REPLACEMENT OF GEAR HOUSING, GASKET…………………………………………………….481

REMOVAL………………………………………………………………………….481

CLEANING AND INSPECTION……………………………………………………………482

INSTALLATION……………………………………………………………………..483

REPOSITIONING OF TIMING PIN………………………………………………………..486

REPLACEMENT OF CAMSHAFT GEAR……………………………………………………….491

REMOVAL………………………………………………………………………491

INSTALLATION (SHRINK-FITTING METHOD)…………………………………………….492

INSTALLATION (METHOD USING SPECIAL TOOL)…………………………………………493

INSTALLATION OF CAMSHAFT MOUNTING BOLTS………………………………………….495

REPLACEMENT OF VIBRATION DAMPER, CRANKSHAFT PULLEY……………………………………….496

REMOVAL ………………………………………………………………………..496

INSPECTION OF RUBBER DAMPER………………………………………………………..496

INSTALLATION …………………………………………………………………….497

INSPECTION OF VISCOUS DAMPER……………………………………………………….497

VIBRATION DAMPER (RUBBER TYPE)……………………………………………………..499

CLEANING AND INSPECTION………………………………………………………..499

CLEANING AND INSPECTION OF VIBRATION DAMPER………………………………………499

PISTON, PIN, CONNECTING ROD……………………………………………………………501

REPLACEMENT OF PISTON AND RING……………………………………………………..501

REMOVAL OF PISTON CONNECTING ROD……………………………………………………502

DISASSEMBLY OF PISTON CONNECTING ROD………………………………………………..504

CLEANING OF PISTON, PIN, CONNECTING ROD……………………………………………..504

INSPECTION OF PISTON………………………………………………………………505

INSPECTION OF PISTON PIN…………………………………………………………..506

ASSEMBLY OF PISTON CONNECTING ROD…………………………………………………..507

INSPECTION OF PISTON RING GAP………………………………………………………508

INSTALLATION OF PISTON RING………………………………………………………..509

INSTALLATION OF PISTON CONNECTING ROD……………………………………………….510

REPLACEMENT OF CONNECTING ROD………………………………………………………514

REMOVAL………………………………………………………………………514

CLEANING AND INSPECTION………………………………………………………..515

INSTALLATION………………………………………………………………….517

REPLACEMENT OF CONNECTING ROD BEARING……………………………………………….518

REMOVAL………………………………………………………………………518

CLEANING AND INSPECTION………………………………………………………..520

INSTALLATION………………………………………………………………….521

DISASSEMBLY OF PISTON CONNECTING ROD…………………………………………….524

CLEANING OF PISTON,PIN,CONNECTING ROD……………………………………………525

INSPECTION OF PISTON…………………………………………………………..526

INSPECTION OF PISTON PIN……………………………………………………….527

INSPECTION OF CONNECTING ROD……………………………………………………527

INSPECTION OF CONNECTING ROD BEARING CLEARANCE……………………………………527

ASSEMBLY OF PISTON CONNECTING ROD……………………………………………….528

INSPECTION OF PISTON RING END GAP……………………………………………….529

INSTALLATION OF PISTON RING…………………………………………………….530

BALANCER …………………………………………………………………………..531

DISASSEMBLY………………………………………………………………………531

ASSEMBLY ……………………………………………………………………….534

GEAR COVER ………………………………………………………………………….541

REPLACEMENT OF GEAR COVER …………………………………………………………541

REMOVAL………………………………………………………………………541

CLEANING AND INSPECTION………………………………………………………..542

INSTALLATION………………………………………………………………….542

INSTALLATION OF GEAR COVER……………………………………………………..544

INSPECTION OF GEAR HOUSING AND TIMING PIN………………………………………..546

DISASSEMBLY OF GEAR HOUSING…………………………………………………….546

REPLACEMENT OF FUEL INJECTION PUMP MOUNTING STUD………………………………….547

REPLACEMENT OF ENGINE NAME PLATE………………………………………………..547

CYLINDER HEAD ……………………………………………………………………….550

DISASSEMBLY AND ASSEMBLY DRAWING……………………………………………………550

OUTLINE………………………………………………………………………….552

REPLACEMENT OF CYLINDER HEAD……………………………………………………….553

REMOVAL………………………………………………………………………553

INSPECTION BEFORE DISASSEMBLY OF CYLINDER HEAD……………………………………556

