$35

Komatsu 108 Series Diesel Engine Shop Manual SEBE62210104 – PDF DOWNLOAD

Komatsu 108 Series Diesel Engine Shop Manual SEBE62210104 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 108 Series Diesel Engine Shop Manual SEBE62210104 – PDF DOWNLOAD

Language : English

Pages : 254

Downloadable : Yes

File Type : PDF

Size: 11.1 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 108 Series Diesel Engine Shop Manual SEBE62210104 – PDF DOWNLOAD

The Komatsu 108 Series Diesel Engine is a powerful and reliable engine that is commonly used in heavy-duty applications. The engine has a four-stroke cycle and is designed to deliver high performance with excellent fuel efficiency. To ensure the proper operation and maintenance of this engine, Komatsu has created the Komatsu 108 Series Diesel Engine Shop Manual SEBE62210104.

The manual is comprehensive and covers all aspects of the engine, including its construction, maintenance, and repair. It is divided into several sections, each focusing on a different aspect of the engine. The sections are as follows:

- General: This section provides an overview of the engine, including specifications, features, and system diagrams. It also includes safety information and precautions that should be taken when working on the engine.

- Structure and Function: This section describes the structure and function of the engine, including its major components, such as the cylinder head, piston, connecting rod, and crankshaft. It also explains the engine’s lubrication and cooling systems and how they work.

- Testing and Adjusting: This section covers the testing and adjustment procedures that should be performed on the engine to ensure proper operation. It includes procedures for checking and adjusting the valve clearance, injection timing, fuel system, and other key components.

- Disassembly and Assembly: This section provides step-by-step instructions for disassembling and assembling the engine. It includes detailed diagrams and illustrations to help ensure that the process is carried out correctly.

- Maintenance Standard: This section outlines the recommended maintenance schedule for the engine, including oil changes, filter replacements, and other routine maintenance tasks.

- Repair and Replacement: This section provides information on repairing and replacing various components of the engine, including the cylinder head, piston, connecting rod, and crankshaft. It includes detailed instructions for each repair or replacement procedure, along with diagrams and illustrations to help ensure that the work is carried out correctly.

Overall, the Komatsu 108 Series Diesel Engine Shop Manual SEBE62210104 is a comprehensive resource for anyone who owns or works on this engine. It provides detailed information on every aspect of the engine, from its construction and operation to its maintenance and repair. With this manual, engine owners and technicians can ensure that the engine operates at its best and remains reliable and efficient for years to come.

TABLE OF CONTENTS:

Komatsu 108 Series Diesel Engine Shop Manual SEBE62210104 – PDF DOWNLOAD

COVER…………………………………………………………………………. 1

CONTENTS………………………………………………………………………. 2

01 GENERAL…………………………………………………………………….. 23

SPECIFICATIONS……………………………………………………………… 24

ENGINE PERFORMANCE CURVE…………………………………………………….. 28

WEIGHT TABLE……………………………………………………………….. 37

11 STRUCTURE AND FUNCTION……………………………………………………….. 39

GENERAL STRUCTURE…………………………………………………………… 40

INTAKE AND EXHAUST SYSTEM……………………………………………………. 42

AFTER -COOLER…………………………………………………………… 42

AIR CLEANER…………………………………………………………….. 43

ELECTRONIC DUST INDICATOR………………………………………………… 44

TURBOCHARGER……………………………………………………………. 45

ENGINE BODY………………………………………………………………… 52

CYLINDER HEAD…………………………………………………………… 52

CYLINDER BLOCK………………………………………………………….. 54

MAIN REVOLVING SYSTEM……………………………………………………. 56

TIMING GEAR…………………………………………………………….. 60

VALVE SYSTEM……………………………………………………………. 62

FLYWHEEL AND FLYWHEEL HOUSING…………………………………………….. 64

LUBRICATION SYSTEM………………………………………………………….. 68

LUBRICATION SYSTEM CHART…………………………………………………. 68

OIL PUMP ………………………………………………………………. 69

OIL FILTER (BUILT-IN SAFETY VALVE)………………………………………… 70

OIL COOLER……………………………………………………………… 71

FUEL SYSTEM………………………………………………………………… 72

FUEL SYSTEM CHART……………………………………………………….. 72

FUEL INJECTION PUMP……………………………………………………… 74

FUEL INJECTION NOZZLE……………………………………………………. 82

FUEL FILTER…………………………………………………………….. 83

FUEL INJECTION PUMP DRIVE CASE……………………………………………. 84

ENGINE STOP MOTOR……………………………………………………….. 86

FUEL CUT SOLENOID……………………………………………………….. 91

COOLING SYSTEM……………………………………………………………… 92

COOLING SYSTEM CHART…………………………………………………….. 92

THERMOSTAT……………………………………………………………… 95

WATER PUMP……………………………………………………………… 96

ELECTRICAL SYSTEM…………………………………………………………… 99

WIRING DIAGRAM………………………………………………………….. 99

ALTERNATOR………………………………………………………………102

STARTING MOTOR…………………………………………………………..106

OIL PRESSURE SWITCH ……………………………………………………..108

RELAY SWITCH…………………………………………………………….108

GLOW PLUG……………………………………………………………….109

12 TESTING AND ADJUSTING…………………………………………………………111

INAKE AND EXHAUST SYSTEM……………………………………………………..113

ADJUSTING VALVE CLEARANCE…………………………………………………113

ENGINE BODY…………………………………………………………………114

MEASURING COMPRESSION PRESSURE…………………………………………….114

FUEL SYSTEM…………………………………………………………………115

TESTING AND ADJUSTING FUEL INJECTION TIMING…………………………………115

ADJUSTING FUEL CUT SOLENOID LINK…………………………………………..118

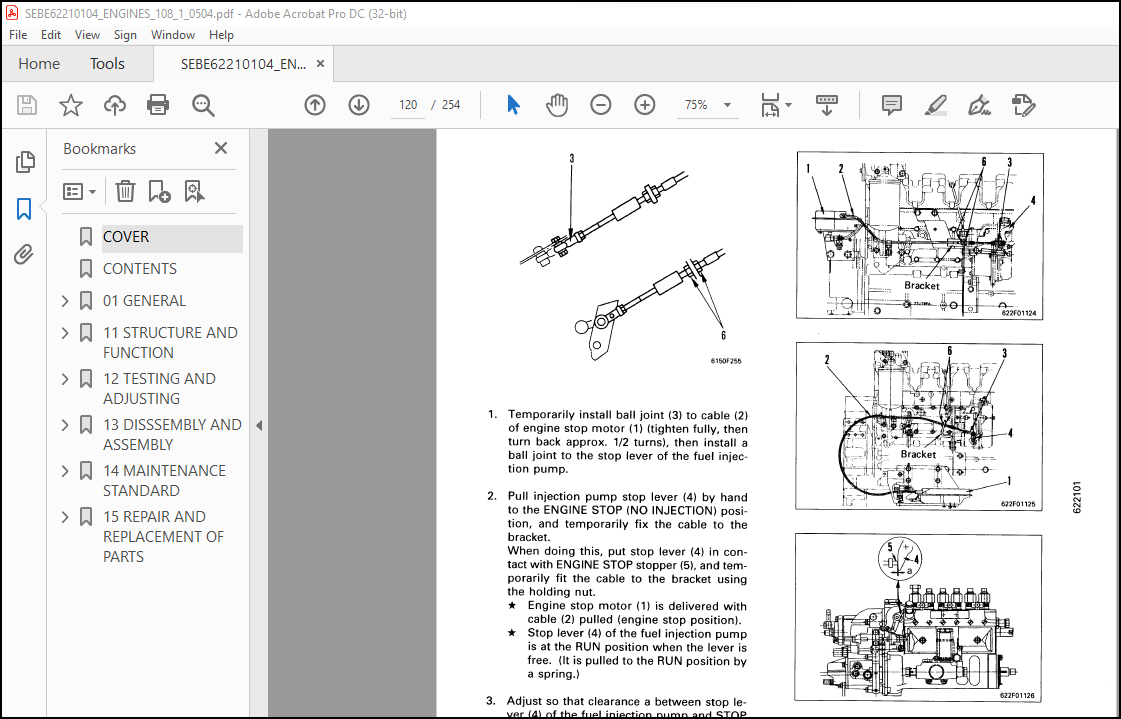

PROCEDURE FOR ADJUSTING ENGINE STOP MOTOR CABLE……………………………..120

ADJUSTING ENGINE SPEED SENSOR……………………………………………..122

PERFORMANCE TEST…………………………………………………………….123

RUNNING-IN STANDARD………………………………………………………123

PERFORMANCE TEST CRITERIA…………………………………………………126

TESTING AND ADJUSTING DATA……………………………………………………130

CALIBRATION DATA…………………………………………………………130

TESTING AND ADJUSTING TOO LIST…………………………………………….143

TESTING AND ADJUSTING DATA………………………………………………..144

TROUBLESHOOTING……………………………………………………………..149

