$35

Komatsu 125-3 Series Diesel Engine Shop Manual SEBM024209 – PDF DOWNLOAD

Komatsu 125-3 Series Diesel Engine Shop Manual SEBM024209 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 125-3 Series Diesel Engine Shop Manual SEBM024209 – PDF DOWNLOAD

Language : English

Pages : 374

Downloadable : Yes

File Type : PDF

Size: 24.1 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 125-3 Series Diesel Engine Shop Manual SEBM024209 – PDF DOWNLOAD

The Komatsu 125-3 Series Diesel Engine Shop Manual SEBM024209 is a comprehensive technical guide that provides detailed information on the maintenance, repair, and overhaul of the Komatsu 125-3 series diesel engine. This engine is commonly used in heavy equipment such as excavators, bulldozers, and wheel loaders.

The manual is organized into several sections, each covering specific aspects of the engine:

- General Information: This section provides an overview of the engine, including specifications, maintenance intervals, and general operating guidelines.

- Inspection and Adjustment: This section provides detailed instructions for inspecting and adjusting engine components, such as the fuel injection system, valves, and timing belts.

- Engine Assembly: This section covers the removal and installation of major engine components, including the cylinder head, crankshaft, and pistons. The manual includes detailed illustrations and specifications to help technicians perform these tasks safely and efficiently.

- Lubrication System: This section provides information on the engine’s lubrication system, including oil pump removal and installation, oil filter replacement, and oil pressure testing.

- Cooling System: This section provides information on the engine’s cooling system, including water pump removal and installation, radiator removal and installation, and thermostat replacement.

- Fuel System: This section covers the engine’s fuel system, including fuel pump removal and installation, fuel injector replacement, and fuel system troubleshooting.

- Air Intake and Exhaust System: This section provides information on the engine’s air intake and exhaust system, including air filter replacement, turbocharger removal and installation, and exhaust manifold removal and installation.

- Electrical System: This section provides information on the engine’s electrical system, including alternator and starter motor removal and installation, as well as troubleshooting procedures for electrical faults.

- Special Tools: This section lists the special tools required for servicing the engine, including part numbers and illustrations.

The Komatsu 125-3 Series Diesel Engine Shop Manual SEBM024209 is an essential reference guide for maintaining and repairing the engine. It provides detailed instructions, specifications, and illustrations to help technicians perform tasks accurately and safely. The manual is a valuable tool for ensuring that the Komatsu 125-3 series diesel engine continues to operate at peak performance, with maximum efficiency and reliability over its long service life.

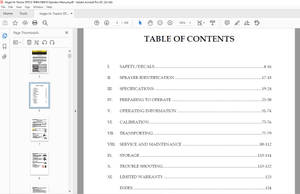

TABLE OF CONTENTS:

Komatsu 125-3 Series Diesel Engine Shop Manual SEBM024209 – PDF DOWNLOAD

COVER…………………………………………………………………………………………………………………………………. 1

CONTENTS………………………………………………………………………………………………………………………………. 2

LIST OF REVISED PAGES…………………………………………………………………………………………………………………… 3

SAFETY………………………………………………………………………………………………………………………………… 7

FOREWORD………………………………………………………………………………………………………………………………. 9

GENERAL……………………………………………………………………………………………………………………………. 9

HOW TO READ THE SHOP MANUAL………………………………………………………………………………………………………….. 10

HOISTING INSTRUCTIONS……………………………………………………………………………………………………………….. 11

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER………………………………………………………………………………. 12

COATING MATERIALS…………………………………………………………………………………………………………………… 14

STANDARD TIGHTENING TORQUE…………………………………………………………………………………………………………… 16

ELECTRIC WIRE CODE………………………………………………………………………………………………………………….. 19

CONVERSION TABLE……………………………………………………………………………………………………………………. 20

UNITS……………………………………………………………………………………………………………………………… 26

01 GENERAL…………………………………………………………………………………………………………………………….. 27

OUTLINE……………………………………………………………………………………………………………………………. 28

SPECIFICATIONS……………………………………………………………………………………………………………………… 32

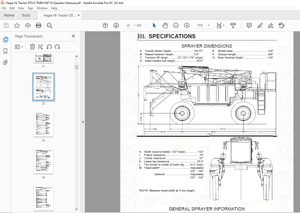

GENERAL ASSEMBLY DRAWING…………………………………………………………………………………………………………….. 36

WEIGHT TABLE……………………………………………………………………………………………………………………….. 49

ENGINE PERFORMANCE CURVE…………………………………………………………………………………………………………….. 50

11 STRUCTURE AND FUNCTION, MAINTENANCE STANDARD……………………………………………………………………………………………. 61

GENERAL STRUCTURE…………………………………………………………………………………………………………………… 62

INTAKE, EXHAUST SYSTEM………………………………………………………………………………………………………………. 66

INTAKE, EXHAUST SYSTEM…………………………………………………………………………………………………………… 66

AIR CLEANER…………………………………………………………………………………………………………………….. 72

TURBOCHARGER……………………………………………………………………………………………………………………. 73

AFTERCOOLER…………………………………………………………………………………………………………………….. 74

ENGINE BODY………………………………………………………………………………………………………………………… 76

CYLINDER HEAD…………………………………………………………………………………………………………………… 76

CYLINDER BLOCK………………………………………………………………………………………………………………….. 80

CYLINDER LINER………………………………………………………………………………………………………………….. 84

MAIN CIRCULATION SYSTEM………………………………………………………………………………………………………….. 86

CRANKSHAFT……………………………………………………………………………………………………………………… 88

PISTON…………………………………………………………………………………………………………………………. 90

CONNECTING ROD………………………………………………………………………………………………………………….. 92

FLYWHEEL AND FLYWHEEL HOUSING…………………………………………………………………………………………………….. 93

VIBRATION DAMPER………………………………………………………………………………………………………………… 95

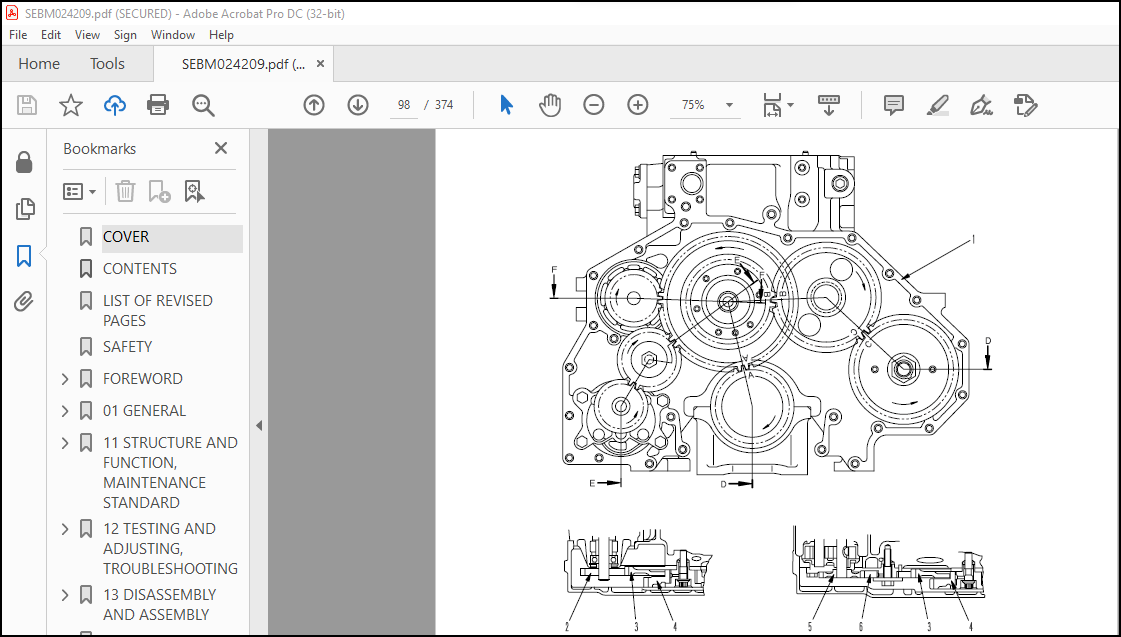

TIMING GEAR…………………………………………………………………………………………………………………….. 98

VALVE MECHANISM………………………………………………………………………………………………………………….102

CAMSHAFT………………………………………………………………………………………………………………………..104

CAM FOLLOWER AND PUSH ROD…………………………………………………………………………………………………………105

VALVE AND VALVE GUIDE…………………………………………………………………………………………………………….106

ROCKER ARM SHAFT…………………………………………………………………………………………………………………108

CROSSHEAD……………………………………………………………………………………………………………………….109

LUBRICATION SYSTEM…………………………………………………………………………………………………………………..110

LUBRICATION SYSTEM DIAGRAM………………………………………………………………………………………………………..110

OIL PUMP………………………………………………………………………………………………………………………..111

MAIN RELIFE VALVE………………………………………………………………………………………………………………..113

OIL FILTER………………………………………………………………………………………………………………………114

SAFETY VALVE…………………………………………………………………………………………………………………….115

OIL COOLER………………………………………………………………………………………………………………………116

FUEL SYSTEM…………………………………………………………………………………………………………………………118

FUEL SYSTEM DIAGRAM………………………………………………………………………………………………………………118

OUTLINE OF CRI SYSTEM…………………………………………………………………………………………………………….119

FUEL PIPING……………………………………………………………………………………………………………………..132

FUEL COOLER……………………………………………………………………………………………………………………..134

FUEL FILTER……………………………………………………………………………………………………………………..135

COOLING SYSTEM………………………………………………………………………………………………………………………137

COOLING SYSTEM CHART……………………………………………………………………………………………………………..137

WATER PUMP………………………………………………………………………………………………………………………138

THERMOSTAT………………………………………………………………………………………………………………………141

CORROSION RESISTOR……………………………………………………………………………………………………………….143

ELECTRICAL SYSTEM……………………………………………………………………………………………………………………144

ALTERNATOR MOUNTING………………………………………………………………………………………………………………144

ALTERNATOR………………………………………………………………………………………………………………………147

STARTING MOTOR…………………………………………………………………………………………………………………..152

STARTING AID…………………………………………………………………………………………………………………….154

12 TESTING AND ADJUSTING, TROUBLESHOOTING………………………………………………………………………………………………….157

TESTING AND ADJUSTING DATA……………………………………………………………………………………………………………160

STANDARD VALUE TABLE FOR ELECTRICAL PARTS………………………………………………………………………………………………166

TESTING AND ADJUSTING TOOL LIST……………………………………………………………………………………………………….168

TESTING AND ADJUSTING………………………………………………………………………………………………………………..169

MEASURING INTAKE AIR PRESSURE (BOOT PRESSURE)……………………………………………………………………………………….169

MEASURING EXHAUST TEMPERATURE……………………………………………………………………………………………………..170

ADJUSTING VALVE CLEARANCE…………………………………………………………………………………………………………172

MEASURING COMPRESSION PRESSURE…………………………………………………………………………………………………….174

MEASURING BLOW-BY PRESSURE………………………………………………………………………………………………………..176

MEASURING ENGINE OIL PRESSURE……………………………………………………………………………………………………..177

MEASURING FUEL PRESSURE…………………………………………………………………………………………………………..178

ADJUSTING ENGINE SPEED SENSOR……………………………………………………………………………………………………..179

TESTING AND ADJUSTING FUEL INJECTION TIMING…………………………………………………………………………………………180

HANDLING EQUIPMENT IN FUEL SYSTEM………………………………………………………………………………………………….186

RELEASING REMAINING PRESSURE IN FUEL SYSTEM…………………………………………………………………………………………186

BLEEDING AIR FROM FUEL CIRCUIT…………………………………………………………………………………………………….187

REDUCED CYLINDER MODE OPERATION FOR ENGINE………………………………………………………………………………………….189

CHECKING FOR LEAKAGE IN FUEL SYSTEM………………………………………………………………………………………………..190

ADJUSTING ENGINE STOP MOTOR LEVER………………………………………………………………………………………………….191

CALIBRATION DATA…………………………………………………………………………………………………………………….194

PERFORMANCE TEST…………………………………………………………………………………………………………………….196

RUN-IN STANDARD………………………………………………………………………………………………………………….196

PERFORMANCE TEST STANDARDS………………………………………………………………………………………………………..198

TROUBLESHOOTING……………………………………………………………………………………………………………………..205

TROUBLESHOOTING OF ENGINE SYSTEM (S MODE)…………………………………………………………………………………………..205

POINTS TO REMEMBER WHEN TROUBLESHOOTING…………………………………………………………………………………………206

METHOD OF USING TROUBLESHOOTING CHARTS………………………………………………………………………………………….207

S-1 Starting performance is poor (starting always takes time)……………………………………………………………………..211

S-2 Engine does not start……………………………………………………………………………………………………..212

S-3 Engine does not pick up smoothly (follow-up is poor)………………………………………………………………………….215

S-4 Engine stops during operations……………………………………………………………………………………………..216

S-5 Engine does not rotate smoothly (hunting)……………………………………………………………………………………217

S-6 Engine lacks output (or lacks power)………………………………………………………………………………………..218

S-7 Exhaust smoke is black (incomplete combustion)……………………………………………………………………………….219

S-8 Oil consumption is excessive (or exhaust smoke is blue)……………………………………………………………………….220

S-9 Oil becomes contaminated quickly……………………………………………………………………………………………221

S-10 Fuel consumption is excessive……………………………………………………………………………………………..222

S-11 Oil is in cooling water (or water spurts back, or water level goes down)……………………………………………………….223

S-12 Oil pressure caution lamp lights up (drop in oil pressure)……………………………………………………………………224

S-13 Oil level rises (water, fuel in oil)……………………………………………………………………………………….225

S-14 Water temperature becomes too high (overheating)…………………………………………………………………………….226

S-15 Abnormal noise is made……………………………………………………………………………………………………227

S-16 Vibration is excessive……………………………………………………………………………………………………228

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)……………………………………………………………………………………….229

POINTS TO REMEMBER WHEN TROUBLESHOOTING…………………………………………………………………………………………231

METHOD OF USING TROUBLESHOOTING FLOWCHART……………………………………………………………………………………….232

ERROR CODE DISPLAYS AND POINTS TO REMEMBER WHEN TROUBLESHOOTING……………………………………………………………………233

ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ERROR CODE IS DISPLAYED…………………………………………………….236

E-1 Error code [E-1b] [Abnormality in NE revolution sensor system]…………………………………………………………………245

E-2 Error code [E-1C] [Abnormality in G revolution sensor system]………………………………………………………………….246

E-3 Error code [E-20] [Abnormality in model selection system]……………………………………………………………………..247

E-4 Error code [E-22] [Overrun]………………………………………………………………………………………………..248

E-5 Error code [E-23] [Overheat]……………………………………………………………………………………………….248

E-6 Error code [E-24] [Drop in oil pressure]…………………………………………………………………………………….249

E-7 Error code [E-30] [Abnormality in idling validation signal system]……………………………………………………………..250

E-8 Error code [E-31] [Abnormality in throttle sensor system]……………………………………………………………………..252

E-9 Error code [E-34] [Abnormality in water temperature high-temperature sensor system]………………………………………………255

E-10 Error code [E-36] [Abnormality in oil pressure switch system]…………………………………………………………………256

E-11 Error code [E-3C] [Abnormality in boost pressure sensor system]……………………………………………………………….258

E-12 Error code [E-3d] [Abnormality in fuel temperature sensor system]……………………………………………………………..259

E-13 Error code [E-50] [Abnormality in preheating relay connecting point system]…………………………………………………….260

E-14 Error code [E-51] [Abnormality in preheat relay coil system]………………………………………………………………….261

E-15 Error code [E-54] [Short circuit in starting switch C system]…………………………………………………………………262

E-16 Error code [E-56] [Power source system abnormality 1]………………………………………………………………………..264

E-17 Error code [E-57] [Power source system abnormality 2]………………………………………………………………………..266

E-18 Error code [E-5A] [Abnormality in fuel injection quantity control switch signal]………………………………………………..267

E-19 Error code [E-6A] [Abnormality in water temperature low-temperature sensor system]………………………………………………268

E-20 Error code [E-70] [Excess current in fuel supply pump PCV1 system]…………………………………………………………….269

E-21 Error code [E-71] [Excess current in fuel supply pump PCV2 system]…………………………………………………………….270

E-22 Error code [E-74] [Disconnection in fuel supply pump PCV1 system]……………………………………………………………..271

E-23 Error code [E-75] [Disconnection in fuel supply pump PCV2 system]……………………………………………………………..272

E-24 Error code [E-77] [Abnormality in common rail fuel pressure sensor system]……………………………………………………..273

E-25 Error code [E-79] [Common rail fuel high pressure abnormality 1] Error code [E-7A] [Common rail fuel high pressure abnormality 2]….274

E-26 Error code [E-7b] [Fuel supply pump non-force feed 1] Error code [E-7C] [Fuel supply pump non-force feed 2]……………………..276

E-27 Error code [E-7d] [Abnormality in common rail fuel pressure]………………………………………………………………….278

E-28 Error code [E-80] [Defective controller]……………………………………………………………………………………278

E-29 Error code [E-81] [Disconnection in No. 1 fuel injector system]……………………………………………………………….279

E-30 Error code [E-82] [Disconnection in No. 2 fuel injector system]……………………………………………………………….280

E-31 Error code [E-83] [Disconnection in No. 3 fuel injector system]……………………………………………………………….281

E-32 Error code [E-84] [Disconnection in No. 4 fuel injector system]……………………………………………………………….282

E-33 Error code [E-85] [Disconnection in No. 5 fuel injector system]……………………………………………………………….283

E-34 Error code [E-86] [Disconnection in No. 6 fuel injector system]……………………………………………………………….284

E-35 Error code [E-8A] [Short circuit in No. 1, No. 2, No. 3 fuel injector system]…………………………………………………..285

E-36 Error code [E-8b] [Short circuit in No. 4, No. 5, No. 6 fuel injector system]…………………………………………………..288

13 DISASSEMBLY AND ASSEMBLY………………………………………………………………………………………………………………291

METHOD OF USING MANUAL……………………………………………………………………………………………………………….293

PRECAUTIONS WHEN CARRYING OUT OPERATION………………………………………………………………………………………………..294

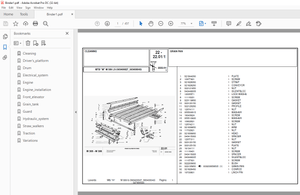

SPECIAL TOOL LIST……………………………………………………………………………………………………………………296

SKETCHES OF SPECIAL TOOLS…………………………………………………………………………………………………………….297

GENERAL DISASSEMBLY………………………………………………………………………………………………………………….298

1. Preparation work………………………………………………………………………………………………………………298

2. Starting motor………………………………………………………………………………………………………………..298

3. Turbocharger lubricant return tube………………………………………………………………………………………………298

4. Radiator lower hose……………………………………………………………………………………………………………298

5. Engine oil cooler……………………………………………………………………………………………………………..298

6. Adapter for engine overhauling………………………………………………………………………………………………….299

7. Radiator upper hose……………………………………………………………………………………………………………299

8. Exhaust muffler……………………………………………………………………………………………………………….299

9. Fan securing bracket…………………………………………………………………………………………………………..299

10. Turbocharger lubrication tube………………………………………………………………………………………………….299

11. Turbocharger and exhaust manifold………………………………………………………………………………………………299

12. Fuel filter assembly………………………………………………………………………………………………………….299

13. Oil filter…………………………………………………………………………………………………………………..300

14. Wiring harness……………………………………………………………………………………………………………….300

15. Air cleaner securing bracket…………………………………………………………………………………………………..300

16. Exhaust muffler securing bracket……………………………………………………………………………………………….300

17. High pressure tube clamp………………………………………………………………………………………………………300

18. Suction manifold assembly……………………………………………………………………………………………………..300

19. Supply pump………………………………………………………………………………………………………………….300

20. Common rail………………………………………………………………………………………………………………….301

21. Spill pipe…………………………………………………………………………………………………………………..302

22. Head cover…………………………………………………………………………………………………………………..302

23. Injector harness……………………………………………………………………………………………………………..302

24. Rocker arm…………………………………………………………………………………………………………………..302

25. Push rod…………………………………………………………………………………………………………………….302

26. Injector…………………………………………………………………………………………………………………….302

27. Nozzle tip…………………………………………………………………………………………………………………..303

28. Crosshead……………………………………………………………………………………………………………………303

29. Rocker arm housing……………………………………………………………………………………………………………304

30. Injector harness connector…………………………………………………………………………………………………….304

31. Thermostat…………………………………………………………………………………………………………………..304

32. Cam follower cover……………………………………………………………………………………………………………304

33. Cam follower…………………………………………………………………………………………………………………304

34. Cylinder head assembly………………………………………………………………………………………………………..304

35. Setting to engine overhaul stand……………………………………………………………………………………………….305

36. Oil pan……………………………………………………………………………………………………………………..305

37. Flywheel…………………………………………………………………………………………………………………….305

38. Flywheel housing……………………………………………………………………………………………………………..305

39. Damper………………………………………………………………………………………………………………………306

40. Front support………………………………………………………………………………………………………………..306

41. Front cover………………………………………………………………………………………………………………….306

42. Water pump…………………………………………………………………………………………………………………..306

43. Camshaft…………………………………………………………………………………………………………………….306

44. Oil pump…………………………………………………………………………………………………………………….306

45. Idler gear…………………………………………………………………………………………………………………..306

46. Oil suction pipe……………………………………………………………………………………………………………..307

47. Piston cooling nozzle…………………………………………………………………………………………………………307

48. Piston and connecting rod assembly……………………………………………………………………………………………..307

49. Crankshaft…………………………………………………………………………………………………………………..308

50. Cylinder liner……………………………………………………………………………………………………………….309

GENERAL ASSEMBLY…………………………………………………………………………………………………………………….310

1. Cylinder liner………………………………………………………………………………………………………………..311

2. Crankshaft……………………………………………………………………………………………………………………312

3. Piston and connecting rod assembly………………………………………………………………………………………………315

4. Piston cooling nozzle………………………………………………………………………………………………………….318

5. Oil suction pipe………………………………………………………………………………………………………………319

6. Idler gear……………………………………………………………………………………………………………………319

7. Oil pump……………………………………………………………………………………………………………………..319

8. Camshaft……………………………………………………………………………………………………………………..320

9. Cam followers…………………………………………………………………………………………………………………320

10. Cam follower covers…………………………………………………………………………………………………………..320

11. Water pump…………………………………………………………………………………………………………………..320

12. Fuel supply pump driving gear………………………………………………………………………………………………….320

13. Front cover………………………………………………………………………………………………………………….321

14. Flywheel housing……………………………………………………………………………………………………………..322

15. Rear seal……………………………………………………………………………………………………………………323

16. Flywheel…………………………………………………………………………………………………………………….325

17. Damper………………………………………………………………………………………………………………………325

18. Oil pan……………………………………………………………………………………………………………………..326

19. Removing engine assembly from engineoverhaul stand……………………………………………………………………………….326

20. Setting engine assembly on blocks………………………………………………………………………………………………326

21. Cylinder head………………………………………………………………………………………………………………..326

22. Cylinder head assembly………………………………………………………………………………………………………..326

23. Rocker arm housing……………………………………………………………………………………………………………328

24. Assembling injector harness connector torocker arm housing………………………………………………………………………..328

25. Crosshead……………………………………………………………………………………………………………………328

26. Pushrod……………………………………………………………………………………………………………………..329

27. Rocker arm…………………………………………………………………………………………………………………..329

28. Adjusting valve clearance……………………………………………………………………………………………………..329

29. Nozzle tip…………………………………………………………………………………………………………………..329

30. Fuel injector………………………………………………………………………………………………………………..331

31. Head cover…………………………………………………………………………………………………………………..331

32. Spill pipe…………………………………………………………………………………………………………………..331

33. Thermostat…………………………………………………………………………………………………………………..332

34. Engine oil cooler…………………………………………………………………………………………………………….332

35. Engine cooling water temperature sensor…………………………………………………………………………………………332

36. Engine oil supply tube………………………………………………………………………………………………………..332

37. High-pressure tube for common rail……………………………………………………………………………………………..332

38. Suction manifold……………………………………………………………………………………………………………..333

39. Engine oil filter…………………………………………………………………………………………………………….334

40. Fuel filter………………………………………………………………………………………………………………….334

41. Turbocharger and exhaust manifold assembly………………………………………………………………………………………334

42. Starting motor……………………………………………………………………………………………………………….334

43. Fan bracket lifting hook………………………………………………………………………………………………………335

44. Wiring harness……………………………………………………………………………………………………………….335

45. Air cleaner………………………………………………………………………………………………………………….335

46. Exhaust muffler………………………………………………………………………………………………………………335

15 REPAIR AND REPLACEMENT OF PARTS………………………………………………………………………………………………………..337

CYLINDER HEAD……………………………………………………………………………………………………………………….339

REPLACING VALVE SEAT INSERT……………………………………………………………………………………………………….339

REPLACING NOZZLE HOLDER SLEEVE…………………………………………………………………………………………………….344

REPLACING VALUE GUIDE…………………………………………………………………………………………………………….347

REPLACING CROSS HEAD GUIDE………………………………………………………………………………………………………..348

GRINDING THE VALVE……………………………………………………………………………………………………………….349

GRINDING THE FITTING FACE OF CYLINDER HEAD………………………………………………………………………………………….349

PRESSURE TEST……………………………………………………………………………………………………………………350

CYLINDER BLOCK………………………………………………………………………………………………………………………352

REPLACING CAM BUSHING…………………………………………………………………………………………………………….352

REPLACING CAM GEAR……………………………………………………………………………………………………………….355

REPLACING FLYWHEEL RING GEAR………………………………………………………………………………………………………355

REPLACING ENGINE REAR SEAL………………………………………………………………………………………………………..356

REPLACING CONNECTING ROD SMALL END BUSHING………………………………………………………………………………………….361

REPLACING MAIN BEARING CAP………………………………………………………………………………………………………..362

GRINDING CRANKSHAFT………………………………………………………………………………………………………………365

REPLACING WEAR SLEEVE (When equipped with sleeve)……………………………………………………………………………………374