$36

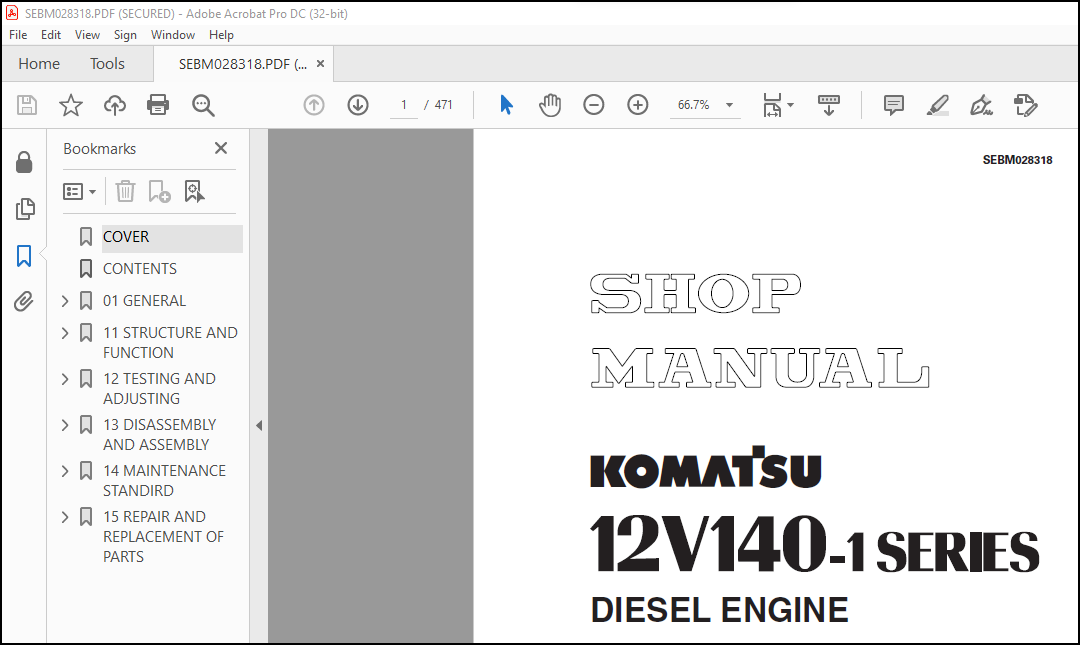

Komatsu 12V140-1 Series Diesel Engine Shop Manual SEBM028318 – PDF DOWNLOAD

Komatsu 12V140-1 Series Diesel Engine Shop Manual SEBM028318 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 12V140-1 Series Diesel Engine Shop Manual SEBM028318 – PDF DOWNLOAD