DISASSEMBLY OF CYLINDER HEAD……………………………………………………557

CLEANING OF CYLINDER HEAD………………………………………………………558

INSPECTION OF VALVE……………………………………………………………560

INSPECTION OF VALVE GUIDE………………………………………………………561

INSPECTION OF CYLINDER DECK…………………………………………………….561

INSPECTION OF VALVE SEAT……………………………………………………….562

STANDARDS FOR CRACKS IN CYLINDER HEAD WHEN REUSING………………………………..562

REPLACEMENT OF VALVE SPRING…………………………………………………….563

ASSEMBLY OF CYLINDER HEAD………………………………………………………563

INSTALLATION OF CYLINDER HEAD…………………………………………………..564

INSTALLATION OF PUSH ROD……………………………………………………….565

INSTALLATION OF ROCKER LEVER……………………………………………………565

ADJUSTING VALVE CLEARANCE………………………………………………………568

INSTALLATION OF THERMOSTAT……………………………………………………..569

INSTALLATION OF FAN HUB………………………………………………………..569

INSTALLATION OF BELT TENSIONER………………………………………………….570

INSTALLATION OF ALTERNATOR……………………………………………………..570

INSTALLATION OF DRIVE BELT……………………………………………………..571

INSPECTION BEFORE DISASSEMBLY…………………………………………………..571

DISASSEMBLY OF CYLINDER HEAD……………………………………………………572

CLEANING OF CYLINDER HEAD………………………………………………………573

INSPECTION OF VALVE……………………………………………………………575

INSPECTION OF VALVE GUIDE………………………………………………………576

INSPECTION OF CYLINDER HEAD COMBUSTION DECK………………………………………576

INSPECTION OF VALVE SEAT……………………………………………………….577

STANDARDS FOR CRACKS IN CYLINDER HEAD WHEN REUSING………………………………..577

REPLACEMENT OF VALVE SPRING…………………………………………………….578

REPLACEMENT OF CAP…………………………………………………………….578

POLISHING VALVE……………………………………………………………….580

POLISHING VALVE SEAT ………………………………………………………….581

CALCULATING GRINDING DEPTH AND MEASURING DEPTH OF VALVE……………………………582

ASSEMBLY OF CYLINDER HEAD………………………………………………………586

ROCKER LEVER…………………………………………………………………………588

DISASSEMBLY AND ASSEMBLY DRAWING……………………………………………………588

OUTLINE………………………………………………………………………….590

REPLACEMENT OF ROCKER LEVER AND PUSH ROD…………………………………………….591

REMOVAL………………………………………………………………………….591

DISASSEMBLY OF ROCKER LEVER………………………………………………………..592

CLEANING OF ROCKER LEVER…………………………………………………………..593

INSPECTION OF ROCKER LEVER…………………………………………………………593

ASSEMBLY OF ROCKER LEVER…………………………………………………………..594

INSTALLATION OF ROCKER LEVER……………………………………………………….595

DISASSEMBLY OF ROCKER LEVER………………………………………………………..597

CLEANING OF ROCKER LEVER, ROCKER LEVER SHAFT…………………………………………598

INSPECTION OF ROCKER LEVER…………………………………………………………598

INSPECTION OF ROCKER LEVER SHAFT……………………………………………………599

ASSEMBLY OF ROCKER LEVER…………………………………………………………..599

TAPPETS AND PUSH RODS…………………………………………………………………601

DISASSEMBLY AND ASSEMBLY DRAWING……………………………………………………601

OUTLINE………………………………………………………………………….602

CLEANING OF PUSH ROD………………………………………………………………603

INSPECTION OF PUSH ROD…………………………………………………………603

INSTALLATION OF PUSH ROD……………………………………………………….603

INSPECTION OF TAPPET…………………………………………………………..604

INSPECTION OF PUSH ROD…………………………………………………………605

ENGINE MOUNT GROUP……………………………………………………………………606

OUTLINE OF FLYWHEEL HOUSING………………………………………………………..606

OUTLINE OF FLYWHEEL, RING GEAR……………………………………………………..606

OUTLINE OF FRONT SUPPORT…………………………………………………………..606

FLYWHEEL, RING GEAR…………………………………………………………………..607

INSPECTION OF FLYWHEEL, RING GEAR…………………………………………………..607

REPLACEMENT OF FLYWHEEL, RING GEAR………………………………………………….607

REPLACEMENT OF RING GEAR……………………………………………………….607

INSTALLTION OF FLYWHEEL………………………………………………………..608

