$38

Komatsu 107E-3 SERIES Series Engine Shop Manual SEN06502-20 – PDF DOWNLOAD

Komatsu 107E-3 SERIES Series Engine Shop Manual SEN06502-20 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 107E-3 SERIES Series Engine Shop Manual SEN06502-20 – PDF DOWNLOAD

Language : English

Pages : 684

Downloadable : Yes

File Type : PDF

Size: 29.7 MB

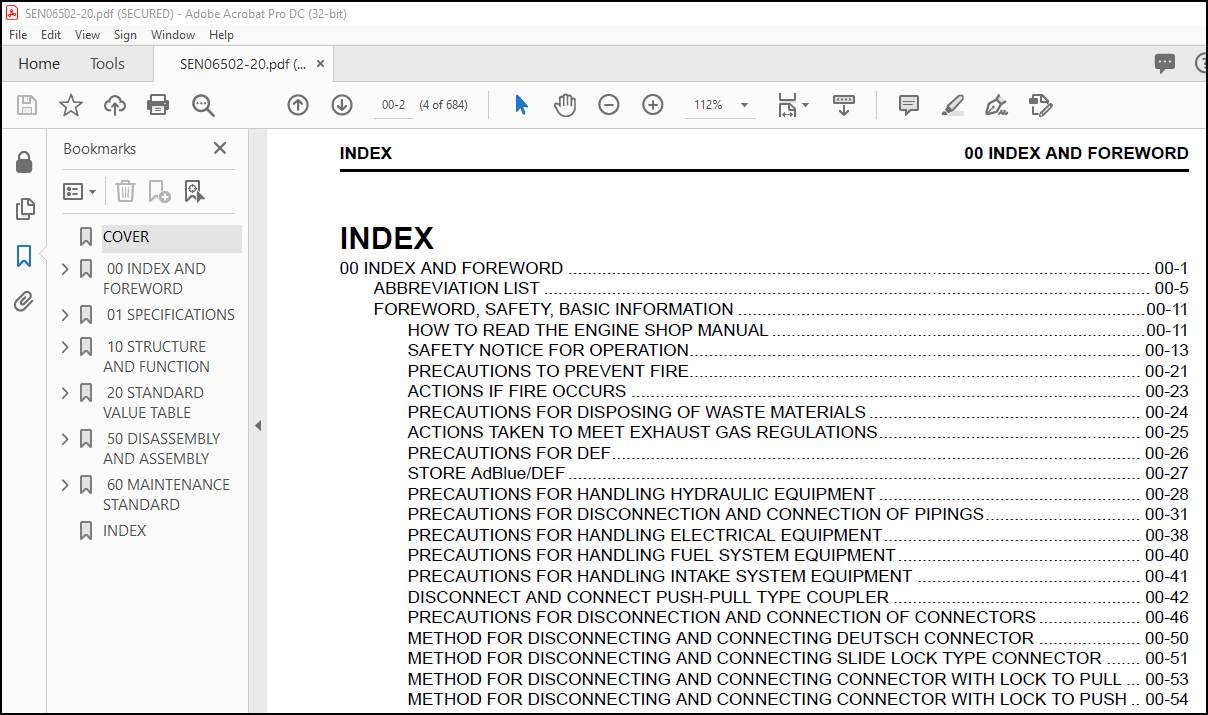

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 107E-3 SERIES Series Engine Shop Manual SEN06502-20 – PDF DOWNLOAD

The Komatsu 107E-3 SERIES engine is a diesel engine used in various heavy-duty equipment such as bulldozers, excavators, and other construction and mining equipment. The Komatsu 107E-3 SERIES engine Shop Manual, SEN06502-20, provides detailed information on the maintenance, repair, and overhaul of the engine.

- The manual includes comprehensive information on the engine’s mechanical and electrical systems, as well as instructions for maintenance tasks such as oil changes, air and fuel filter replacements, and more. It also includes troubleshooting information to help diagnose and repair any engine issues, as well as detailed schematics and diagrams to aid in the repair process.

- The manual also covers the removal and installation of engine components, including the cylinder head, pistons, crankshaft, and other internal engine parts. Additionally, it provides specifications and tolerances for each component, as well as procedures for engine overhaul and rebuilding.

- Overall, the Komatsu 107E-3 SERIES engine Shop Manual is an essential resource for anyone responsible for maintaining or repairing the engine. It provides detailed information to help ensure that the engine is running smoothly and efficiently, and can help to minimize downtime and reduce the costs associated with repairs.

