$34

Komatsu 107E-5 Series Engine Shop Manual SEN06896-02 – PDF DOWNLOAD

Komatsu 107E-5 Series Engine Shop Manual SEN06896-02 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 107E-5 Series Engine Shop Manual SEN06896-02 – PDF DOWNLOAD

Language : English

Pages : 340

Downloadable : Yes

File Type : PDF

Size: 15.6 MB

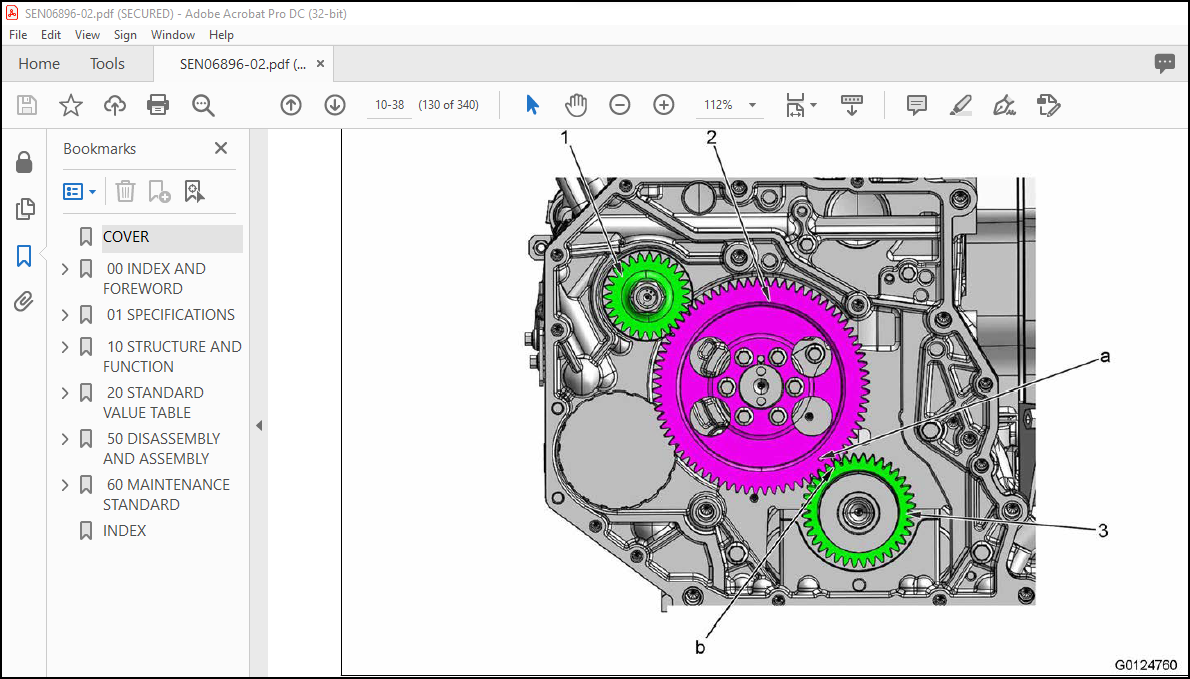

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 107E-5 Series Engine Shop Manual SEN06896-02 – PDF DOWNLOAD

The Komatsu 107E-5 Series Engine Shop Manual SEN06896-02 is a technical reference guide that provides comprehensive information on the maintenance, repair, and overhaul of the Komatsu 107E-5 series diesel engine. The engine is commonly used in heavy-duty equipment, such as construction machinery, mining equipment, and marine vessels.

The shop manual is organized into several sections, each covering specific aspects of the engine:

- General Information: This section provides an overview of the engine, including specifications, maintenance intervals, and general operating guidelines.

- Inspection and Adjustment: This section provides detailed instructions for inspecting and adjusting engine components, such as fuel injection systems, valves, and timing belts.

- Engine Assembly: This section covers the removal and installation of major engine components, including the cylinder head, crankshaft, and pistons. The manual includes detailed illustrations and specifications to help technicians perform these tasks safely and efficiently.

- Lubrication System: This section provides information on the engine’s lubrication system, including oil pump removal and installation, oil filter replacement, and oil pressure testing.

- Cooling System: This section provides information on the engine’s cooling system, including water pump removal and installation, radiator removal and installation, and thermostat replacement.