Language : English

Pages : 471

Downloadable : Yes

File Type : PDF

Size: 12.8 MB

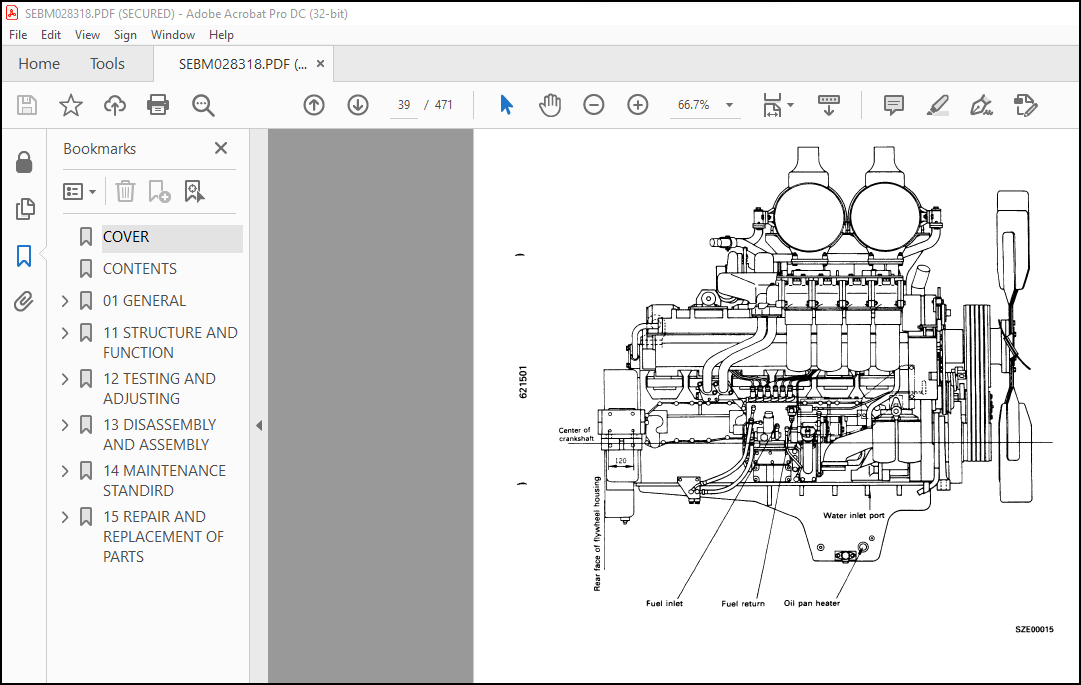

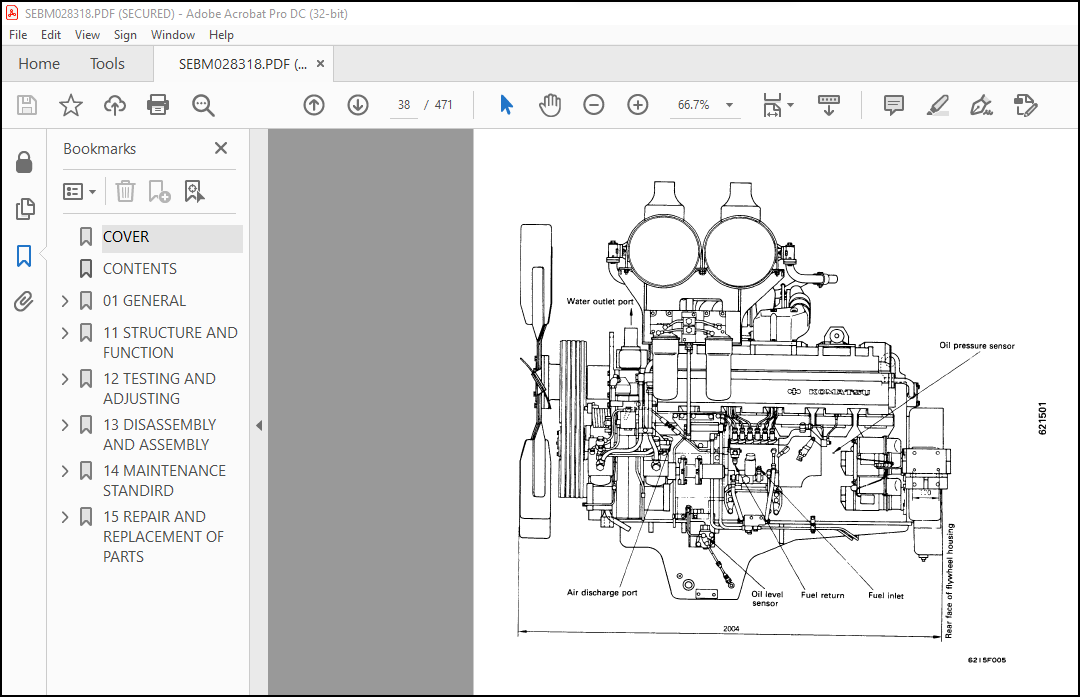

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 12V140-1 Series Diesel Engine Shop Manual SEBM028318 – PDF DOWNLOAD

The Komatsu 12V140-1 Series Diesel Engine Shop Manual is a comprehensive guide to servicing, maintaining, and repairing the Komatsu 12V140-1 diesel engine. This engine is commonly used in a variety of heavy equipment, including excavators, bulldozers, and other construction machinery.

The manual is published by Komatsu, a leading manufacturer of heavy equipment and diesel engines. It is designed to provide detailed information on the engine to qualified mechanics and technicians, enabling them to service and repair the engine to the highest standards.

The manual is divided into several sections, each of which provides specific information on different aspects of the engine. The sections include:

- General information: This section provides an overview of the engine, including its specifications, features, and operating principles. It also includes information on safety precautions, tools, and equipment needed for maintenance and repair.

