$36

Komatsu 125-5 Series Engine Shop Manual SEN00177-19 – PDF DOWNLOAD

Komatsu 125-5 Series Engine Shop Manual SEN00177-19 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 125-5 Series Engine Shop Manual SEN00177-19 – PDF DOWNLOAD

Language : English

Pages : 666

Downloadable : Yes

File Type : PDF

Size: 43.6 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 125-5 Series Engine Shop Manual SEN00177-19 – PDF DOWNLOAD

The Komatsu 125-5 Series Engine Shop Manual SEN00177-19 is a comprehensive technical guide that provides detailed information on the maintenance, repair, and overhaul of the Komatsu 125-5 series diesel engine. This engine is commonly used in heavy equipment such as excavators, bulldozers, and wheel loaders.

The manual is organized into several sections, each covering specific aspects of the engine:

- General Information: This section provides an overview of the engine, including specifications, maintenance intervals, and general operating guidelines.

- Inspection and Adjustment: This section provides detailed instructions for inspecting and adjusting engine components, such as the fuel injection system, valves, and timing belts.

- Engine Assembly: This section covers the removal and installation of major engine components, including the cylinder head, crankshaft, and pistons. The manual includes detailed illustrations and specifications to help technicians perform these tasks safely and efficiently.

- Lubrication System: This section provides information on the engine’s lubrication system, including oil pump removal and installation, oil filter replacement, and oil pressure testing.

- Cooling System: This section provides information on the engine’s cooling system, including water pump removal and installation, radiator removal and installation, and thermostat replacement.

- Fuel System: This section covers the engine’s fuel system, including fuel pump removal and installation, fuel injector replacement, and fuel system troubleshooting.

- Air Intake and Exhaust System: This section provides information on the engine’s air intake and exhaust system, including air filter replacement, turbocharger removal and installation, and exhaust manifold removal and installation.

- Electrical System: This section provides information on the engine’s electrical system, including alternator and starter motor removal and installation, as well as troubleshooting procedures for electrical faults.

- Special Tools: This section lists the special tools required for servicing the engine, including part numbers and illustrations.

The Komatsu 125-5 Series Engine Shop Manual SEN00177-19 is an essential reference guide for maintaining and repairing the engine. It provides detailed instructions, specifications, and illustrations to help technicians perform tasks accurately and safely. The manual is a valuable tool for ensuring that the Komatsu 125-5 series diesel engine continues to operate at peak performance, with maximum efficiency and reliability over its long service life.

Overall, the Komatsu 125-5 Series Engine Shop Manual SEN00177-19 is an essential guide for technicians working on this engine. The manual covers every aspect of maintenance, repair, and overhaul, making it an indispensable resource for anyone who wants to keep their Komatsu equipment running smoothly and reliably.

TABLE OF CONTENTS:

Komatsu 125-5 Series Engine Shop Manual SEN00177-19 – PDF DOWNLOAD

COVER…………………………………………………………………………. 1

00 Index and foreword…………………………………………………………… 3

Index……………………………………………………………………… 3

Composition of shop manual……………………………………………….. 4

Table of contents……………………………………………………….. 5

Foreword and general information……………………………………………… 11

Safety notice…………………………………………………………… 12

How to read the shop manual………………………………………………. 17

Explanation of terms for maintenance standard………………………………. 19

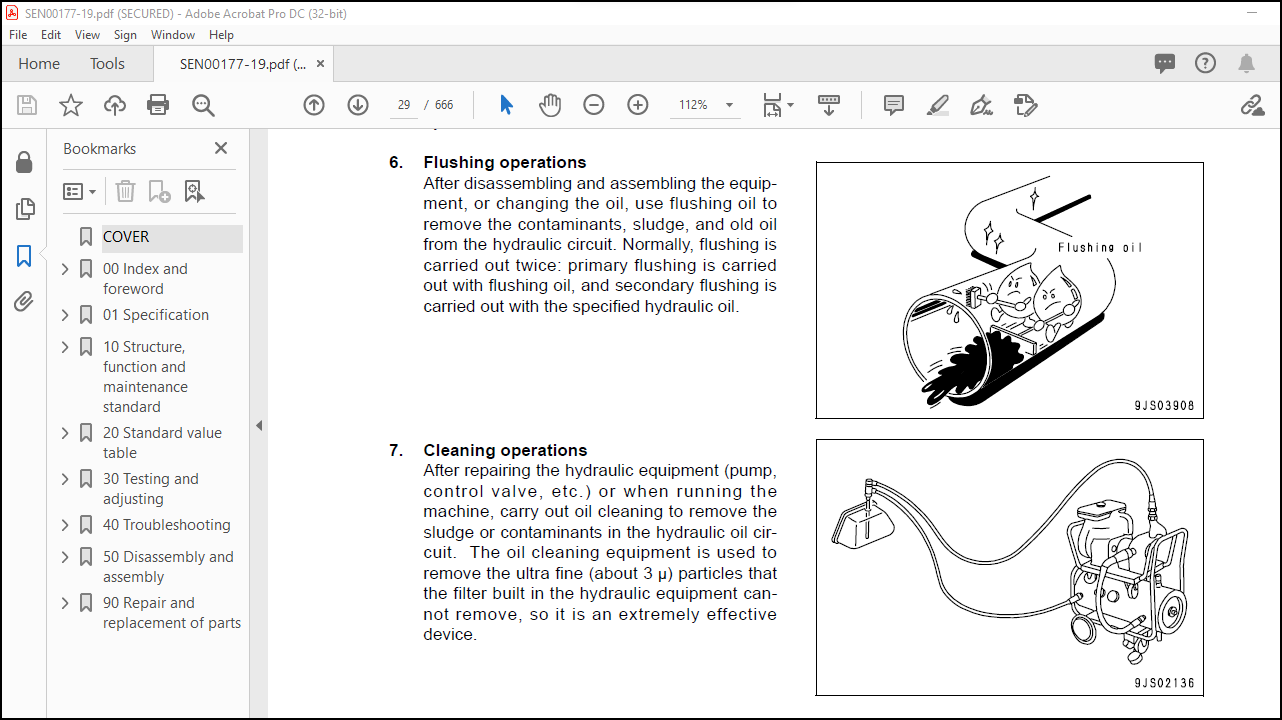

Handling of electric equipment and hydraulic component………………………. 21

Handling of connectors newly used for engines………………………………. 30

How to read electric wire code……………………………………………. 33

Precautions when carrying out operation……………………………………. 36

Method of disassembling and connecting push-pull type coupler………………… 39

Standard tightening torque table………………………………………….. 42

Conversion table………………………………………………………… 46

01 Specification……………………………………………………………….. 53

Specification and technical data……………………………………………… 53

Outline………………………………………………………………… 54

Specifications………………………………………………………….. 58

General view……………………………………………………………. 74

Weight table…………………………………………………………….110

Engine performance curves…………………………………………………113

10 Structure, function and maintenance standard…………………………………….125

Structure, function and maintenance standard, Part 1…………………………….125

General structure………………………………………………………..128

Air intake and exhaust unit……………………………………………….130

Air cleaner……………………………………………………………..134

Turbocharger…………………………………………………………….136

Aftercooler……………………………………………………………..143

EGR system………………………………………………………………144

Cylinder head……………………………………………………………151

Cylinder block…………………………………………………………..154

Cylinder liner…………………………………………………………..158

Main moving parts………………………………………………………..159

Crankshaft………………………………………………………………161

Camshaft………………………………………………………………..162

Cam follower and push rod…………………………………………………163

Piston, piston ring and piston pin…………………………………………164

Connecting rod…………………………………………………………..166

Flywheel and flywheel housing……………………………………………..167

Vibration damper…………………………………………………………172

Timing gear……………………………………………………………..174

Valve system…………………………………………………………….182

Valve and valve guide…………………………………………………….186

Rocker arm and shaft……………………………………………………..188

Crosshead and guide………………………………………………………189

Structure, function and maintenance standard, Part 2…………………………….191

Lubrication system……………………………………………………….194

Lubrication system diagram…………………………………………….194

Oil pump…………………………………………………………….198

Main relief valve…………………………………………………….199

EGR oil pump…………………………………………………………200

Oil filter…………………………………………………………..201

Safety valve…………………………………………………………203

Oil cooler…………………………………………………………..204

Fuel system……………………………………………………………..206

CRI system diagram……………………………………………………206

Outline of CRI system…………………………………………………208

Structure and operation of component parts………………………………211

Fuel piping………………………………………………………….230

Fuel filter………………………………………………………….232

Electric priming pump…………………………………………………234

Engine controller cooler………………………………………………235

Cooling system…………………………………………………………..236

Cooling system diagram………………………………………………..236

Water pump…………………………………………………………..238

Thermostat…………………………………………………………..240

Electrical equipment……………………………………………………..242

Alternator…………………………………………………………..242

Starting motor……………………………………………………….252

Electrical intake air heater…………………………………………..256

Engine controller…………………………………………………….257

20 Standard value table………………………………………………………….259

Standard service value table………………………………………………….259

Standard service value table………………………………………………260

Standard service value table for testing, adjusting, and troubleshooting……260

Running-in standard and performance test standard………………………..276

30 Testing and adjusting…………………………………………………………287

Testing and adjusting………………………………………………………..287

Testing and adjusting (With EGR)…………………………………………..289

Testing and adjusting tools list……………………………………….289

Sketches of special tools……………………………………………..291

Testing air boost pressure…………………………………………….292

Testing exhaust temperature……………………………………………293

Adjusting valve clearance……………………………………………..294

Testing compression pressure…………………………………………..295

Testing blow-by pressure………………………………………………297

Testing engine oil pressure……………………………………………298

Measuring EGR valve and bypass valve drive pressure………………………299

Handling fuel system parts…………………………………………….300

Releasing residual pressure in fuel system………………………………300

Testing fuel pressure…………………………………………………301

Reduced cylinder mode operation………………………………………..302

No-injection cranking…………………………………………………302

Testing leakage from pressure limiter and return rate from injector………..303

Bleeding air from fuel circuit…………………………………………306

Testing fuel system for leakage………………………………………..308

Adjusting speed sensor………………………………………………..309

Testing and adjusting alternator belt tension……………………………310

Handling controller voltage circuit…………………………………….311

Testing and adjusting (EGR-less)…………………………………………..312

Testing and adjusting tools list……………………………………….312

Sketches of special tools……………………………………………..314

Testing air boost pressure…………………………………………….315

Testing exhaust temperature……………………………………………316

Adjusting valve clearance……………………………………………..317

Testing compression pressure…………………………………………..318

Testing blow-by pressure………………………………………………320

Testing engine oil pressure……………………………………………321

Handling fuel system parts…………………………………………….322

Releasing residual pressure in fuel system………………………………322

Testing fuel pressure…………………………………………………323

Reduced cylinder mode operation………………………………………..324

No-injection cranking…………………………………………………324

Testing leakage from pressure limiter and return rate from injector………..325

Bleeding air from fuel circuit…………………………………………327

Testing fuel system for leakage………………………………………..329

Adjusting speed sensor………………………………………………..330

Testing and adjusting alternator belt tension……………………………331

Handling controller voltage circuit…………………………………….332

40 Troubleshooting………………………………………………………………335

General information on troubleshooting…………………………………………335

General information on troubleshooting……………………………………..336

Points on troubleshooting……………………………………………..336

Error code and failure code table………………………………………338

Information in troubleshooting table……………………………………342

Troubleshooting of electrical system (E-mode), Part 1……………………………345

Troubleshooting of electrical system (E-mode), Part 1………………………..348

E-1 Code [111/CA111] ECM Critical Internal Failure……………………….348

E-2 Code [115/CA115] Eng. Ne and Bkup Speed Sensor Error………………….350

E-3 Code [122/CA122] Charge Air Press Sensor High Error…………………..352

E-4 Code [123/CA123] Charge Air Press Sensor Low Error……………………354

E-5 Code [131/CA131] Throttle Sensor High Error………………………….356

E-6 Code [132/CA132] Throttle Sensor Low Error…………………………..360

E-7 Code [135/CA135] Oil press. Sensor High Error………………………..362

E-8 Code [141/CA141] Oil press. Sensor Low Error…………………………364

E-9 Code [144/CA144] Coolant Temp. Sensor High Error……………………..366

E-10 Code [145/CA145] Coolant Temp. Sensor Low Error……………………..368

E-11 Code [153/CA153] Charge Air Temp. Sensor High Error………………….370

E-12 Code [154/CA154] Charge Air Temp. Sensor Low Error…………………..372

E-13 Code [187/CA187] Sensor Sup. 2 Volt. Low Error………………………373

E-14 Code [221/CA221] Ambient Air Press. Sensor High Error………………..374

E-15 Code [222/CA222] Ambient Air Press. Sensor Low Error…………………376

E-16 Code [227/CA227] Sensor Sup. 2 Volt. High Error……………………..378

E-17 Code [234/CA234] Eng. Overspeed……………………………………380

E-18 Code [238/CA238] Ne Speed Sensor Sup. Volt. Error……………………382

E-19 Code [263/CA263] Fuel Temp. Sensor High Error……………………….384

E-20 Code [265/CA265] Fuel Temp. Sensor Low Error………………………..386

E-21 Code [271/CA271] PCV1 Short Error………………………………….388

E-22 Code [272/CA272] PCV1 Open Error…………………………………..390

E-23 Code [273/CA273] PCV2 Short Error………………………………….392

E-24 Code [274/CA274] PCV2 Open Error…………………………………..394

E-25 Code [322/CA322] Injector #1 (L/B #1) System Open/Short Error…………396

E-26 Code [323/CA323] Injector #5 (L/B #5) System Open/Short Error…………398

E-27 Code [324/CA324] Injector #3 (L/B #3) System Open/Short Error…………400

E-28 Code [325/CA325] Injector #6 (L/B #6) System Open/Short Error…………402

E-29 Code [331/CA331] Injector #2 (L/B #2) System Open/Short Error…………404

E-30 Code [332/CA332] Injector #4 (L/B #4) System Open/Short Error…………406

E-31 Code [342/CA342] Calibration Code Incompatibility……………………408

E-32 Code [351/CA351] INJ. Drive Circuit Error…………………………..410

E-33 Code [352/CA352] Sensor Sup. 1 Volt. Low Error………………………412

E-34 Code [386/CA386] Sensor Sup. 1 Volt. High Error……………………..414

E-35 Code [431/CA431] Idle Validation SW Low error……………………….416

E-36 Code [432/CA432] Idle Validation Process error………………………418

E-37 Code [441/CA441] Battery voltage low error………………………….418

E-38 Code [442/CA442] Battery voltage high error…………………………419

Troubleshooting of electrical system (E-mode), Part 2……………………………421

Troubleshooting of electrical system (E-mode), Part 2………………………..423

E-39 Code [449/CA449] Rail Press. Very High Error………………………..423

E-40 Code [451/CA451] Rail Press. Sensor High Error………………………424

E-41 Code [452/CA452] Rail Press. Sensor Low Error……………………….426

E-42 Code [553/CA553] Rail Press. High Error…………………………….426

E-43 Code [554/CA554] Rail Press Sensor In Range Error……………………427

E-44 Code [559/CA559] Rail Press. Low Error……………………………..428

E-45 Code [689/CA689] Eng. Ne Speed Sensor Error…………………………432

E-46 Code [731/CA731] Eng. Bkup Speed Sensor Phase Error………………….434

E-47 Code [757/CA757] All Persistent Data Lost Error……………………..435

E-48 Code [778/CA778] Eng. Bkup Speed Sensor Error……………………….436

E-49 Code [1228/CA1228] EGR Valve Servo Error 1………………………….438

E-50 Code [1625/CA1625] EGR Valve Servo Error 2………………………….439

E-51 Code [1626/CA1626] Bypass Valve Solenoid Current High Error…………..440

E-52 Code [1627/CA1627] Bypass Valve Solenoid Current Low Error……………442

E-53 Code [1628/CA1628] Bypass Valve Servo Error 1……………………….443

E-54 Code [1629/CA1629] Bypass Valve Servo Error 2……………………….444

E-55 Code [1631/CA1631] BP valve Lift Position Sensor High Error…………..446

E-56 Code [1632/CA1632] BP valve Lift Position Sensor Low Error……………448

E-57 Code [1633/CA1633] KOMNET Datalink Timeout Error…………………….448

E-58 Code [1642/CA1642] EGR Inlet Press Sensor Low Error………………….449

E-59 Code [1653/CA1653] EGR Inlet Press Sensor High Error…………………450

E-60 Code [2185/CA2185] Throttle Sens. Sup. Volt. High Error………………452

E-61 Code [2186/CA2186] Throttle Sens. Sup. Volt. Low Error……………….456

E-62 Code [2249/CA2249] Rail Press. Very Low Error……………………….457

E-63 Code [2271/CA2271] EGR Valve Lift Position Sensor High Error………….458

E-64 Code [2272/CA2272] EGR Valve Lift Position Sensor Low Error…………..460

E-65 Code [2351/CA2351] EGR Valve Solenoid Current High Error……………..462

E-66 Code [2352/CA2352] EGR Valve Solenoid Current Low Error………………464

E-67 Code [2555/CA2555] Grid Heater Relay Volt. Low Error…………………465

E-68 Code [2556/CA2556] Grid Heater Relay Volt. High Error………………..466

E-69 Code [(143)/B@BAZG] Eng. Oil press. Torque Derate……………………468

E-70 Code [(146)/B@BCNS] Eng. Overheat………………………………….468

E-71 Code [(415)/B@BAZG] Eng. Oil press. Low Speed Derate…………………469

Troubleshooting of mechanical system (S-mode)…………………………………..471

Troubleshooting of mechanical system (S-mode)……………………………….474

Method of using troubleshooting charts………………………………….474

S-1 Starting performance is poor……………………………………….478

S-2 Engine does not start……………………………………………..480

S-3 Engine does not pick up smoothly……………………………………484

S-4 Engine stops during operations……………………………………..485

S-5 Engine does not rotate smoothly…………………………………….486

S-6 Engine lacks output (or lacks power)………………………………..487

S-7 Exhaust smoke is black (incomplete combustion)……………………….488

S-8 Oil consumption is excessive (or exhaust smoke is blue)……………….490

S-9 Oil becomes contaminated quickly……………………………………491

S-10 Fuel consumption is excessive……………………………………..492

S-11 Oil is in coolant (or coolant spurts back or coolant level goes down)….493

S-12 Oil pressure drops……………………………………………….494

S-13 Oil level rises (Entry of coolant or fuel)………………………….495

S-14 Coolant temperature becomes too high (overheating)…………………..497

S-15 Abnormal noise is made……………………………………………498

S-16 Vibration is excessive……………………………………………499

50 Disassembly and assembly………………………………………………………501

General information on disassembly and assembly…………………………………501

General information on disassembly and assembly……………………………..502

How to read this manual……………………………………………….502

Coating materials list………………………………………………..504

Special tools list……………………………………………………507

Disassembly and assembly, Part 1 (With EGR)…………………………………….509

General disassembly of engine……………………………………………..510

General assembly of engine………………………………………………..525

Disassembly and assembly, Part 2 (EGR-less)…………………………………….557

Disassembly and assembly, Part 2 (EGR-less)…………………………………558

General disassembly of engine………………………………………….558

General assembly of engine…………………………………………….572

Disassembly and assembly, Part 3………………………………………………605

Disassembly and assembly, Part 3…………………………………………..606

Removal and installation of fuel supply pump unit………………………..606

Replacement of oil seal of engine mounted on machine……………………..608

90 Repair and replacement of parts………………………………………………..613

Information related to repair and replacement…………………………………..613

Flowchart……………………………………………………………….614

Special tool table……………………………………………………….616

Special tool sketch………………………………………………………618

Parts related to cylinder head………………………………………………..621

Part names related to cylinder head………………………………………..622

Testing and inspection of cylinder head…………………………………….623

Pressure test of cylinder head…………………………………………….625

Replacement of valve guide………………………………………………..625

Replacement of valve seat insert…………………………………………..626

Replacement of crosshead guide…………………………………………….633

Repair of valve by grinding……………………………………………….634

Parts related to cylinder block……………………………………………….637

Part names related to cylinder block……………………………………….638

Testing and inspection of cylinder block……………………………………639

Part names related to crankshaft…………………………………………..642

Testing and inspection of crankshaft……………………………………….643

Part names related to connecting rod……………………………………….644

Testing and inspection of connecting rod……………………………………645

Replacement of flywheel ring gear………………………………………….647

Replacement of camshaft gear………………………………………………647

Replacement of main bearing metal cap………………………………………648

Replacement of connecting rod small end bushing……………………………..650

Replacement of cam bushing………………………………………………..651

Replacement of engine rear seal……………………………………………653

Replacement of wear sleeve (when sleeve is installed)………………………..657

Repair of crankshaft by grinding…………………………………………..658