$39

Komatsu 114 Series Diesel Engine Shop Manual SEBM020400 – PDF DOWNLOAD

Komatsu 114 Series Diesel Engine Shop Manual SEBM020400 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 114 Series Diesel Engine Shop Manual SEBM020400 – PDF DOWNLOAD

Language : English

Pages : 978

Downloadable : Yes

File Type : PDF

Size: 41.4 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 114 Series Diesel Engine Shop Manual SEBM020400 – PDF DOWNLOAD

The Komatsu 114 Series Diesel Engine Shop Manual SEBM020400 is a comprehensive guide that provides detailed information on the maintenance, repair, and overhaul of the 114 series engine. This engine is used in a variety of Komatsu equipment, including bulldozers, excavators, and other heavy equipment.

- The manual is organized into several sections, each covering a different aspect of the engine. The first section provides an overview of the engine, including its specifications and performance data. This section also includes a table of contents, a list of illustrations, and a list of symbols and abbreviations used throughout the manual.

- The second section of the manual covers engine inspection and measurement procedures. This section provides step-by-step instructions for checking and measuring various components of the engine, including the cylinder block, crankshaft, and connecting rods. The manual includes detailed illustrations to help the reader understand the procedures.

- The third section covers engine disassembly and assembly procedures. This section provides instructions for removing and installing various components of the engine, including the cylinder head, pistons, and crankshaft. The manual also includes torque specifications for each component.

- The fourth section covers engine testing and adjusting procedures. This section provides instructions for testing and adjusting various components of the engine, including the fuel injection system, the turbocharger, and the valve clearance. The manual includes detailed illustrations to help the reader understand the procedures.

- The fifth section covers engine maintenance procedures, including routine maintenance and inspections. This section provides instructions for maintaining the engine to ensure its continued performance and longevity.

- The sixth section covers engine troubleshooting and diagnosis procedures. This section provides instructions for diagnosing and troubleshooting various engine problems, including starting problems, low power output, and excessive smoke. The manual includes a troubleshooting chart and detailed illustrations to help the reader diagnose and fix the problem.

- Overall, the Komatsu 114 Series Diesel Engine Shop Manual SEBM020400 is an essential tool for anyone working on or maintaining this engine. The manual is available in print or digital formats, making it a convenient and accessible resource for mechanics and technicians. It is designed to be user-friendly and easy to understand, with clear instructions and detailed illustrations. With this manual, you can ensure that your Komatsu equipment is operating at its best and avoid costly repairs and downtime.

TABLE OF CONTENTS:

Komatsu 114 Series Diesel Engine Shop Manual SEBM020400 – PDF DOWNLOAD

COVER……………………………………………………………………………………. 1

PRODUCT PUBLICATIONS INFORMATION……………………………………………………………. 3

FOREWORD…………………………………………………………………………………. 5

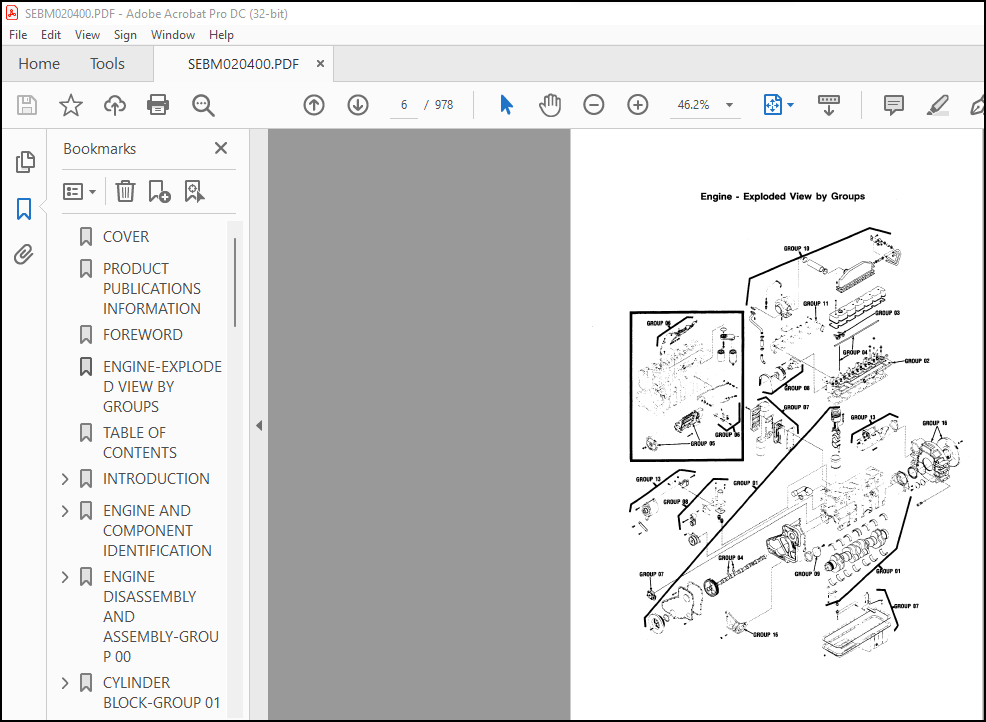

ENGINE-EXPLODED VIEW BY GROUPS……………………………………………………………… 6

TABLE OF CONTENTS…………………………………………………………………………. 7

INTRODUCTION……………………………………………………………………………… 8

ABOUT THE MANUAL………………………………………………………………………. 9

HOW TO USE THIS MANUAL…………………………………………………………………. 10

TABLE OF CONTENTS………………………………………………………………….. 10

GROUP CONTENTS…………………………………………………………………….. 10

INDEX…………………………………………………………………………….. 10

METRIC INFORMATION…………………………………………………………………. 10

GENERIC SYMBOLS……………………………………………………………………….. 11

ILLUSTRATIONS…………………………………………………………………………. 12

GENERAL SAFETY INSTRUCTIONS…………………………………………………………….. 13

GENERAL REPAIR INSTRUCTIONS…………………………………………………………….. 14

GENERAL CLEANING INSTRUCTIONS…………………………………………………………… 15

SOLVENT AND ACID CLEANING…………………………………………………………… 15

STEAM CLEANING…………………………………………………………………….. 15

GLASS OR PLASTIC BEAD CLEANING………………………………………………………. 15

GLOSSARY OF TERMS……………………………………………………………………… 16

ENGINE AND COMPONENT IDENTIFICATION…………………………………………………………. 18

ENGINE IDENTIFICATION………………………………………………………………….. 19

ENGINE DATAPLATES………………………………………………………………….. 19

FUEL INJECTION PUMP DATAPLATE……………………………………………………….. 20

GENERAL ENGINE SPECIFICATIONS…………………………………………………………… 21

GENERAL ENGINE DATA………………………………………………………………… 21

LUBRICATION SYSTEM…………………………………………………………………. 21

COOLING SYSTEM…………………………………………………………………….. 22

INTAKE AIR AND EXHAUST SYSTEM……………………………………………………….. 22

FUEL SYSTEM……………………………………………………………………….. 22

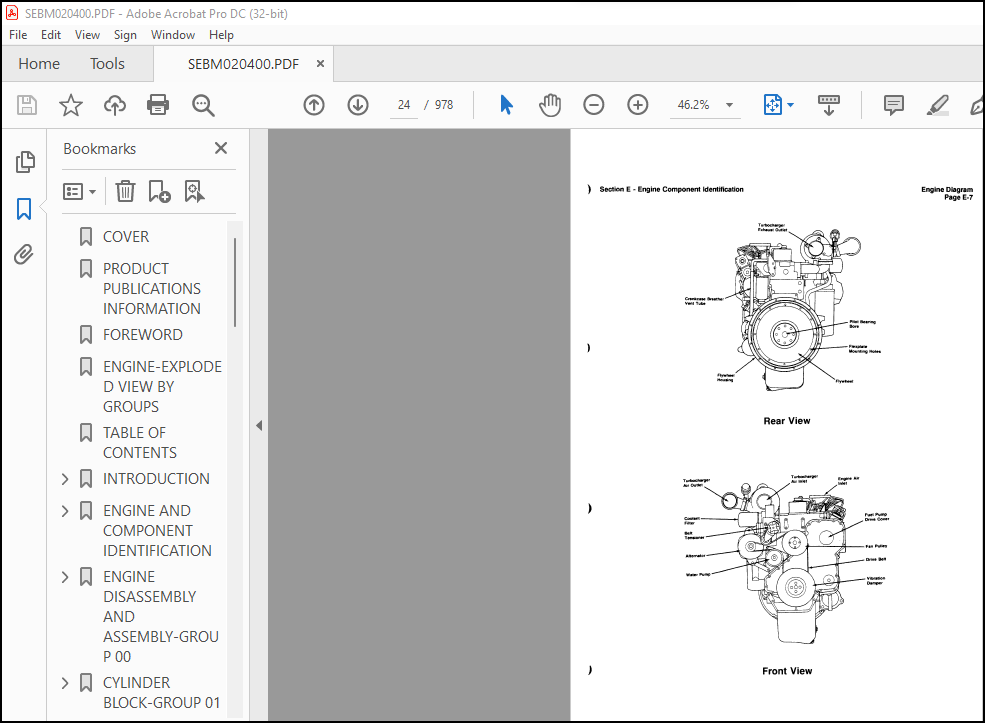

ENGINE DIAGRAMS……………………………………………………………………….. 23

ENGINE DISASSEMBLY AND ASSEMBLY-GROUP 00…………………………………………………….. 26

ENGINE DISASSEMBLY AND ASSEMBLY-SERVICE TOOLS…………………………………………….. 29

GENERAL INFORMATION……………………………………………………………………. 33

DISASSEMBLY……………………………………………………………………….. 33

ASSEMBLY………………………………………………………………………….. 33

ENGINE LIFTING EQUIPMENT AND BRACKETS……………………………………………………. 34

ENGINE-PREPARATION FOR STEAM CLEANING……………………………………………………. 34

ENGINE-STEAM CLEANING………………………………………………………………….. 34

LUBRICATING OIL-DRAINING……………………………………………………………….. 35

COOLANT-DRAINING………………………………………………………………………. 35

COOLANT FILTER-REMOVAL…………………………………………………………………. 35

LUBRICATING OIL FILTER-REMOVAL………………………………………………………….. 35

FUEL FILTER-REMOVAL……………………………………………………………………. 36

FUEL FILTER HEAD-REMOVAL……………………………………………………………….. 36

FUEL LINES,LOW PRESSURE-REMOVAL…………………………………………………………. 36

FUEL TRANSFER PUMP-REMOVAL……………………………………………………………… 36

FUEL LINES,HIGH PRESSURE-REMOVAL………………………………………………………… 37

FUEL INJECTION PUMP SUPPLY LINE-REMOVAL………………………………………………….. 37

AFC TUBE-REMOVAL………………………………………………………………………. 37

TACHOMETER DRIVE-REMOVAL……………………………………………………………….. 38

FUEL INJECTION PUMP-REMOVAL…………………………………………………………….. 38

AIR COMPRESSOR-REMOVAL…………………………………………………………………. 39

FUEL PUMP SOLENOID-REMOVAL……………………………………………………………… 40

ENGINE-INSTALLATION ONTO ENGINE REBUILD STAND…………………………………………….. 40

TURBOCHARGER EXHAUST OUTLET CONNECTION-REMOVAL……………………………………………. 41

WASTEGATE ACTUATOR HOSE-REMOVAL…………………………………………………………. 41

CRANKCASE BREATHER TUBE-REMOVAL…………………………………………………………. 41

AIR CROSSOVER TUBE-REMOVAL……………………………………………………………… 42

INTAKE MANIFOLD COVER-REMOVAL…………………………………………………………… 42

AFTERCOOLER-REMOVAL……………………………………………………………………. 42

FUEL DRAIN MANIFOLD-REMOVAL…………………………………………………………….. 43

INJECTOR-REMOVAL………………………………………………………………………. 43

VALVE COVER-REMOVAL……………………………………………………………………. 43

ROCKER LEVER ASSEMBLY-REMOVAL…………………………………………………………… 44

PUSH ROD-REMOVAL………………………………………………………………………. 44

TURBOCHARGER OIL SUPPLY HOSE-REMOVAL…………………………………………………….. 45

TURBOCHARGER OIL DRAIN TUBE-REMOVAL……………………………………………………… 45

TURBOCHARGER-REMOVAL…………………………………………………………………… 45

EXHAUST MANIFOLD-REMOVAL……………………………………………………………….. 45

DRIVE BELT-REMOVAL…………………………………………………………………….. 46

BELT TENSIONER-REMOVAL…………………………………………………………………. 46

BELT TENSIONER BRACKET-REMOVAL………………………………………………………….. 46

ALTERNATOR BRACE-REMOVAL……………………………………………………………….. 46

ALTERNATOR-REMOVAL…………………………………………………………………….. 47

ALTERNATOR MOUNTING BRACKET-REMOVAL……………………………………………………… 47

COOLANT OUTLET CONNECTION-REMOVAL……………………………………………………….. 47

THERMOSTAT AND HOUSING-REMOVAL………………………………………………………….. 47

COOLANT VENT TUBE-REMOVAL………………………………………………………………. 48

COOLANT VENT PETCOCK-REMOVAL……………………………………………………………. 48

COOLANT VENT TUBE FITTING-REMOVAL……………………………………………………….. 48

CYLINDER HEAD-REMOVAL………………………………………………………………….. 48

LUBRICATING OIL COOLER-REMOVAL………………………………………………………….. 49

COOLANT INLET CONNECTION-REMOVAL………………………………………………………… 49

FAN HUB ASSEMBLY-REMOVAL……………………………………………………………….. 49

WATER PUMP-REMOVAL…………………………………………………………………….. 50

VIBRATION DAMPER-REMOVAL……………………………………………………………….. 50

GEAR COVER-REMOVAL…………………………………………………………………….. 51

SEAL,FRONT CRANKSHAFT-REMOVAL…………………………………………………………… 51

STARTING MOTOR-REMOVAL…………………………………………………………………. 51

COOLANT HEATER-REMOVAL…………………………………………………………………. 51

FLYWHEEL-REMOVAL………………………………………………………………………. 52

FLYWHEEL HOUSING-REMOVAL……………………………………………………………….. 52

LUBRICATING OIL PAN-REMOVAL…………………………………………………………….. 52

LUBRICATING OIL SUCTION TUBE-REMOVAL…………………………………………………….. 52

SEAL,REAR CRANKSHAFT-REMOVAL……………………………………………………………. 53

CAMSHAFT-REMOVAL………………………………………………………………………. 53

VALVE TAPPET-REMOVAL…………………………………………………………………… 54

LUBRICATING OIL PUMP GEAR BACKLASH-MEASUREMENT……………………………………………. 55

LUBRICATING OIL PUMP-REMOVAL……………………………………………………………. 56

ENGINE SUPPORT,FRONT-REMOVAL……………………………………………………………. 56

GEAR HOUSING-REMOVAL…………………………………………………………………… 56

CYLINDER LINER CARBON DEPOSITS-REMOVAL…………………………………………………… 57

PISTON ASSEMBLY-REMOVAL………………………………………………………………… 58

PISTON PIN-REMOVAL…………………………………………………………………….. 59

PISTON RING-REMOVAL……………………………………………………………………. 60

MAIN BEARING CAP-REMOVAL……………………………………………………………….. 60

MAIN BEARING(LOWER)-REMOVAL…………………………………………………………….. 61

CRANKSHAFT-REMOVAL…………………………………………………………………….. 61

MAIN BEARING(UPPER)-REMOVAL…………………………………………………………….. 61

PISTON COOLING NOZZLE-REMOVAL…………………………………………………………… 61

CYLINDER LINER PROTRUSION-CHECKING………………………………………………………. 62

CYLINDER LINER-REMOVAL…………………………………………………………………. 62

EXPANSION PLUG-REPLACEMENT……………………………………………………………… 63

EXPANSION PLUG-REMOVAL…………………………………………………………………. 64

CYLINDER BLOCK-REMOVAL FROM ENGINE REBUILD STAND………………………………………….. 64

ENGINE-ASSEMBLY……………………………………………………………………….. 64

CYLINDER LINER-INSTALLATION…………………………………………………………….. 65

VALVE TAPPET-INSTALLATION………………………………………………………………. 69

PISTON COOLING NOZZLE-INSTALLATION………………………………………………………. 70

MAIN BEARING(UPPER)-INSTALLATION………………………………………………………… 71

CRANKSHAFT-INSTALLATION………………………………………………………………… 72

MAIN BEARING(LOWER)-INSTALLATION………………………………………………………… 73

MAIN BEARING CAP-INSTALLATION…………………………………………………………… 73

SEAL,REAR CRANKSHAFT-INSTALLATION……………………………………………………….. 77

WEAR SLEEVE,REAR CRANKSHAFT SEAL-INSTALLATION…………………………………………….. 78

CONNECTING ROD BOLT-INSTALLATION………………………………………………………… 81

PISTON PIN-INSTALLATION………………………………………………………………… 81

PISTON RING END GAP-MEASUREMENT…………………………………………………………. 82

PISTON RING-INSTALLATION……………………………………………………………….. 83

PISTON ASSEMBLY-INSTALLATION……………………………………………………………. 85

GEAR HOUSING-INSTALLATION………………………………………………………………. 89

LUBRICATING OIL PUMP-INSTALLATION……………………………………………………….. 91

CAMSHAFT-INSTALLATION………………………………………………………………….. 92

WATER PUMP-INSTALLATION………………………………………………………………… 94

LUBRICATING OIL SUCTION TUBE-INSTALLATION………………………………………………… 95

LUBRICATING OIL PAN-INSTALLATION………………………………………………………… 95

TIMING PIN ASSEMBLY-INSTALLATION………………………………………………………… 96

FLYWHEEL HOUSING-INSTALLATION…………………………………………………………… 99

FLYWHEEL-INSTALLATION…………………………………………………………………..104

FLYWHEEL BORE RUNOUT MEASUREMENT…………………………………………………………106

FLYWHEEL FACE RUNOUT MEASUREMENT…………………………………………………………108

STARTING MOTOR-INSTALLATION……………………………………………………………..109

COOLANT HEATER-INSTALLATION……………………………………………………………..109

LUBRICATING OIL COOLER-INSTALLATION………………………………………………………111

LUBRICATING OIL FILTER-INSTALLATION………………………………………………………112

CYLINDER HEAD-INSTALLATION………………………………………………………………112

PUSH ROD-INSTALLATION…………………………………………………………………..116

ROCKER LEVER AND SHAFT-ASSEMBLY………………………………………………………….116

ROCKER LEVER ASSEMBLY-INSTALLATION……………………………………………………….118

VALVE CLEARANCE-ADJUSTMENT………………………………………………………………119

VALVE ARRANGEMENT………………………………………………………………………120

VALVE COVER-INSTALLATION………………………………………………………………..121