- Inspection and adjustment: This section provides detailed instructions on how to inspect and adjust various components of the engine, including the cylinder head, valves, fuel system, and cooling system.

- Engine disassembly and assembly: This section provides step-by-step instructions on how to disassemble and assemble the engine. It includes detailed diagrams and illustrations to help users understand each step of the process.

- Troubleshooting: This section provides a comprehensive list of potential problems that may arise with the engine, along with diagnostic procedures to help identify and fix these issues.

- Maintenance: This section provides information on the regular maintenance tasks that should be performed on the engine, including oil changes, filter replacements, and other routine tasks.

- Reassembly and testing: This section provides detailed instructions on how to reassemble the engine after repairs have been made. It also includes information on how to test the engine to ensure that it is functioning properly.

- Service data: This section provides detailed technical data on the engine, including torque specifications, compression pressures, and other important information.

The manual is written in clear, concise language and is filled with detailed diagrams and illustrations to help users understand each step of the process. It is an essential tool for anyone who works with Komatsu diesel engines and can help to ensure that the engine is maintained and repaired to the highest standards.

However, it should be noted that the manual is designed for use by qualified mechanics and technicians and should not be used by individuals without the appropriate training and experience. The manual is also specifically for the Komatsu 12V140-1 engine and should not be used as a reference for other engines in the Komatsu lineup.

TABLE OF CONTENTS:

Komatsu 12V140-1 Series Diesel Engine Shop Manual SEBM028318 – PDF DOWNLOAD

COVER…………………………………………………………………………………………………………………….. 1

CONTENTS………………………………………………………………………………………………………………….. 2

01 GENERAL………………………………………………………………………………………………………………… 27

APPLICABLE MACHINE……………………………………………………………………………………………………… 28

SPECIFICATIONS…………………………………………………………………………………………………………. 29

GENERAL ASSEMBLY DRAWING………………………………………………………………………………………………… 38

ENGINE PERFORMANCE CURVE………………………………………………………………………………………………… 51

WEIGHT TABLE…………………………………………………………………………………………………………… 64

11 STRUCTURE AND FUNCTION…………………………………………………………………………………………………… 66

GENERAL STRUCTRE……………………………………………………………………………………………………….. 67

INTAKE AND EXHAUST SYSTEM……………………………………………………………………………………………….. 69

AIR CLEANER………………………………………………………………………………………………………… 71

TURBOCHARGER……………………………………………………………………………………………………….. 72

AFTER-COOLER……………………………………………………………………………………………………….. 74

ENGINE BODY……………………………………………………………………………………………………………. 75

CYLINDER HEAD………………………………………………………………………………………………………. 75

CYLINDER BLOCK……………………………………………………………………………………………………… 79

MAIN REVOLVING SYSTEM……………………………………………………………………………………………….. 81

TIMING GEAR………………………………………………………………………………………………………… 83

VALVE SYSTEM……………………………………………………………………………………………………….. 87

FLYWHEEL AND FLYWHEEL HOUSING………………………………………………………………………………………… 91

LUBRICATION SYSTEM……………………………………………………………………………………………………… 92

LUBRICATION SYSTEM CHART…………………………………………………………………………………………….. 92

OIL PUMP…………………………………………………………………………………………………………… 94

MAIN RELIEF………………………………………………………………………………………………………… 95

OIL COOLER BY-PASS VALVE, REGULATOR VALVE……………………………………………………………………………… 96

OIL FILTER…………………………………………………………………………………………………………. 98

OIL COOLER………………………………………………………………………………………………………….102

FUEL SYSTEM ……………………………………………………………………………………………………………103

FUEL SYSTEM CHART……………………………………………………………………………………………………103

FUEL INJECTION PUMP………………………………………………………………………………………………….106

FUEL INJECTION NOZZLE………………………………………………………………………………………………..120

FUEL FILTER…………………………………………………………………………………………………………121

ENGINE STOP MOTOR……………………………………………………………………………………………………123

COOLING SYSTEM………………………………………………………………………………………………………….128

COLING SYSTEM SHART………………………………………………………………………………………………….128

WATER PUMP………………………………………………………………………………………………………….129

COOLING FAN…………………………………………………………………………………………………………130

THERMOSTAT………………………………………………………………………………………………………….136

CORROSION RESISTOR…………………………………………………………………………………………………..137

ACCESSORY………………………………………………………………………………………………………………138

AIR COMPRESSOR………………………………………………………………………………………………………138

EXHAUST BRAKE……………………………………………………………………………………………………….140

ELECTRICAL SYSTEM……………………………………………………………………………………………………….141

ALTERNATOR………………………………………………………………………………………………………….141

STARTING MOTOR………………………………………………………………………………………………………144

ELECTRICAL INTAKE AIR HEATER………………………………………………………………………………………….145

OIL PAN HEATER………………………………………………………………………………………………………146

COOLING WATER HEATER…………………………………………………………………………………………………147

12 TESTING AND ADJUSTING…………………………………………………………………………………………………….148

ENGINE BODY…………………………………………………………………………………………………………….149

ADJUSTING VALVE CLEARANCE…………………………………………………………………………………………….149

MEASURING COMPRESSION PRESSURE………………………………………………………………………………………..150

MEASURING BLOW-BY……………………………………………………………………………………………………151

FUEL SYSTEM…………………………………………………………………………………………………………….152

TESTING AND ADJUSTMENT OF FUEL INJECTION TIMAING………………………………………………………………………..152

(WITH ZEXEL MECHANICAL GOVERNOR)…………………………………………………………………………………..152

(WITH ZEXEL ELECTRONICAL GOVERNOR)…………………………………………………………………………………155

TESTING AND ADJUSTMENT OF FUEL INJECTION TIMING (WITH KOMATSU ELECTRONICAL GOVERNOR)………………………………………..158

ADJUSTING INJECTION PUMP GOVERNOR LINK…………………………………………………………………………………161

(WITH MECHANICAL GOVERNOR)………………………………………………………………………………………..161

(WITH ZECEL ELECTRONICAL GOVERNOR)…………………………………………………………………………………163

PROCEFURE FOR ADJUSTING ENGINE STOP MOTOR CABLE (APPLICABLE FOR MODELSUSING ENGINE STOP MOTOR)……………………………….165

METHOD FOR INSTALLING (ADJUSTMENT) OF ENGINE SPEED SENSOR………………………………………………………………..166

ADJUSTING FUEL INJECTION PRESSURE……………………………………………………………………………………..167

FUEL INJECTION PUMP CALIBRATION DATA…………………………………………………………………………………..168

ADJUSTMENT OF ELECTRONICAL GOVERNOR MADE BY KOMATSU……………………………………………………………………..192

HANDLING OF THROTTLE BOX……………………………………………………………………………………………..209

HANDLING OF XEP CHECKER………………………………………………………………………………………………219

COOLING SYSTEM………………………………………………………………………………………………………….224

CHECKING AND ADJUSTING V-BELT TENSION………………………………………………………………………………….224

PERFORMANCE TEST………………………………………………………………………………………………………..226

RUNNING IN STANDARD………………………………………………………………………………………………….226

PERFORMANCE TEST CRITERIA…………………………………………………………………………………………….230

TESING AND ADJUSTING TOOL LIST………………………………………………………………………………………..240

TESTING AND ADJUSTING DATA……………………………………………………………………………………………241

TROUBLESHOOTING…………………………………………………………………………………………………………252

POINTS TO REMEMBER WHEN TROUBLESHOOTING………………………………………………………………………………..254

METHOD OF USING TROUBLESHOOTING CHART………………………………………………………………………………….255

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME) (WITH ELECTRONICAL GOVERNOR)…………………………………..259

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME) (WITH MECHANICAL GOVERNOR)…………………………………….260

S-2 EGINE DOES NOT START……………………………………………………………………………………………..261

① ENGINE DOES NOT TURN……………………………………………………………………………………………261

② ENGINE TURNS BUT NO EXHAUST GAS COMES OUT (FUEL IS NOT BEING INJECTED) (WITH ELECTRONICAL GOVERNOR) …………………….262

② ENGINE TURNS BUT NO EXHAUST GAS COMES OUT (FUEL IS NOT BEING INJECTED) (WITH MECHANICAL GOVERNOR)……………………….263

③ EXHAUST GAS COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED) …………………………………………….264

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)…………………………………………………………………265

