$35

Komatsu 108-2 Series Diesel Engine Shop Manual SEBM006906 – PDF DOWNLOAD

Komatsu 108-2 Series Diesel Engine Shop Manual SEBM006906 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 108-2 Series Diesel Engine Shop Manual SEBM006906 – PDF DOWNLOAD

Language : English

Pages : 226

Downloadable : Yes

File Type : PDF

Size: 9.16 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 108-2 Series Diesel Engine Shop Manual SEBM006906 – PDF DOWNLOAD

The Komatsu 108-2 Series Diesel Engine Shop Manual SEBM006906 is a comprehensive guidebook that provides detailed technical information and instructions on how to operate, maintain, and repair the Komatsu 108-2 series diesel engines. These engines are commonly used in heavy equipment such as excavators, bulldozers, and other heavy machinery.

- The manual is divided into several sections, each providing detailed information on specific topics. These sections include specifications, structure and function, testing and adjusting, disassembly and assembly, maintenance, and troubleshooting.

- The specifications section of the manual provides detailed information on the engine’s physical and operational characteristics, including its dimensions, weight, performance, and power output. It also provides information on the engine’s cooling system, fuel system, and lubrication system.

- The structure and function section of the manual provides an overview of the engine’s internal components and their functions. This section includes detailed diagrams and descriptions of the engine’s various components, such as the cylinder block, cylinder head, crankshaft, pistons, and valves.

- The testing and adjusting section of the manual provides instructions on how to test and adjust the engine’s various components to ensure they are functioning correctly. This section includes detailed procedures for testing and adjusting the engine’s fuel injection system, valve clearances, and oil pressure.

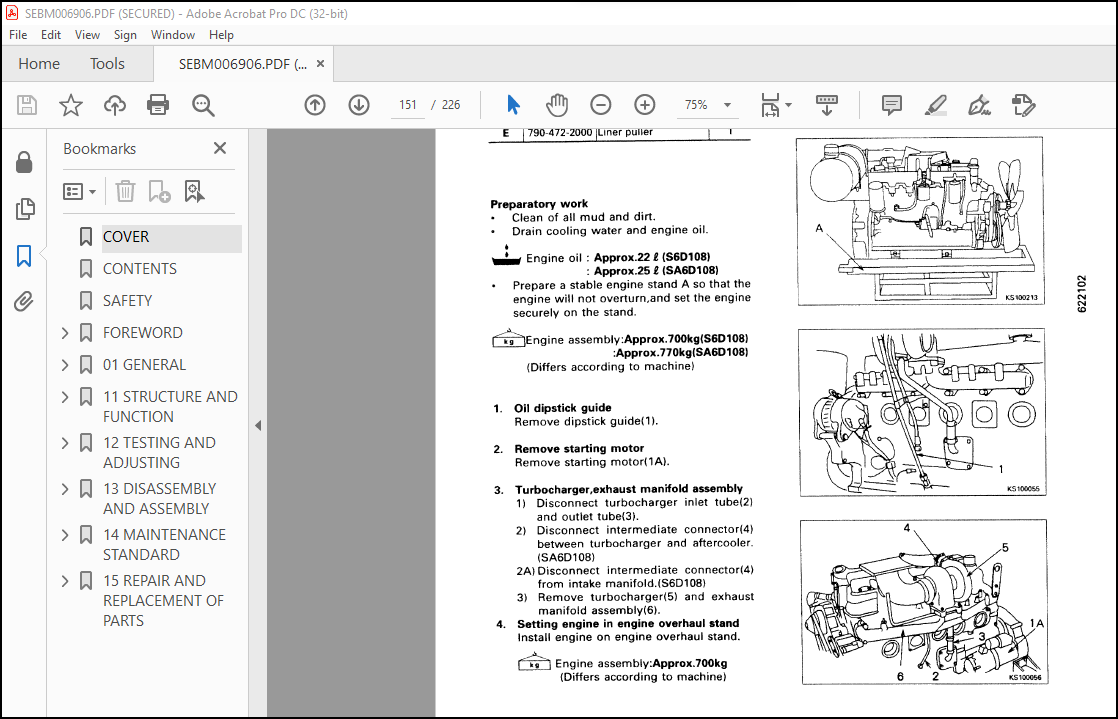

- The disassembly and assembly section of the manual provides step-by-step instructions on how to disassemble and reassemble the engine’s various components. This section includes detailed diagrams and photographs to guide the user through the process.

- The maintenance section of the manual provides information on routine maintenance tasks that should be performed to keep the engine in good working condition. This section includes instructions on how to perform tasks such as changing the engine oil and replacing the air filter.

