$36

Komatsu 12V140E-3 Series Diesel Engine Shop Manual SEN00291-16 – PDF DOWNLOAD

Komatsu 12V140E-3 Series Diesel Engine Shop Manual SEN00291-16 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 12V140E-3 Series Diesel Engine Shop Manual SEN00291-16 – PDF DOWNLOAD

Language : English

Pages : 604

Downloadable : Yes

File Type : PDF

Size: 36.6 MB

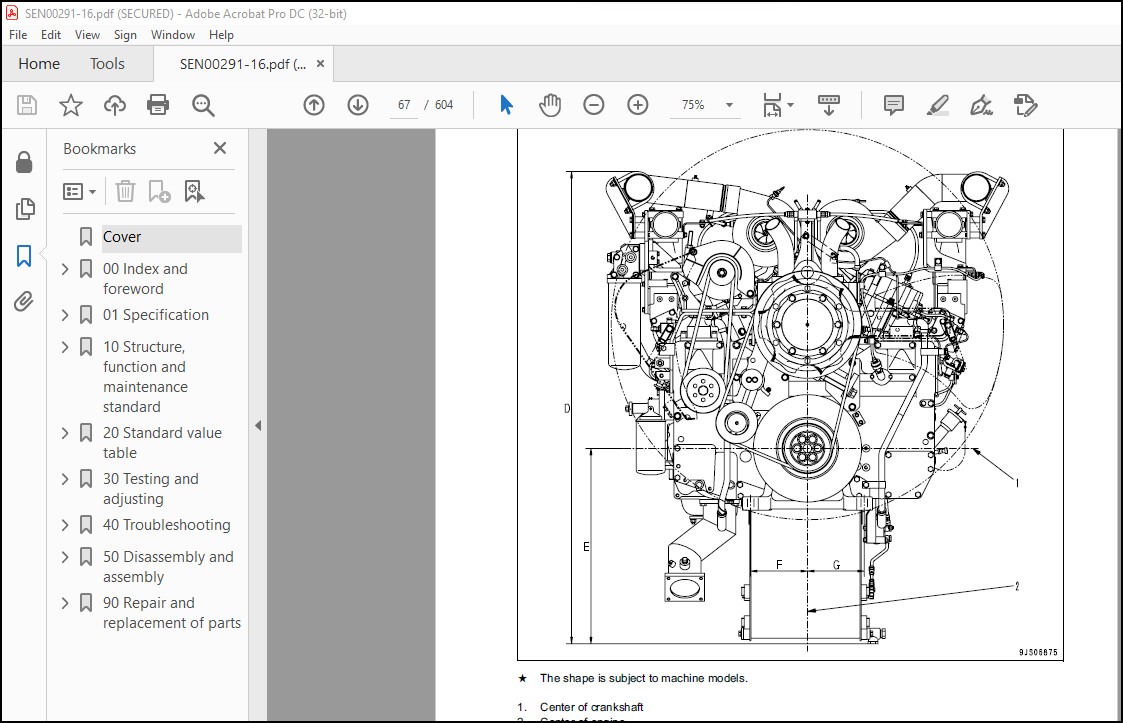

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 12V140E-3 Series Diesel Engine Shop Manual SEN00291-16 – PDF DOWNLOAD

The Komatsu 12V140E-3 Series Diesel Engine Shop Manual SEN00291-16 is a comprehensive guide that provides detailed information on the service, repair, and maintenance of the 12V140E-3 Series diesel engine. This engine is a twelve-cylinder, turbocharged engine that is commonly used in heavy construction equipment, such as large excavators and mining trucks.

The manual is published by Komatsu, a leading manufacturer of heavy equipment and construction machinery. The manual is designed to be used by mechanics and technicians who are responsible for maintaining and repairing Komatsu equipment. It is an essential tool for anyone who works with Komatsu engines.

The manual is divided into several sections, each of which provides specific information on different aspects of the engine. The sections include:

- General information: This section provides an overview of the engine, including its specifications, features, and operating principles. It also includes information on safety precautions, tools, and equipment needed for maintenance and repair.

- Inspection and adjustment: This section provides detailed instructions on how to inspect and adjust various components of the engine, including the cylinder head, valves, fuel system, and cooling system.

- Engine disassembly and assembly: This section provides step-by-step instructions on how to disassemble and assemble the engine. It includes detailed diagrams and illustrations to help users understand each step of the process.

