$34

Komatsu 108 Series Diesel Engine Shop Manual SEBE62210103 – PDF DOWNLOAD

Komatsu 108 Series Diesel Engine Shop Manual SEBE62210103 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 108 Series Diesel Engine Shop Manual SEBE62210103 – PDF DOWNLOAD

Language : English

Pages : 256

Downloadable : Yes

File Type : PDF

Size: 16.5 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 108 Series Diesel Engine Shop Manual SEBE62210103 – PDF DOWNLOAD

The Komatsu 108 Series Diesel Engine Shop Manual SEBE62210103 is a comprehensive technical guide that provides detailed information and instructions for the maintenance, repair, and overhaul of the Komatsu 108 series diesel engine. The manual covers a range of Komatsu 108 engines commonly used in various construction equipment such as dozers, excavators, wheel loaders, and motor graders.

- The manual is divided into several sections, each of which covers different aspects of engine maintenance and repair. The general specifications section provides an overview of the engine’s technical specifications, including dimensions, weight, power output, and torque ratings. It also includes information on the engine’s various components, such as the cylinder block, cylinder head, crankshaft, and pistons.

- The testing and adjusting procedures section of the manual provides step-by-step instructions for performing various tests and adjustments on the engine. These procedures include compression tests, fuel injection timing adjustment, and valve clearance adjustment. The manual also provides information on the tools and equipment required for performing these procedures.

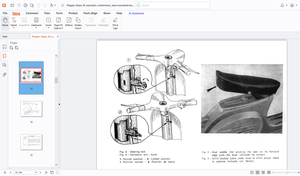

- The disassembly and assembly instructions section of the manual provides detailed guidance on how to disassemble and reassemble the engine, including the removal and installation of various components such as the cylinder head, pistons, and crankshaft. This section also includes detailed diagrams and illustrations that provide a clear understanding of the engine’s internal components and how they fit together.

- The troubleshooting guidelines section of the manual provides information on how to diagnose and repair common problems that may occur with the engine. This section provides a list of potential symptoms and causes, along with step-by-step instructions for identifying and fixing the problem.

- The manual also covers maintenance and safety guidelines, including routine inspections, cleaning, lubrication, and safety precautions that must be followed while working with the engine.

- Overall, the Komatsu 108 Series Diesel Engine Shop Manual SEBE62210103 is an essential resource for technicians and mechanics working with the Komatsu 108 series engines. Its comprehensive coverage of maintenance, repair, and troubleshooting procedures makes it an indispensable tool for ensuring the reliable and efficient operation of Komatsu construction equipment.

TABLE OF CONTENTS:

Komatsu 108 Series Diesel Engine Shop Manual SEBE62210103 – PDF DOWNLOAD

MAIN MENU……………………………………………………………………… 0

CONTENTS………………………………………………………………………. 2

01 GENERAL…………………………………………………………………….. 23

SPECIFICATIONS……………………………………………………………… 24

ENGINE PERFORMANCE CURVE…………………………………………………….. 28

WEIGHT TABLE……………………………………………………………….. 38

11 STRUCTURE AND FUNCTION……………………………………………………….. 41

GENERAL STRUCTURE…………………………………………………………… 42

INTAKE AND EXHAUST SYSTEM……………………………………………………. 44

AFTER-COOLER …………………………………………………………… 44

AIR CLEANER…………………………………………………………….. 45

ELECTRONIC DUST INDICATOR………………………………………………… 46

TURBOCHARGER……………………………………………………………. 47

ENGINE BODY………………………………………………………………… 54

CYLINDER HEAD…………………………………………………………… 54

CYLINDER BLOCK………………………………………………………….. 56

MAIN REVOLVING SYSTEM……………………………………………………. 58

TIMING GEAR…………………………………………………………….. 62

VALVE SYSTEM……………………………………………………………. 64

FLWHEEL AND FLYWHEEL HOUSING……………………………………………… 66

LUBRICATION SYSTEM………………………………………………………….. 70

LUBRICATION SYSTEM CHART…………………………………………………. 70

OIL PUMP……………………………………………………………….. 71

OIL FILTER (BUILT-IN SAFETY VALVE)………………………………………… 72

OIL COOLER……………………………………………………………… 73

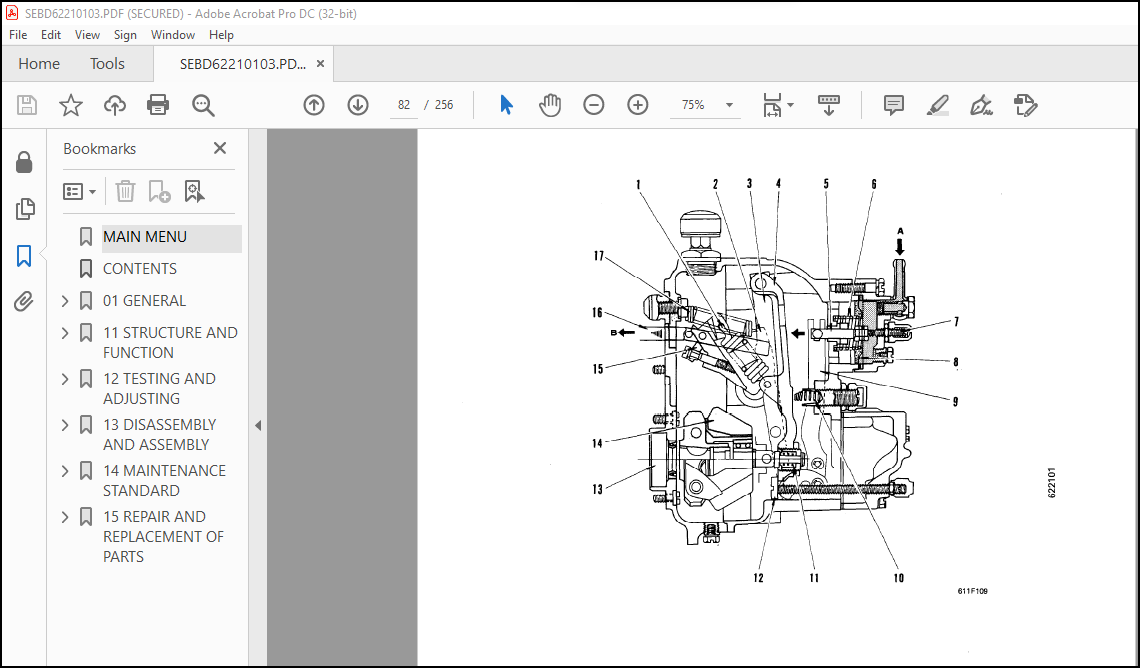

FUEL SYSTEM………………………………………………………………… 74

FUEL SYSTEM CHART……………………………………………………….. 74

FUEL INJECTION PUMP……………………………………………………… 76

FUEL INJECTION NOZZLE……………………………………………………. 84

FUEL FILTER…………………………………………………………….. 85

FUEL INJECTION PUMP DRIVE CASE……………………………………………. 86

ENGINE STOP MOTOR……………………………………………………….. 88

FUEL CUT SOLENOID……………………………………………………….. 93

COOLING SYSTEM……………………………………………………………… 94

COOLING SYSTEM CHART…………………………………………………….. 94

THERMOSTAT……………………………………………………………… 97

WATER PUMP……………………………………………………………… 98

ELECTRICAL SYSTEM……………………………………………………………101

WIRING DIAGRAM…………………………………………………………..101

ALTERNATOR………………………………………………………………104

STARTING MOTOR…………………………………………………………..108

OIL PRESSURE SWITCH………………………………………………………110

RELAY SWITCH…………………………………………………………….110

GLOW PLUG……………………………………………………………….111

12 TESTING AND ADJUSTING…………………………………………………………113

INTAKE AND EXHAUST SYSTEM…………………………………………………….115

ADJUSTING VALVE CLEARANCE…………………………………………………115

ENGINE BODY…………………………………………………………………116

MEASURING COMPRESSION PRESSURE…………………………………………….116

FUEL SYSTEM…………………………………………………………………117

TESTING AND ADJUSTING FUEL INJECTION TIMING…………………………………117

ADJUSTMENT FUEL CUT SOLENOID LINK………………………………………….120

PROCEDURE FOR ADJUSTING ENGINE STOP MOTOR CABLE……………………………..122

ADJUSTING ENGINE SPEED SENSOR (MECHANICAL GOVERNOR)………………………….124

PERFORMANCE TEST…………………………………………………………….125

RUN-IN STANDARD………………………………………………………….125

PERFORMANCE TEST CRITERIA…………………………………………………128

TESTING AND ADJUSTING DATA……………………………………………………132

FUEL INJECTION PUMP CALIBRATION DATA……………………………………….132

TESTING AND ADJUSTING TOOL LIST……………………………………………143

STANDARD VALVE TABLE……………………………………………………..144

TROUBLESHOOTING……………………………………………………………..149

POINTS TO REMEMBER WHEN TROUBLESHOOTING…………………………………….151