- The troubleshooting section of the manual provides guidance on how to diagnose and resolve common issues that may arise with the engine. This section includes a list of common symptoms and their likely causes, as well as step-by-step instructions for troubleshooting and resolving each issue.

- Overall, the Komatsu 108-2 Series Diesel Engine Shop Manual SEBM006906 is an essential resource for anyone who works with or operates machinery that utilizes these engine series. It provides a wealth of technical information, detailed instructions, and troubleshooting guidance that can help keep the engine running smoothly and extend its lifespan. The manual is designed to be user-friendly and easy to understand, with clear and concise language and illustrations to guide the user through each process. Whether you are a mechanic or an equipment operator, this manual will provide you with the information you need to keep your Komatsu engine in good working order.

TABLE OF CONTENTS:

Komatsu 108-2 Series Diesel Engine Shop Manual SEBM006906 – PDF DOWNLOAD

COVER…………………………………………………………………………… 1

CONTENTS………………………………………………………………………… 4

SAFETY………………………………………………………………………….. 5

FOREWORD………………………………………………………………………… 7

GENERAL……………………………………………………………………… 7

HOW TO READ THE SHOP MANUAL……………………………………………………. 8

HOISTING INSTRUCTIONS…………………………………………………………. 9

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER………………………… 10

COATING MATERIALS…………………………………………………………….. 12

STANDARD TIGHTENING TORQUE…………………………………………………….. 14

ELECTRICAL WIRE CODE………………………………………………………….. 17

CONVERSION TABLE……………………………………………………………… 18

UNITS……………………………………………………………………….. 24

01 GENERAL………………………………………………………………………. 25

APPLICABLE MACHINE……………………………………………………………. 26

SPECIFICATIONS……………………………………………………………….. 28

GENERAL ASSEMBLY DRAWING………………………………………………………. 31

ENGINE PERFORMANCE CURVE………………………………………………………. 35

WEIGHT TABLE…………………………………………………………………. 37

11 STRUCTURE AND FUNCTION…………………………………………………………. 39

GENERAL STRUCTURE…………………………………………………………….. 40

INTAKE AND EXHAUST SYSTEM……………………………………………………… 42

AFTERCOOLER………………………………………………………………. 42

AIR-COOLED AFTERCOOLER MOUNT……………………………………………….. 43

AIR CLEANER………………………………………………………………. 47

ELECTRONIC DUST INDICATOR………………………………………………….. 48

TURBOCHARGER……………………………………………………………… 49

ENGINE BODY………………………………………………………………….. 52

CYLINDER HEAD…………………………………………………………….. 52

CYLINDER BLOCK……………………………………………………………. 54

MAIN REVOLVING SYSTEM……………………………………………………… 56

TIMING GEAR………………………………………………………………. 58

VALVE MECHANISM…………………………………………………………… 60

FLYWHEEL AND FLYWHEEL HOUSING………………………………………………. 62

LUBRICATION SYSTEM……………………………………………………………. 64

LUBRICATION SYSTEM CHART…………………………………………………… 64

OIL PUMP…………………………………………………………………. 65

OIL FILTER……………………………………………………………….. 66

OIL COOLER……………………………………………………………….. 67

FUEL SYSTEM………………………………………………………………….. 69

FUEL SYSTEM CHART…………………………………………………………. 69

FUEL INJECTION PUMP……………………………………………………….. 70

SPEED CONTROL LEVER ANGLE………………………………………………….. 71

BOOST COMPENSATOR DEVICE…………………………………………………… 72

FUEL INJECTION NOZZLE……………………………………………………… 73

FUEL FILTER………………………………………………………………. 74

FUEL INJECTION PUMP DRIVE CASE……………………………………………… 77

COOLING SYSTEM……………………………………………………………….. 84

COOLING SYSTEM, CHART……………………………………………………… 84

WATER PUMP……………………………………………………………….. 86

THERMOSTAT……………………………………………………………….. 88

ELECTRICAL SYSTEM…………………………………………………………….. 89

WIRING DIAGRAM……………………………………………………………. 89

ALTERNATOR……………………………………………………………….. 92

STARTING MOTOR……………………………………………………………. 95

OIL PRESSURE SWITCH……………………………………………………….. 97

RELAY SWITCH……………………………………………………………… 97

GLOW PLUG………………………………………………………………… 98

12 TESTING AND ADJUSTING………………………………………………………….. 99

INTAKE AND EXHAUST SYSTEM………………………………………………………101

ADJUSTING VALVE CLEARANCE…………………………………………………..101