REPLACEMENT OF RING GEAR……………………………………………………….608

FLYWHEEL HOUSING……………………………………………………………………..609

REPLACEMENT OF REAR OIL SEAL ………………………………………………………609

REMOVAL………………………………………………………………………609

CLEANING AND INSPECTION………………………………………………………..611

INSTALLATION………………………………………………………………….611

REPLACEMENT OF FLYWHEEL HOUSING…………………………………………………….614

REMOVAL………………………………………………………………………614

CLEANING AND INSPECTION………………………………………………………..615

INSTALLATION(DRY CLUTCH SPECIFICATION)…………………………………………..616

INSPECTION OF RADIAL RUNOUT OF FLYWHEEL HOUSING…………………………………..617

INSPECTION OF FACE RUNOUT OF FLYWHEEL HOUSING…………………………………….619

INSTALLATION (WET CLUTCH SPECIFICATION)………………………………………….620

INSPECTION……………………………………………………………………622

INSTALLATION………………………………………………………………….623

FRONT SUPPORT………………………………………………………………………..624

CLEANING AND INSPECTION……………………………………………………………624

REMOVAL OF ENGINE…………………………………………………………………….625

INSPECTION OF ENGINE MOUNT…………………………………………………………….627

INSTALLATION OF ENGINE………………………………………………………………..628

CONNECTION OF FUEL CONTROL LEVER……………………………………………………629

OIL PAN AND SUCTION TUBE………………………………………………………………632

DISASSEMBLY AND ASSEMBLY DRAWING……………………………………………………632

REPLACEMENT OF OIL PAN, SUCTION TUBE, GASKET…………………………………………633

CLEANING AND INSPECTION……………………………………………………………635

REGULATOR VALVE………………………………………………………………………636

REPLACEMENT OF REGULATOR VALVE, SPRING………………………………………………636

DISASSEMBLY…………………………………………………………………..636

CLEANING AND INSPECTION……………………………………………………………636

ASSEMBLY ……………………………………………………………………637

DISASSEMBLY ………………………………………………………………….637

INSPECTION……………………………………………………………………638

ASSEMBLY …………………………………………………………………….638

OIL FILTER BYPASS VALVE……………………………………………………………….639

REPLACEMENT………………………………………………………………………639

OIL COOLER…………………………………………………………………………..640

DISASSEMBLY AND ASSEMBLY DRAWING……………………………………………………640

REPLACEMENT OF OIL COOLER CORE, GASKET………………………………………………641

CLEANING ……………………………………………………………………….643

INSPECTION ……………………………………………………………………..644

OIL PUMP …………………………………………………………………………..645

DISASSEMBLY AND ASSEMBLY DRAWING……………………………………………………645

REPLACEMENT OF OIL PUMP……………………………………………………………646

REMOVAL OF OIL PUMP……………………………………………………………646

CLEANING AND INSPECTION………………………………………………………..647

INSTALLATION OF OIL PUMP…………………………………………………………..650

INSPECTION……………………………………………………………………….651

FUEL INJECTION PUMP GROUP……………………………………………………………..655

DISASSEMBLY AND ASSEMBLY DRAWING……………………………………………………655

FUEL INJECTION NOZZLE GROUP……………………………………………………………656

FUEL INJECTION NOZZLE……………………………………………………………..657

DISASSEMBLY…………………………………………………………………..657

CLEANING AND INSPECTION……………………………………………………………658

ASSEMBLY …………………………………………………………………….660

TEST…………………………………………………………………………662

FEED PUMP(CYLINDER BLOCK MOUNT TYPE)……………………………………………………663

REPLACEMENT OF FEED PUMP(DIAPHRAGM TYPE)…………………………………………….663

REPLACEMENT, ASSEMBLY OF FEED PUMP(PISTON TYPE)………………………………………665

REMOVAL………………………………………………………………………665

CLEANING ……………………………………………………………………666

ASSEMBLY …………………………………………………………………….666

INSTALLATION………………………………………………………………….667

CLEANING AND INSPECTION………………………………………………………..667

ASSEMBLY(PISTON TYPE)………………………………………………………….669

CLEANING ……………………………………………………………………669

ASSEMBLY ……………………………………………………………………670

REPLACEMENT OF FUEL FILTER …………………………………………………………..670

FUEL PIPING………………………………………………………………………….672