- Troubleshooting: This section provides a comprehensive list of potential problems that may arise with the engine, along with diagnostic procedures to help identify and fix these issues.

- Maintenance: This section provides information on the regular maintenance tasks that should be performed on the engine, including oil changes, filter replacements, and other routine tasks.

- Reassembly and testing: This section provides detailed instructions on how to reassemble the engine after repairs have been made. It also includes information on how to test the engine to ensure that it is functioning properly.

- Service data: This section provides detailed technical data on the engine, including torque specifications, compression pressures, and other important information.

The manual is written in clear, concise language, and is filled with detailed diagrams and illustrations to help users understand each step of the process. It is an essential tool for anyone who works with Komatsu engines, and can help to ensure that the engine is maintained and repaired to the highest standards. It is important to note that the manual is designed for use by qualified mechanics and technicians, and should not be used by individuals without the appropriate training and experience.

TABLE OF CONTENTS:

Komatsu 12V140E-3 Series Diesel Engine Shop Manual SEN00291-16 – PDF DOWNLOAD

Cover………………………………………………………………………….. 1

00 Index and foreword……………………………………………………………. 0

Index………………………………………………………………………. 3

Composition of shop manual………………………………………………… 4

Table of contents………………………………………………………… 5

Foreword and general information………………………………………………. 13

Safety notice……………………………………………………………. 14

How to read the shop manual……………………………………………….. 19

Explanation of terms for maintenance standard……………………………….. 21

Handling of electric equipment and hydraulic component……………………….. 23

Handling of connectors newly used for engines……………………………….. 32

How to read electric wire code…………………………………………….. 35

Precautions when carrying out operation…………………………………….. 38

Method of disassembling and connecting push-pull type coupler…………………. 41

Standard tightening torque table…………………………………………… 44

Conversion table…………………………………………………………. 48

01 Specification………………………………………………………………… 0

Specification and technical data………………………………………………. 55

Outline…………………………………………………………………. 56

Specifications…………………………………………………………… 58

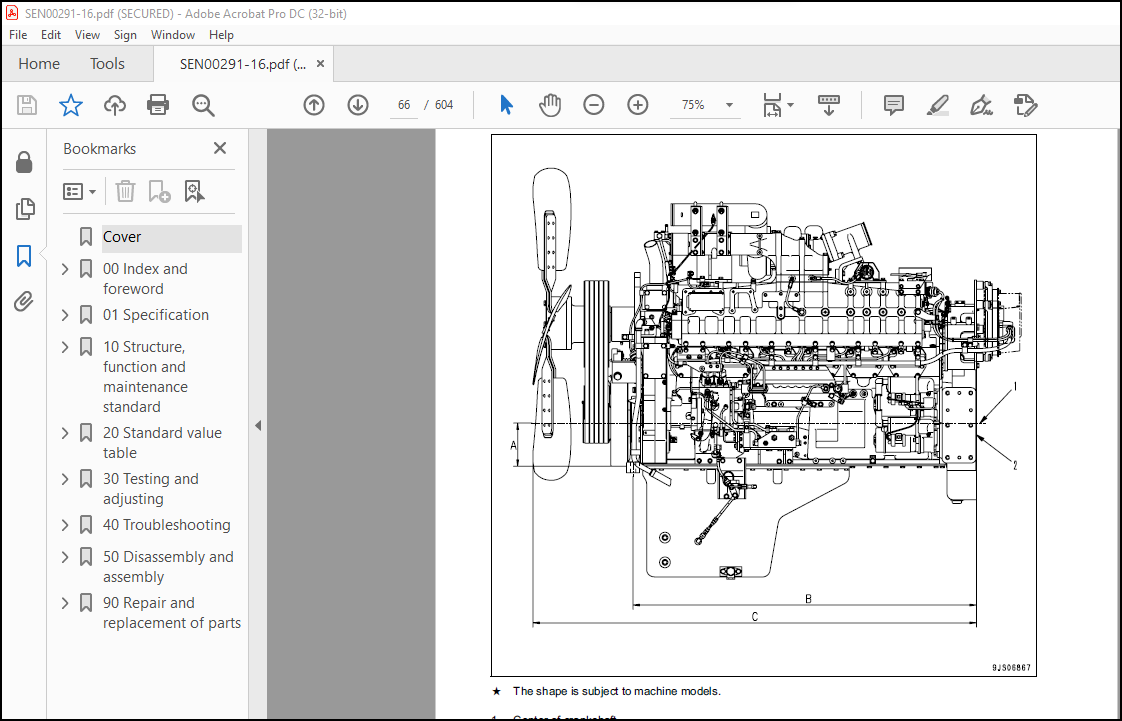

General view…………………………………………………………….. 64

Weight table…………………………………………………………….. 75

Engine performance curves…………………………………………………. 76

10 Structure, function and maintenance standard…………………………………….. 0

Structure, function and maintenance standard, Part 1…………………………….. 83

Air intake and exhaust unit……………………………………………….. 85

Air cleaner……………………………………………………………… 86

Turbocharger…………………………………………………………….. 88

Aftercooler……………………………………………………………… 93

Muffler…………………………………………………………………. 94

Cylinder head……………………………………………………………. 96

Cylinder block……………………………………………………………100

Cylinder liner……………………………………………………………104

Main moving parts…………………………………………………………106

Crankshaft……………………………………………………………….108

Camshaft…………………………………………………………………110

Cam follower and push rod………………………………………………….111

Piston, piston ring, and piston pin…………………………………………112

Connecting rod……………………………………………………………114

Flywheel and flywheel housing………………………………………………116