S-4 ENGINE STOPS DURING OPERATIONS (WITH MECHANICAL GOVERNOR)…………………………………………………………….267

S-5 ENGINE DOES NOT ROTATE SMOOTHLY(HUNTING) (WITH ELECTRONICAL GOVERNOR)………………………………………………….268

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING) (WITH MECHANICAL GOVERNOR)…………………………………………………..269

S-6 ENGINE LACKS OUTPUT (NO POWER) (WITH ELECTRONICAL GOVERNOR)…………………………………………………………..270

S-6 ENGINE LACKS OUTPUT (NO POWER) (WITH MECHANICAL GOVERNOR)…………………………………………………………….271

S-7 EXHAUST GAS IS BLACK (INCOMPLETE COMBUSTION) (WITH ELECTRONICAL GOVERNOR)……………………………………………..272

S-7 EXHAUST GAS IS BLACK (INCOMPLETE COMBUSTION) (WITH MECHANICAL GOVERNOR)……………………………………………….273

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST GAS IS BLUE)………………………………………………………………..274

S-9 OIL BECOMES CONTAMINATED QUICKLY…………………………………………………………………………………..275

S-10 FUEL CONSUMPTION IS EXCESSIVE (WITH ELECTRONICAL GOVERNOR) ………………………………………………………….276

S-10 FUEL CONSUMPTION IS EXCESSIVE (WITH MECHANICAL GOVERNOR)…………………………………………………………….277

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN……………………………………………….278

S-12 OIL PRESSURE LAMP LIGHTS UP (DROP IN OIL PRESSURE)………………………………………………………………….279

S-13 OIL LEVEL RISES…………………………………………………………………………………………………280

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)……………………………………………………………………281

S-15 ABNORMAL NOISE IS MADE…………………………………………………………………………………………..282

S-16 VIBRATION IS EXCESSIVE…………………………………………………………………………………………..283

S-17 DIAGNOSIS OF ELECTRONICAL GOVERNOR BY DIAGNOSIS DISPLAY (ELECTRONICAL GOVERNOR MADE BY ZEXEL)……………………………284

1. CONTROLLER SYSTEM ABNORMALITY…………………………………………………………………………………..287

2. GOVERNOR SERVO SYSTEM ABNORMALITY……………………………………………………………………………….287

3. RACK SENSOR SYSTEM ABORMALITY…………………………………………………………………………………..289

4. OVERRUN ABNORMALITY……………………………………………………………………………………………291

5. 1ST SPEED SENSOR ABNORMALITY……………………………………………………………………………………292

6. 2ND SPEED SENSOR ABNORMALITY……………………………………………………………………………………292

7. LOW IDLING SPEED CONTROL DIAL ABNORMALITY………………………………………………………………………..293

8. DROOP CONTROL DIAL ABNORMALITY………………………………………………………………………………….294

9. DIAGNOSIS LAMP FAILS TO MAKE INDICATION………………………………………………………………………….295

10. NORMAIL INDICATION……………………………………………………………………………………………296

11. MEMORY CLEAR CANNOT BE ACHIEVED BY PRESSING THE MEMORY CLEAR SWITCH (WHEN FAILURE INDICATION IS MADE BY DIAGNOSIS LAMP)….301