INJECTOR-INSTALLATION…………………………………………………………………..122

FUEL DRAIN MANIFOLD-INSTALLATION…………………………………………………………123

ENGINE LIFTING BRACKET-INSTALLATION………………………………………………………123

INTAKE MANIFOLD COVER-INSTALATION………………………………………………………..123

AFTERCOOLER-INSTALLATION………………………………………………………………..124

EXHAUST MANIFOLD-INSTALLATION……………………………………………………………124

TURBOCHARGER-INSTALLATION……………………………………………………………….125

TURBOCHARGER OIL DRAIN TUBE-INSTALLATION………………………………………………….126

TURBOCHARGER OIL SUPPLY HOSE-INSTALLATION…………………………………………………128

TURBOCHARGER EXHAUST OUTLET CONNECTION-INNSTALLATION……………………………………….129

AIR CROSSOVER TUBE-INSTALLATION………………………………………………………….129

THERMOSTAT AND HOUSING-INSTALLATION………………………………………………………129

COOLANT OUTLET CONNECTION-INSTALLATION……………………………………………………130

COOLANT FILTER-INSTALLATION……………………………………………………………..130

COOLANT VENT FITTING-INSTALLATION………………………………………………………..130

COOLANT VENT PETCOCK-INSTALLATION………………………………………………………..130

COOLANT VENT TUBE-INSTALLATION…………………………………………………………..131

COOLANT INLET CONNECTION-INSTALLATION…………………………………………………….131

ALTERNATOR MOUNTING BRACKET-INSTALLATION………………………………………………….131

ALTERNATOR-INSTALLATION…………………………………………………………………131

ALTERNATOR BRACE-INSTALLATION……………………………………………………………132

BELT TENSIONER BRACKET-INSTALLATION………………………………………………………133

BELT TENSIONER-INSTALLATION……………………………………………………………..133

FAN HUB ASSEMBLY-INSTALLATION……………………………………………………………134

FUEL INJECTION PUMP-INSTALLATION…………………………………………………………134

FUEL INJECTION PUMP SUPPLY LINE-INSTALLATION………………………………………………138

FUEL FILTER HEAD-INSTALLATION……………………………………………………………139

FUEL FILTER-INSTALLATION………………………………………………………………..139

FUEL LINES,HIGH PRESSURE-INSTALLATION…………………………………………………….140

AFC TUBE-INSTALLATION…………………………………………………………………..140

SEAL,FRONT CRANKSHAFT-INSTALLATION……………………………………………………….141

GEAR COVER-INSTALLATION…………………………………………………………………144

TACHOMETER DRIVE-INSTALLATION……………………………………………………………145

VIBRATION DAMPER-INSTALLATION……………………………………………………………145

DRIVE BELT-INSTALLATION…………………………………………………………………146

ENGINE SUPPORT,FRONT-INSTALLATION………………………………………………………..146

FUEL TRANSFER PUMP-INSTALLATION………………………………………………………….146

FUEL LINES,LOW PRESSURE-INSTALLATION……………………………………………………..147

FUEL PUMP SOLENOLD-INSTALLATION………………………………………………………….147

AIR COMPRESSOR-INSTALLATION……………………………………………………………..147

ENGINE ACCESSORIES-INSTALLATION………………………………………………………….149

CYLINDER BLOCK-GROUP 01…………………………………………………………………….150

CYLINDER BLOCK-SERVICE TOOLS…………………………………………………………….152

CYLINDER BLOCK-EXPLODED VIEW…………………………………………………………….155

CYLINDER BLOCK-GENERAL INFORMATION……………………………………………………….157

CAMSHAFT…………………………………………………………………………..157

CRANKSHAFT…………………………………………………………………………157

CYLINDER BLOCK……………………………………………………………………..157

CYLINDER LINER……………………………………………………………………..157

OIL SEALS………………………………………………………………………….157

PISTONS……………………………………………………………………………157

VIBRATION DAMPER……………………………………………………………………157

CONNECTING RODS…………………………………………………………………….157

CYLINDER BLOCK-PREPARATION FOR CLEANING…………………………………………………..158

CYLINDER BLOCK-DISASSEMBLY………………………………………………………………158

DOWEL PINS(CYLINDER HEAD)-REMOVAL………………………………………………………..159

CYLINDER BLOCK-CLEANING WITH SOLVENT……………………………………………………..160

CYLINDER BLOCK-CLEANING IN A HOT TANK…………………………………………………….163

CYLINDER BLOCK-INSPECTION FOR REUSE………………………………………………………164

EXPANSION PLUG-INSTALLATION……………………………………………………………..167

PIPE PLUG-INSTALLATION………………………………………………………………168

CAMSHAFT BORE EXPANSION PLUG INSTALLATION…………………………………………………169

CAMSHAFT BUSHING-REMOVAL………………………………………………………………..170

CAMSHAFT BUSHING BORE-CLEANING…………………………………………………………..171

CAMSHAFT BUSHING-INSTALLATION……………………………………………………………171

CYLINDER LINERS-CLEANING AND INSPECTION FOR REUSE………………………………………….172

CYLINDER LINERS-CLEANING…………………………………………………………….172

CYLINDER LINERS-INSPECTION…………………………………………………………..173

PISTONS-CLEANING AND INSPECTION FOR REUSE…………………………………………………175

PISTON RINGS-REMOVAL………………………………………………………………..175

PISTONS-CLEANING……………………………………………………………………175

PISTON-INSPECTION…………………………………………………………………..176

CRANKSHAFT-CLEANING AND INSPECTION FOR REUSE………………………………………………178

CRANKSHAFT-CLEANING…………………………………………………………………178

CRANKSHAFT-INSPECTION……………………………………………………………….179

CRANKSHAFT GEAR-REPLACEMENT……………………………………………………………..182

GENERAL INFORMATION…………………………………………………………………182

CRANKSHAFT GEAR-REMOVAL……………………………………………………………..182

CRANKSHAFT GEAR-INSPECTION…………………………………………………………..183

CRANKSHAFT GEAR-INSTALLATION…………………………………………………………184

MAIN BEARINGS-CLEANING AND INSPECTION FOR REUSE……………………………………………185

GENERAL INFORMATION…………………………………………………………………185

MAIN BEARINGS-CLEANING………………………………………………………………186

MAIN BEARINGS-INSPECTION…………………………………………………………….186

THRUST BEARINGS-INSPECTION…………………………………………………………..187

MAIN BEARING CAPS AND CAPSCREWS-CLEANING AND INSPECTION FOR REUSE……………………………187

CLEANING…………………………………………………………………………..187

INSPECTION…………………………………………………………………………188

CONNECTING ROD BEARINGS-CLEANING AND INSPECTION FOR REUSE…………………………………..188

CONNECTING ROD BEARINGS-CLEANING……………………………………………………..188

CONNECTING ROD BEARINGS-INSPECTION……………………………………………………188

CONNECTING RODS-CLEANING AND INSPECTION FOR REUSE………………………………………….189

CONNECTING RODS-CLEANING…………………………………………………………….189

CONNECTING RODS-INSPECTION…………………………………………………………..190

CONNECTING RODS-BEND AND TWIST INSPECTION…………………………………………………192

FIXTURE CALIBRATION…………………………………………………………………192

CONNECTING ROD ALIGNMENT-INSPECTION…………………………………………………..193

CONNECTING ROD TWIST-INSPECTION………………………………………………………193

CONNECTING ROD BUSHING-REPLACEMENT……………………………………………………….194

REMOVAL……………………………………………………………………………194

INSTALLATION……………………………………………………………………….196

MACHINING………………………………………………………………………….198

INSPECTION…………………………………………………………………………198

CAMSHAFT-CLEANING AND INSPECTION FOR REUSE………………………………………………..199

CAMSHAFT-CLEANING…………………………………………………………………..199

CAMSHAFT-INSPECTION…………………………………………………………………199

CAMSHAFT GEAR-INSPECTION…………………………………………………………….202

CAMSHAFT GEAR-REPLACEMENT……………………………………………………………….203

CAMSHAFT GEAR-REMOVAL……………………………………………………………….203

CAMSHAFT GEAR-CLEANING………………………………………………………………203

CAMSHAFT GEAR-INSPECTION…………………………………………………………….203

CAMSHAFT GEAR-INSTALLATION…………………………………………………………..205

GEAR HOUSING-CLEANING AND INSPECTION FOR REUSE…………………………………………….206

GEAR HOUSING-CLEANING……………………………………………………………….206

GEAR HOUSING-INSPECTION……………………………………………………………..206

ENGINE DATAPLATE-REPLACEMENT…………………………………………………………….208

ENGINE DATAPLATE-REMOVAL…………………………………………………………….208

ENGINE DATAPLATE-INSTALLATION………………………………………………………..208

GEAR COVER-CLEANING AND INSPECTION FOR REUSE………………………………………………209

GEAR COVER-CLEANING…………………………………………………………………209

GEAR COVER-INSPECTION……………………………………………………………….209

VIBRATION DAMPER-CLEANING AND CHECKING FOR REUSE…………………………………………..210

GENERAL INFORMATION…………………………………………………………………210

RUBBER VIBRATION DAMPER-CLEANING……………………………………………………..210

RUBBER ELEMENT VIBRATION DAMPER-INSPECTION…………………………………………….210

VISCOUS VIBRATION DAMPER-CLEANING…………………………………………………….211

VISCOUS VIBRATION DAMPER-INSPECTION…………………………………………………..211

REAR COVER-CLEANING AND INSPECTION……………………………………………………….212

CLEANING…………………………………………………………………………..212

INSPECTION…………………………………………………………………………213

CYLINDER HEAD CAPSCREWS-CLEANING AND INSPECTION FOR REUSE…………………………………..213

CLEANING…………………………………………………………………………..213

INSPECTION…………………………………………………………………………214

FREE LENGTH-MEASUREMENT……………………………………………………………..215

ENGINE LIFTING BRACKETS-CLEANING AND INSPECTION FOR REUSE…………………………………..215

CYLINDER HEAD-GROUP 02……………………………………………………………………..216

CYLINDER HEAD-SERVICE TOOLS……………………………………………………………..217

CYLINDER HEAD-EXPLODED VIEW……………………………………………………………..221

CYLINDER HEAD-GENERAL INFORMATION………………………………………………………..223

CYLINDER HEAD-CLEANING AND INSPECTION FOR REUSE……………………………………………224

HANDLING…………………………………………………………………………..224

CLEANING…………………………………………………………………………..224

INSPECTION…………………………………………………………………………225

CYLINDER HEAD-REBUILD…………………………………………………………………..226

DISASSEMBLY………………………………………………………………………..226

CLEANING…………………………………………………………………………..227

INSPECTION…………………………………………………………………………228

VALVE GUIDE-INSPECTION………………………………………………………………232

VALVE SEAT INSERT-INSPECTION…………………………………………………………233

VALVE SPRING-INSPECTION……………………………………………………………..234

VALVE STEM SEAL-INSPECTION…………………………………………………………..235

VALVE-INSPECTION……………………………………………………………………236

VALVE-GRINDING……………………………………………………………………..237

VALVE SEAT INSERT-GRINDING…………………………………………………………..238

ASSEMBLY…………………………………………………………………………..242

CYLINDER HEAD-VALVE GUIDE REPLACEMENT…………………………………………………….244

