$35

Komatsu 107E -2 SERIES ENGINE Shop Manual(SEN05623-09) – PDF DOWNLOAD

Komatsu 4D98E 4D108 S4D108 SERIES DIESEL ENGINE SHOP MANUAL(WEBM4D9801) – PDF DOWNLOAD

DESCRIPTION:

Komatsu 107E -2 SERIES ENGINE Shop Manual(SEN05623-09) – PDF DOWNLOAD

Foreword, safety and general information (ALL-0370-001-A-00-A)

Important safety notice (ALL-1120-012-A-01-A)

• Appropriate servicing and repair are extremely important to ensure safe operation of the machine. The

shop manual describes the effective and safe servicing and repair methods recommended by Komatsu.

Some of these methods require the use of the special tools designed by Komatsu for the specific purpose.

• The symbol markkis used for such matters that require special cautions during the work. The work

indicated by the caution mark should be performed according to the instructions with special attention to

the cautions. Should hazardous situation occur or be anticipated during such work, be sure to keep safe

first and take every necessary measure.

Safety points

• Good arrangement

• Correct work clothes

• Observance of work standard

• Practice of making and checking signals

• Prohibition of operation and handling by

unlicensed workers

• Safety check before starting work

• Wearing protective goggles (for cleaning or

grinding work)

• Wearing shielding goggles and protectors (for

welding work)

• Good physical condition and preparation

• Precautions against work which you are not

used to or you are used to too much

General precautions

kInappropriate handling causes an extreme

danger. Read and understand what is

described in the operation and maintenance

manual before operating the machine. Read

and understand what is described in this

manual before starting the work.

• Before performing any greasing or repairs, read

all the safety labels stuck to the machine. For

the locations of the safety labels and detailed

explanation of precautions, see the operation

and maintenance manual.

• Locate a place in the repair workshop to keep

the tools and removed parts. Always keep the

tools and parts in their correct places. Always

keep the work area clean and make sure that

there is no dirt, water or oil on the floor. Smoke

only in the areas provided for smoking. Never

smoke while working.

• When performing any work, always wear the

safety shoes and helmet. Do not wear loose

work cloths, or clothes with buttons missing.

1. Always wear the protective eyeglasses when

hitting parts with a hammer.

2. Always wear the protective eyeglasses when

grinding parts with a grinder, etc.

• When performing any work with 2 or more

workers, always agree on the working procedure

before starting. While working, always keep

conversations of the work between your fellow

workers and your self on any step of the work.

During the work, hang the warning tag of

“UNDER WORKING” in the operator’s

compartment.

• Only qualified workers must perform the work

and operation which require license or

qualification.

• Keep the tools in good condition. And learn the

correct way to use the tools, and use the proper

ones among them. Before starting the work,

thoroughly check the tools, lift truck, service

vehicle, etc.

• If welding repairs is required, always have a

trained and experienced welder with good

knowledge of welding perform the work. When

performing welding work, always wear welding

gloves, apron, shielding goggles, cap, etc.

• Before starting work, warm up your body

thoroughly to start work under good condition.

• Avoid continuing work for long hours and take

rests with proper intervals to keep your body in

good condition. Take a rest in a specified safe

place.

Preparation

• Before adding oil or making any repairs, place

the machine on a firm and level ground, and

apply the parking brake and chock the wheels or

tracks to prevent the machine from moving.

• Before starting work, lower the work equipment

(blade, ripper, bucket, etc.) to the ground. If it is

not possible to lower the equipment to the

ground, insert the lock pin or use blocks to

prevent the work equipment from falling. And be

sure to lock all the work equipment control levers

and hang a warning tag on them.

• When performing the disassembling or

assembling work, support the machine securely

with blocks, jacks, or stands before starting the

work.