TABLE OF CONTENTS:

Komatsu 107E-3 SERIES Series Engine Shop Manual SEN06502-20 – PDF DOWNLOAD

COVER…………………………………………………………………………………………………………. 1

00 INDEX AND FOREWORD………………………………………………………………………………………….. 3

INDEX…………………………………………………………………………………………………….. 4

ABBREVIATION LIST………………………………………………………………………………………….. 7

FOREWORD, SAFETY, BASIC INFORMATION………………………………………………………………………….. 13

HOW TO READ THE ENGINE SHOP MANUAL……………………………………………………………………….. 13

SAFETY NOTICE FOR OPERATION……………………………………………………………………………… 15

PRECAUTIONS TO PREVENT FIRE……………………………………………………………………………… 23

ACTIONS IF FIRE OCCURS………………………………………………………………………………….. 25

PRECAUTIONS FOR DISPOSING OF WASTE MATERIALS………………………………………………………………. 26

ACTIONS TAKEN TO MEET EXHAUST GAS REGULATIONS……………………………………………………………… 27

PRECAUTIONS FOR DEF…………………………………………………………………………………….. 28

GENERAL CHARACTER AND PRECAUTIONS FOR HANDLING…………………………………………………………. 28

PRECAUTIONS FOR ADDING………………………………………………………………………………. 28

PRECAUTIONS FOR STORING……………………………………………………………………………… 28

PRECAUTIONS FOR FIRE HAZARD AND LEAKAGE……………………………………………………………….. 28

THE OTHER PRECAUTIONS……………………………………………………………………………….. 28

STORE AdBlue/DEF……………………………………………………………………………………….. 29

PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT………………………………………………………………. 30

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF PIPINGS…………………………………………………….. 33

PRECAUTIONS FOR HANDLING ELECTRICAL EQUIPMENT……………………………………………………………… 40

PRECAUTIONS FOR HANDLING FUEL SYSTEM EQUIPMENT…………………………………………………………….. 42

PRECAUTIONS FOR HANDLING INTAKE SYSTEM EQUIPMENT…………………………………………………………… 43

DISCONNECT AND CONNECT PUSH-PULL TYPE COUPLER……………………………………………………………… 44

METHOD FOR DISCONNECTING AND CONNECTING TYPE 1 PUSH-PULL TYPE COUPLER…………………………………….. 44

METHOD FOR DISCONNECTING AND CONNECTING TYPE 2 PUSH-PULL TYPE COUPLER…………………………………….. 45

METHOD FOR DISCONNECTING AND CONNECTING TYPE 3 PUSH-PULL TYPE COUPLER…………………………………….. 46

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF CONNECTORS………………………………………………….. 48

METHOD FOR DISCONNECTING AND CONNECTING DEUTSCH CONNECTOR…………………………………………………… 52

METHOD FOR DISCONNECTING AND CONNECTING SLIDE LOCK TYPE CONNECTOR……………………………………………. 53

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PULL………………………………………….. 55

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PUSH………………………………………….. 56

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH HOUSING TO ROTATE……………………………………… 58