DISASSEMBLY………………………………………………………………………..244

INSPECTION…………………………………………………………………………245

ASSEMBLY…………………………………………………………………………..245

CYLINDER HEAD-VALVE SEAT INSERT REPLACEMENT……………………………………………….247

REMOVAL……………………………………………………………………………247

INSPECTION…………………………………………………………………………249

INSTALLATION……………………………………………………………………….249

CYLINDER HEAD-PRESSURE TESTING…………………………………………………………..250

CYLINDER HEAD-VACUUM TESTING VALVE SEATING………………………………………………..252

CYLINDER HEAD CAPSCREW-CLEANING AND INSPECTION…………………………………………….253

CLEANING…………………………………………………………………………..254

INSPECTION…………………………………………………………………………254

FREE LENGTH-MEASUREMENT…………………………………………………………………255

ROCKER LEVERS-GROUP 03……………………………………………………………………..256

ROCKER LEVER ASSEMBLY-EXPLODED VIEW………………………………………………………257

ROCKER LEVER ASSEMBLY-GENERAL INFORMATION…………………………………………………258

ROCKER LEVER ASSEMBLY-CLEANING AND INSPECTION……………………………………………..259

DISASSEMBLY………………………………………………………………………..259

CLEANING…………………………………………………………………………..260

INSPECTION…………………………………………………………………………260

ASSEMBLY…………………………………………………………………………..261

ROCKER ASSEMBLY OIL MANIFOLD-CLEANING AND INSPECTION FOR REUSE………………………………262

CLEANING…………………………………………………………………………..262

INSPECTION…………………………………………………………………………262

VALVE COVER-CLEANING AND INSPECTION FOR REUSE……………………………………………..263

CLEANING…………………………………………………………………………..263

INSPECTION…………………………………………………………………………263

CRANKCASE BREATHER TUBE-CLEANING AND INSPECTION FOR REUSE…………………………………..263

CLEANING AND INSPECTION……………………………………………………………..263

VALVE TAPPETS AND PUSH RODS-GROUP 04…………………………………………………………264

VALVE TAPPETS AND PUSH RODS-EXPLODED VIEW…………………………………………………265

VALVE TAPPETS AND PUSH RODS-GENERAL INFORMATION……………………………………………266

VALVE TAPPET CLEANING AND INSPECTION FOR REUSE…………………………………………….266

CLEANING…………………………………………………………………………..266

INSPECTION…………………………………………………………………………266

PUSH RODS-CLEANING AND INSPECTION FOR REUSE……………………………………………….267

CLEANING…………………………………………………………………………..267

INSPECTION…………………………………………………………………………267

FUEL SYSTEMS-GROUP 05………………………………………………………………………269

FUEL SYSTEM-GENERAL INFORMATION………………………………………………………….270

FUEL INJECTION PUMP…………………………………………………………………270

FUEL INJECTION PUMP-DATA TAG LOCATION…………………………………………………270

FUEL INJECTION PUMP-DATA TAG INFORMATION………………………………………………270

GOVERNOR-DATA TAG INFORMATION ……………………………………………………….271

DERIVATIVE FUEL INJECTION PUMP-DATA TAG INFORMATION…………………………………….271

FUEL SHUTOFF SOLENOID-WIRING REQUIREMENTS……………………………………………..271

FUEL TRANSFER PUMP-EXPLODED VIEW…………………………………………………………272

FUEL TRANSFER PUMP-REBUILD………………………………………………………………273

CLEANING…………………………………………………………………………..273

ASSEMBLY…………………………………………………………………………..273

RSV GOVERNOR FUEL SHUTOFF SOLENOID-ORIENTATION AND ADJUSTMENT……………………………….274

FUEL SHUTOFF SOLENOID-ORIENTATION…………………………………………………….274

FUEL SHUTOFF SOLENOID-ADJUSTMENT……………………………………………………..276

RQVK GOVERNOR FUEL SHUTOFF SOLENOID-ADJUSTMENT…………………………………………….277

SHUTDOWN LEVER OR SPRING-REPLACEMENT……………………………………………………..278

DIRECT LINK SHUTDOWN LEVER-REPLACEMENT……………………………………………………279

FUEL INJECTION PUMP GASKETS AND SEALS-REPLACEMENT………………………………………….280

INJECTORS AND FUEL LINES-GROUP 06……………………………………………………………281

INJECTORS AND FUEL LINES-SERVICE TOOLS……………………………………………………282

INJECTORS AND FUEL LINES-EXPLODED VIEW……………………………………………………283

INJECTORS AND FUEL LINES-EXPLODED VIEW……………………………………………………285

INJECTORS AND FUEL LINES-EXPLODED VIEW……………………………………………………286

INJECTORS AND FUEL LINES-GENERAL INFORMATION………………………………………………287

INJECTORS-CLEANING AND INSPECTION FOR REUSE……………………………………………….288

GENERAL INFORMATION…………………………………………………………………288

INJECTOR-DISASSEMBLY………………………………………………………………..288

INJECTOR-CLEANING AND INSPECTION……………………………………………………..290

INJECTOR-ASSEMBLY…………………………………………………………………..292

INJECTOR-SPRAY TESTING………………………………………………………………….293

INJECTOR-CHATTER TESTING………………………………………………………………..294

FUEL LINES,HIGH PRESSURE-CLEANING AND INSPECTION FOR REUSE………………………………….294

GENERAL INFORMATION…………………………………………………………………294

FUEL LINES-CLEANING AND INSPECTION……………………………………………………295

FUEL DRAIN MANIFOLD-INSPECTION…………………………………………………………..296

FUEL LINES,LOW PRESSURE-CLEANING AND INSPECTION FOR REUSE…………………………………..296

LUBRICATING OIL SYSTEM-GROUP 07……………………………………………………………..298

LUBRICATING OIL SYSTEM-SERVICE TOOLS……………………………………………………..299

LUBRICATING OIL SYSTEM-GENERAL INFORMATION………………………………………………..300

LUBRICATING OIL COOLER AND FILTER HEAD………………………………………………..300

OIL PRESSURE REGULATOR………………………………………………………………300

OIL FILTER HEAD…………………………………………………………………….300

OIL TEMPERATURE THERMOSTAT…………………………………………………………..300

LUBRICATING OIL PUMP………………………………………………………………..300

DIPSTICK…………………………………………………………………………..300

OIL PAN……………………………………………………………………………300

LUBRICATING OIL SYSTEM-EXPLODED VIEW……………………………………………………..301

LUBRICATING OIL PAN-CLEANING AND INSPECTION FOR REUSE………………………………………302

CLEANING…………………………………………………………………………..302

INSPECTION…………………………………………………………………………302

OIL COOLER ELEMENT-CLEANING AND INSPECTION FOR REUSE……………………………………….303

CLEANING…………………………………………………………………………..303

INSPECTION…………………………………………………………………………303

PRESSURE TEST………………………………………………………………………303

OIL PRESSURE REGULATING VALVE-CLEANING AND INSPECTION………………………………………304

DISASSEMBLY………………………………………………………………………..304

CLEANING…………………………………………………………………………..305

INSPECTION…………………………………………………………………………305

ASSEMBLY…………………………………………………………………………..305

OIL FILTER BYPASS VALVE-REPLACEMENT………………………………………………………306

OIL COOLER COVER-DISASSEMBLY AND ASSEMBLY…………………………………………………307

DISASSEMBLY………………………………………………………………………..307

CLEANING…………………………………………………………………………..307

ASSEMBLY…………………………………………………………………………..308

LUBRICATING OIL TEMPERATURE THERMOSTAT-CLEANING AND INSPECTION………………………………309

CLEANING…………………………………………………………………………..309

INSPECTION…………………………………………………………………………309

LUBRICATING OIL DIPSTICK-CALIBRATION……………………………………………………..310

LUBRICATING OIL PUMP-CLEANING AND INSPECTION FOR REUSE……………………………………..311

DISASSEMBLY………………………………………………………………………..311

CLEANING…………………………………………………………………………..312

INSPECTION…………………………………………………………………………312

COOLING SYSTEM-GROUP 08…………………………………………………………………….315

COOLING SYSTEM-SERVICE TOOLS…………………………………………………………….316

COOLING SYSTEM COMPONENTS-EXPLODED VIEW…………………………………………………..317

COOLING SYSTEM-GENERAL INFORMATION……………………………………………………….318

WATER PUMP…………………………………………………………………………318

THERMOSTATS………………………………………………………………………..318

PRESSURE CAPS………………………………………………………………………318

FAN HUB……………………………………………………………………………318

BELT TENSIONER……………………………………………………………………..318

COOLING FANS……………………………………………………………………….318

WATER PUMP ASSEMBLY-CLEANING AND INSPECTION FOR REUSE………………………………………320

CLEANING…………………………………………………………………………..320

INSPECTION…………………………………………………………………………320

THERMOSTAT HOUSING-CLEANING AND INSPECTION FOR REUSE……………………………………….321

CLEANING…………………………………………………………………………..321

INSPECTION…………………………………………………………………………321

THERMOSTAT-INSPECTION…………………………………………………………………..321

WATER OUTLET CONNECTION-CLEANING AND INSPECTION FOR REUSE…………………………………..322

FAN HUB-CLEANING AND INSPECTION FOR REUSE…………………………………………………322

CLEANING…………………………………………………………………………..322

INSPECTION…………………………………………………………………………323

FAN HUB-REBUILD………………………………………………………………………..323

DISASSEMBLY………………………………………………………………………..323

ASSEMBLY…………………………………………………………………………..324

BELT TENSIONER INSPECTION……………………………………………………………….325

COOLANT FILTER SHUTOFF VALVE-CLEANING AND INSPECTION FOR REUSE………………………………325

DISASSEMBLY………………………………………………………………………..325

CLEANING…………………………………………………………………………..326

ASSEMBLY…………………………………………………………………………..326

FAN-CLEANING AND INSPECTION FOR REUSE…………………………………………………….327

DRIVE UNITS-GROUP 09……………………………………………………………………….328

DRIVE UNITS-SERVICE TOOLS……………………………………………………………….329

ACCESSORY DRIVE ADAPTER-EXPLODED VIEW…………………………………………………….330

ACCESSORY DRIVE-GENERAL INFORMATION………………………………………………………331

ACCESSORY DRIVE ADAPTER……………………………………………………………..331

ACCESSORY DRIVE ADAPTER-CLEANING AND INSPECTION FOR REUSE…………………………………..332

CLEANING…………………………………………………………………………..332

INSPECTION…………………………………………………………………………332

ACCESSORY DRIVE ADAPTER-REBUILD………………………………………………………….332

DISASSEMBLY………………………………………………………………………..332

ASSEMBLY…………………………………………………………………………..333

AIR INTAKE SYSTEM-GROUP 10………………………………………………………………….335

AIR INTAKE SYSTEM-SERVICE TOOLS………………………………………………………….336

AIR INTAKE SYSTEM-EXPLODED VIEW………………………………………………………….337

AIR INTAKE SYSTEM-GENERAL INFORMATION…………………………………………………….339

TURBOCHARGER-CLEANING AND INSPECTION FOR REUSE…………………………………………….340

INSPECTION…………………………………………………………………………340