• Remove all of mud and oil from the steps or

other places used to get on and off the machine

completely. Always use the handrails, ladders of

steps when getting on or off the machine. Never

TABLE OF CONTENTS:

Komatsu 107E -2 SERIES ENGINE Shop Manual(SEN05623-09) – PDF DOWNLOAD

Cover……………………………………………………………… 1

00 Index and foreword ………………………………………………. 3

Index …………………………………………………………. 4

Foreword, safety and general information ………………………….. 7

Important safety notice ……………………………………… 7

How to read the shop manual ………………………………….. 14

Explanation of terms for maintenance standard ………………….. 16

Handling equipment of fuel system devices ……………………… 18

Handling of intake system parts ………………………………. 19

Handling of hydraulic equipment ………………………………. 20

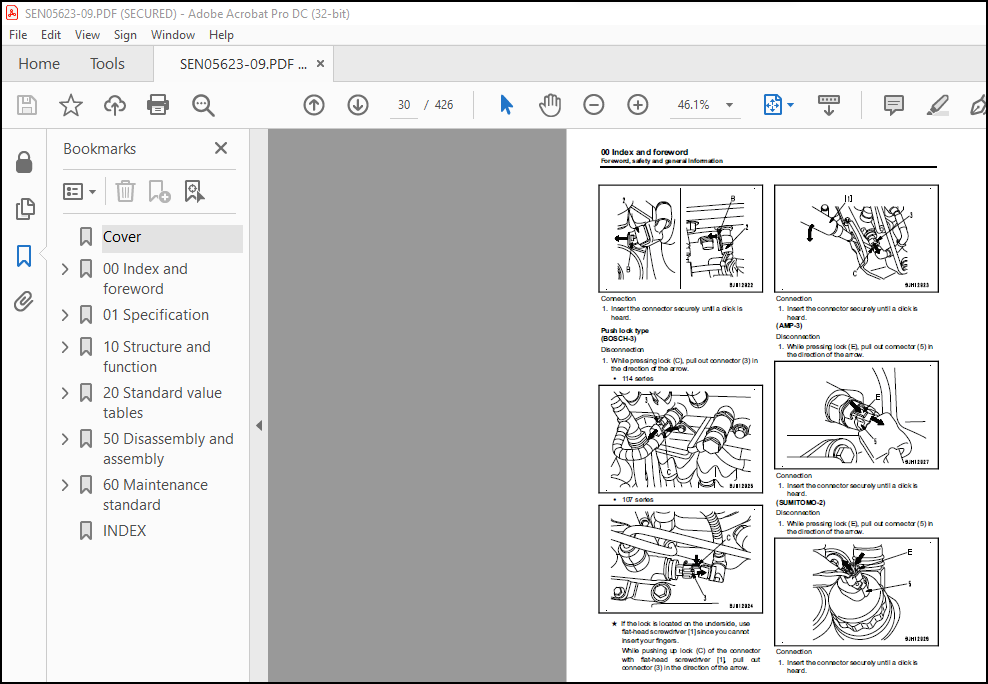

Method of disconnecting and connecting of push-pull type coupler …. 22

Handling of electrical equipment ……………………………… 25

How to read electric wire code ……………………………….. 33

Precautions when performing operation …………………………. 36

Standard tightening torque table ……………………………… 41

List of abbreviation ………………………………………… 47

Conversion table ……………………………………………. 52

01 Specification …………………………………………………… 57

Table of contents ………………………………………………. 58

General information …………………………………………….. 59

Exhaust gas regulation ………………………………………. 59

Specifications …………………………………………………. 65

Applicable machines …………………………………………. 65

Specifications ……………………………………………… 66

General view ……………………………………………….. 76

Engine performance curve ……………………………………..109

10 Structure and function ……………………………………………119

Table of contents ……………………………………………….120

Components layout ……………………………………………….122

Components layout drawing (4D107) ……………………………..122

Components layout drawing (6D107) ……………………………..124

Intake and exhaust system parts …………………………………..126

Intake and exhaust system layout drawing (4D107) ………………..126

Intake and exhaust system layout drawing (6D107) ………………..127

Intake and exhaust system circuit diagram (4D107) ……………….128

Intake and exhaust system circuit diagram (6D107) ……………….130

Air cleaner (4D107) ………………………………………….132

Air cleaner (6D107) ………………………………………….133

VFT (4D107) …………………………………………………135

VGT(6D107) ………………………………………………….139

Aftercooler …………………………………………………147

EGR system piping drawing (4D107) ……………………………..148

EGR system piping drawing (6D107) ……………………………..150

EGR system circuit diagram (4D107) …………………………….152

EGR system circuit diagram (6D107) …………………………….154

EGR valve (4D107) ……………………………………………156

EGR valve (6D107) ……………………………………………158

EGR cooler ………………………………………………….160

Layout of KCCV (4D107) ……………………………………….161

Layout of KCCV (6D107) ……………………………………….164

KCCV ventilator ……………………………………………..166

KDOC muffler (4D107) …………………………………………170

KDPF (6D107) ………………………………………………..172

Engine main body parts …………………………………………..177

Cylinder head ……………………………………………….177

Cylinder block ………………………………………………179

Main moving parts ……………………………………………181

Vibration damper (6D107) ……………………………………..185

Timing gear …………………………………………………186

Front cover …………………………………………………187

Valve system ………………………………………………..188

Flywheel ……………………………………………………191

Lubrication system ………………………………………………193

Lubrication system parts layout drawing (4D107) …………………193