REPLACEMENT OF HIGH-PRESSURE FUEL PIPING(BOSCH VE, LUCAS CAV) …………………………672

REPLACEMENT OF FUEL SUPPLY PIPING(BOSCH VE, LUCAS CAV) ……………………………….673

CLEANING AND INSPECTION OF HIGH-PRESSURE FUEL PIPING………………………………….675

REPLACEMENT OF FUEL RETURN PIPING(BOSCH VE, LUCAS CAV) ……………………………676

CLEANING AND INSPECTION OF FUEL DRAIN PIPING……………………………………..678

REPLACEMENT OF LOW-PRESSURE FUEL PIPING (BOSCH VE, LUCAS CAV)………………………….678

CLEANING AND INSPECTION OF LOW-PRESSURE FUEL PIPING…………………………………..679

REPLACEMENT OF AIR-FUEL RATIO CONTROL TUBE(BOSCH VE) …………………………………680

WATER PUMP…………………………………………………………………………..681

DISASSEMBLY AND ASSEMBLY DRAWING……………………………………………………681

REPLACEMENT OF WATER PUMP………………………………………………………….682

INSPECTION……………………………………………………………………….683

FAN HUB……………………………………………………………………………..683

REPLACEMENT OF FAN PULLEY………………………………………………………….683

REPLACEMENT OF FAN HUB…………………………………………………………….684

INSPECTION……………………………………………………………………….684

DISASSEMBLY………………………………………………………………………685

ASSEMBLY ……………………………………………………………………….686

BELT TENSIONER……………………………………………………………………….688

DISASSEMBLY AND ASSEMBLY DRAWING……………………………………………………688

REPLACEMENT OF BELT……………………………………………………………….689

REPLACEMENT OF BELT TENSIONER………………………………………………………689

INSPECTION……………………………………………………………………….689

THERMOSTAT…………………………………………………………………………..690

DISASSEMBLY AND ASSEMBLY DRAWING……………………………………………………690

REPLACEMENT OF THERMOSTAT………………………………………………………….691

INSPECTION……………………………………………………………………….692

FAN…………………………………………………………………………………694

COOLANT……………………………………………………………………………..694

FILLING WITH WATER………………………………………………………………..695

ACCESSORY DRIVE ADAPTER……………………………………………………………….696

DISASSEMBLY AND ASSEMBLY DRAWING……………………………………………………696

CLEANING ……………………………………………………………………….697

INSPECTION ………………………………………………………………………697

DISASSEMBLY ……………………………………………………………………..697

ASSEMBLY ………………………………………………………………………..698

DISASSEMBLY OF UNLOADER VALVE, CYLINDER HEAD…………………………………………700

CLEANING …………………………………………………………………….701

INSPECTION …………………………………………………………………..702

ASSEMBLY ……………………………………………………………………706

REPLACEMENT OF AIR COMPRESSOR………………………………………………………709

REMOVAL………………………………………………………………………709

POWER STEERING COUPLING(WHEN USED) ……………………………………………..711

INSTALLATION………………………………………………………………….712

CLEANING AND INSPECTION……………………………………………………………714

INSPECTION……………………………………………………………………714

ALTERNATOR…………………………………………………………………………..715

REPLACEMENT OF ALTERNATOR………………………………………………………….715

INSPECTION……………………………………………………………………….716

STARTING MOTOR……………………………………………………………………….716

REPLACEMENT OF STARTING MOTOR………………………………………………………716

INSPECTION……………………………………………………………………….717

REPLACE HYDRAULIC SWITCH……………………………………………………….717

REPLACEMENT OF WATER TEMPERATURE SENSOR………………………………………….717

14 MAINTENANCE STANDARD…………………………………………………………………..719

TURBOCHARGER…………………………………………………………………………720

EXHAUST MANIFOLD……………………………………………………………………..722

CYLINDER HEAD………………………………………………………………………..724

VALVE, VALVE GUIDE……………………………………………………………………726

LOCKER ARM SHAFT, PUSH ROD AND TAPPET…………………………………………………..728

CYLINDER BLOCK……………………………………………………………………….730

CYLINDER ………………………………………………………………………….734

CRANKSHAFT …………………………………………………………………………736

CAMSHAFT …………………………………………………………………………..738

TIMING GEAR………………………………………………………………………….742

PISTON, PISTON RING AND PISTON PIN……………………………………………………..744

CONNECTING ROD……………………………………………………………………….746