INTAKE MANIFOLD COVER-CLEANING AND INSPECTION FOR REUSE…………………………………….344

INSPECTION…………………………………………………………………………344

AFTERCOOLER ASSEMBLY-CLEANING AND INSPECTION FOR REUSE……………………………………..344

INSPECTION…………………………………………………………………………345

AFTERCOOLER ASSEMBLY-REBUILD…………………………………………………………….345

AIR TRANSFER PIPE-CLEANING AND INSPECTION FOR REUSE………………………………………..346

CLEANING…………………………………………………………………………..346

INSPECTION…………………………………………………………………………346

AIR CROSSOVER TUBE-CLEANING AND INSPECTION FOR REUSE……………………………………….346

CLEANING…………………………………………………………………………..346

INSPECTION…………………………………………………………………………346

CHARGE AIR COOLER(CAC)-CLEANING AND INSPECTION FOR REUSE……………………………………347

CLEANING…………………………………………………………………………..347

INSPECTION…………………………………………………………………………347

CHARGE AIR COOLER(CAC)-PRESSURE TESTING…………………………………………………..348

EXHAUST SYSTEM-GROUP 11…………………………………………………………………….350

EXHAUST MANIFOLD-EXPLODED VIEW…………………………………………………………..351

EXHAUST SYSTEM-GENERAL INFORMATION……………………………………………………….352

EXHAUST MANIFOLD……………………………………………………………………352

EXHAUST MANIFOLD-CLEANING AND INSPECTION FOR REUSE…………………………………………353

CLEANING…………………………………………………………………………..353

INSPECTION…………………………………………………………………………353

EXHAUST MANIFOLD TURBOCHARGER MOUNTING STUD-REPLACEMENT…………………………………….354

REMOVAL……………………………………………………………………………354

INSPECTION…………………………………………………………………………354

INSTALLATION……………………………………………………………………….354

EXHAUST MANIFOLD OUTLET CONNECTION-CLEANING AND INSPECTION FOR REUSE…………………………355

CLEANING…………………………………………………………………………..355

INSPECTION…………………………………………………………………………355

AIR EQUIPMENT-GROUP 12……………………………………………………………………..356

ELECTRICAL EQUIPMENT-GROUP 13……………………………………………………………….357

ENGINE TESTING-GROUP 14…………………………………………………………………….358

ENGINE TESTING-SERVICE TOOLS…………………………………………………………….359

ENGINE TESTING-COMPONENT IDENTIFICATION AND DIAGRAMS……………………………………….360

ENGINE TESTING-GENERAL INFORMATION……………………………………………………….362

IN-CHASSIS RUN-IN…………………………………………………………………..362

ENGINE DYNAMOMETER RUN-IN……………………………………………………………362

ENGINE TESTING-GENERAL SPECIFICATIONS…………………………………………………….363

BLOWBY MEASUREMENT……………………………………………………………………..364

ENGINE RUN-IN-GENERAL PROCEDURES…………………………………………………………365

ENGINE DYNAMOMETER TEST-INSTALLATION OF THE ENGINE…………………………………………366

ENGINE DYNAMOMETER TEST-ENGINE RUN-IN…………………………………………………….374

ENGINE DYNAMOMETER TEST-PERFORMANCE CHECKING………………………………………………378

GENERAL ENGINE TEST PROCEDURE-IN CHASSIS………………………………………………….380

ENGINE RUN-IN PROCEDURE-“IN-CHASSIS”……………………………………………………..385

FUEL INJECTION PUMP-IDLE SPEED ADJUSTMENT…………………………………………………386

RSV GOVERNOR……………………………………………………………………….386

RQV AND RQVK GOVERNOR……………………………………………………………….387

ENGINE PAINTING………………………………………………………………………..387

ENGINE STORAGE-SHORT TERM……………………………………………………………….388

ENGINE REMOVAL FROM SHORT TERM STORAGE………………………………………………..390

ENGINE STORAGE-LONG TERM………………………………………………………………..390

ENGINE REMOVAL FROM TERM STORAGE……………………………………………………..393

INSTRUMENTS AND CONTROLS-GROUP 15……………………………………………………………397

MOUNTING ADAPTATIONS-GROUP 16……………………………………………………………….398

MOUNTING ADAPTATIONS-SERVICE TOOLS……………………………………………………….399

MOUNTING ADAPTATIONS-EXPLODED VIEW……………………………………………………….400

MOUNTING ADAPTATIONS-GENERAL INFORMATION………………………………………………….401

FLYWHEEL HOUSING……………………………………………………………………401

FLYWHEEL AND RING GEAR………………………………………………………………401

FLYWHEEL-CLEANING AND INSPECTION FOR REUSE………………………………………………..402

CLEANING…………………………………………………………………………..402

INSPECTION…………………………………………………………………………402

FLEXPLATE ASSEMBLY-CLEANING AND INSPECTION FOR REUSE……………………………………….403

FLYWHEEL RING GEAR-REPLACEMENT…………………………………………………………..403

REMOVAL……………………………………………………………………………403

INSTALLATION……………………………………………………………………….403

FLYWHEEL HOUSING-CLEANING AND INSPECTION FOR REUSE…………………………………………404

CLEANING…………………………………………………………………………..404

INSPECTION…………………………………………………………………………404

FLYWHEEL HOUSING-ASSEMBLY(WET CLUTCH APPLICATION)………………………………………….405

ENGINE SUPPORT BRACKET,FRONT-CLEANING AND INSPECTION FOR REUSE………………………………406

CLEANING…………………………………………………………………………..406

INSPECTION…………………………………………………………………………406

SPECIFICATIONS AND TORQUE VALUES-GROUP 18…………………………………………………….407

ENGINE COMPONENTS-GENERAL INFORMATION…………………………………………………….408

COMPONENT SPECIFICATIONS AND TORQUE VALUES………………………………………………..409

ENGINE ASSEMBLY-SPECIFICATIONS……………………………………………………….409

ENGINE ASSEMBLY-TORQUE VALUES………………………………………………………..411

CYLINDER BLOCK-REBUILD SPECIFICATIONS…………………………………………………421

CYLINDER BLOCK-TORQUE VALUES…………………………………………………………427

CYLINDER HEAD-REBUILD SPECIFICATIONS………………………………………………….428

ROCKER LEVER ASSEMBLY-REBUILD SPECIFICATIONS………………………………………………432

VALVE TAPPET-REBUILD SPECIFICATIONS………………………………………………………432

FUEL SYSTEMS-REBUILD SPECIFICATIONS………………………………………………………432

FUEL SYSTEM SPECIFICATIONS…………………………………………………………..432

FUEL SHUTOFF SOLENOID ADJUSTMENT……………………………………………………..434

FUEL SYSTEM TORQUE VALUES……………………………………………………………434

FUEL INJECTION PUMP SEALING WASHER……………………………………………………434

LUBRICATING OIL SYSTEM SPECIFICATIONS…………………………………………………….437

LUBRICATING OIL SYSTEM TORQUE VALUES……………………………………………………..438

COOLING SYSTEM SPECIFICATIONS……………………………………………………………440

COOLING SYSTEM TORQUE VALUES…………………………………………………………441

AIR INTAKE SYSTEM SPECIFICATIONS……………………………………………………..442

AIR INTAKE SYSTEM TORQUE VALUES………………………………………………………442

EXHAUST SYSTEM SPECIFICATIONS……………………………………………………………444

EXHAUST SYSTEM TORQUE VALUES…………………………………………………………….444

AIR COMPRESSOR INSPECTION SPECIFICATIONS………………………………………………….444

AIR COMPRESSOR TORQUE VALUES…………………………………………………………….444

ELECTRICAL SYSTEM SPECIFICATIONS…………………………………………………………445

ELECTRICAL SYSTEM TORQUE VALUES………………………………………………………….445

ENGINE TESTING-TEST SPECIFICATIONS……………………………………………………….446

MOUNTING ADAPTATIONS SPECIFICATIONS………………………………………………………446

FLYWHEEL HOUSING(WET APPLICATION)…………………………………………………….446

FLYWHEEL RING GEAR INSTALLATION………………………………………………………447

MOUNTING ADAPTATIONS-TORQUE VALUES……………………………………………………….447

DRIVE BELT TENSION……………………………………………………………………..448

WEIGHT AND MEASURES-CONVERSION FACTORS……………………………………………………450

NEWTON-METER TO FOOT-POUND CONVERSION CHART……………………………………………….451

CAPSCREW MARKINGS AND TORQUE VALUES………………………………………………………452

CAPSCREW MARKINGS AND TORQUE VALUES-METRIC…………………………………………….453

CAPSCREW MARKINGS AND TORQUE VALUES-U.S. CUSTOMARY……………………………………..453

PIPE PLUG TORQUE VALUES…………………………………………………………………454

TAP-DRILL CHART-U.S. CUSTOMARY & METRIC…………………………………………………..455

INDEX…………………………………………………………………………………….456

COVER…………………………………………………………………………………….460

CONTENTS………………………………………………………………………………….461

PRODUCT PUBLICATIONS INFORMATION…………………………………………………………….462

TROUBLESHOOTING AND REPAIR MANUAL……………………………………………………………464

FOREWORD………………………………………………………………………………….465

TABLE OF CONTENTS………………………………………………………………………….466

INTRODUCTION………………………………………………………………………………467

ABOUT THE MANUAL……………………………………………………………………….468

HOW TO USE THIS MANUAL………………………………………………………………….468

TABLE OF CONTENTS…………………………………………………………………..468

INDEX……………………………………………………………………………..468

METRIC INFORMATION………………………………………………………………….468

GENERIC SYMBOLS………………………………………………………………………..469

ILLUSTRATIONS………………………………………………………………………….470

GENERAL SAFETY INSTRUCTIONS……………………………………………………………..471

GENERAL REPAIR INSTRUCTIONS……………………………………………………………..472

GENERAL CLEANING INSTRUCTIONS……………………………………………………………473

SOLVENT AND ACID CLEANING……………………………………………………………473

STEAM CLEANING……………………………………………………………………..473

GLASS OR PLASTIC BEAD CLEANING……………………………………………………….473

GLOSSARY OF TERMS………………………………………………………………………475

ENGINE AND COMPONENT IDENTIFICATION………………………………………………………….477

ENGINE IDENTIFICATION…………………………………………………………………..478

ENGINE DATAPLATES…………………………………………………………………..478

FUEL INJECTION PUMP DATAPLATE………………………………………………………..479

GENERAL ENGINE SPECIFICATIONS……………………………………………………………480

GENERAL ENGINE DATA…………………………………………………………………480

LUBRICATION SYSTEM………………………………………………………………….480

COOLING SYSTEM……………………………………………………………………..481

INTAKE AIR AND EXHAUST SYSTEM………………………………………………………..481

FUEL SYSTEM………………………………………………………………………..481

ELECTRICAL SYSTEM…………………………………………………………………..482

BATTERIES(SPECIFIC GRAVITY)………………………………………………………….482

ENGINE DIAGRAMS………………………………………………………………………..483

TROUBLESHOOTING LOGIC………………………………………………………………………486

SECTION T-TROUBLESHOOTING……………………………………………………………….487

PROCEDURES AND TECHNIQUES……………………………………………………………487

TROUBLESHOOTING SYMPTOMS CHARTS………………………………………………………….487

AIR COMPRESSOR OPERATES WITH EXCESSIVE NOISE…………………………………………..488

AIR COMPRESSOR PUMPING EXCESSIVE LUBRICATING OIL INTO AIR SYSTEM…………………………489