ENGINE BODY…………………………………………………………………..102

MEASURING COMPRESSION PRESSURE………………………………………………102

FUEL SYSTEM…………………………………………………………………..103

TESTING AND ADJUSTING FUEL INJECTION TIMING…………………………………..103

PROCEDURE FOR ADJUSTING FUEL CUT SOLENOID LINKAGE……………………………..107

PROCEDURE FOR ADJUSTING ENGINE STOP MOTOR CABLE……………………………….108

PERFORMANCE TEST………………………………………………………………109

RUNNING IN STANDARD………………………………………………………..109

PERFORMANCE TEST CRITERIA…………………………………………………..110

FUEL INJECTION PUMP CALIBRATION DATA…………………………………………….112

TROUBLESHOOTING……………………………………………………………….120

POINTS TO REMEMBER WHEN TROUBLESHOOTING………………………………………121

METHOD OF USING TROUBLESHOOTING CHART………………………………………..123

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME) ………………….127

S-2 ENGINE DOES NOT START…………………………………………………..128

(1) ENGINE DOES NOT TURN………………………………………………..128

(2) ENGINE TURNS BUT NO EXHAUST GAS COMES OUT (FUEL IS NOT BEING INJECTED)……129

(3) EXHAUST GAS COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)….130

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)……………………….131

S-4 ENGINE STOPS DURING OPERATIONS…………………………………………..132

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)…………………………………133

S-6 ENGINE LACKS OUTPUT (NO POWER)…………………………………………..134

S-7 EXHAUST GAS IS BLACK (INCOMPLETE COMBUSTION)………………………………135

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST GAS IS BLUE)………………………136

S-9 OIL BECOMES CONTAMINATED QUICKLY…………………………………………137

S-10 FUEL CONSUMPTION IS EXCESSIVE…………………………………………..138

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN……..139

S-12 OIL PRESSURE LAMP LIGHTS UP (DROP IN OIL PRESSURE)………………………..140

S-13 OIL LEVEL RISES……………………………………………………….141

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING) …………………………142

S-15 ABNORMAL NOISE IS MADE…………………………………………………143

S-16 VIBRATION IS EXCESSIVE…………………………………………………144

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING…………………………………145

TESTING AND ADJUSTING DATA……………………………………………………..147

13 DISASSEMBLY AND ASSEMBLY………………………………………………………..150

OVERALL DISASSEMBLY……………………………………………………………151

OVERALL ASSEMBLY………………………………………………………………163

14 MAINTENANCE STANDARD……………………………………………………………186

INTAKE AND EXHAUST SYSTEM………………………………………………………187

TURBOCHARGER………………………………………………………………187

ENGINE BODY…………………………………………………………………..188

CYLINDER HEAD……………………………………………………………..188

VALVE AND VALVE GUIDE………………………………………………………189

ROCKER ARM, PUSH ROD AND TAPPET……………………………………………..191

CYLINDER LINER…………………………………………………………….192

CYLINDER BLOCK…………………………………………………………….193

CRANKSHAFT………………………………………………………………..195

CAMSHAFT………………………………………………………………….196

PISTON, PISTON RING AND PISTON PIN…………………………………………..197

CONNECTING ROD…………………………………………………………….198

TIMING GEAR……………………………………………………………….199

FLYWHEEL AND FLYWHEEL HOUSING……………………………………………….200

LUBRICATION SYSTEM…………………………………………………………….201

OIL PUMP………………………………………………………………….201

REGULATOR VALVE……………………………………………………………202

SAFETY VALVE………………………………………………………………202

COOLING SYSTEM………………………………………………………………..203

WATER PUMP AND THERMOSTAT…………………………………………………..203

15 REPAIR AND REPLACEMENT OF PARTS………………………………………………….204

REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING………………………………205

REPLACING VALVE SEAT INSERTS……………………………………………………206

PRESSURE TEST…………………………………………………………………210

REPLACING VALVE GUIDE………………………………………………………….211

GRINDING THE VALVE…………………………………………………………….212

REPLACING CAM BUSHING………………………………………………………….213

REPLACING CRANK GEAR…………………………………………………………..215

REPLACING CAM GEAR…………………………………………………………….215

REPLACING FLYWHEEL RING GEAR……………………………………………………216

REPLACING MAIN BEARING CAP……………………………………………………..217

GRINDING CRANKSHAFT……………………………………………………………218

REPLACING ENGINE REAR SEAL……………………………………………………..223

REPLACING CONNECTING ROD SMALL END BUSHING……………………………………….226