HOW TO READ ELECTRICAL WIRE CODE…………………………………………………………………………. 59

EXPLANATION OF TERMS FOR MAINTENANCE STANDARD……………………………………………………………… 63

STANDARD TIGHTENING TORQUE TABLE…………………………………………………………………………. 66

CONVERSION TABLE……………………………………………………………………………………….. 73

01 SPECIFICATIONS……………………………………………………………………………………………… 79

CONTENTS………………………………………………………………………………………………….. 80

ABBREVIATION LIST………………………………………………………………………………………….. 82

SPECIFICATIONS…………………………………………………………………………………………….. 88

OUTLINE OF EXHAUST GAS REGULATION………………………………………………………………………… 88

SYSTEM DRAWINGS OF ENGINE CONFORMED TO TIER4 REGULATION…………………………………………………. 89

IMPROVED POINTS OF ENGINE CONFORMED TO TIER4 REGULATION…………………………………………………. 90

LIST OF APPLICABLE MACHINES: 107E-3………………………………………………………………………. 91

SPECIFICATIONS…………………………………………………………………………………………. 92

SPECIFICATIONS: SAA4D107E-3 (D51EX-24, D51EXI-24, D51PX-24, D51PXI-24)……………………………………. 92

SPECIFICATIONS: SAA4D107E-3 (HB215LC-3)……………………………………………………………….. 93

SPECIFICATIONS: SAA4D107E-3 (PC170LC-11)………………………………………………………………. 94

SPECIFICATIONS: SAA4D107E-3 (WA200-8)…………………………………………………………………. 95

SPECIFICATIONS: SAA6D107E-3 (BR380JG-3, BR380JG-3E0)……………………………………………………. 96

SPECIFICATIONS: SAA6D107E-3 (D61EX-24, D61EXI-24, D61PX-24, D61PXI-24)……………………………………. 97

SPECIFICATIONS: SAA6D107E-3 (D61EX-24E0, D61EXI-24E0, D61PX-24E0, D61PXI-24E0)…………………………….. 98

SPECIFICATIONS: SAA6D107E-3 (GD655-6, GD655-7, GD675-6, GD675-7E0)……………………………………….. 99

SPECIFICATIONS: SAA6D107E-3 (PC210LC-11, PC210LCI-11, PC210LCI-11E0)………………………………………100

SPECIFICATIONS: SAA6D107E-3 (PC228USLC-11, PC238USLC-11)…………………………………………………101

SPECIFICATIONS: SAA6D107E-3 (PC240LC-11)……………………………………………………………….102

SPECIFICATIONS: SAA6D107E-3 (PC290LC-11, PC290LCI-11)……………………………………………………103

SPECIFICATIONS: SAA6D107E-3 (WA270-8, WA270-8E0)………………………………………………………..104

SPECIFICATIONS: SAA6D107E-3 (WA320-8, WA320-8E0)………………………………………………………..105

SPECIFICATIONS: SAA6D107E-3 (WA380-8)………………………………………………………………….106

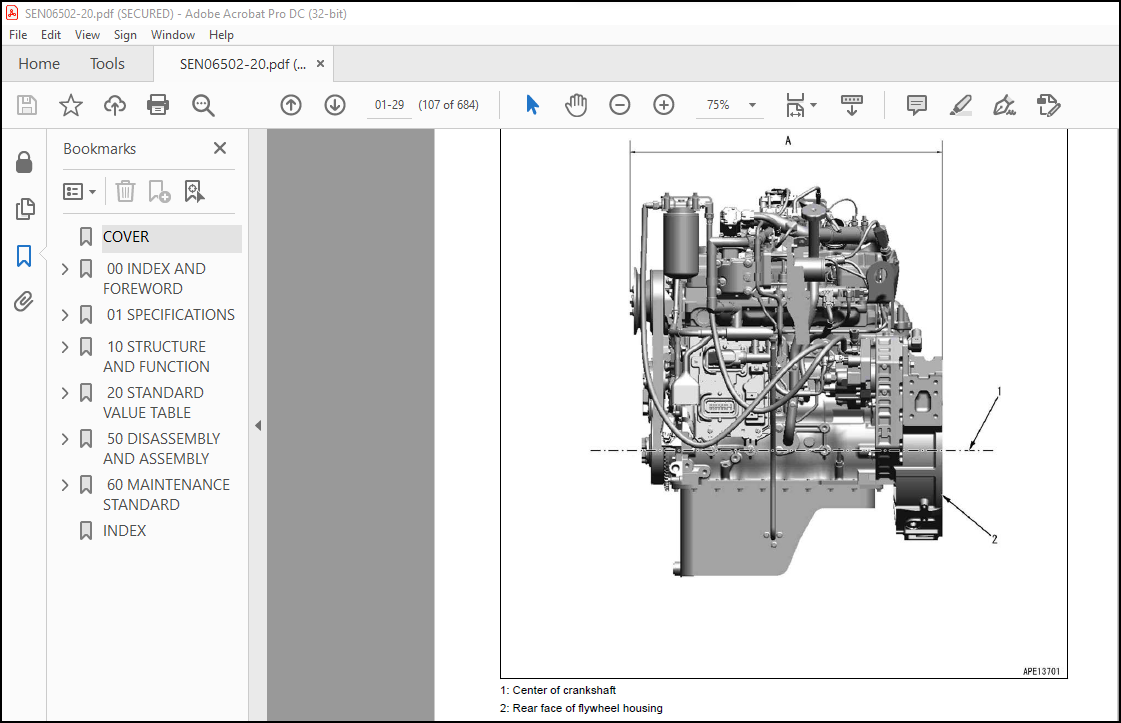

ENGINE GENERAL VIEW……………………………………………………………………………………..107

ENGINE GENERAL VIEW: SAA4D107E-3 (D51EX-24, D51EXI-24, D51PX-24, D51PXI-24)………………………………..107

ENGINE GENERAL VIEW: SAA4D107E-3 (HB215LC-3)……………………………………………………………111

ENGINE GENERAL VIEW: SAA4D107E-3 (PC170LC-11)…………………………………………………………..115

ENGINE GENERAL VIEW: SAA4D107E-3 (WA200-8)……………………………………………………………..119

ENGINE GENERAL VIEW: SAA6D107E-3 (BR380JG-3, BR380JG-3E0)………………………………………………..123

ENGINE GENERAL VIEW: SAA6D107E-3 (D61EX-24, D61EXI-24, D61PX-24, D61PXI-24)………………………………..127

ENGINE GENERAL VIEW: SAA6D107E-3 (D61EX-24E0, D61EXI-24E0, D61PX-24E0, D61PXI-24E0)…………………………131

ENGINE GENERAL VIEW: SAA6D107E-3 (GD655-6, GD655-7, GD675-6, GD675-7E0)……………………………………135

ENGINE GENERAL VIEW: SAA6D107E-3 (PC210LC-11, PC210LCI-11, PC210LCI-11E0)………………………………….139

ENGINE GENERAL VIEW: SAA6D107E-3 (PC228USLC-11, PC238USLC-11)…………………………………………….143

ENGINE GENERAL VIEW: SAA6D107E-3 (PC240LC-11, PC290LC-11, PC290LCI-11)…………………………………….147

ENGINE GENERAL VIEW: SAA6D107E-3 (WA270-8, WA270-8E0)……………………………………………………151