VIBRATION DAMPER……………………………………………………………………..748

FLYWHEEL, FLYWHEEL HOUSING…………………………………………………………….750

FAN HUB……………………………………………………………………………..752

OIL PUMP …………………………………………………………………………..753

WATER PUMP, THERMOSTAT………………………………………………………………..754

FUEL INJECTION PUMP ………………………………………………………………….755

FUEL INJECTION NOZZLE…………………………………………………………………756

15 REPAIR AND REPLACEMENT OF PARTS…………………………………………………………759

OUTLINE……………………………………………………………………………..760

REPAIR GUIDELINE………………………………………………………………….760

WHEN SHOULD SUBSTITUTE REPAIRS BE CARRIED OUT………………………………………..760

INSPECTION……………………………………………………………………….760

TO ENSURE SAFETY, FOLLOW ALL INSTRUCTIONS IN MANUAL…………………………………..760

FOLLOW WASHING METHODS GIVEN IN MANUAL………………………………………………760

FOLLOW INSPECTION METHODS GIVEN IN MANUAL……………………………………………760

REPAIR METHODS FOR SCREWS USING COIL THREAD INSERT……………………………………….761

METHOD FOR USING TAPER THREAD PLUGS TO SEAL POCKETS AND SMALL HOLES IN CASTINGS……………..762

METHOD FOR REPAIRING TRPER THREAD PLUG HOLES WORN BY LARGE SIZE COPPER PLATED PLUGS………….765

METHOD OF USING FILLER METAL IN EMERGENCY REPAIRS………………………………………..766

PROCEDURE AND TOOLS FOR REPAIRING CYLINDER BLOCK…………………………………………767

INSPECTION AND GRINDING TO REPAIR COMBUSTION DECK………………………………………..767

INSPECTION AND INSTALLATION OF VALVE GUIDE………………………………………………768

PROCEDURE 1 FOR BUILDING UP USING SERVICE VALVE GUIDE…………………………………….769

PROCEDURE 2 FOR BUILDING UP USING SERVICE VALVE GUIDE…………………………………….770

OUTLINE OF VALVE SEAT REPAIR…………………………………………………………..770

CALCULATING GRINDING DEPTH OF VALVE SEAT………………………………………………..771

METHOD OF GRINDING VALVE SEAT………………………………………………………….771

METHOD OF INSTALLING VALVE SEAT………………………………………………………..775

MACHINING EXHAUST VALVE INSERT POCKET…………………………………………………..775

REPLACING VALVE SEAT………………………………………………………………778

METHOD OF GRINDING VALVE………………………………………………………………779

CHECKING TENSION OF VALVE SPRING……………………………………………………780

ASSEMBLY OF CYLINDER HEAD……………………………………………………………..781

PROCEDURE FOR REPAIRING CYLINDER BLOCK………………………………………………….782

COMBUSTION DECK…………………………………………………………………..782

CAM BORE ……………………………………………………………………….783

OUTLINE OF REPAIR OF CYLINDER BORE ………………………………………………..784

CYLINDER BORE …………………………………………………………………..784

INSTALLATION OF REPAIR SLEEVE………………………………………………………786

PROCEDURE FOR REPAIRING CRANKSHAFT……………………………………………………..790

REPAIR TOOLS……………………………………………………………………..790

OUTLINE OF GRINDING GRANKSHAFT……………………………………………………..790

REGRINDING SPECIFICATIONS FOR CRANKSHAFT JOURNAL……………………………………..791

REGRINDING CRANKSHAFT JOURNAL RADIUS………………………………………………..792

SPECIFICATION FOR REGRINDING CRANKSHAFT ROD JOURNAL…………………………………..793

REGRINDING CRANKSHAFT ROD JOURNAL RADIUS…………………………………………….793

OPTIONAL PROCEDURE………………………………………………………………..794

PROCEDURE FOR REPAIRING CONNECTING ROD………………………………………………….795

REMOVAL OF PIN BORE BUSHING………………………………………………………..795

INSTALLATION OF PIN BORE BUSHING……………………………………………………797

MACHINING OF CONNECTING ROD BUSHING…………………………………………………799

INSPECTION OF CURVATURE AND TWISTING OF CONNECTING ROD………………………………..800

TESTING ALIGNMENT OF CONNECTING ROD…………………………………………………801

INSPECTION OF TWISTING OF CONNECTING ROD…………………………………………….801

REPLACING VALVE SEAT INSERT………………………………………………………..802

PACKING STYLE OF CYLINDER HEAD AND HOW TO INSTALL PLUGS…………………………………..805

UNDER COVER…………………………………………………………………………………806