METHOD OF USING TROUBLESHOOTING CHART………………………………………152

S-1 Starting performance is poor (Starting always takes time)…………………156

S-2 Engine does not start…………………………………………………157

1 Engine does not turn………………………………………………..157

2 Engine turns but no exhaust gas comes out……………………………..158

3 Exhaust gas comes out but engine does not start (Fuel is being injected)….159

S-3 Engine does not pick up smoothly (Follow-up is poor)……………………..160

S-4 Engine stops during operations…………………………………………161

S-5 Engine does not rotate smoothly (hunting)……………………………….162

S-6 Engine lacks output (no power)…………………………………………163

S-7 Exhaust gas is black (incomplete combustion)…………………………….164

S-8 Oil consumption is excessive (or exhaust gas is blue)…………………….165

S-9 Oil becomes contaminated quickly……………………………………….166

S-10 Fuel consumption is excessive…………………………………………167

S-11 Oil is in cooling water, or water spurts back, or water level goes down……168

S-12 Oil pressure lamp lights up (drop in oil pressure)………………………169

S-13 Oil level rises……………………………………………………..170

S-14 Water temperature becomes too high (overheating)………………………..171

S-15 Abnormal noise is made……………………………………………….172

S-16 Vibration is excessive……………………………………………….173

13 DISASSEMBLY AND ASSEMBLY………………………………………………………175

OVERALL DISASSEMBLY………………………………………………………….176

OVERALL ASSEMBLY…………………………………………………………….188

14 MAINTENANCE STANDARD………………………………………………………….211

INTAKE AND EXHAUST SYSTEM…………………………………………………….212

TURBOCHARGER…………………………………………………………….212

ENGINE BODY…………………………………………………………………214

CYLINDER HEAD……………………………………………………………214

VALVE AND VALVE GUIDE…………………………………………………….216

ROCKER ARM, PUSH ROD AND TAPPET……………………………………………218

CYLINDER LINER…………………………………………………………..219

CYLINDER BLOCK…………………………………………………………..220

CRANKSHAFT………………………………………………………………222

CAMSHAFT………………………………………………………………..223

PISTON, PISTON RING AND PISTON PIN…………………………………………224

CONNECTING ROD…………………………………………………………..225

TIMING GEAR……………………………………………………………..226

FLYWHEEL AND FLYWHEEL HOUSING……………………………………………..227

LUBRICATION SYSTEM…………………………………………………………..228

OIL PUMP………………………………………………………………..228

REGULATOR VALVE………………………………………………………….229

SAFETY VALVE…………………………………………………………….229

COOLING SYSTEM………………………………………………………………230

WATER PUMP AND THERMOSTAT…………………………………………………230

15 REPAIR AND REPLACEMENT OF PARTS………………………………………………..233

REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING…………………………….234

REPLACING VALVE SEAT INSERTS………………………………………………….235

PRESSURE TEST……………………………………………………………….239

REPLACING VALVE GUIDE………………………………………………………..240

GRINDING THE VALVE…………………………………………………………..241

REPLACING CAM BUSHING………………………………………………………..242

REPLACING CRANK GEAR…………………………………………………………244

REPLACING CAM GEAR…………………………………………………………..244

REPLACING FLYWHEEL RING GEAR………………………………………………….245

REPLACING MAIN BEARING CAP……………………………………………………246

GRINDING CRANKSHAFT………………………………………………………….247

REPLACING ENGINE REAR SEAL……………………………………………………252