POINTS TO REMEMBER WHEN TROUBLESHOOTING…………………………………….151

METHOD OF USING TROUBLESHOOTING CHART………………………………………152

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)…………………156

S-2 ENGINE DOES NOT START…………………………………………………157

① ENGINE DOES NOT TURN………………………………………………..157

② ENGINE TURNS BUT NO EXHAUST GAS COMES OUT (FUEL IS NOT BEING INJECTED)……158

③ EXHAUST GAS COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)….159

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)……………………..160

S-4 ENGINE STOPS DURING OPERATIONS…………………………………………161

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)……………………………….162

S-6 ENGINE LACKS OUTPUT (NO POWER)…………………………………………163

S-7 EXHAUST GAS IS BLACK (INCOMPLETE COMBUSTION)…………………………….164

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST GAS IS BLUE)…………………….165

S-9 OIL BECOMES CONTAMINATED QUICKLY……………………………………….166

S-10 FUEL CONSUMPTION IS EXCESSIVE…………………………………………167

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVER GOES DOWN……168

S-12 OIL PRESSURE LAMP LIGHTS UP (DROP IN OIL PRSSURE)……………………….169

S-13 OIL LEVEL RISES……………………………………………………..170

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)………………………..171

S-15 ABNORMAL NOISE IS MADE……………………………………………….172

S-16 VIBRATION IS EXCESSIVE……………………………………………….173

13 DISSSEMBLY AND ASSEMBLY……………………………………………………….175

OVERALL DISASSEMBLY………………………………………………………….176

OVERALL ASSEMBLY…………………………………………………………….188

14 MAINTENANCE STANDARD………………………………………………………….211

TURBOCHARGER………………………………………………………………..212

CYLINDER HEAD……………………………………………………………….214

VALVE AND VALVE GUIDE………………………………………………………..216

ROCKER ARM, PUSH ROD AND TAPPET……………………………………………….218

CYLINDER LINER………………………………………………………………219

CYLINDER BLOCK………………………………………………………………220

CRANKSHAFT………………………………………………………………….222

CAMSHAFT……………………………………………………………………223

PISION,PISTON RING AND PISTON PIN……………………………………………..224

CONNECTING ROD………………………………………………………………225

TIMING GEAR…………………………………………………………………226

FLYWHEEL AND FLYWHEEL HOUSING…………………………………………………227

LUBRICATION SYSTEM…………………………………………………………..228

OIL PUMP ……………………………………………………………….228

REGULATOR VALVE………………………………………………………….229

SAFETY VALVE…………………………………………………………….229

COOLING SYSTEM………………………………………………………………230

WATER PUMP AND THERMOSTAT…………………………………………………….230

15 REPAIR AND REPLACEMENT OF PARTS………………………………………………..233

REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING…………………………….234

REPLACING VALVE SEAT INSERTS………………………………………………….235

PRESSURE TEST……………………………………………………………….239

REPLACING VALVE GUIDE………………………………………………………..240

GRINDING THE VALVE…………………………………………………………..241

REPLACING CAM BUSHING………………………………………………………..242

REPLACING CRANK GEAR…………………………………………………………244

REPLACING CAM GEAR…………………………………………………………..244

REPLACING FLYWHEEL RING GEAR………………………………………………….245

REPLACING MAIN BEARING CAP……………………………………………………246

GRINDING CRANKSHAFT………………………………………………………….247

REPLACING ENGINE REAR SEAL……………………………………………………252