ENGINE GENERAL VIEW: SAA6D107E-3 (WA320-8, WA320-8E0)……………………………………………………155

ENGINE GENERAL VIEW: SAA6D107E-3 (WA380-8)……………………………………………………………..159

ENGINE PERFORMANCE CURVE…………………………………………………………………………………163

ENGINE PERFORMANCE CURVE: SAA4D107E-3 (D51EX-24, D51EXI-24, D51PX-24, D51PXI-24)……………………………163

ENGINE PERFORMANCE CURVE: SAA4D107E-3 (HB215LC-3)……………………………………………………….164

ENGINE PERFORMANCE CURVE: SAA4D107E-3 (PC170LC-11)………………………………………………………165

ENGINE PERFORMANCE CURVE: SAA4D107E-3 (WA200-8)…………………………………………………………166

ENGINE PERFORMANCE CURVE: SAA6D107E-3 (BR380JG-3, BR380JG-3E0)……………………………………………167

ENGINE PERFORMANCE CURVE: SAA6D107E-3 (D61EX-24, D61EXI-24, D61PX-24, D61PXI-24)……………………………168

ENGINE PERFORMANCE CURVE: SAA6D107E-3 (D61EX-24E0, D61EXI-24E0, D61PX-24E0, D61PXI-24E0)…………………….169

ENGINE PERFORMANCE CURVE: SAA6D107E-3 (GD655-6, GD655-7, GD675-6, GD675-7E0)……………………………….170

ENGINE PERFORMANCE CURVE: SAA6D107E-3 (PC210LC-11, PC210LCI-11, PC210LCI-11E0)……………………………..171

ENGINE PERFORMANCE CURVE: SAA6D107E-3 (PC228USLC-11, PC238USLC-11)………………………………………..172

ENGINE PERFORMANCE CURVE: SAA6D107E-3 (PC240LC-11)………………………………………………………173

ENGINE PERFORMANCE CURVE: SAA6D107E-3 (PC290LC-11, PC290LCI-11)…………………………………………..174

ENGINE PERFORMANCE CURVE: SAA6D107E-3 (WA270-8, WA270-8E0)……………………………………………….175

ENGINE PERFORMANCE CURVE: SAA6D107E-3 (WA320-8, WA320-8E0)……………………………………………….176

ENGINE PERFORMANCE CURVE: SAA6D107E-3 (WA380-8)…………………………………………………………177

10 STRUCTURE AND FUNCTION……………………………………………………………………………………….179

CONTENTS…………………………………………………………………………………………………..180

ABBREVIATION LIST…………………………………………………………………………………………..183

UREA SCR SYSTEM…………………………………………………………………………………………….189

LAYOUT DRAWING OF UREA SCR SYSTEM…………………………………………………………………………189

UREA SCR SYSTEM DIAGRAM………………………………………………………………………………….197

UREA SCR SYSTEM DIAGRAM………………………………………………………………………………….199

FUNCTION OF UREA SCR SYSTEM………………………………………………………………………………200

FUNCTION OF UREA SCR SYSTEM………………………………………………………………………………201

FUNCTION OF AdBlue/DEF SUPPLY SYSTEM…………………………………………………………………..201

INDUCEMENT STRATEGY………………………………………………………………………………….204

COMPONENT PARTS OF UREA SCR SYSTEM………………………………………………………………………..223

AdBlue/DEF MIXING TUBE……………………………………………………………………………….223

SCR ASSEMBLY………………………………………………………………………………………..225

AdBlue/DEF TANK……………………………………………………………………………………..229

AdBlue/DEF PUMP……………………………………………………………………………………..231

AdBlue/DEF INJECTOR………………………………………………………………………………….232

AdBlue/DEF HOSE……………………………………………………………………………………..233

AdBlue/DEF TANK HEATING VALVE…………………………………………………………………………234

ENGINE SYSTEM………………………………………………………………………………………………235

LAYOUT OF ENGINE COMPONENTS………………………………………………………………………………235

LAYOUT DRAWING OF ENGINE COMPONENTS……………………………………………………………………235

LAYOUT DRAWING OF ENGINE COMPONENTS……………………………………………………………………238

INTAKE AND EXHAUST SYSTEM PARTS…………………………………………………………………………..239

LAYOUT DRAWING OF INTAKE AND EXHAUST SYSTEM…………………………………………………………….239

LAYOUT DRAWING OF INTAKE AND EXHAUST SYSTEM…………………………………………………………….240

INTAKE AND EXHAUST SYSTEM CIRCUIT DIAGRAM………………………………………………………………241