13 DISASSEMBLY AND ASSEMBLY………………………………………………………………………………………………….302

GENERAL DISASSEMBLY……………………………………………………………………………………………………..303

1. WASHING………………………………………………………………………………………………………….304

2. SETTING ENGINE STAND………………………………………………………………………………………………304

3. ENGINE COOLING WATER AND ENGINE OIL…………………………………………………………………………………305

4. FILTER…………………………………………………………………………………………………………..305

5. MUFFLER ASSERMBLY…………………………………………………………………………………………………305

6. FAN……………………………………………………………………………………………………………..305

7. FAN BELT…………………………………………………………………………………………………………306

8. FAN PULLEY ASSEMBLY……………………………………………………………………………………………….306

9. LNTAKE CONNECTOR………………………………………………………………………………………………….306

10. EXHAUST BRAKE ASSEMBLY……………………………………………………………………………………………306

11. TURBOCHARGER ASSEMBLY…………………………………………………………………………………………….307

12. INTAKE MANIFOLD, AFTERCOOLER ASSEMBLY………………………………………………………………………………307

13. EXHAUST MANIFOLD ASSEMBLY…………………………………………………………………………………………308

14. FUEL INJECTION PIPE,SPIL TUBE……………………………………………………………………………………..308

15. FUEL INJECTION PUMP ASSEMBLY………………………………………………………………………………………309

16. WATER PUMP ASSEBLY……………………………………………………………………………………………….310

17. BREATHER………………………………………………………………………………………………………..310

18. AIR COMPRESSOR…………………………………………………………………………………………………..310

19. OIL COOLER ASSEMBLY………………………………………………………………………………………………311

20. OIL FILLER, OIL LEVEL GAUGE……………………………………………………………………………………….311

21. HEAD COVER………………………………………………………………………………………………………312

22. NOZZZLE HOLDER, CONNECTION………………………………………………………………………………………..312

23. ROCKER ARM………………………………………………………………………………………………………313

24. PUSH ROD………………………………………………………………………………………………………..313

25. CROSSHEAD……………………………………………………………………………………………………….313

26. ROCKER ARM HOUSING……………………………………………………………………………………………….313

27. CYLINDER HEAR ASSEMBLY……………………………………………………………………………………………313

28. CAM FOLLOWER ASSEMBLY…………………………………………………………………………………………….314

29. THERMOSTAT HOUSING……………………………………………………………………………………………….314

30. ASSESSORY DRIVE ASSEMBLY………………………………………………………………………………………….315

31. DAMPER, CRANKSHAFT PULLEY ASSEMBLY…………………………………………………………………………………315

32. OIL PAN…………………………………………………………………………………………………………316

33. MAN RELIEF VALVE, SUCTION TUBE…………………………………………………………………………………….316

34. FRONT SUPPOR…………………………………………………………………………………………………….316

35. FLYWHEEL………………………………………………………………………………………………………..316

36. FLYWHEEL HOUSING, REAR SEAL……………………………………………………………………………………….317

37. GEAR CASE COVER, FRONT SEAL……………………………………………………………………………………….317

38. IDLER GEAR (LARGE)……………………………………………………………………………………………….317

39. INJECTION PUMP DRIVE GEAR…………………………………………………………………………………………317

40. INJECTION PUMP DRIVE CASE ASSEMLY………………………………………………………………………………….318

41. OIL PUMP ASSEMBLY………………………………………………………………………………………………..318

42. IDLER GEAR (SMALL)……………………………………………………………………………………………….318

43. CAMSHAFT ASSEMBLY………………………………………………………………………………………………..319

44. TIMING GEAR CASE…………………………………………………………………………………………………319

45. PISTON COOLING NOZZLE…………………………………………………………………………………………….319

46. PISTON AND CONNECTING ROD ASSEMBLY…………………………………………………………………………………319

47. CRANKSHAFT………………………………………………………………………………………………………321

48. CYLINDER LINER…………………………………………………………………………………………………..322

WASHING………………………………………………………………………………………………………………..323

WASHING CYLINDER BLOCK……………………………………………………………………………………………….324

WASHING CRANKSHFT……………………………………………………………………………………………………326

WASHING CONNECTING ROD……………………………………………………………………………………………….326

MEASURING AND INSPECTING PARTS……………………………………………………………………………………………327

MEASURING PARTS……………………………………………………………………………………………………..328

MEASURING CURVATURE OF CRANKSHAFT………………………………………………………………………………….328

MEASURING OUTSIDE DIAMETER OF JOURNAL………………………………………………………………………………328

MEASURING OUT-OF-ROUNDNESS OF JOURNAL………………………………………………………………………………328

MEASURING SURFACE ROUGHNESS OF OUTSIDE DIAMETER OF JOURNAL……………………………………………………………329

MEASURING DEPTH OF CYLINDER LINER COUNTERBORE……………………………………………………………………….330

MEASURING MAIN BERING BORE………………………………………………………………………………………..330

MEASURING CUVATURE OF CAMSHAFT…………………………………………………………………………………….331

MEASURING OUTSIDE DIAMETER OF JOURNAL………………………………………………………………………………331

MEASURING HELGHT OF CAM…………………………………………………………………………………………..331

MEASURING PISTON RING GROOVE………………………………………………………………………………………332

MEASURING OUTSIDE DIAMETER OF PISTON……………………………………………………………………………….332

MEASURING LENGTH OF CONNECTING ROD…………………………………………………………………………………333

MEASURING INSIDE DIAMETER AT SMALL END OF CONNECTING ROD……………………………………………………………..333

MEASUING INSIDE DIAMENTER AT BIG END OF CONNECTING ROD……………………………………………………………….333

MEASURING SURVATURE, TWISTING OF CONNECTING ROD……………………………………………………………………..334

STANDARD PRESSURE FOR PARTS PRESSURE TESTING………………………………………………………………………..335

GENERAL ASSEMBLY………………………………………………………………………………………………………..336

1. CYLINDER LINER……………………………………………………………………………………………………339

2. CRANKSHAFT……………………………………………………………………………………………………….342

3. PISTON, CONNECTING ROD ASSEMBLY…………………………………………………………………………………….345

4. PISTON COOLING NOZZLE……………………………………………………………………………………………..351

5. GEAR CASE ……………………………………………………………………………………………………….352

6. CAMSHAFT ASSEMBLY…………………………………………………………………………………………………352

7. IDLER GEAR (SMALL)………………………………………………………………………………………………..352

8. OIL PUMP ASSEMBLY…………………………………………………………………………………………………353

9. INJECTION PUMP DRIVE CASE………………………………………………………………………………………….353

10. INJECION PUMP DRIVE GEAR………………………………………………………………………………………….354

11. IDIER GEAR (LARGE) (RIGHT BANK)……………………………………………………………………………………354

12. IDIER GGEAR (LARGE) (LEFT BANK)……………………………………………………………………………………355

13. MEASURING BACKLASH OF GEAR………………………………………………………………………………………..355

14. GEAR CASE COVER………………………………………………………………………………………………….357

15. FRONT OIL SEAL, SLEEVE……………………………………………………………………………………………357

16. FLYWHEEL HOUSING…………………………………………………………………………………………………360

17. REAR OIL SEAL, SLEEVE…………………………………………………………………………………………….360

18. FLYWHEEL………………………………………………………………………………………………………..363

19. FRONT SUPPORT……………………………………………………………………………………………………364

20. MAIN RELIEF VALVE, SUCTION PIPE……………………………………………………………………………………365

21. OIL PAN ………………………………………………………………………………………………………..365

22. DAMPER, CRANKSHAFT PULLEY ASSEMBLY…………………………………………………………………………………365

23. ACCESSORY DRIVE ASSEMBLY………………………………………………………………………………………….366

24. THERMOSTAT HOUSING……………………………………………………………………………………………….367

25. CAM FOLLOWER ASSEMBLY…………………………………………………………………………………………….367

26. CYLINDER HEAD ASSEMBLY……………………………………………………………………………………………367

27. ROCKER ARM HOUSING……………………………………………………………………………………………….370

28. CROSSHEAD……………………………………………………………………………………………………….370

29. PUSH ROD………………………………………………………………………………………………………..370

30. ROCKER ARM………………………………………………………………………………………………………370

31. NOZZLE HOLDER, CONNECTION…………………………………………………………………………………………372

32. ADJUSTING VALVE CLEARANCE…………………………………………………………………………………………372

33. HEAD COVER, TURBOCHARGER LUBRICATION TUBE…………………………………………………………………………..373

34. OIL LEVEL GAUGE,OIL FILLER………………………………………………………………………………………..373

35. OIL COOLER ASSEMBLY………………………………………………………………………………………………373

36. AIR COMPRESSOR…………………………………………………………………………………………………..373

37. BREATHER………………………………………………………………………………………………………..374

38. WATER PUMP ASSEMBLY………………………………………………………………………………………………375

39. FUEL INJECTION PUMP ASSEMBLY………………………………………………………………………………………375

40. FUEL INJECTION PIPES, SPILL TUBE…………………………………………………………………………………..377

41. EXHAUST MANIFOLD ASSEMBLY…………………………………………………………………………………………377

42. INTAKE MANIFOLD, AFTER-COOLER ASSEMBLY……………………………………………………………………………..378