- Fuel System: This section covers the engine’s fuel system, including fuel pump removal and installation, fuel injector replacement, and fuel system troubleshooting.

- Air Intake and Exhaust System: This section provides information on the engine’s air intake and exhaust system, including air filter replacement, turbocharger removal and installation, and exhaust manifold removal and installation.

- Electrical System: This section provides information on the engine’s electrical system, including alternator and starter motor removal and installation, as well as troubleshooting procedures for electrical faults.

- Special Tools: This section lists the special tools required for servicing the engine, including part numbers and illustrations.

The Komatsu 107E-5 Series Engine Shop Manual SEN06896-02 is an essential reference guide for maintaining and repairing the engine. It provides detailed instructions, specifications, and illustrations to help technicians perform tasks accurately and safely. The manual is a valuable tool for ensuring that the Komatsu 107E-5 series diesel engine continues to operate at peak performance, with maximum efficiency and reliability over its long service life.

TABLE OF CONTENTS:

Komatsu 107E-5 Series Engine Shop Manual SEN06896-02 – PDF DOWNLOAD

COVER………………………………………………………………………………………………………………………………………. 1

00 INDEX AND FOREWORD……………………………………………………………………………………………………………………….. 3

INDEX………………………………………………………………………………………………………………………………….. 4

FOREWORD, SAFETY, BASIC INFORMATION……………………………………………………………………………………………………….. 6

HOW TO READ THE ENGINE SHOP MANUAL…………………………………………………………………………………………………….. 6

SAFETY NOTICE FOR OPERATION…………………………………………………………………………………………………………… 8

PRECAUTIONS TO PREVENT FIRE…………………………………………………………………………………………………………… 16

ACTIONS IF FIRE OCCURS……………………………………………………………………………………………………………….. 18

PRECAUTIONS FOR DISPOSING OF WASTE MATERIALS……………………………………………………………………………………………. 19

ENGINE TECHNOLOGY TO CONFORM EXHAUST GAS EMISSION……………………………………………………………………………………….. 20

PRECAUTIONS FOR DEF………………………………………………………………………………………………………………….. 21

GENERAL CHARACTER AND PRECAUTIONS FOR HANDLING………………………………………………………………………………………. 21

PRECAUTIONS FOR ADDING……………………………………………………………………………………………………………. 21

PRECAUTIONS FOR STORING…………………………………………………………………………………………………………… 21

PRECAUTIONS FOR FIRE HAZARD AND LEAKAGE…………………………………………………………………………………………….. 21

THE OTHER PRECAUTIONS…………………………………………………………………………………………………………….. 21

STORE AdBlue/DEF…………………………………………………………………………………………………………………….. 22

PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT……………………………………………………………………………………………. 23

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF PIPINGS………………………………………………………………………………….. 26

PRECAUTIONS FOR HANDLING ELECTRICAL EQUIPMENT…………………………………………………………………………………………… 33

PRECAUTIONS FOR HANDLING FUEL SYSTEM EQUIPMENT………………………………………………………………………………………….. 35

PRECAUTIONS FOR HANDLING INTAKE SYSTEM EQUIPMENT………………………………………………………………………………………… 36

DISCONNECT AND CONNECT PUSH-PULL TYPE COUPLER…………………………………………………………………………………………… 37

METHOD FOR DISCONNECTING AND CONNECTING TYPE 1 PUSH-PULL TYPE COUPLER………………………………………………………………….. 37

METHOD FOR DISCONNECTING AND CONNECTING TYPE 2 PUSH-PULL TYPE COUPLER………………………………………………………………….. 38

METHOD FOR DISCONNECTING AND CONNECTING TYPE 3 PUSH-PULL TYPE COUPLER………………………………………………………………….. 39

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF CONNECTORS……………………………………………………………………………….. 41

METHOD FOR DISCONNECTING AND CONNECTING DEUTSCH CONNECTOR………………………………………………………………………………… 45

METHOD FOR DISCONNECTING AND CONNECTING SLIDE LOCK TYPE CONNECTOR…………………………………………………………………………. 46

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PULL……………………………………………………………………….. 48

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PUSH……………………………………………………………………….. 49

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH HOUSING TO ROTATE…………………………………………………………………… 51