FUNCTION OF INTAKE AND EXHAUST SYSTEM………………………………………………………………….241

AIR CLEANER…………………………………………………………………………………………243

INTAKE AIR HEATER……………………………………………………………………………………245

ENGINE MAIN BODY PARTS…………………………………………………………………………………..246

CYLINDER HEAD……………………………………………………………………………………….246

CYLINDER BLOCK………………………………………………………………………………………248

MAIN MOVING PARTS……………………………………………………………………………………250

VIBRATION DAMPER…………………………………………………………………………………….254

TIMING GEAR…………………………………………………………………………………………255

FRONT COVER…………………………………………………………………………………………256

VALVE SYSTEM………………………………………………………………………………………..257

FLYWHEEL AND FLYWHEEL HOUSING…………………………………………………………………………260

TURBOCHARGER SYSTEM……………………………………………………………………………………..262

CIRCUIT DIAGRAM OF VGT SYSTEM…………………………………………………………………………262

FUNCTION OF VGT SYSTEM……………………………………………………………………………….263

VGT………………………………………………………………………………………………..265

EGR SYSTEM………………………………………………………………………………………….271

EGR VALVE…………………………………………………………………………………………..276

EGR COOLER………………………………………………………………………………………….280

KCCV SYSTEM…………………………………………………………………………………………283

KCCV VENTILATOR……………………………………………………………………………………..287

KDPF……………………………………………………………………………………………….289

KDOC……………………………………………………………………………………………….293

LUBRICATION SYSTEM………………………………………………………………………………………296

LAYOUT DRAWING OF LUBRICATION SYSTEM PARTS……………………………………………………………..296

LAYOUT DRAWING OF LUBRICATION SYSTEM PARTS……………………………………………………………..298

LUBRICATION SYSTEM CIRCUIT DIAGRAM…………………………………………………………………….299

LUBRICATION SYSTEM CIRCUIT DIAGRAM…………………………………………………………………….300

ENGINE OIL PUMP……………………………………………………………………………………..301

ENGINE BOOST OIL PUMP………………………………………………………………………………..302

ENGINE OIL FILTER……………………………………………………………………………………303

ENGINE OIL COOLER……………………………………………………………………………………304

ENGINE OIL REGULATOR VALVE……………………………………………………………………………305

SAFETY VALVE OF ENGINE OIL……………………………………………………………………………306

ENGINE OIL PAN………………………………………………………………………………………307

FUEL SYSTEM…………………………………………………………………………………………….308

LAYOUT DRAWING OF FUEL SYSTEM PARTS……………………………………………………………………308

FUEL SYSTEM CIRCUIT DIAGRAM…………………………………………………………………………..311

FUNCTION OF FUEL SYSTEM………………………………………………………………………………312

SUPPLY PUMP…………………………………………………………………………………………314

FUEL PREFILTER………………………………………………………………………………………315

FUEL MAIN FILTER…………………………………………………………………………………….316

COOLING SYSTEM………………………………………………………………………………………….317

LAYOUT DRAWING OF COOLING SYSTEM PARTS…………………………………………………………………317

COOLING SYSTEM CIRCUIT DIAGRAM………………………………………………………………………..318

COOLING SYSTEM CIRCUIT DIAGRAM………………………………………………………………………..319

DRIVE PULLEY………………………………………………………………………………………..320

WATER PUMP………………………………………………………………………………………….322

THERMOSTAT………………………………………………………………………………………….323

ELECTRICAL SYSTEM…………………………………………………………………………………………..324

COMPONENT PARTS OF ELECTRICAL SYSTEM………………………………………………………………………324

ALTERNATOR………………………………………………………………………………………….324

STARTING MOTOR………………………………………………………………………………………330

ENGINE WIRING HARNESS………………………………………………………………………………..332

ENGINE CONTROLLER……………………………………………………………………………………336

SENSOR…………………………………………………………………………………………………350

LAYOUT DRAWING OF ENGINE SENSOR……………………………………………………………………….350

LAYOUT DRAWING OF ENGINE SENSOR……………………………………………………………………….352

STRUCTURE OF AMBIENT PRESSURE SENSOR…………………………………………………………………..354

FUNCTION OF AMBIENT PRESSURE SENSOR……………………………………………………………………354

STRUCTURE OF ENGINE OIL PRESSURE SWITCH………………………………………………………………..355

FUNCTION OF ENGINE OIL PRESSURE SWITCH…………………………………………………………………355

STRUCTURE OF CHARGE (BOOST) PRESSURE AND TEMPERATURE SENSOR………………………………………………356

FUNCTION OF CHARGE (BOOST) PRESSURE AND TEMPERATURE SENSOR……………………………………………….356

STRUCTURE OF COOLANT TEMPERATURE SENSOR………………………………………………………………..357

FUNCTION OF COOLANT TEMPERATURE SENSOR…………………………………………………………………357

STRUCTURE OF NE (CRANKSHAFT) SPEED SENSOR………………………………………………………………358

FUNCTION OF NE (CRANKSHAFT) SPEED SENSOR……………………………………………………………….358

STRUCTURE OF Bkup (CAMSHAFT) SPEED SENSOR………………………………………………………………359

FUNCTION OF Bkup (CAMSHAFT) SPEED SENSOR……………………………………………………………….359

STRUCTURE OF COMMON RAIL PRESSURE SENSOR……………………………………………………………….360

FUNCTION OF COMMON RAIL PRESSURE SENSOR………………………………………………………………..360

STRUCTURE OF EGR VALVE LIFT SENSOR…………………………………………………………………….361

FUNCTION OF EGR VALVE LIFT SENSOR……………………………………………………………………..361

STRUCTURE OF VGT SPEED SENSOR…………………………………………………………………………362

FUNCTION OF VGT SPEED SENSOR………………………………………………………………………….362

STRUCTURE OF VGT POSITION SENSOR………………………………………………………………………363

FUNCTION OF VGT POSITION SENSOR……………………………………………………………………….363

STRUCTURE OF MASS AIR FLOW AND TEMPERATURE SENSOR……………………………………………………….364

FUNCTION OF MASS AIR FLOW AND TEMPERATURE SENSOR………………………………………………………..364

STRUCTURE OF KDPF DIFFERENTIAL PRESSURE AND OUTLET PRESSURE SENSOR………………………………………..365

FUNCTION OF KDPF DIFFERENTIAL PRESSURE AND OUTLET PRESSURE SENSOR…………………………………………365

STRUCTURE OF CRANKCASE PRESSURE SENSOR…………………………………………………………………366

FUNCTION OF CRANKCASE PRESSURE SENSOR………………………………………………………………….366

STRUCTURE OF ENGINE OIL LEVEL SENSOR…………………………………………………………………..367

FUNCTION OF ENGINE OIL LEVEL SENSOR……………………………………………………………………367

STRUCTURE OF AIR CLEANER CLOGGING SENSOR……………………………………………………………….368

FUNCTION OF AIR CLEANER CLOGGING SENSOR………………………………………………………………..368

STRUCTURE OF WATER-IN-FUEL SENSOR……………………………………………………………………..369

FUNCTION OF WATER-IN-FUEL SENSOR………………………………………………………………………369

STRUCTURE OF EGR VALVE (WITH BUILT-IN POSITION SENSOR)…………………………………………………..370

FUNCTION OF EGR VALVE (WITH BUILT-IN POSITION SENSOR)……………………………………………………370

STRUCTURE OF EXHAUST MANIFOLD PRESSURE SENSOR…………………………………………………………..371

FUNCTION OF EXHAUST MANIFOLD PRESSURE SENSOR……………………………………………………………371

STRUCTURE OF EGR ORIFICE TEMPERATURE SENSOR…………………………………………………………….372

FUNCTION OF EGR ORIFICE TEMPERATURE SENSOR……………………………………………………………..372

STRUCTURE OF VGT ACTUATOR (WITH BUILT-IN POSITION SENSOR)………………………………………………..373

FUNCTION OF VGT ACTUATOR (WITH BUILT-IN POSITION SENSOR)…………………………………………………373

20 STANDARD VALUE TABLE…………………………………………………………………………………………375

CONTENTS…………………………………………………………………………………………………..376

ABBREVIATION LIST…………………………………………………………………………………………..377

STANDARD VALUE TABLE FOR ENGINE………………………………………………………………………………383

STANDARD VALUE TABLE FOR ENGINE: SAA4D107E-3 (D51EX-24, D51EXI-24, D51PX-24, D51PXI-24)…………………………383

STANDARD VALUE TABLE FOR ENGINE: SAA4D107E-3 (HB215LC-3)…………………………………………………….386

STANDARD VALUE TABLE FOR ENGINE: SAA4D107E-3 (PC170LC-11)……………………………………………………389

STANDARD VALUE TABLE FOR ENGINE: SAA4D107E-3 (WA200-8)………………………………………………………392

STANDARD VALUE TABLE FOR ENGINE: SAA6D107E-3 (BR380JG-3, BR380JG-3E0)…………………………………………395

STANDARD VALUE TABLE FOR ENGINE: SAA6D107E-3 (D61EX-24, D61EXI-24, D61PX-24, D61PXI-24)…………………………398

STANDARD VALUE TABLE FOR ENGINE: SAA6D107E-3 (D61EX-24E0, D61EXI-24E0, D61PX-24E0, D61PXI-24E0)………………….401

STANDARD VALUE TABLE FOR ENGINE: SAA6D107E-3 (GD655-6, GD655-7, GD675-6, GD675-7E0)…………………………….404

STANDARD VALUE TABLE FOR ENGINE: SAA6D107E-3 (PC210LC-11, PC210LCI-11, PC210LCI-11E0)…………………………..407

STANDARD VALUE TABLE FOR ENGINE: SAA6D107E-3 (PC228USLC-11, PC238USLC-11)……………………………………..410

STANDARD VALUE TABLE FOR ENGINE: SAA6D107E-3 (PC240LC-11)……………………………………………………413

STANDARD VALUE TABLE FOR ENGINE: SAA6D107E-3 (PC290LC-11, PC290LCI-11)………………………………………..416

STANDARD VALUE TABLE FOR ENGINE: SAA6D107E-3 (WA270-8, WA270-8E0)…………………………………………….419

STANDARD VALUE TABLE FOR ENGINE: SAA6D107E-3 (WA320-8, WA320-8E0)…………………………………………….422

STANDARD VALUE TABLE FOR ENGINE: SAA6D107E-3 (WA380-8)………………………………………………………425

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD………………………………………………………………428

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA4D107E-3 (D51EX-24, D51EXI-24, D51PX-24, D51PXI-24)…………428

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA4D107E-3 (HB215LC-3)…………………………………….430

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA4D107E-3 (PC170LC-11)……………………………………431

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA4D107E-3 (WA200-8)………………………………………433

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D107E-3 (BR380JG-3, BR380JG-3E0)…………………………435

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D107E-3 (D61EX-24, D61EXI-24, D61PX-24, D61PXI-24)…………437

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D107E-3 (D61EX-24E0, D61EXI-24E0, D61PX-24E0, D61PXI-24E0)….439

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D107E-3 (GD655-6, GD655-7, GD675-6, GD675-7E0)…………….441

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D107E-3 (PC210LC-11, PC210LCI-11, PC210LCI-11E0)…………..443

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D107E-3 (PC228USLC-11, PC238USLC-11)……………………..445

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D107E-3 (PC240LC-11)……………………………………447

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D107E-3 (PC290LC-11, PC290LCI-11)………………………..449

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D107E-3 (WA270-8, WA270-8E0)…………………………….451

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D107E-3 (WA320-8, WA320-8E0)…………………………….453

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D107E-3 (WA380-8)………………………………………455

50 DISASSEMBLY AND ASSEMBLY……………………………………………………………………………………..457

CONTENTS…………………………………………………………………………………………………..458

ABBREVIATION LIST…………………………………………………………………………………………..459

RELATED INFORMATION ON DISASSEMBLY AND ASSEMBLY………………………………………………………………..465

HOW TO READ THIS MANUAL………………………………………………………………………………….465

COATING MATERIALS LIST…………………………………………………………………………………..467

SPECIAL TOOLS LIST………………………………………………………………………………………471

SKETCHES OF SPECIAL TOOLS………………………………………………………………………………..473

ENGINE SYSTEM………………………………………………………………………………………………474

DISASSEMBLE AND ASSEMBLE ENGINE GENERALLY (4D107E-3)………………………………………………………..474

METHOD FOR DISASEMBLING ENGINE GENERALLY (4D107E-3)……………………………………………………..474

METHOD FOR ASEMBLING ENGINE GENERALLY (4D107E-3)………………………………………………………..501

DISASSEMBLE AND ASSEMBLE ENGINE GENERALLY (6D107E-3)………………………………………………………..548

METHOD FOR DISASEMBLING ENGINE GENERALLY (6D107E-3)……………………………………………………..549

METHOD FOR ASEMBLING ENGINE GENERALLY (6D107E-3)………………………………………………………..574

REMOVE AND INSTALL SUPPLY PUMP ASSEMBLY (4D107E-3)………………………………………………………….617

METHOD FOR REMOVING SUPPLY PUMP ASSEMBLY (4D107E-3)……………………………………………………..617

METHOD FOR INSTALLING SUPPLY PUMP ASSEMBLY (4D107E-3)……………………………………………………620

REMOVE AND INSTALL SUPPLY PUMP ASSEMBLY (6D107E-3)………………………………………………………….623

METHOD FOR REMOVING SUPPLY PUMP ASSEMBLY (6D107E-3)……………………………………………………..623

METHOD FOR INSTALLING SUPPLY PUMP ASSEMBLY (6D107E-3)……………………………………………………625

REMOVE AND INSTALL ENGINE FRONT OIL SEAL (4D107E-3)…………………………………………………………628

METHOD FOR REMOVING ENGINE FRONT OIL SEAL (4D107E-3)…………………………………………………….628

METHOD FOR INSTALLING ENGINE FRONT OIL SEAL (4D107E-3)…………………………………………………..630

REMOVE AND INSTALL ENGINE FRONT OIL SEAL (6D107E-3)…………………………………………………………633

METHOD FOR REMOVING ENGINE FRONT OIL SEAL (6D107E-3)…………………………………………………….633

METHOD FOR INSTALLING ENGINE FRONT OIL SEAL (6D107E-3)…………………………………………………..635

REMOVE AND INSTALL ENGINE REAR OIL SEAL (4D107E-3)………………………………………………………….637

METHOD FOR REMOVING ENGINE REAR OIL SEAL (4D107E-3)……………………………………………………..637

METHOD FOR INSTALLING ENGINE REAR OIL SEAL (4D107E-3)……………………………………………………638

REMOVE AND INSTALL ENGINE REAR OIL SEAL (6D107E-3)………………………………………………………….641

METHOD FOR REMOVING ENGINE REAR OIL SEAL (6D107E-3)……………………………………………………..641

METHOD FOR INSTALLING ENGINE REAR OIL SEAL (6D107E-3)……………………………………………………641

60 MAINTENANCE STANDARD…………………………………………………………………………………………645

CONTENTS…………………………………………………………………………………………………..646

ABBREVIATION LIST…………………………………………………………………………………………..647

ENGINE SYSTEM………………………………………………………………………………………………653

INTAKE AND EXHAUST SYSTEM PARTS…………………………………………………………………………..653

MAINTENANCE STANDARD OF VGT…………………………………………………………………………..653

MAINTENANCE STANDARD OF VGT…………………………………………………………………………..654

ENGINE MAIN BODY PARTS…………………………………………………………………………………..655

MAINTENANCE STANDARD OF CYLINDER HEAD………………………………………………………………….655

MAINTENANCE STANDARD OF CYLINDER BLOCK…………………………………………………………………657

MAINTENANCE STANDARD OF CRANKSHAFT…………………………………………………………………….660

MAINTENANCE STANDARD OF PISTON………………………………………………………………………..662

MAINTENANCE STANDARD OF CONROD………………………………………………………………………..663

MAINTENANCE STANDARD OF VIBRATION DAMPER……………………………………………………………….665

MAINTENANCE STANDARD OF TIMING GEAR……………………………………………………………………666

MAINTENANCE STANDARD OF CAMSHAFT………………………………………………………………………667

MAINTENANCE STANDARD OF VALVE AND VALVE GUIDE…………………………………………………………..669

MAINTENANCE STANDARD OF ROCKER ARM…………………………………………………………………….671

MAINTENANCE STANDARD OF TAPPET………………………………………………………………………..672

MAINTENANCE STANDARD OF FLYWHEEL………………………………………………………………………673

LUBRICATION SYSTEM………………………………………………………………………………………675

MAINTENANCE STANDARD OF ENGINE OIL PUMP………………………………………………………………..675

INDEX………………………………………………………………………………………………………….677