Lubrication system parts layout drawing (6D107) …………………195

Lubrication system circuit diagram (4D107) ……………………..197

Lubrication system circuit diagram (6D107) ……………………..198

Oil pump ……………………………………………………199

Boost oil pump (6D107) ……………………………………….200

Oil filter ………………………………………………….201

Oil cooler ………………………………………………….202

Regulator valve ……………………………………………..203

Safety valve ………………………………………………..204

Oil pan …………………………………………………….205

Fuel system …………………………………………………….206

Fuel system parts layout drawing ………………………………206

Fuel system circuit diagram …………………………………..209

Supply pump …………………………………………………213

Fuel cooler …………………………………………………214

Pre-filter ………………………………………………….215

Main filter …………………………………………………216

Cooling system ………………………………………………….217

Cooling system parts layout drawing ……………………………217

Cooling system circuit diagram (4D107) …………………………218

Cooling system circuit diagram (6D107) …………………………219

Drive pulley ………………………………………………..220

Water pump ………………………………………………….225

Thermostat ………………………………………………….226

Electrical equipment …………………………………………….227

Alternator ………………………………………………….227

Starting motor ………………………………………………235

Intake air heater ……………………………………………239

Engine wiring harness (4D107) …………………………………240

Engine wiring harness (6D107) …………………………………242

Engine controller (4D107) …………………………………….244

Engine controller (6D107) …………………………………….250

Sensor ……………………………………………………..256

20 Standard value tables …………………………………………….273

Table of contents ……………………………………………….274

Standard service value table ……………………………………..275

Standard value table for engine ……………………………….275

Running-in standard and performance test standard ……………….305

50 Disassembly and assembly ………………………………………….315

Table of contents ……………………………………………….316

Related information on disassembly and assembly …………………….317

How to read this manual ………………………………………317

Coating materials list ……………………………………….319

Special tool list ……………………………………………323

Sketch of special tool ……………………………………….325

Disassembly and assembly …………………………………………326

General disassembly of engine …………………………………326

General assembly of engine ……………………………………348

Removal and installation procedure of supply pump unit alone ……..389

Engine front oil seal replacement procedure …………………….393

Engine rear oil seal replacement procedure ……………………..396

60 Maintenance standard ……………………………………………..399

Table of contents ……………………………………………….400

Intake and exhaust system parts …………………………………..401

VFT (4D107) …………………………………………………401

VGT(6D107) ………………………………………………….402

Engine main body parts …………………………………………..403

Cylinder head ……………………………………………….403

Cylinder block ………………………………………………405

Crankshaft ………………………………………………….407

Piston ……………………………………………………..409

Connecting rod ………………………………………………410

Vibration damper (6D107) ……………………………………..412

Timing gear …………………………………………………413

Camshaft ……………………………………………………414

Valve and valve guide ………………………………………..416

Rocker arm ………………………………………………….418

Tappet ……………………………………………………..419

Flywheel ……………………………………………………420

Lubrication system ………………………………………………422

Oil pump ……………………………………………………422

INDEX………………………………………………………………423

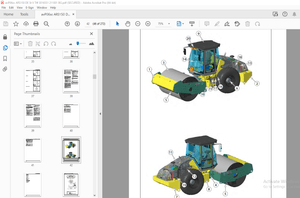

IMAGES PREVIEW OF THE MANUAL: