$35

Komatsu 114 Series Diesel Engine Shop Manual SEBM024609 – PDF DOWNLOAD

Komatsu 114 Series Diesel Engine Shop Manual SEBM024609 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 114 Series Diesel Engine Shop Manual SEBM024609 – PDF DOWNLOAD

Language : English

Pages : 444

Downloadable : Yes

File Type : PDF

Size: 16 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 114 Series Diesel Engine Shop Manual SEBM024609 – PDF DOWNLOAD

The Komatsu 114 Series Diesel Engine Shop Manual SEBM024609 is a comprehensive technical guide that provides information and instructions for the maintenance, repair, and overhaul of several Komatsu diesel engines. These engines are commonly used in a wide range of Komatsu equipment, including bulldozers, excavators, and wheel loaders.

- The manual is organized into several sections, each of which covers different aspects of engine maintenance and repair. These sections include general specifications, testing and adjusting procedures, disassembly and assembly instructions, and troubleshooting guidelines.

- The general specifications section provides an overview of the engine’s technical specifications, including its dimensions, weight, power output, and torque ratings. It also includes information on the engine’s various components, such as the cylinder block, cylinder head, crankshaft, and pistons.

- The testing and adjusting procedures section of the manual provides step-by-step instructions for performing various tests and adjustments on the engine. These procedures include compression tests, fuel injection timing adjustment, and valve clearance adjustment. The manual also provides information on the tools and equipment required for performing these procedures.

- The disassembly and assembly instructions section of the manual provides detailed guidance on how to disassemble and reassemble the engine, including the removal and installation of various components such as the cylinder head, pistons, and crankshaft. This section also includes detailed diagrams and illustrations that provide a clear understanding of the engine’s internal components and how they fit together.

- The troubleshooting guidelines section of the manual provides information on how to diagnose and repair common problems that may occur with the engine. This section provides a list of potential symptoms and causes, along with step-by-step instructions for identifying and fixing the problem.

- The manual also covers maintenance and safety guidelines, including routine inspections, cleaning, lubrication, and safety precautions that must be followed while working with the engine.

- Overall, the Komatsu 114 Series Diesel Engine Shop Manual SEBM024609 is an essential resource for technicians and mechanics working with the Komatsu 114 series engines. Its comprehensive coverage of maintenance, repair, and troubleshooting procedures makes it an indispensable tool for ensuring the reliable and efficient operation of Komatsu construction equipment.

TABLE OF CONTENTS:

Komatsu 114 Series Diesel Engine Shop Manual SEBM024609 – PDF DOWNLOAD

COVER ……………………………………………………………………………. 1

CONTENTS………………………………………………………………………….. 2

LIST OF REVISED PAGES………………………………………………………………. 3

SAFETY……………………………………………………………………………. 5

SAFETY NOTICE………………………………………………………………….. 5

FOREWORD………………………………………………………………………….. 7

GENERAL……………………………………………………………………….. 7

HOW TO READ THE SHOP MANUAL……………………………………………………… 8

HOISTING INSTRUCTIONS…………………………………………………………… 9

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER………………………….. 10

COATING MATERIALS………………………………………………………………. 12

STANDARD TIGHTENING TORQUE………………………………………………………. 14

ELECTRIC WIRE CODE……………………………………………………………… 17

CONVERSION TABLE……………………………………………………………….. 18

UNITS…………………………………………………………………………. 24

CAPSCREW MARKINGS AND TORQUE VALUES………………………………………………. 25

CAPSCREW MARKINGS AND TORQUE VALUES – METRIC………………………………………. 26

CAPSCREW MARKINGS AND TORQUE VALUES – U.S. CUSTOMARY……………………………….. 27

PIPE PLUG TORQUE VALUES…………………………………………………………. 28

SYMBOLS……………………………………………………………………….. 29

ILLUSTRATIONS………………………………………………………………….. 30

01 GENERAL ……………………………………………………………………….. 31

APPLICABLE MACHINE……………………………………………………………… 32

SPECIFICATION………………………………………………………………….. 34

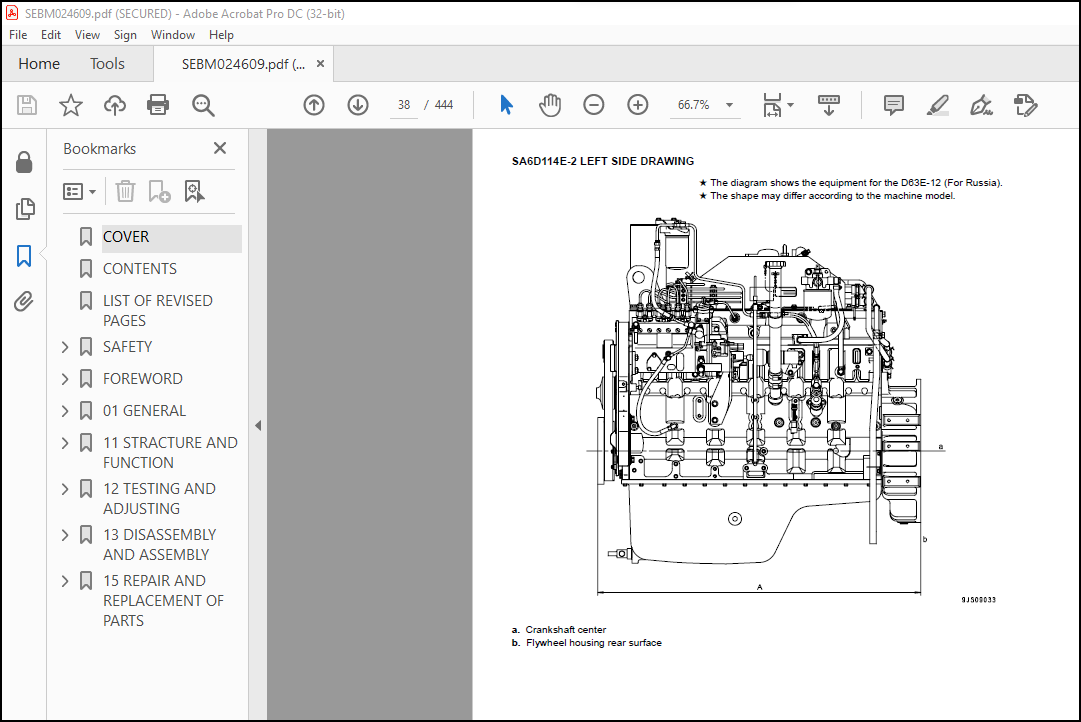

OVERALL DRAWING………………………………………………………………… 36

WEIGHT TABLE…………………………………………………………………… 41

ENGINE PERFORMANCE CURVE………………………………………………………… 42

11 STRACTURE AND FUNCTION ………………………………………………………….. 49

AIR INTAKE DEVICE………………………………………………………………. 50

EXHAUST MANIFOLD……………………………………………………………….. 53

AIR CLEANER……………………………………………………………………. 54

TURBOCHARGER…………………………………………………………………… 55

AFTERCOOLER……………………………………………………………………. 60

CYLINDER HEAD………………………………………………………………….. 62

CYLINDER BLOCK…………………………………………………………………. 66

CYLINDER LINER…………………………………………………………………. 70

MAIN CIRCULATION PART…………………………………………………………… 72

CRANK SHAFT……………………………………………………………………. 76

PISTON・PISTON RING・PISTON PIN……………………………………………………. 78

CONNECTING ROD…………………………………………………………………. 80

VIBRATION DAMPER……………………………………………………………….. 82

TIMING GEAR PORTION…………………………………………………………….. 84

FRONT GEAR COVER……………………………………………………………….. 85

CAMSHAFT TIMING PIN…………………………………………………………….. 86

TIMING GEAR……………………………………………………………………. 87

CAM SHAFT……………………………………………………………………… 88

VALVE MECHANISM………………………………………………………………… 90

VALVE, VALVE GUIDE……………………………………………………………… 94

ROCKER-ARM SHAFT・PUSH ROD・TAPPET…………………………………………………. 96

OIL PAN……………………………………………………………………….. 98

FLYWHEEL, FLYWHEEL HOUSING……………………………………………………….100

LUBRICATION SYSTEM DIAGRAM……………………………………………………….104

OIL PUMP……………………………………………………………………….105

OIL FILTER, OIL COOLER…………………………………………………………..108