43. TURBOCHARGER ASSEMBLY…………………………………………………………………………………………….379

44. EXHAUST BRAKE ASSEMBLY……………………………………………………………………………………………379

45. INTAKE CONNECTOR…………………………………………………………………………………………………380

46. FAN PULLEY ASSEMBLY………………………………………………………………………………………………380

47. FAN BELT………………………………………………………………………………………………………..380

48. FAN…………………………………………………………………………………………………………….380

49. MUFFLER ASSEMBLY…………………………………………………………………………………………………381

50. FILTER………………………………………………………………………………………………………….381

51. SETTING ON ENGINE STAND…………………………………………………………………………………………..381

52. ALTERNATOR ASSEMBLY………………………………………………………………………………………………381

53. STARTING MOTOR ASSEMBLY…………………………………………………………………………………………..382

14 MAINTENANCE STANDIRD……………………………………………………………………………………………………..383

INTAKE AND EXHAUST SYSTEM………………………………………………………………………………………………..384

TRBOCHARGER…………………………………………………………………………………………………………384

ENGINE BODY…………………………………………………………………………………………………………….386

CYLINDER HEAD……………………………………………………………………………………………………….386

VALVE, VALVE SPRING AND VALVE GUIDE …………………………………………………………………………………..387

ROCKER ARM AND SHAFT…………………………………………………………………………………………………389

CROSSHEAD AND GUIDE………………………………………………………………………………………………….390

CYLINDER BLOCK………………………………………………………………………………………………………391

CYLINDER LINER………………………………………………………………………………………………………393

CRANKSHAFT………………………………………………………………………………………………………….394

CAMSHAFT……………………………………………………………………………………………………………396

CAM FOLLOWER AND PUSH ROD…………………………………………………………………………………………….397

TIMING GEAR…………………………………………………………………………………………………………398

PISTON, PISTON RING AND PISTON PIN…………………………………………………………………………………….400

CONNECTING ROD………………………………………………………………………………………………………402

FLYWHEEL AND FLYWHEEL HOUSING…………………………………………………………………………………………404

LUBRICATION SYSTEM………………………………………………………………………………………………………405

OIL PUMP …………………………………………………………………………………………………………..405

MAIN RELIEF VALVE……………………………………………………………………………………………………409

OIL COOLER BY-PASS VALVE, REGULATOR VALVE………………………………………………………………………………410

COOLING SYSTEM………………………………………………………………………………………………………….412

WATER PUMP………………………………………………………………………………………………………….412

THRMOSTAT…………………………………………………………………………………………………………..413

15 REPAIR AND REPLACEMENT OF PARTS……………………………………………………………………………………………414

TABLE OF SPECIAL TOOLS…………………………………………………………………………………………………..415

TESTING ANF INSPECTING CYINDER HEAD……………………………………………………………………………………….417

GRINDING CYLINDER HEAD MOUNTING FACE………………………………………………………………………………………420

REPLACING VALVE SEAT…………………………………………………………………………………………………….421

PRESSURE TEST OF CYLONDER HEAD……………………………………………………………………………………………426

REPLACING VALVE GUIDE……………………………………………………………………………………………………427

REPLACING CROSSHEAD GUIDE………………………………………………………………………………………………..428

GRINDING VALVE………………………………………………………………………………………………………….429

TESTING AND INSPECTING CYLINDER BLOCK……………………………………………………………………………………..430

CORRECTING CYLINDRE BLOCK TOP SURFACE, COUNTERBORE………………………………………………………………………….434

REPLACING MAIN BEARING CAP……………………………………………………………………………………………….442

REPLACING CAM BUSHING……………………………………………………………………………………………………444

TESTING AND INSPECTING CRANKSHAFT…………………………………………………………………………………………446

CORRECTING SURFACE ROUGHESS OF CRANKSHAFT JOURNAL PORTION……………………………………………………………………448

GRINDING CRANKSHAFT……………………………………………………………………………………………………..453

CORRECTING FRONT SEAL CONTACT SURFCE………………………………………………………………………………………462

CORRECTING REAR SEAL CONTACT SURFACE………………………………………………………………………………………464

TESTING AND INSPECTING CONNECTING ROD……………………………………………………………………………………..466

REPLACING CONNECTING ROD SMALL END BUSHING…………………………………………………………………………………468

REPLACING CRANKSHAFT GEAR………………………………………………………………………………………………..469

REPLACING CAMSHAFT GEAR………………………………………………………………………………………………….470

REPLACING FLYWHEEL RING GEAR……………………………………………………………………………………………..471