AIR COMPRESSOR AIR PRESSURE RISES SLOWLY………………………………………………490

AIR COMPRESSOR WILL NOT MAINTAIN ADEQUATE AIR PRESSURE(NOT PUMPING CONTINUOUSLY)…………..491

AIR COMPRESSOR WILL NOT PUMP AIR PRESSURE……………………………………………..492

AIR COMPRESSOR WILL NOT STOP PUMPING AIR………………………………………………493

ALTERNATOR NOT CHARGING OR INSUFFICIENT CHARGING……………………………………….494

COMPRESSION KNOCK…………………………………………………………………..495

COOLANT CONTAMINATED………………………………………………………………..496

COOLANT LOSS……………………………………………………………………….497

COOLANT TEMPERATURE ABOVE NORMAL-GRADUAL OVERHEAT………………………………………499

COOLANT TEMPERATURE ABOVE NORMAL-SUDDEN OVERHEAT……………………………………….502

COOLANT TEMPERATURE BELOW NORMAL……………………………………………………..504

ENGINE CRANKCASE GASES(BLOWBY)-EXCESSIVE………………………………………………505

ENGINE CRANKS,BUT WILL NOT START-NO SMOKE FROM EXHAUST………………………………….506

ENGINE DIFFICULT TO START OR WILL NOT START-EXHAUST SMOKE PRESENT………………………..509

ENGINE IDLE ROUGH,WARM ENGINE………………………………………………………..511

ENGINE MISFIRING……………………………………………………………………513

ENGINE POWER OUTPUT LOW……………………………………………………………..515

ENGINE NOISE EXCESSIVE………………………………………………………………519

ENGINE STARTS BUT WILL NOT KEEP RUNNING……………………………………………….520

ENGINE SURGES AT IDLE……………………………………………………………….521

ENGINE VIBRATION EXCESSIVE…………………………………………………………..522

ENGINE WILL NOT CRANK OR CRANKS SLOWLY………………………………………………..523

ENGINE WILL NOT REACH RATED SPEED WHEN LOADED………………………………………….524

ENGINE WILL NOT SHUT OFF…………………………………………………………….526

EXHAUST BLACK SMOKE EXCESSIVE UNDER LOAD………………………………………………527

EXHAUST WHITE SMOKE EXCESSIVE(WARM ENGINE)…………………………………………….529

FUEL CONSUMPTION EXCESSIVE…………………………………………………………..530

FUEL OR OIL LEAKING FROM EXHAUST MANIFOLD……………………………………………..531

LUBRICATING OIL CONTAMINATED…………………………………………………………532

LUBRICATING OIL CONSUMPTION EXCESSIVE…………………………………………………533

LUBRICATING OIL PRESSURE LOW…………………………………………………………535

LUBRICATING OIL PRESSURE HIGH………………………………………………………..537

ENGINE NOISE DIAGNOSTIC PROCEDURES-GENERAL INFORMATION………………………………….538

MAIN BEARING NOISE(REFER TO ENGINE NOISE EXCESSIVE-MAIN BEARING SYSTEM CHART)……………..538

CONNECTING ROD BEARING NOISE(REFER TO ENGINE NOISE EXCESSIVE-CONNECTING ROD SYMPTOM CHART)….538

PISTON NOISE(REFER TO ENGINE NOISE EXCESSIVE-PISTON SYMPTOM CHART)……………………….538

FUEL CONSUMPTION-GENERAL INFORMATION………………………………………………….538

FUEL CONSUMPTION-INDUSTRIAL CUSTOMER COMPLAINT FORM…………………………………….539

OIL CONSUMPTION…………………………………………………………………….540

COOLING SYSTEM…………………………………………………………………………….542

COOLING SYSTEM-GENERAL INFORMATION……………………………………………………….543

COOLING SYSTEM-FLOW DIAGRAMS…………………………………………………………….544

COOLING SYSTEM-SPECIFICATIONS……………………………………………………………546

COOLING SYSTEM-SERVICE TOOLS…………………………………………………………….547

COOLING SYSTEM-MAINTENANCE………………………………………………………………548

ANTIFREEZE…………………………………………………………………………548

ANTIFREEZE CONCENTRATION-CHECKING…………………………………………………….548

COOLING SYSTEM-DRAINING……………………………………………………………..548

ADDITIVE CONCENTRATION-CHECKING………………………………………………………548

COOLING SYSTEM-CLEANING……………………………………………………………..549

FILLING AND VENTING…………………………………………………………………553

COOLING SYSTEM-DIAGNOSING MALFUNCTIONS……………………………………………………554

RADIATOR CAP-PRESSURE TEST…………………………………………………………..555

COOLING SYSTEM-TEST FOR COMBUSTION GASES………………………………………………555

BELT TENSION……………………………………………………………………….559

COOLANT HOSE-INSPECTION……………………………………………………………..560

WATER PUMP-INSPECTION……………………………………………………………….560

WATER PUMP SEAL WEEP HOLE-INSPECTION………………………………………………….560

COOLANT PRESSURE-MEASUREMENT…………………………………………………………562

RADIATOR,FAN AND SHUTTERS……………………………………………………………562

THERMOSTAT OPERATION AND TESTING……………………………………………………..564

THERMOSTAT LEAKAGE AND OPENING TEMPERATURE-TESTING”IN-CHASSIS”…………………………..565

THERMOSTAT OPENING TEMPERATURE-TESTING”THERMOSTAT REMOVED”………………………………566

TEMPERATURE GAUGE OPERATION………………………………………………………….567

FUEL PUMP OVERFUELED………………………………………………………………..567

VEHICLE OVERLOADED………………………………………………………………….568

DRIVE BELT-REPLACEMENT………………………………………………………………….568

BELT TENSIONER-REPLACEMENT………………………………………………………………568

REMOVAL……………………………………………………………………………568

INSTALLATION……………………………………………………………………….569

FAN PULLEY-REPLACEMENT………………………………………………………………….569

REMOVAL AND INSTALLATION…………………………………………………………….569

FAN HUB-REPLACEMENT…………………………………………………………………….569

REMOVAL AND INSTALLATION…………………………………………………………….570

WATER PUMP-REPLACEMENT………………………………………………………………….570

REMOVAL……………………………………………………………………………570

CLEANING…………………………………………………………………………..571

INSTALLATION……………………………………………………………………….571

THERMOSTAT-REPLACEMENT………………………………………………………………….573

REMOVAL……………………………………………………………………………573

CLEANING…………………………………………………………………………..574

INSTALLATION……………………………………………………………………….574

LUBRICATING OIL SYSTEM……………………………………………………………………..577

LUBRICATING OIL SYSTEM-SERVICE TOOLS……………………………………………………..579

LUBRICATING OIL SYSTEM-GENERAL INFORMATION………………………………………………..580

LUBRICATING OIL SYSTEM-SPECIFICATIONS…………………………………………………….581

LUBRICATING OIL SYSTEM-FLOW DIAGRAM………………………………………………………582

LUBRICATING OIL LEAKS(EXTERNAL)-CHECKING………………………………………………….586

INTERNAL ENGINE DAMAGE-CHECKING………………………………………………………….587

LUBRICATING OIL ANALYSIS…………………………………………………………….587

LUBRICATING OIL FILTER INSPECTION…………………………………………………….587

LUBRICATING OIL SYSTEM-DIAGNOSING MALFUNTIONS……………………………………………..588

HIGH OIL PRESSURE…………………………………………………………………..588

OIL PRESSURE REGULATION VALVE………………………………………………………..588

LOW OIL PRESSURE……………………………………………………………………588

OIL LEVEL………………………………………………………………………….588

OIL FILTER…………………………………………………………………………589

OIL PRESSURE GAUGE-CHECKING………………………………………………………….589

OIL TEMPERATURE GAUGE-CHECKING……………………………………………………….590

OIL TEMPERATURE THERMOSTAT…………………………………………………………..590

OIL SUCTION TUBE……………………………………………………………………591

BEARINGS AND OIL PUMP……………………………………………………………….591

OIL DILUTION……………………………………………………………………….591

COOLANT DILUTED OIL…………………………………………………………………591

OIL COOLER…………………………………………………………………………592

AFTERCOOLER………………………………………………………………………..592

CYLINDER HEAD EXPANSION PLUGS………………………………………………………..593

CYLINDER LINER SEALS………………………………………………………………..593

CYLINDER HEAD GASKET………………………………………………………………..593

CRACKED CYLINDER HEAD……………………………………………………………….593

CRACKED CYLINDER LINER………………………………………………………………594

CRACKED CYLINDER BLOCK………………………………………………………………594

FUEL DILUTED OIL……………………………………………………………………594

FUEL TRANSFER PUMP………………………………………………………………….595

FUEL LEAKING BY PISTON RINGS…………………………………………………………595

INJECTION PUMP……………………………………………………………………..596

OIL LEAKS………………………………………………………………………….596

LUBRICATING OIL PAN-DRAINING…………………………………………………………….598

LUBRICATING OIL PAN-FILLING……………………………………………………………..598

LUBRICATING OIL LEVEL-CHECKING…………………………………………………………..599

LUBRICATING OIL FILTER-CHANGING………………………………………………………….600

LUBRICATING OIL DIPSTICK-CALIBRATION……………………………………………………..601

LUBRICATING OIL DIPSTICK TUBE-REPLACEMENT…………………………………………………602

REMOVAL……………………………………………………………………………602

INSTALLATION……………………………………………………………………….602

LUBRICATING OIL PRESSURE REGULATOR,VALVE AND SPRING-REPLACEMENT……………………………..603

REMOVAL……………………………………………………………………………603

CLEANING AND INSPECTION……………………………………………………………..603

INSTALLATION……………………………………………………………………….604

LUBRICATING OIL COOLER ELEMENT AND GASKET-REPLACEMENT………………………………………604

REMOVAL……………………………………………………………………………604

CLEANING AND INSPECTION……………………………………………………………..605

INSTALLATION……………………………………………………………………….606

LUBRICATING OIL TEMPERATURE THERMOSTAT-REPLACEMENT…………………………………………607

REMOVAL……………………………………………………………………………607

INSPECTION…………………………………………………………………………608

INSTALLATION……………………………………………………………………….609

LUBRICATING OIL PAN,SUCTION TUBE AND GASKET-REPLACEMENT…………………………………….609

OIL PAN -REMOVAL……………………………………………………………………609

CLEANING…………………………………………………………………………..609

SUCTION TUBE-REPLACEMENT…………………………………………………………….610

OIL PAN -INSTALLATION……………………………………………………………….610

LUBRICATING OIL PUMP-REPLACEMENT…………………………………………………………612

REMOVAL……………………………………………………………………………613

CLEANING AND INSPECTION……………………………………………………………..613

INSTALLATION……………………………………………………………………….616

COMBUSTION AIR SYSTEM………………………………………………………………………620

COMBUSTION AIR SYSTEM FLOW-GENERAL INFORMATION…………………………………………….622

AIR SYSTEM FLOW-DIAGRAMS………………………………………………………………..623

INTAKE AIR AND EXHAUST SYSTEM SPECIFICATIONS………………………………………………624

TURBOCHARGER BOOST PRESSURE SPECIFICATIONS………………………………………………..624

COMBUSTION AIR SYSTEM-SERVICE TOOLS………………………………………………………625

COMBUSTION AIR SYSTEM-DIAGNOSING MALFUNCTIONS……………………………………………..626

CLEAN AIR………………………………………………………………………….626

INTAKE AIR RESTRICTION-CHECKING………………………………………………………626

