$36

Komatsu 125E-7 Series Engine Shop Manual SEN06495-10 – PDF DOWNLOAD

Komatsu 125E-7 Series Engine Shop Manual SEN06495-10 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 125E-7 Series Engine Shop Manual SEN06495-10 – PDF DOWNLOAD

Language : English

Pages : 508

Downloadable : Yes

File Type : PDF

Size: 18.3 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 125E-7 Series Engine Shop Manual SEN06495-10 – PDF DOWNLOAD

- The Komatsu 125E-7 Series Engine Shop Manual SEN06495-10 is a comprehensive guidebook that provides detailed technical information and instructions on how to operate, maintain, and repair the Komatsu 125E-7 series diesel engine. This engine series is commonly used in heavy equipment such as excavators, bulldozers, and other heavy machinery.

- The manual is divided into several sections, each providing detailed information on specific topics. These sections include specifications, structure and function, testing and adjusting, disassembly and assembly, maintenance, and troubleshooting.

- The specifications section of the manual provides detailed information on the engine’s physical and operational characteristics, including its dimensions, weight, performance, and power output. It also provides information on the engine’s cooling system, fuel system, and lubrication system.

- The structure and function section of the manual provides an overview of the engine’s internal components and their functions. This section includes detailed diagrams and descriptions of the engine’s various components, such as the cylinder block, cylinder head, crankshaft, pistons, and valves.

- The testing and adjusting section of the manual provides instructions on how to test and adjust the engine’s various components to ensure they are functioning correctly. This section includes detailed procedures for testing and adjusting the engine’s fuel injection system, valve clearances, and oil pressure.

- The disassembly and assembly section of the manual provides step-by-step instructions on how to disassemble and reassemble the engine’s various components. This section includes detailed diagrams and photographs to guide the user through the process.

- The maintenance section of the manual provides information on routine maintenance tasks that should be performed to keep the engine in good working condition. This section includes instructions on how to perform tasks such as changing the engine oil and replacing the air filter.

- The troubleshooting section of the manual provides guidance on how to diagnose and resolve common issues that may arise with the engine. This section includes a list of common symptoms and their likely causes, as well as step-by-step instructions for troubleshooting and resolving each issue.

- Overall, the Komatsu 125E-7 Series Engine Shop Manual SEN06495-10 is an essential resource for anyone who works with or operates machinery that utilizes this engine series. It provides a wealth of technical information, detailed instructions, and troubleshooting guidance that can help keep the engine running smoothly and extend its lifespan. The manual is designed to be user-friendly and easy to understand, with clear and concise language and illustrations to guide the user through each process. Whether you are a mechanic or an equipment operator, this manual will provide you with the information you need to keep your Komatsu 125E-7 engine in good working order.

TABLE OF CONTENTS:

Komatsu 125E-7 Series Engine Shop Manual SEN06495-10 – PDF DOWNLOAD

00 INDEX AND FOREWORD ………………………………………………………………………………………………………… 00-1

ABBREVIATION LIST …………………………………………………………………………………………………………….. 00-4

FOREWORD, SAFETY, BASIC INFORMATION ……………………………………………………………………….. 00-10

HOW TO READ THE ENGINE SHOP MANUAL …………………………………………………………………. 00-10

SAFETY NOTICE FOR OPERATION………………………………………………………………………………… 00-12

PRECAUTIONS TO PREVENT FIRE………………………………………………………………………………… 00-20

ACTIONS IF FIRE OCCURS …………………………………………………………………………………………… 00-22

PRECAUTIONS FOR DISPOSING OF WASTE MATERIALS ……………………………………………….. 00-23

ACTIONS TAKEN TO MEET EXHAUST GAS REGULATIONS……………………………………………… 00-24

PRECAUTIONS FOR DEF………………………………………………………………………………………………. 00-25

STORE AdBlue/DEF ………………………………………………………………………………………………………. 00-26

PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT ……………………………………………… 00-27

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF PIPINGS………………………….. 00-30

PRECAUTIONS FOR HANDLING ELECTRICAL EQUIPMENT…………………………………………….. 00-37

PRECAUTIONS FOR HANDLING FUEL SYSTEM EQUIPMENT ………………………………………….. 00-39

PRECAUTIONS FOR HANDLING INTAKE SYSTEM EQUIPMENT ………………………………………. 00-40

DISCONNECT AND CONNECT PUSH-PULL TYPE COUPLER …………………………………………… 00-41

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF CONNECTORS ………………… 00-45

METHOD FOR DISCONNECTING AND CONNECTING DEUTSCH CONNECTOR ………………… 00-49

METHOD FOR DISCONNECTING AND CONNECTING SLIDE LOCK TYPE CONNECTOR ……. 00-50

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PULL … 00-52

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PUSH .. 00-53

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH HOUSING TO ROTATE .

………………………………………………………………………………………………………………………………… 00-55

HOW TO READ ELECTRICAL WIRE CODE ……………………………………………………………………… 00-56

EXPLANATION OF TERMS FOR MAINTENANCE STANDARD……………………………………………. 00-60

STANDARD TIGHTENING TORQUE TABLE……………………………………………………………………… 00-63

CONVERSION TABLE……………………………………………………………………………………………………. 00-70

01 SPECIFICATIONS …………………………………………………………………………………………………………………… 01-1

CONTENTS ………………………………………………………………………………………………………………………….. 01-2

ABBREVIATION LIST …………………………………………………………………………………………………………….. 01-3

SPECIFICATIONS …………………………………………………………………………………………………………………. 01-9

OUTLINE OF EXHAUST GAS REGULATION………………………………………………………………………. 01-9

LIST OF APPLICABLE MACHINES: 125E-7………………………………………………………………………. 01-12

SPECIFICATIONS …………………………………………………………………………………………………………. 01-13

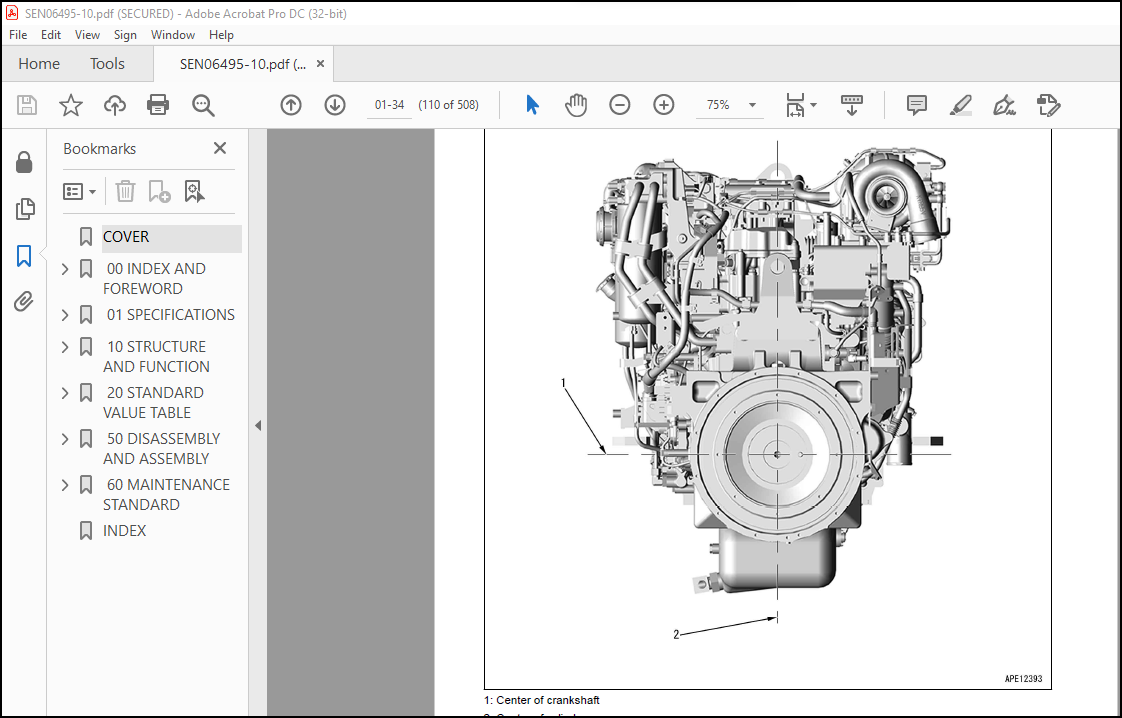

ENGINE GENERAL VIEW ………………………………………………………………………………………………. 01-19

WEIGHT TABLE ……………………………………………………………………………………………………………. 01-43

ENGINE PERFORMANCE CURVE ………………………………………………………………………………….. 01-46

10 STRUCTURE AND FUNCTION …………………………………………………………………………………………………. 10-1

CONTENTS ………………………………………………………………………………………………………………………….. 10-2

ABBREVIATION LIST …………………………………………………………………………………………………………….. 10-4

UREA SCR SYSTEM……………………………………………………………………………………………………………. 10-10

LAYOUT DRAWING OF UREA SCR SYSTEM …………………………………………………………………… 10-10

UREA SCR SYSTEM DIAGRAM ……………………………………………………………………………………… 10-15

FUNCTION OF UREA SCR SYSTEM……………………………………………………………………………….. 10-16

COMPONENT PARTS OF UREA SCR SYSTEM………………………………………………………………… 10-32

ENGINE SYSTEM ……………………………………………………………………………………………………………….. 10-41

LAYOUT OF ENGINE COMPONENTS ……………………………………………………………………………… 10-41

INTAKE AND EXHAUST SYSTEM PARTS ………………………………………………………………………… 10-43

ENGINE MAIN BODY PARTS………………………………………………………………………………………….. 10-48

TURBOCHARGER SYSTEM …………………………………………………………………………………………… 10-65

LUBRICATION SYSTEM…………………………………………………………………………………………………. 10-89

FUEL SYSTEM ……………………………………………………………………………………………………………… 10-97

COOLING SYSTEM……………………………………………………………………………………………………….10-118

ELECTRICAL SYSTEM ………………………………………………………………………………………………………..10-123

COMPONENT PARTS OF ELECTRICAL SYSTEM …………………………………………………………….10-123

INDEX 00 INDEX AND FOREWORD

00-2 125E-7 SERIES

SENSOR………………………………………………………………………………………………………………………10-144

20 STANDARD VALUE TABLE ………………………………………………………………………………………………………. 20-1

CONTENTS ………………………………………………………………………………………………………………………….. 20-2

ABBREVIATION LIST …………………………………………………………………………………………………………….. 20-3

STANDARD VALUE TABLE FOR ENGINE ………………………………………………………………………………… 20-9

STANDARD VALUE TABLE FOR ENGINE: SAA6D125E-7 (D85EX-18, D85EXI-18, D85PX-18,

D85PXI-18)………………………………………………………………………………………………………………….. 20-9

STANDARD VALUE TABLE FOR ENGINE: SAA6D125E-7 (HM300-5, HM300-5E0)………………….20-11

STANDARD VALUE TABLE FOR ENGINE: SAA6D125E-7 (PC490LC-11, PC490LCI-11)…………. 20-13

STANDARD VALUE TABLE FOR ENGINE: SAA6D125E-7 (WA470-8) ………………………………….. 20-15

STANDARD VALUE TABLE FOR ENGINE: SAA6D125E-7 (WA475-10) ………………………………… 20-17

STANDARD VALUE TABLE FOR ENGINE: SAA6D125E-7 (WA480-8) ………………………………….. 20-19

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD …………………………………………. 20-21

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D125E-7 (D85EX-18,

D85EXI-18, D85PX-18, D85PXI-18) ………………………………………………………………………………. 20-21

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D125E-7 (HM300-5,

HM300-5E0) ………………………………………………………………………………………………………………. 20-23

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D125E-7 (PC490LC-11,

PC490LCI-11)…………………………………………………………………………………………………………….. 20-25

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D125E-7 (WA470-8) ………

………………………………………………………………………………………………………………………………… 20-27

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D125E-7 (WA475-10) …….

………………………………………………………………………………………………………………………………… 20-29

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D125E-7 (WA480-8) ………

………………………………………………………………………………………………………………………………… 20-31

50 DISASSEMBLY AND ASSEMBLY………………………………………………………………………………………………. 50-1

CONTENTS ………………………………………………………………………………………………………………………….. 50-2

ABBREVIATION LIST …………………………………………………………………………………………………………….. 50-3

RELATED INFORMATION ON DISASSEMBLY AND ASSEMBLY …………………………………………………. 50-9

HOW TO READ THIS MANUAL…………………………………………………………………………………………. 50-9

COATING MATERIALS LIST……………………………………………………………………………………………..50-11

SPECIAL TOOLS LIST …………………………………………………………………………………………………… 50-15

SKETCHES OF SPECIAL TOOLS……………………………………………………………………………………. 50-17

ENGINE SYSTEM ……………………………………………………………………………………………………………….. 50-20

DISASSEMBLE AND ASSEMBLE ENGINE GENERALLY……………………………………………………. 50-20

REMOVE AND INSTALL SUPPLY PUMP ASSEMBLY ………………………………………………………..50-123

REMOVE AND INSTALL ENGINE FRONT OIL SEAL …………………………………………………………50-132

REMOVE AND INSTALL ENGINE REAR OIL SEAL……………………………………………………………50-135

60 MAINTENANCE STANDARD…………………………………………………………………………………………………….. 60-1

CONTENTS ………………………………………………………………………………………………………………………….. 60-2

ABBREVIATION LIST …………………………………………………………………………………………………………….. 60-3

ENGINE SYSTEM …………………………………………………………………………………………………………………. 60-9

INTAKE AND EXHAUST SYSTEM PARTS ………………………………………………………………………….. 60-9

ENGINE MAIN BODY PARTS………………………………………………………………………………………….. 60-10

LUBRICATION SYSTEM…………………………………………………………………………………………………. 60-33

COOLING SYSTEM……………………………………………………………………………………………………….. 60-36

INDEX………………………………………………………………………………………………………………………………………………1