HOW TO READ ELECTRICAL WIRE CODE………………………………………………………………………………………………………. 52

EXPLANATION OF TERMS FOR MAINTENANCE STANDARD…………………………………………………………………………………………… 56

STANDARD TIGHTENING TORQUE TABLE………………………………………………………………………………………………………. 59

CONVERSION TABLE…………………………………………………………………………………………………………………….. 66

ABBREVIATION LIST……………………………………………………………………………………………………………………. 71

01 SPECIFICATIONS…………………………………………………………………………………………………………………………… 75

CONTENTS……………………………………………………………………………………………………………………………….. 76

SPECIFICATIONS………………………………………………………………………………………………………………………….. 77

OUTLINE OF EXHAUST GAS REGULATION……………………………………………………………………………………………………… 77

SYSTEM DIAGRAM OF ENGINE CONFORMED TO STAGE V REGULATION……………………………………………………………………………… 79

LIST OF APPLICABLE MACHINES: 107E-5……………………………………………………………………………………………………. 80

SPECIFICATIONS………………………………………………………………………………………………………………………. 81

PECIFICATIONS: SAA4D107E-5 (D51EX-24E0, D51EXI-24E0, D51PX-24E0, D51PXI-24E0)…………………………………………………………… 81

SPECIFICATIONS: SAA4D107E-5 (WA200-8E0)…………………………………………………………………………………………….. 82

ENGINE GENERAL VIEW………………………………………………………………………………………………………………….. 83

ENGINE GENERAL VIEW: SAA4D107E-5 (D51EX-24E0, D51EXI-24E0, D51PX-24E0, D51PXI-24E0)……………………………………………………… 83

ENGINE GENERAL VIEW: SAA4D107E-5 (WA200-8E0)………………………………………………………………………………………… 87

ENGINE PERFORMANCE CURVE……………………………………………………………………………………………………………… 91

ENGINE PERFORMANCE CURVE: SAA4D107E-5 (D51EX-24E0, D51EXI-24E0, D51PX-24E0, D51PXI-24E0)…………………………………………………. 91

ENGINE PERFORMANCE CURVE: SAA4D107E-5 (WA200-8E0)……………………………………………………………………………………. 92

10 STRUCTURE AND FUNCTION……………………………………………………………………………………………………………………. 93

CONTENTS……………………………………………………………………………………………………………………………….. 94

UREA SCR SYSTEM…………………………………………………………………………………………………………………………. 96

LAYOUT DRAWING OF UREA SCR SYSTEM……………………………………………………………………………………………………… 96

UREA SCR SYSTEM DIAGRAM………………………………………………………………………………………………………………. 98

FUNCTION OF UREA SCR SYSTEM…………………………………………………………………………………………………………… 99

FUNCTION OF AdBlue/DEF SUPPLY SYSTEM……………………………………………………………………………………………….. 99

INDUCEMENT STRATEGY……………………………………………………………………………………………………………….101

COMPONENT PARTS OF UREA SCR SYSTEM……………………………………………………………………………………………………..108

SCR ASSEMBLY……………………………………………………………………………………………………………………..108

AdBlue/DEF TANK…………………………………………………………………………………………………………………..110

AdBlue/DEF PUMP…………………………………………………………………………………………………………………..112

AdBlue/DEF INJECTOR……………………………………………………………………………………………………………….113

AdBlue/DEF HOSE…………………………………………………………………………………………………………………..114

AdBlue/DEF TANK HEATING VALVE………………………………………………………………………………………………………115

ENGINE SYSTEM……………………………………………………………………………………………………………………………116

LAYOUT OF ENGINE COMPONENTS……………………………………………………………………………………………………………116

LAYOUT DRAWING OF ENGINE COMPONENTS…………………………………………………………………………………………………116

INTAKE AND EXHAUST SYSTEM PARTS………………………………………………………………………………………………………..117

LAYOUT DRAWING OF INTAKE AND EXHAUST SYSTEM………………………………………………………………………………………….117

INTAKE AND EXHAUST SYSTEM CIRCUIT DIAGRAM……………………………………………………………………………………………118

FUNCTION OF INTAKE AND EXHAUST SYSTEM……………………………………………………………………………………………….118

AIR CLEANER………………………………………………………………………………………………………………………120

INTAKE AIR HEATER…………………………………………………………………………………………………………………121

ENGINE MAIN BODY PARTS………………………………………………………………………………………………………………..122

CYLINDER HEAD…………………………………………………………………………………………………………………….122

CYLINDER BLOCK……………………………………………………………………………………………………………………124

MAIN MOVING PARTS…………………………………………………………………………………………………………………126

CRANKSHAFT PULLEY…………………………………………………………………………………………………………………129

TIMING GEAR………………………………………………………………………………………………………………………130

FRONT COVER………………………………………………………………………………………………………………………131

VALVE SYSTEM……………………………………………………………………………………………………………………..132

FLYWHEEL AND FLYWHEEL HOUSING………………………………………………………………………………………………………134

TURBOCHARGER…………………………………………………………………………………………………………………………136

STRUCTURE OF TURBOCHARGER………………………………………………………………………………………………………….136

SPECIFICATIONS OF TURBOCHARGER……………………………………………………………………………………………………..137

FUNCTION OF TURBOCHARGER…………………………………………………………………………………………………………..137

CRANKCASE VENTILATION SYSTEM…………………………………………………………………………………………………………..139

SYSTEM DIAGRAM OF CRANKCASE VENTILATION SYSTEM……………………………………………………………………………………….139

FUNCTION OF CRANKCASE VENTILATION SYSTEM…………………………………………………………………………………………….139

IMPACTOR (FILTERLESS)…………………………………………………………………………………………………………………140

STRUCTURE OF IMPACTOR (FILTERLESS)………………………………………………………………………………………………….140

OPERATION OF IMPACTOR (FILTERLESS)………………………………………………………………………………………………….140

EXHAUST THROTTLE VALVE………………………………………………………………………………………………………………..141

STRUCTURE OF EXHAUST THROTTLE VALVE…………………………………………………………………………………………………141

FUNCTION OF EXHAUST THROTTLE VALVE………………………………………………………………………………………………….141

OPERATION OF EXHAUST THROTTLE VALVE…………………………………………………………………………………………………141

KDPF………………………………………………………………………………………………………………………………..142

STRUCTURE OF KDPF…………………………………………………………………………………………………………………142

FUNCTION OF KDPF………………………………………………………………………………………………………………….143

TYPES OF REGENERATION FUNCTION……………………………………………………………………………………………………..144

LUBRICATION SYSTEM……………………………………………………………………………………………………………………146

LAYOUT DRAWING OF LUBRICATION SYSTEM PARTS…………………………………………………………………………………………..146

LUBRICATION SYSTEM CIRCUIT DIAGRAM………………………………………………………………………………………………….147

ENGINE OIL PUMP…………………………………………………………………………………………………………………..148

ENGINE OIL FILTER…………………………………………………………………………………………………………………149

ENGINE OIL COOLER…………………………………………………………………………………………………………………150

ENGINE OIL REGULATOR VALVE…………………………………………………………………………………………………………152

SAFETY VALVE OF ENGINE OIL…………………………………………………………………………………………………………153

ENGINE OIL PAN……………………………………………………………………………………………………………………154

FUEL SYSTEM………………………………………………………………………………………………………………………….155

LAYOUT DRAWING OF FUEL SYSTEM PARTS…………………………………………………………………………………………………155

FUEL SYSTEM CIRCUIT DIAGRAM………………………………………………………………………………………………………..156

CRI SYSTEM……………………………………………………………………………………………………………………….157

SUPPLY PUMP………………………………………………………………………………………………………………………159

COMMON RAIL………………………………………………………………………………………………………………………160

INJECTOR…………………………………………………………………………………………………………………………161

FUEL PREFILTER……………………………………………………………………………………………………………………163

FUEL MAIN FILTER………………………………………………………………………………………………………………….164

COOLING SYSTEM……………………………………………………………………………………………………………………….165

LAYOUT DRAWING OF COOLING SYSTEM PARTS………………………………………………………………………………………………165

COOLING SYSTEM CIRCUIT DIAGRAM……………………………………………………………………………………………………..166

DRIVE PULLEY……………………………………………………………………………………………………………………..167

WATER PUMP……………………………………………………………………………………………………………………….168

THERMOSTAT……………………………………………………………………………………………………………………….169

ELECTRICAL SYSTEM………………………………………………………………………………………………………………………..170

COMPONENT PARTS OF ELECTRICAL SYSTEM……………………………………………………………………………………………………170

ALTERNATOR……………………………………………………………………………………………………………………….170

STARTING MOTOR……………………………………………………………………………………………………………………172

ENGINE WIRING HARNESS……………………………………………………………………………………………………………..173

ENGINE CONTROLLER…………………………………………………………………………………………………………………175

SENSOR………………………………………………………………………………………………………………………………183

LAYOUT DRAWING OF ENGINE SENSOR…………………………………………………………………………………………………….183

STRUCTURE OF INTAKE MANIFOLD PRESSURE AND TEMPERATURE SENSOR…………………………………………………………………………..186

FUNCTION OF INTAKE MANIFOLD PRESSURE AND TEMPERATURE SENSOR……………………………………………………………………………186

STRUCTURE OF ENGINE OIL PRESSURE SWITCH……………………………………………………………………………………………..187

FUNCTION OF ENGINE OIL PRESSURE SWITCH………………………………………………………………………………………………187

STRUCTURE OF CHARGE (BOOST) PRESSURE AND TEMPERATURE SENSOR……………………………………………………………………………188

FUNCTION OF CHARGE (BOOST) PRESSURE AND TEMPERATURE SENSOR…………………………………………………………………………….188

STRUCTURE OF COOLANT TEMPERATURE SENSOR……………………………………………………………………………………………..189

FUNCTION OF COOLANT TEMPERATURE SENSOR………………………………………………………………………………………………189

STRUCTURE OF NE (CRANKSHAFT) SPEED SENSOR……………………………………………………………………………………………190

FUNCTION OF NE (CRANKSHAFT) SPEED SENSOR…………………………………………………………………………………………….190

STRUCTURE OF Bkup (CAM) SPEED SENSOR………………………………………………………………………………………………..191

FUNCTION OF Bkup (CAM) SPEED SENSOR…………………………………………………………………………………………………191

STRUCTURE OF COMMON RAIL PRESSURE SENSOR…………………………………………………………………………………………….192

FUNCTION OF COMMON RAIL PRESSURE SENSOR……………………………………………………………………………………………..192

STRUCTURE OF KDPF DIFFERENTIAL PRESSURE AND OUTLET PRESSURE SENSOR……………………………………………………………………..193

FUNCTION OF KDPF DIFFERENTIAL PRESSURE AND OUTLET PRESSURE SENSOR………………………………………………………………………193

STRUCTURE OF CRANKCASE PRESSURE SENSOR………………………………………………………………………………………………194

FUNCTION OF CRANKCASE PRESSURE SENSOR……………………………………………………………………………………………….194

STRUCTURE OF ENGINE OIL LEVEL SENSOR………………………………………………………………………………………………..195

FUNCTION OF ENGINE OIL LEVEL SENSOR…………………………………………………………………………………………………195

STRUCTURE OF AIR CLEANER CLOGGING SENSOR…………………………………………………………………………………………….196

FUNCTION OF AIR CLEANER CLOGGING SENSOR……………………………………………………………………………………………..196

STRUCTURE OF WATER-IN-FUEL SENSOR…………………………………………………………………………………………………..197

FUNCTION OF WATER-IN-FUEL SENSOR……………………………………………………………………………………………………197

STRUCTURE OF EXHAUST MANIFOLD PRESSURE SENSOR………………………………………………………………………………………..198

FUNCTION OF EXHAUST MANIFOLD PRESSURE SENSOR…………………………………………………………………………………………198

STRUCTURE OF EXHAUST THROTTLE VALVE (WITH BUILT-IN POSITION SENSOR)…………………………………………………………………….199

FUNCTION OF EXHAUST THROTTLE VALVE (WITH BUILT-IN POSITION SENSOR)……………………………………………………………………..199

20 STANDARD VALUE TABLE………………………………………………………………………………………………………………………201

CONTENTS………………………………………………………………………………………………………………………………..202

STANDARD VALUE TABLE FOR ENGINE……………………………………………………………………………………………………………203

STANDARD VALUE TABLE FOR ENGINE: SAA4D107E-5 (D51EX-24E0, D51EXI-24E0, D51PX-24E0, D51PXI-24E0)……………………………………………….203

STANDARD VALUE TABLE FOR ENGINE: SAA4D107E-5 (WA200-8E0)………………………………………………………………………………….206

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD……………………………………………………………………………………………209