DAMAGE FROM NON-FILTERED AIR…………………………………………………………627

TURBOCHARGED ENGINES-AIR LEAKS,PRESSURE SIDE…………………………………………..627

TURBOCHARGED ENGINES-EXHAUST LEAKS……………………………………………………628

TURBOCHARGED BOOST PRESSURE-MEASUREMENT……………………………………………….628

MALFUNCTIONING TURBOCHARGER………………………………………………………….629

OIL CONSUMPTION AND LEAKS……………………………………………………………629

TURBOCHARGER NOISE………………………………………………………………….630

ROTOR ASSEMBLY CLEARANCE-MEASUREMENT………………………………………………….631

TURBOCHARGER WASTEGATE ACTUATOR-VISUAL INSPECTION………………………………………….632

TURBOCHARGER WASTEGATE ACTUATOR-FUNCTIONAL CHECKING………………………………………..633

TURBOCHARGER WASTEGATE ACTUATOR-REPLACEMENT……………………………………………….634

AIR REGULATOR WITH PRESSURE GAUGE…………………………………………………….634

TURBOCHARGER WASTEGATE ACTUATOR-CALIBRATION……………………………………………….636

EXHAUST RESTRICTION-MEASUREMENT………………………………………………………637

CHARGE AIR COOLER(CAC)-TROUBLESHOOTING……………………………………………………637

PRESSURE DROP-CHECKING………………………………………………………………637

CHECKING-AIR LEAK…………………………………………………………………..639

CHARGE AIR COOLER………………………………………………………………………640

CLEANING AND INSPECTION……………………………………………………………..640

AIR CROSSOVER TUBE-REPLACEMENT…………………………………………………………..641

REMOVAL AND INSTALLATION…………………………………………………………….641

INTAKE MANIFOLD COVER AND GASKET-REPLACEMENT………………………………………………642

REMOVAL……………………………………………………………………………642

CLEANING…………………………………………………………………………..643

INSTALLATION……………………………………………………………………….643

AFTERCOOLER AND GASKET-REPLACEMENT……………………………………………………….643

REMOVAL……………………………………………………………………………644

CLEANING…………………………………………………………………………..644

INSTALLATION……………………………………………………………………….644

TURBOCHARGER-REPLACEMENT………………………………………………………………..645

REMOVAL……………………………………………………………………………645

CLEANING AND INSPECTION……………………………………………………………..646

INSTALLATION……………………………………………………………………….647

EXHAUST MANIFOLD AND GASKETS-REPLACEMENT………………………………………………….649

REMOVAL……………………………………………………………………………649

CLEANING AND INSPECTION……………………………………………………………..650

INSTALLATION……………………………………………………………………….650

COMPRESSED AIR SYSTEM………………………………………………………………………652

COMPRESSED AIR SYSTEM GENERAL INFORMATION…………………………………………………653

COMPRESSED AIR SYSTEM SPECIFICATIONS……………………………………………………..654

COMPRESSED AIR SYSTEM FLOW DIAGRAMS………………………………………………………655

AIR COMPRESSOR CARBON BUILDUP-CHECKING……………………………………………………656

AIR COMPRESSOR GASKET LEAKS-CHECKING……………………………………………………..658

AIR GOVERNOR AND COMPRESSOR UNLOADER VALVE-CHECKING………………………………………..658

AIR GOVERNOR-CHECKING…………………………………………………………………..659

AIR COMPRESSOR-REPLACEMENT………………………………………………………………661

REMOVAL……………………………………………………………………………662

INSPECTION…………………………………………………………………………663

INSTALLATION……………………………………………………………………….663

FUEL SYSTEM……………………………………………………………………………….666

FUEL SYSTEM COMPONENTS AND FLOW………………………………………………………….668

FUEL SYSTEM SPECIFICATIONS………………………………………………………………669

FUEL SYSTEM -SERVICE TOOLS………………………………………………………………670

FUEL SYSTEM DIAGNOSING-MALFUNCTIONS………………………………………………………672

FUEL TRANSFER PUMP………………………………………………………………….672

AIR IN THE FUEL SYSTEM………………………………………………………………676

FUEL WATER SEPARATOR/FILTER UNIT……………………………………………………..678

FUEL INJECTION PUMP…………………………………………………………………679

GOVERNOR MALFUNCTIONS……………………………………………………………….679

AIR FUEL CONTROL(AFC)MALFUNCTIONS…………………………………………………….679

FUEL CONTROL LEVER TRAVEL AND ADJUSTMENT………………………………………………680

FUEL INJECTION PUMP IDLE ADJUSTMENT SCREWS…………………………………………….680

MANUAL SHUT DOWN LEVERS……………………………………………………………..680

ELECTRICAL SHUT DOWN DEVICES…………………………………………………………681

FUEL INJECTION PUMP TIMING…………………………………………………………..682

HIGH PRESSURE PUMP TIMING……………………………………………………………683

INJECTORS………………………………………………………………………….684

FUEL DRAIN MANIFOLD…………………………………………………………………685

LOW PRESSURE FUEL LINE-REPLACEMENT……………………………………………………….686

REMOVAL AND INSTALLATION…………………………………………………………….686

FUEL FILTER HEAD ADAPTER-REPLACEMENT……………………………………………………..686

REMOVAL AND INSTALLATION…………………………………………………………….686

FUEL TRANSFER PUMP-REPLACEMENT/REBUILD……………………………………………………687

REMOVAL……………………………………………………………………………687

REBUILD……………………………………………………………………………687

CLEANING…………………………………………………………………………..688

ASSEMBLY…………………………………………………………………………..688

CLEANING MOUNTING SURFACE……………………………………………………………689

INSTALLATION……………………………………………………………………….689

HIGH PRESSURE FUEL LINES-REPLACEMENT……………………………………………………..689

REMOVAL……………………………………………………………………………689

INSTALLATION……………………………………………………………………….690

FUEL DRAIN MANIFOLD-REPLACEMENT………………………………………………………….691

REMOVAL AND INSTALLATION…………………………………………………………….691

INJECTOR-REPLACEMENT……………………………………………………………………691

REMOVAL……………………………………………………………………………691

CLEANING AND INSPECTION……………………………………………………………..691

INSTALLATION……………………………………………………………………….692

FUEL SHUTOFF SOLENOID-REPLACEMENT………………………………………………………..693

RSV GOVERNOR FUEL SHUTOFF SOLENOID-REMOVAL…………………………………………….693

RSV GOVERNOR FUEL SHUTOFF SOLENOID-INSTALLATION………………………………………..694

DIRECT LINK SOLENOID,CYLINDER BLOCK MOUNTED……………………………………………694

RQVK GOVERNOR FUEL SHUTOFF SOLENOID-REMOVAL AND INSTALLATION…………………………….694

FUEL RETURN OVERFLOW VALVE-REPLACEMENT……………………………………………………695

AFC TUBE-REPLACEMENT……………………………………………………………………696

REMOVAL……………………………………………………………………………696

INSTALLATION……………………………………………………………………….696

FUEL INJECTION PUMP-REPLACEMENT………………………………………………………….696

REMOVAL……………………………………………………………………………697

INSTALLATION……………………………………………………………………….698

IDLE SPEED-ADJUSTMENT…………………………………………………………………..703

BOSCH RSV GOVERNOR………………………………………………………………….703

BOSCH RQVK GOVERNOR…………………………………………………………………704

INLINE FUEL INJECTION PUMP SPILL-PORT TIMING………………………………………………704

GOVERNOR LEVER POSITIONING…………………………………………………………..706

ELECTRICAL SYSTEM………………………………………………………………………….711

ELECTRICAL SYSTEM DESCRIPTION AND OPERATION……………………………………………….712

CRANKING MOTOR AND ELECTRICAL CIRCUITS………………………………………………..712

DELCO REMY MODEL 37MT/41MT STARTING MOTOR……………………………………………..713

DELCO REMY MODEL 42MT STARTING MOTOR………………………………………………….713

NIPPENDENSO MODEL F2 STARTING MOTOR…………………………………………………..714

NIPPENDENSO MODEL F2 BASIC CRANKING CURRENT FLOW……………………………………….714

DELCO REMY MODEL 15SI 116 ALTERNATOR(WIRING DIAGRAM)……………………………………715

BOSCH K1 MODEL ALTERNATOR(WIRING DIAGRAM)……………………………………………..715

NIPPONDENSO F4 STARTING MOTOR………………………………………………………..716

DELCO 42MT STARTING MOTOR……………………………………………………………716

ELECTRICAL SYSTEM-SPECIFICATIONS…………………………………………………………717

MINIMUM RECOMMENDED BATTERY CAPACITY………………………………………………….717

MAXIMUM ALLOWABLE RESISTANCE OF STARTING CIRCUIT……………………………………….717

WIRING SIZE RECOMMENDATIONS FOR STARTER SOLENOID AND FUEL SOLENOID CIRCUIT………………..718

ELECTRICAL SYSTEM-SERVICE TOOLS………………………………………………………….719

ELECTRICAL SYSTEM-DIAGNOSING MALFUNCTIONS…………………………………………………720

BATTERIES-CHECKING………………………………………………………………….720

STARTING CIRCUIT-CHECKING……………………………………………………………721

STARTING MOTOR SOLENOID AND STARTING MOTOR CHECKING…………………………………….724

ENGINE CRANKING SPEED TOO SLOW……………………………………………………….726

ALTERNATOR…………………………………………………………………………727

OIL PRESSURE SWITCH AND TEMPERATURE SENSOR-CHECKING…………………………………….730

COOLANT OR PAN HEATERS-CHECKING………………………………………………………731

STARTING MOTOR-REPLACEMENT………………………………………………………………731

REMOVAL AND INSTALLATION…………………………………………………………….732

ALTERNATOR-REPLACEMENT………………………………………………………………….732

REMOVAL……………………………………………………………………………732

INSTALLATION……………………………………………………………………….733

COOLANT TEMPERATURE SENSOR-REPLACEMENT……………………………………………………733

REMOVAL……………………………………………………………………………734

INSTALLATION……………………………………………………………………….734

ENGINE BLOCK AND COOLANT HEATER(750 AND 500 WATS)-REPLACEMENT……………………………….734

REMOVAL……………………………………………………………………………735

INSTALLATION……………………………………………………………………….735

LUBRICATING OIL PAN HEATER-REPLACEMENT……………………………………………………735

REMOVAL……………………………………………………………………………736

INSTALLATION……………………………………………………………………….736

LUBRICATING OIL PRESSURE SWITCH REPLACEMENT……………………………………………….736

REMOVAL……………………………………………………………………………736

INSTALLATION……………………………………………………………………….736

BASE ENGINE COMPONENTS……………………………………………………………………..737

BASE ENGINE COMPONENTS-SERVICE TOOLS……………………………………………………..740

BASE ENGINE COMPONENTS-GENERAL INFORMATION………………………………………………..745

ENGINE COMPRESSION-CHECKING……………………………………………………………..745

COMPRESSION GUAGE AND ADAPTER………………………………………………………..745

PISTON RING SEALING…………………………………………………………………746

INTAKE AND EXHAUST VALVE SEALING……………………………………………………..746

CYLINDER HEAD GASKET SEALING…………………………………………………………746

VALVE COVER-REPLACEMENT…………………………………………………………………747

REMOVAL……………………………………………………………………………747

CLEANING AND INSPECTION……………………………………………………………..748

INSTALLATION……………………………………………………………………….748