REGULATOR VALVE, SAFETY VALVE…………………………………………………….109

FUEL SYSTEM DIAGRAM……………………………………………………………..110

FUEL INJECTION PUMP……………………………………………………………..112

TIMING LOCK PIN OF FUEL INJECTION PUMP…………………………………………….116

FUEL FILTER…………………………………………………………………….117

FUEL INJECTION NOZZLE……………………………………………………………118

FUEL CUT SOLENOID……………………………………………………………….120

COOLING SYSTEM DIAGRAM…………………………………………………………..121

WATER PUMP DRIVE………………………………………………………………..122

WATER PUMP (WITH ONE-PIECE BEARING, SHAFT, ONE-PIECE WATER SEAL)……………………..124

THERMOSTAT……………………………………………………………………..125

FAN DRIVE………………………………………………………………………128

ALTERNATOR……………………………………………………………………..130

STARTING MOTOR………………………………………………………………….133

STARTING AID……………………………………………………………………135

12 TESTING AND ADJUSTING ……………………………………………………………137

SPECIAL TOOL LIST……………………………………………………………….140

SPECIAL TOOLS FOR INTAKE AND EXHAUST SYSTEM…………………………………….140

SPECIAL TOOLS FOR CYLINDER HEAD SYSTEM…………………………………………141

SPECIAL TOOLS FOR ENGINE……………………………………………………..145

SPECIAL TOOLS FOR FUEL SYSTEM…………………………………………………149

SPECIAL TOOLS FOR ACCESSORY COMPONENT SYSTEM……………………………………150

SPECIAL TOOLS FOR ELECTRICAL COMPONENT…………………………………………151

SPECIAL TOOLS FOR ENGINE PERFORMANCE TEST………………………………………152

TROUBLESHOOTING DEFECTIVE ACTUATION OF INTAKE AND EXHAUST SYSTEM……………………..154

MEASURING PLAY OF TURBOCHARGER ROTOR IN AXIAL AND RADIAL DIRECTION……………………159

TESTING TURBOCHARGER WESTGATE VALVE……………………………………………….160

TESTING TURBOCHARGER WESTGATE CAPSULE……………………………………………..161

TESTING ACTUATION OF TURBOCHARGER WESTGATE…………………………………………161

REPLACING TURBOCHARGER WESTGATE ACTUATOR BOOST CAPSULE………………………………162

ADJUSTING TURBOCHARGER WESTGATE ACTUATOR…………………………………………..164

MEASURING EXHAUST RESISTANCE……………………………………………………..165

REPLACING TURBOCHARGER…………………………………………………………..165

TROUBLESHOOTING DEFECTIVE ACTUATION OF ENGINE………………………………………166

VALVE MECHANISM AND CYLINDER HEAD……………………………………………..166

TESTING AIR SYSTEM AND FUEL SYSTEM…………………………………………….166

TESTING VALVE CLEARANCE………………………………………………………167

TESTING COMPRESSION………………………………………………………….167

PISTON RING SEALING PERFORMANCE……………………………………………….167

VALVE SEALING PERFORMANCE…………………………………………………….168

HEAD GASKET SEALIN PERFORMANCE………………………………………………..168

VALVE SEAL WEAR……………………………………………………………..169

PROTRUDING PORTION OF FUEL INJECTION NOZZLE…………………………………….170

FRONT GEAR HOUSING AND GEAR TRAIN……………………………………………..171

ROCKER LEVER, VALVE STEM, PUSH ROD, TAPPET, AND CAMSHAFT…………………………172

PISTON AND CONNECTING ROD…………………………………………………….173

CRANKSHAFT AND MAIN BEARING…………………………………………………..175

CYLINDER BLOCK………………………………………………………………176

FLYWHEEL HOUSING AND FLYWHEEL…………………………………………………177

ADJUSTING VALVE CLEARANCE………………………………………………………..178

ADJUSTING 6-CYLINDER ENGINE…………………………………………………..179

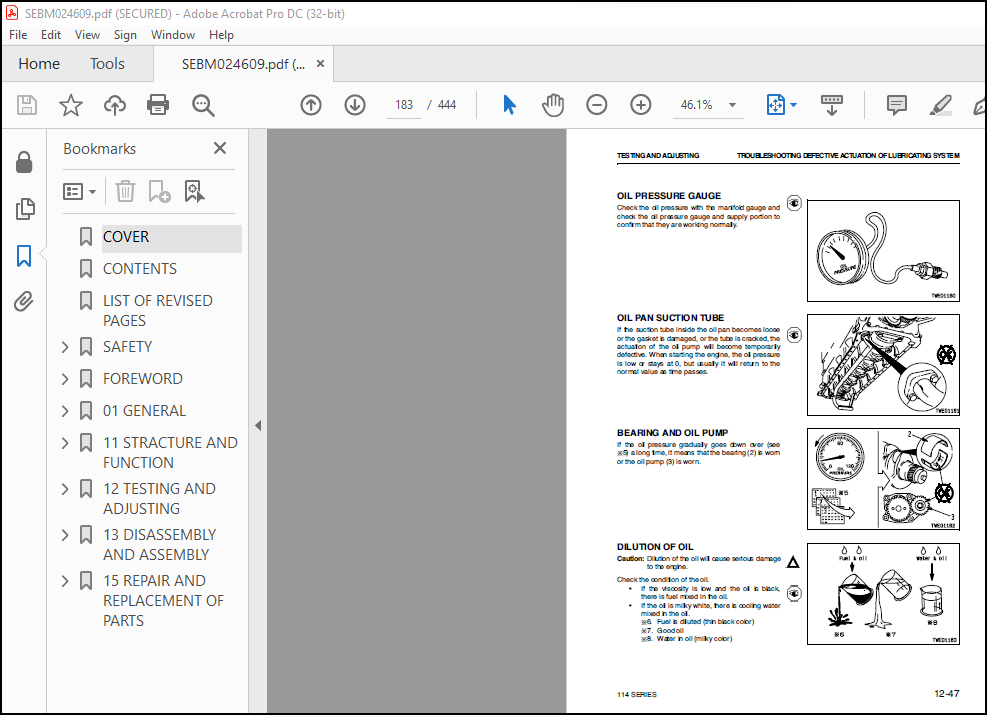

TROUBLESHOOTING DEFECTIVE ACTUATION OF LUBRICATING SYSTEM……………………………181

HIGH PRESSURE……………………………………………………………….181

REGULATOR VALVE……………………………………………………………..181

LOW PRESSURE………………………………………………………………..182

OIL LEVEL…………………………………………………………………..182

OIL FILTER………………………………………………………………….182

OIL PRESSURE GAUGE…………………………………………………………..183

OIL PAN SUCTION TUBE…………………………………………………………183

BEARING AND OIL PUMP…………………………………………………………183

DILUTION OF OIL……………………………………………………………..183

COOLING WATER IN OIL…………………………………………………………184

FUEL IN OIL ………………………………………………………………..185

FUEL INJECTION PUMP CALIBRATION DATA………………………………………………188

RUNNING IN STANDARD……………………………………………………………..193

PERFORMANCE TEST CRITERIA………………………………………………………..196

TESTING FUEL FEED PUMP…………………………………………………………..198

DISASSEMBLY AND ASSEMBLY OF FUEL FEED PUMP……………………………………..199

ADJUSTING FUEL CUT-OFF SOLENOID…………………………………………………..201

DIRECTION OF FUEL CUT-OFF SOLENOID…………………………………………….201

ADJUSTING FUEL CUT-OFF SOLENOID……………………………………………….202

INSTALLATION OF MECHANICALLY OPERATED SOLENOID, CYLINDER BLOCK……………………203

TESTING FOR AIR INSIDE THE FUEL SYSTEM…………………………………………….204

TESTING WATER SEPARATOR, FUEL FILTER………………………………………………206

TESTING HIGH-PRESSURE FUEL PIPING…………………………………………………207

TESTING FUEL INJECTION NOZZLE…………………………………………………….208

TESTING FUEL DRAIN PIPING………………………………………………………..210

BLEEDING AIR FROM FUEL SYSTEM…………………………………………………….210

BLEEDING AIR FROM LOW-PRESSURE CIRCUIT AND FUEL FILTER…………………………..211

BLEEDING AIR FROM FUEL INJECTION PUMP………………………………………….211

BLEEDING AIR FROM HIGH-PRESSURE CIRCUIT………………………………………..212

ADJUSTING TIMING OF FUEL INJECTION PUMP……………………………………………213

TROUBLESHOOTING DEFECTIVE OPERATION OF COOLING SYSTEM……………………………….216

TROUBLESHOOTING……………………………………………………………..216

RADIATOR CAP………………………………………………………………..218

WATER PUMP………………………………………………………………….219

RADIATOR, FAN, AND RADIATOR SHUTTER……………………………………………220

THERMOSTAT………………………………………………………………….221

WATER TEMPERATURE GAUGE, EXCESSIVE FUEL, OVERLOAD……………………………….223

STANDARD VALUE TABLE FOR TESTING, ADJUSTING, AND TROUBLESHOOTING……………………..224

TROUBLESHOOTING OF ENGINE (S MODE)………………………………………………..227

METHOD OF USING TROUBLESHOOTING CHARTS…………………………………………228

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)…………………….232

S-2 ENGINE DOES NOT START…………………………………………………….233

(1) ENGINE DOES NOT TURN………………………………………………….233

(2) ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT (FUEL IS NOT BEING INJECTED)……234

(3) EXHAUST SMOKE COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)….235

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)…………………………236

S-4 ENGINE STOPS DURING OPERATIONS…………………………………………….237

S-5 ENGING DOES NOT ROTATE SMOOTHLY (HUNTING)…………………………………..238

S-6 ENGINE LACKS OUTPUT (OR LACKS POWER)……………………………………….239

S-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION)………………………………240

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE)………………………241

S-9 OIL BECOMES CONTAMINATED QUICKLY…………………………………………..242

S-10 FUEL CONSUMPTION IS EXCESSIVE…………………………………………….243

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN……….244

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE)…………………..245

S-13 OIL LEVEL RISES (WATER, FUEL IN OIL)………………………………………246

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)……………………………247

S-15 ABNORMAL NOISE IS MADE…………………………………………………..248

S-16 VIBRATION IS EXCESSIVE…………………………………………………..249

13 DISASSEMBLY AND ASSEMBLY …………………………………………………………251

SPECIAL TOOL LIST……………………………………………………………….254

SPECIAL TOOLS FOR DISASSEMBLY AND ASSEMBLY……………………………………..254

OUTLINE OF DISASSEMBLY AND ASSEMBLY OF ENGINE………………………………………258

OUTLINE…………………………………………………………………….258

OVERALL DISASSEMBLY OF ENGINE…………………………………………………….259

ENGINE LIFTING TOOL AND BRACKET……………………………………………….259

PREPARATION FOR STEAM CLEANING OF ENGINE……………………………………….259

STEAM CLEANING OF ENGINE……………………………………………………..259

DRAINING OIL………………………………………………………………..260

DRAINING COOLANT…………………………………………………………….260

REMOVAL OF OIL FILTER………………………………………………………..260

REMOVAL OF FUEL FILTER……………………………………………………….261

REMOVAL OF FUEL SUPPLY PIPE (LOW-PRESSURE SIDE)…………………………………261

REMOVAL OF FUEL FEED PUMP…………………………………………………….261

REMOVAL OF FUEL SUPPLY PIPE (HIGH-PRESSURE SIDE)………………………………..262

REMOVAL OF FUEL INJECTION PUMP FUEL SUPPLY PIPES………………………………..262

REMOVAL OF BOOST COMPENSATOR TUBE……………………………………………..262

REMOVAL OF TACHOMETER DRIVE…………………………………………………..263

REMOVAL OF FUEL INJECTION PUMP………………………………………………..263

REMOVAL OF AIR CONDITIONER COMPRESSOR………………………………………….264

INSTALLATION OF ENGINE TO ENGINE STAND…………………………………………265

REMOVAL OF TURBOCHARGER EXHAUST OUTLET CONNECTOR………………………………..266

REMOVAL OF WESTGATE ACTUATOR HOSE……………………………………………..266

REMOVAL OF CYLINDER BLOCK BREATHER TUBE………………………………………..266

REMOVAL OF CROSSOVER TUBE…………………………………………………….267

REMOVAL OF INTAKE MANIFOLD COVER………………………………………………267

REMOVAL OF AFTERCOOLER……………………………………………………….267

REMOVAL OF FUEL DRAIN MANIFOLD………………………………………………..268

REMOVAL OF INJECTOR………………………………………………………….268

REMOVAL OF CYLINDER HEAD COVER………………………………………………..269

REMOVAL OF ROCKER LEVER………………………………………………………269

REMOVAL OF PUSH ROD………………………………………………………….270

REMOVAL OF TURBOCHARGER OIL SUPPLY HOSE………………………………………..270

REMOVAL OF TURBOCHARGER OIL DRAIN TUBE…………………………………………270

REMOVAL OF TURBOCHARGER………………………………………………………270

REMOVAL OF EXHAUST MANIFOLD…………………………………………………..271

REMOVAL OF DRIVE BELT………………………………………………………..271

REMOVAL OF BELT TENSIONER…………………………………………………….271

REMOVAL OF BELT TENSIONER BRACKET……………………………………………..271

REMOVAL OF ALTERNATOR BRACKET…………………………………………………272

REMOVAL OF ALTERNATOR………………………………………………………..272

REMOVAL OF ALTERNATOR BRACKET…………………………………………………272

REMOVAL OF COOLANT OUTLET CONNECTOR……………………………………………272

REMOVAL OF COOLANT AIR BLEED TUBE……………………………………………..273

REMOVAL OF COOLANT AIR BLEED VALVE…………………………………………….273

REMOVAL OF THERMOSTAT AND HOUSING……………………………………………..273

REMOVAL OF THERMOSTAT AND HOUSING……………………………………………..273

REMOVAL OF CYLINDER HEAD……………………………………………………..274

DRAINING OIL FROM OIL COOLER………………………………………………….274

REMOVAL OF COOLANT INLET CONNECTOR…………………………………………….274

REMOVAL OF FAN HUB ASSEMBLY…………………………………………………..275

REMOVAL OF WATER PUMP………………………………………………………..275

REMOVAL OF VIBRATION DAMPER…………………………………………………..276

REMOVAL OF GEAR COVER………………………………………………………..276

REMOVAL OF FRONT CRANKSHAFT SEAL………………………………………………276

REMOVAL OF STARTING MOTOR…………………………………………………….276

REMOVAL OF COOLANT HEATER…………………………………………………….277

REMOVAL OF FLYWHEEL………………………………………………………….277

REMOVAL OF FLYWHEEL HOUSING…………………………………………………..277

REMOVAL OF OIL PAN…………………………………………………………..277

REMOVAL OF SUCTION TUBE………………………………………………………278

REMOVAL OF REAR CRANKSHAFT SEAL……………………………………………….278

REMOVAL OF CAMSHAFT………………………………………………………….278

REMOVAL OF VALVE TAPPET………………………………………………………280

MEASUREMENT OF OIL PUMP GEAR BACKLASH………………………………………….280

REMOVAL OF OIL PUMP………………………………………………………….281

REMOVAL OF ENGINE FRONT SUPPORT……………………………………………….281

REMOVAL OF GEAR HOUSING………………………………………………………281

REMOVAL OF CARBON ACCUMULATED ON CYLINDER LINER…………………………………282

REMOVAL OF PISTON ASSEMBLY……………………………………………………283

REMOVAL OF PISTON PIN………………………………………………………..284

REMOVAL OF PISTON RING……………………………………………………….284

REMOVAL OF MAIN BEARING CAP…………………………………………………..285

REMOVAL OF MAIN BEARING (LOWER)……………………………………………….285

REMOVAL OF CRANKSHAFT………………………………………………………..286

REMOVAL OF MAIN BEARING (UPPER)……………………………………………….286

REMOVAL OF PISTON COOLING NOZZLE………………………………………………286

TESTING PROTRUSION OF CYLINDER LINER…………………………………………..286

REMOVAL OF CYLINDER LINER…………………………………………………….287

REPLACEMENT OF EXPANSION PLUG…………………………………………………288

REMOVAL OF EXPANSION PLUG…………………………………………………….288

REMOVAL OF CYLINDER BLOCK FROM ENGINE STAND…………………………………….289

ASSEMBLY OF ENGINE………………………………………………………………290

INSTALL THE CYLINDER BLOCK TO THE ROLL-OVER STAND……………………………….290

INSTALLATION OF CYLINDER LINER………………………………………………..290

INSTALLATION OF TAPPET……………………………………………………….295

INSTALLATION OF PISTON COOLING NOZZLE………………………………………….295

INSTALLATION OF MAIN BEARING (UPPER)…………………………………………..296

INSTALLATION OF CRANKSHAFT……………………………………………………298

INSTALLATION OF MAIN BEARING (LOWER)…………………………………………..299

INSTALLATION OF MAIN BEARING CAP………………………………………………299

INSTALLATION OF CONNECTING ROD BOLT……………………………………………302

INSTALLATION OF PISTON PIN……………………………………………………303

MEASURING PISTON RING END GAP…………………………………………………303

INSTALLATION OF PISTON RING…………………………………………………..304

INSTALLATION OF PISTON ASSEMBLY……………………………………………….306

INSTALLATION OH GEAR HOUSING………………………………………………….311

INSTALLATION OF OIL PUMP……………………………………………………..312

INSTALLATION OF CAMSHAFT……………………………………………………..314

INSTALLATION OF WATER PUMP……………………………………………………316

INSTALLATION OF OIL SUCTION TUBE………………………………………………316

INSTALLATION OF REAR CRANKSHAFT SEAL…………………………………………..316

INSTALLATION OF WEAR SLEEVE, REAR CRANKSHAFT SEAL……………………………….317

INSTALLATION OF OIL PAN………………………………………………………320

INSTALLATION OF TIMING PIN ASSEMBLY……………………………………………321

INSTALLATION OF FLYWHEEL HOUSING………………………………………………324

TESTING COAXIALITY OF FLYWHEEL HOUSING BORE…………………………………….325

INSTALLATION OF FLYWHEEL……………………………………………………..329

MEASURING RUNOUT OF FLYWHEEL BORE……………………………………………..331

MEASURING FACE RUNOUT OF FLYWHEEL……………………………………………..333

INSTALLATION OF STARTING MOTOR………………………………………………..334

INSTALLATION OF OIL COOLER……………………………………………………334

INSTALLATION OF OIL FILTER……………………………………………………335

INSTALLATION OF CYLINDER HEAD…………………………………………………335

INSTALLATION OF PUSH ROD……………………………………………………..339

ASSEMBLY OF ROCKER LEVER AND SHAFT…………………………………………….339

INSTALLATION OF ROCKER LEVER ASSEMBLY………………………………………….341

ADJUSTING VALVE CLEARANCE…………………………………………………….342

INSTALLATION OF HEAD COVER……………………………………………………344

INSTALLATION OF CYLINDER BLOCK BREATHER TUBE……………………………………345

INSTALLATION OF INJECTOR……………………………………………………..345

INSTALLATION OF FUEL DRAIN MANIFOLD……………………………………………346

INSTALLATION OF ENGINE LIFTING BRACKET…………………………………………346

INSTALLATION OF INTAKE MANIFOLD COVER………………………………………….346

INSTALLATION OF AFTERCOOLER…………………………………………………..347

INSTALLATION OF EXHAUST MANIFOLD………………………………………………347

INSTALLATION OF TURBOCHARGER………………………………………………….348

INSTALLATION OF TURBOCHARGER OIL DRAIN TUBE…………………………………….349

INSTALLATION OF TURBOCHARGER OIL SUPPLY HOSE……………………………………351

INSTALLATION OF TURBOCHARGER EXHAUST OUTLET PORT CONNECTOR……………………….351

INSTALLATION OF CROSSOVER…………………………………………………….351

INSTALLATION OF THERMOSTAT AND HOUSING…………………………………………351

INSTALLATION OF COOLANT OUTLET CONNECTOR……………………………………….352

INSTALLATION OF COOLANT AIR BLEED JOINT………………………………………..352

INSTALLATION OF COOLANT AIR BLEED VALVE………………………………………..352

INSTALLATION OF COOLANT AIR BLEED TUBE…………………………………………353

INSTALLATION OF COOLANT INLET CONNECTOR………………………………………..353

INSTALLATION OF ALTERNATOR BRACKET…………………………………………….353

INSTALLATION OF ALTERNATOR……………………………………………………353

INSTALLATION OF ALTERNATOR BRACE………………………………………………354

INSTALLATION OF BELT TENSIONER BRACKET…………………………………………355

INSTALLATION OF BELT TENSIONER………………………………………………..355

REMOVAL FROM ENGINE ASSEMBLY STAND…………………………………………….355

INSTALLATION OF FAN HUB ASSEMBLY………………………………………………356

INSTALLATION OF FUEL INJECTION PUMP……………………………………………356

INSTALLATION OF FUEL INJECTION PUMP, FUEL SUPPLY LINE……………………………361

INSTALLATION OF FUEL FILTER HEAD………………………………………………361

INSTALLATION OF FUEL FILTER…………………………………………………..362

INSTALLATION OF FUEL INJECTION PIPE (HIGH-PRESSURE SIDE)…………………………362

INSTALLATION OF BOOST COMPENSATOR TUBE…………………………………………363

INSTALLATION OF FRONT CRANKSHAFT SEAL………………………………………….363

INSTALLATION OF FRONT CRANKSHAFT WEAR SLEEVE……………………………………363

INSTALLATION OF GEAR COVER……………………………………………………366

INSTALLATION OF TACHOMETER DRIVE………………………………………………367

INSTALLATION OF CRANKSHAFT PULLEY, VIBRATION DAMPER……………………………..367

INSTALLATION OF BELT…………………………………………………………368

INSTALLATION OF ENGINE FRONT SUPPORT…………………………………………..368

INSTALLATION OF FUEL FEED PUMP………………………………………………..368

INSTALLATION OF FUEL PIPING TUBE (LOW-PRESSURE SIDE)…………………………….369

INSTALLATION OF FUEL PUMP SOLENOID…………………………………………….369

INSTALLATION OF AIR COMPRESSOR………………………………………………..369

INSTALLATION OF ENGINE ACCESSORY………………………………………………371

15 REPAIR AND REPLACEMENT OF PARTS …………………………………………………..373

OUTLINE………………………………………………………………………..374

REPAIR GUIDE LINE……………………………………………………………374

WHEN SHOULD SUBSTITUTE REPAIRS BE CARRIED OUT…………………………………..374

INSPECTION………………………………………………………………….374

TO ENSURE SAFETY, FOLLOW ALL INSTRUCTIONS IN MANUAL……………………………..374

FOLLOW WASHING METHODS GIVEN IN MANUAL…………………………………………374

FOLLOW INSPECTION METHODS GIVEN IN MANUAL………………………………………374

REPAIR METHODS FOR SCREWS USING COIL THREAD INSERT………………………………….375

METHOD FOR USING TAPER THREAD PLUGS TO SEAL POCKETS AND SMALL HOLES IN CASTINGS………..376

REPAIR PROCEDURE…………………………………………………………….376

METHOD FOR REPAIRING TAPER THREAD PLUG HOLES WORN BY LARGE SIZE COPPER PLATED PLUGS…….379

METHOD OF USING FILLER METAL IN EMERGENCY REPAIRS…………………………………..380

INSPECTION FOR REUSE OF CYLINDER BLOCK…………………………………………….381

INSTALLATION OF EXPANSION PLUGS…………………………………………………..385

INSTALLATION OF PIPE PLUGS……………………………………………………385

INSTALLATION OF EXPANSION PLUG TO CAMSHAFT HOLE…………………………………….388

REMOVAL OF CAMSHAFT BUSHING………………………………………………………389

CLEANING OF CAMSHAFT BUSHING HOLE……………………………………………..389

INSTALLATION OF CAMSHAFT BUSHING………………………………………………….390

CLEANING AND INSPECTION OF CYLINDER LINERS BEFORE REUSING THEM……………………….393

CREANING OF CYLINDER LINERS…………………………………………………..393

INSPECTION OF CYLINDER LINERS…………………………………………………394

CLEANING AND INSPECTION OF PISTON BEFORE REUSING IT…………………………………396

REMOVE THE PISTON RINGS………………………………………………………396

CLEANING OF PISTONS………………………………………………………….396

INSPECTION OF PISTONS………………………………………………………..397

CLEANING AND INSPECTION OF CRANKSHAFT BEFORE REUSING IT……………………………..399

CLEANING OF CRANKSHAFT……………………………………………………….399

INSPECTION OF CRANKSHAFT……………………………………………………..399

REPLACEMENT OF CRANKSHAFT GEAR……………………………………………………403

REMOVAL OF CRANKSHAFT GEAR……………………………………………………403

INSPECTION OF CRANKSHAFT……………………………………………………..403

INSTALLATION OF CRANKSHAFT GEAR……………………………………………….404

CLEANING AND INSPECTION OF MAIN BEARINGS BEFORE REUSING THEM…………………………406

GENERAL INFORMATION………………………………………………………….406

CLEANING OF MAIN BEARINGS…………………………………………………….406

INSPECTION OF MAIN BEARINGS…………………………………………………..406

INSPECTION OF THRUST BEARING………………………………………………….407

CLEANING AND INSPECTION OF MAIN BEARING CAPS AND MOUNTING BOLTS BEFORE REUSING THEM…….408

CLEANING……………………………………………………………………408

INSPECTION………………………………………………………………….408

CLEANING AND INSPECTION OF CONNECTING ROD BEARINGS BEFORE REUSING THEM………………..409

CLEANING OF CONNECTING ROD BEARINGS……………………………………………409

INSPECTION OF CONNECTING ROD BEARINGS………………………………………….409

CLEANING AND INSPECTION OF CONNECTING RODS BEFORE REUSING THEM……………………….411

CLEANING OF CONNECTING RODS…………………………………………………..411

INSPECTION OF CONNECTIONG RODS………………………………………………..411

INSPECTION OF CONNECTING RODS FOR BEND AND TORSION………………………………….414

CALIBRATION OF FIXING TOOL……………………………………………………414

INSPECTION OF ALIGNMENT OF CONNECTING RODS……………………………………..415

REPAIR PROCEDURE FOR CONNECTING RODS…………………………………………..415

REPLACEMENT OF CONNECTING ROD BUSHINGS…………………………………………….416

REMOVAL…………………………………………………………………….416

INSTALLATION………………………………………………………………..418

INSPECTION………………………………………………………………….420

REPLACEMENT OF VALVE INSERTS OF CYLINDER HEAD………………………………………421

REMOVAL…………………………………………………………………….421

INSPECTION………………………………………………………………….423

ASSEMBLY……………………………………………………………………423

INSPECTION OF VALVE GUIDES……………………………………………………424

INSPECTION OF VALVE SEAT INSERTS………………………………………………425

INSPECTION OF VALVE SPRINGS…………………………………………………..426

INSPECTION OF VALVE STEM SEAL…………………………………………………427

INSPECTION OF VALVES…………………………………………………………427

GRINDING OF VALVES…………………………………………………………..428

GRINDING OF VALVE SEAT INSERTS………………………………………………..429

ASSEMBLY……………………………………………………………………433

INSTALLATION OF PIPE PLUGS……………………………………………………433

REPLACEMENT OF VALVE GUIDES OF CYLINDER HEAD……………………………………….436

DISASSEMBLY…………………………………………………………………436

INSPECTION………………………………………………………………….436

ASSEMBLY……………………………………………………………………436

CYLINDER HEAD-PRESSURE TEST………………………………………………………439

VACUUM TEST ON VALVE SEATS OF CYLINDER HEAD………………………………………..441

CLEANING AND INSPECTION OF CYLINDER HEAD BOLTS……………………………………..443

CLEANING……………………………………………………………………443

INSPECTION………………………………………………………………….443

FREE LENGTH-MEASUREMENT………………………………………………………444