PERFORMANCE TEST STANDARD AND STANDARD FOR OPERATION OF ENGINE FOR BREAK IN PERIOD: SAA4D107E-5 (D51EX-24E0, D51EXI-24E0, D51PX-24E0, D51PXI-24E0)….209

PERFORMANCE TEST STANDARD AND STANDARD FOR OPERATION OF ENGINE FOR BREAK IN PERIOD: SAA4D107E-5 (WA200-8E0)…………………………………….211

50 DISASSEMBLY AND ASSEMBLY…………………………………………………………………………………………………………………..213

CONTENTS………………………………………………………………………………………………………………………………..214

RELATED INFORMATION ON DISASSEMBLY AND ASSEMBLY……………………………………………………………………………………………..215

HOW TO READ THIS MANUAL……………………………………………………………………………………………………………….215

COATING MATERIALS LIST………………………………………………………………………………………………………………..217

SPECIAL TOOLS LIST……………………………………………………………………………………………………………………221

SKETCHES OF SPECIAL TOOLS……………………………………………………………………………………………………………..223

ENGINE SYSTEM……………………………………………………………………………………………………………………………224

DISASSEMBLE AND ASSEMBLE ENGINE GENERALLY……………………………………………………………………………………………….224

DISASSEMBLE ENGINE GENERALLY……………………………………………………………………………………………………….225

ASSEMBLE ENGINE GENERALLY………………………………………………………………………………………………………….252

REMOVE AND INSTALL SUPPLY PUMP ASSEMBLY…………………………………………………………………………………………………298

REMOVE SUPPLY PUMP ASSEMBLY………………………………………………………………………………………………………..298

INSTALL SUPPLY PUMP ASSEMBLY……………………………………………………………………………………………………….301

REMOVE AND INSTALL ENGINE FRONT OIL SEAL………………………………………………………………………………………………..304

REMOVE ENGINE FRONT OIL SEAL……………………………………………………………………………………………………….304

INSTALL ENGINE FRONT OIL SEAL………………………………………………………………………………………………………306

REMOVE AND INSTALL ENGINE REAR OIL SEAL…………………………………………………………………………………………………309

REMOVE ENGINE REAR OIL SEAL………………………………………………………………………………………………………..309

INSTALL ENGINE REAR OIL SEAL……………………………………………………………………………………………………….310

60 MAINTENANCE STANDARD………………………………………………………………………………………………………………………313

CONTENTS………………………………………………………………………………………………………………………………..314

ENGINE SYSTEM……………………………………………………………………………………………………………………………315

INTAKE AND EXHAUST SYSTEM PARTS………………………………………………………………………………………………………..315

MAINTENANCE STANDARD OF TURBOCHARGER………………………………………………………………………………………………..315

ENGINE MAIN BODY PARTS………………………………………………………………………………………………………………..316

MAINTENANCE STANDARD OF CYLINDER HEAD……………………………………………………………………………………………….316

MAINTENANCE STANDARD OF CYLINDER BLOCK………………………………………………………………………………………………318

MAINTENANCE STANDARD OF CRANKSHAFT………………………………………………………………………………………………….320

MAINTENANCE STANDARD OF PISTON……………………………………………………………………………………………………..322

MAINTENANCE STANDARD OF CONROD……………………………………………………………………………………………………..323

MAINTENANCE STANDARD OF TIMING GEAR…………………………………………………………………………………………………325

MAINTENANCE STANDARD OF CAMSHAFT……………………………………………………………………………………………………326

MAINTENANCE STANDARD OF VALVE AND VALVE GUIDE………………………………………………………………………………………..328

MAINTENANCE STANDARD OF ROCKER ARM………………………………………………………………………………………………….330

MAINTENANCE STANDARD OF TAPPET……………………………………………………………………………………………………..331

MAINTENANCE STANDARD OF FLYWHEEL……………………………………………………………………………………………………332

LUBRICATION SYSTEM……………………………………………………………………………………………………………………334

MAINTENANCE STANDARD OF ENGINE OIL PUMP……………………………………………………………………………………………..334

INDEX……………………………………………………………………………………………………………………………………….335