CRANKCASE BREATHER TUBE-REPLACEMENT………………………………………………………749

REMOVAL……………………………………………………………………………749

CLEANING AND INSPECTION……………………………………………………………..749

INSTALLATION……………………………………………………………………….750

ROCKER LEVER DIAGNOSING-MALFUNCTIONS……………………………………………………..750

VALVE LASH SPECIFICATIONS……………………………………………………………750

ROCKER LEVER-REPLACEMENT………………………………………………………………..751

REMOVAL……………………………………………………………………………751

DISASSEMBLY………………………………………………………………………..752

CLEANING AND INSPECTION……………………………………………………………..753

ASSEMBLY…………………………………………………………………………..754

INSTALLATION……………………………………………………………………….755

VALVE LASH-ADJUSTMENT…………………………………………………………………..756

VALVE ARRANGEMENT…………………………………………………………………..758

TIMING PIN ASSEMBLY-INSTALLATION…………………………………………………………759

PUSH ROD-REPLACEMENT……………………………………………………………………763

REMOVAL……………………………………………………………………………763

CLEANING AND INSPECTION……………………………………………………………..764

INSTALLATION……………………………………………………………………….765

CYLINDER HEAD-REPLACEMENT……………………………………………………………….766

GENERAL INFORMATION…………………………………………………………………766

DIAGNOSING MALFUNCTIONS……………………………………………………………..766

REMOVAL……………………………………………………………………………769

CYLINDER BLOCK/HEAD DECK-CLEANING AND INSPECTION……………………………………….770

CYLINDER HEAD-CLEANING AND INSPECTION…………………………………………………773

INSTALLATION……………………………………………………………………….778

CYLINDER HEAD-PRESSURE TEST……………………………………………………………..783

MAIN AND THRUST BEARINGS-REPLACEMENT……………………………………………………..784

GENERAL INFORMATION…………………………………………………………………784

DIAGNOSING MALFUNCTIONS……………………………………………………………..785

REMOVAL……………………………………………………………………………786

CLEANING AND INSPECTION……………………………………………………………..788

INSTALLATION……………………………………………………………………….790

CONNECTING ROD BEARINGS-REPLACEMENT………………………………………………………795

DIAGNOSING MALFUNCTIONS……………………………………………………………..795

REMOVAL……………………………………………………………………………796

CLEANING AND INSPECTION……………………………………………………………..797

INSTALLATION……………………………………………………………………….800

PISTON AND RINGS-REPLACEMENT…………………………………………………………….802

PISTON-GENERAL INFORMATION…………………………………………………………..802

PISTON AND RINGS-DIAGNOSING MALFUNCTIONS………………………………………………802

REMOVAL……………………………………………………………………………804

CLEANING AND INSPECTION……………………………………………………………..807

INSTALLATION……………………………………………………………………….812

CONNECTING RODS-REPLACEMENT……………………………………………………………..819

GENERAL INFORMATION…………………………………………………………………819

REMOVAL……………………………………………………………………………820

CLEANING AND INSPECTION……………………………………………………………..821

INSTALLATION……………………………………………………………………….823

CYLINDER LINERS-REPLACEMENT……………………………………………………………..825

GENERAL INFORMATION…………………………………………………………………825

REMOVAL……………………………………………………………………………825

CLEANING AND INSPECTION……………………………………………………………..829

INSTALLATION……………………………………………………………………….832

VIBRATION DAMPER-REPLACEMENT…………………………………………………………….839

GENERAL INFORMATION…………………………………………………………………839

RUBBER ELEMENT VIBRATION DAMPER-INSPECTION(IN-CHASSIS)………………………………….839

VISCOUS VIBRATION DAMPER-INSPECTION…………………………………………………..841

REMOVAL……………………………………………………………………………842

INSTALLATION……………………………………………………………………….843

GEAR COVER-REPLACEMENT………………………………………………………………….844

REMOVAL……………………………………………………………………………844

CLEANING AND INSPECTION……………………………………………………………..845

INSTALATION………………………………………………………………………..846

SEAL,FRONT CRANKSHAFT-REPLACEMENT………………………………………………………..848

GENERAL INFORMATION…………………………………………………………………848

REMOVAL AND INSTALLATION…………………………………………………………….849

WEAR SLEEVE,FRONT CRANKSHAFT-REPLACEMENT………………………………………………….849

REMOVAL……………………………………………………………………………849

CLEANING AND INSPECTION……………………………………………………………..850

INSTALLATION……………………………………………………………………….850

GEAR HOUSING-REPLACEMENT………………………………………………………………..853

GENERAL INFORMATION…………………………………………………………………853

REMOVAL……………………………………………………………………………854

CLEANING AND INSPECTION……………………………………………………………..855

INSTALLATION……………………………………………………………………….857

ENGINE DATAPLATE-REPLACEMENT…………………………………………………………….862

REMOVAL……………………………………………………………………………863

INSTALLATION……………………………………………………………………….863

CAMSHAFT-REPLACEMENT……………………………………………………………………864

GENERAL INFORMATION…………………………………………………………………864

REMOVAL……………………………………………………………………………866

CLEANING AND INSPECTION……………………………………………………………..869

INSTALLATION……………………………………………………………………….873

CAMSHAFT GEAR-REPLACEMENT……………………………………………………………….876

REMOVAL……………………………………………………………………………876

CLEANING AND INSPECTION……………………………………………………………..876

INSTALLATION……………………………………………………………………….878

VALVE TAPPET-REPLACEMENT………………………………………………………………..879

GENERAL INFORMATION…………………………………………………………………879

REMOVAL……………………………………………………………………………880

CLEANING AND INSPECTION……………………………………………………………..883

INSTALLATION……………………………………………………………………….884

CRANKSHAFT GEAR-REPLACEMENT……………………………………………………………..888

GENERAL INFORMATION…………………………………………………………………888

REMOVAL……………………………………………………………………………889

CLEANING AND INSPECTION……………………………………………………………..891

INSTALLATION……………………………………………………………………….892

FLYWHEEL-REPLACEMENT……………………………………………………………………895

REMOVAL……………………………………………………………………………895

CLEANING AND INSPECTION……………………………………………………………..896

INSTALLATION……………………………………………………………………….897

FLYWHEEL BORE RUNOUT MEASUREMENT……………………………………………………..899

FLYWHEEL FACE RUNOUT MEASUREMENT……………………………………………………..900

FLYWHEEL RING GEAR-REPLACEMENT…………………………………………………………..902

REMOVAL……………………………………………………………………………902

INSTALLATION……………………………………………………………………….902

FLYWHEEL HOUSING-REPLACEMENT…………………………………………………………….902

REMOVAL……………………………………………………………………………902

CLEANING AND INSPECTION……………………………………………………………..904

INSTALLATION(DRY CLUTCH APPLICATION)………………………………………………….905

CONCENTRICITY-CHECKING………………………………………………………………906

INSTALLATION(WET CLUTCH APPLICATION)………………………………………………….908

SEAL,REAR CRANKSHAFT-REPLACEMENT…………………………………………………………910

REMOVAL……………………………………………………………………………910

CLEANING AND INSPECTION……………………………………………………………..911

INSTALLATION……………………………………………………………………….912

WEAR SLEEVE,REAR CRANKSHAFT SEAL-REPLACEMENT………………………………………………913

REMOVAL……………………………………………………………………………913

CLEANING AND INSPECTION……………………………………………………………..915

INSTALLATION……………………………………………………………………….916

PIPE PLUG-REPLACEMENT…………………………………………………………………..919

REMOVAL……………………………………………………………………………919

CLEANING AND INSPECTION……………………………………………………………..919

INSTALLATION……………………………………………………………………….920

CUP PLUG-REPLACEMENT……………………………………………………………………920

REMOVAL……………………………………………………………………………920

CLEANING AND INSPECTION……………………………………………………………..921

INSTALLATION……………………………………………………………………….921

ENGINE TESTING…………………………………………………………………………….923

ENGINE TESTING-GENERAL INFORMATION……………………………………………………….924

ENGINE TESTING-GENERAL SPECIFICATIONS…………………………………………………….925

BLOWBY MEASUREMENT……………………………………………………………………..926

ENGINE TESTING-SERVICE TOOLS…………………………………………………………….927

GENERAL ENGINE TEST PROCEDURES…………………………………………………………..928

ENGINE RUN-IN PROCEDURE…………………………………………………………………930

ENGINE REMOVAL AND INSTALLATION……………………………………………………………..932

ENGINE REMOVAL AND INSTALLATION-GENERAL INFORMATION………………………………………..933

ENGINE-REMOVAL…………………………………………………………………………933

ENGINE MOUNT-INSPECTION…………………………………………………………………936

ENGINE-INSTALLATION…………………………………………………………………….936

THROTTLE CONTROL LEVER CONNECTION…………………………………………………….937

ENGINE COMPONENT SPECIFICATIONS……………………………………………………………..941

SPECIFICATION-GENERAL INFORMATION………………………………………………………..942

COMPONENT SPECIFICATIONS AND TORQUE VALUES………………………………………………..943

COOLING SYSTEM SPECIFICATIONS………………………………………………………..943

COOLING SYSTEM TORQUE VALUES…………………………………………………………943

LUBRICATING OIL SYSTEM SPECIFICATIONS…………………………………………………944

LUBRICATING OIL SYSTEM TORQUE VALUES………………………………………………….945

COMBUSTION AIR SYSTEM SPECIFICATIONS………………………………………………….947

COMBUSTION AIR SYSTEM TORQUE VALUES…………………………………………………..947

COMPRESSED AIR SYSTEM TORQUE VALUES…………………………………………………..948

FUEL SYSTEM SPECIFICATIONS…………………………………………………………..949

FUEL SHUTOFF SOLENOID ADJUSTMENT……………………………………………………..949

FUEL SYSTEM TORQUE VALUES……………………………………………………………950

ELECTRICAL SYSTEM SPECIFICATIONS……………………………………………………..953

ELECTRICAL SYSTEM TORQUE VALUES………………………………………………………953

BASE ENGINE COMPONENT SPECIFICATIONS………………………………………………….954

BASE ENGINE TORQUE VALUES……………………………………………………………965

DRIVE BELT TENSION……………………………………………………………………..967

WEIGHT AND MEASURES-CONVERSION FACTORS……………………………………………………969

NEWTON-METER TO FOOT-POUND CONVERSION CHART……………………………………………….970

CAPSCREW MARKINGS AND TORQUE VALUES………………………………………………………971

CAPSCREW MARKINGS AND TORQUE VALUES-METRIC…………………………………………….972

CAPSCREW MARKINGS AND TORQUE VALUES-U.S. CUSTOMARY……………………………………..973

PIPE PLUG TORQUE VALUES…………………………………………………………………974

INDEX…………………………………………………………………………………….975