Vibration damper………………………………………………………….117

Timing gear………………………………………………………………118

Valve system……………………………………………………………..120

Valve and valve guide……………………………………………………..122

Rocker arm and shaft………………………………………………………124

Crosshead and guide……………………………………………………….125

Structure, function and maintenance standard, Part 2……………………………..127

Lubrication system………………………………………………………..130

Lubrication system diagram……………………………………………..130

Oil pump……………………………………………………………..132

Oil cooler……………………………………………………………133

Oil filter……………………………………………………………134

Main relief valve……………………………………………………..135

Oil cooler bypass valve and regulator valve………………………………136

Fuel system………………………………………………………………138

CRI system diagram…………………………………………………….138

CRI system diagram (Poor fuel spec.)…………………………………….140

Outline of CRI system………………………………………………….142

Fuel piping…………………………………………………………..160

Fuel piping (Poor fuel spec.)…………………………………………..165

Fuel filter…………………………………………………………..170

Water separator……………………………………………………….172

Priming pump………………………………………………………….173

Electric priming pump………………………………………………….174

Cooling system……………………………………………………………176

Cooling system diagram…………………………………………………176

Water pump……………………………………………………………178

Thermostat……………………………………………………………180

Corrosion resistor…………………………………………………….181

Cooling fan drive……………………………………………………..183

Electrical equipment………………………………………………………186

Alternator……………………………………………………………186

Starting motor………………………………………………………..189

Starting aid………………………………………………………….191

Engine controller……………………………………………………..194

Engine controller cooler……………………………………………….195

20 Standard value table………………………………………………………….. 0

Standard service value table…………………………………………………..197

Standard service value table……………………………………………….198

Standard service value table for testing, adjusting, and troubleshooting…….198

Running-in standard and performance test standard…………………………203

30 Testing and adjusting…………………………………………………………. 0

Testing and adjusting…………………………………………………………209

Testing and adjusting tools list……………………………………………211

Testing air boost pressure…………………………………………………213

Testing exhaust temperature………………………………………………..214

Adjusting valve clearance………………………………………………….215

Testing compression pressure……………………………………………….217

Testing blow-by pressure…………………………………………………..219

Testing oil pressure………………………………………………………220

Handling fuel system parts…………………………………………………221

Releasing residual pressure in fuel system…………………………………..221

Testing fuel pressure……………………………………………………..222

Reduced cylinder mode operation…………………………………………….223

No-injection cranking……………………………………………………..223

Testing leakage-from pressure limiter and return rate from injector…………….224

Bleeding air from fuel circuit (for D475A-5)…………………………………227

Bleeding air from fuel circuit (for PC2000)………………………………….230

Bleeding air from fuel circuit (Poor fuel spec.)……………………………..232

Testing fuel system for leakage…………………………………………….234

Adjusting speed sensor…………………………………………………….235

Testing and adjusting alternator belt tension………………………………..235

Handling controller high-voltage circuit…………………………………….236

40 Troubleshooting………………………………………………………………. 0

General Information on troubleshooting………………………………………….239

Points to remember when troubleshooting……………………………………..240

Error codes and failure codes list………………………………………….241

Information in troubleshooting table………………………………………..245

Connection table for connector pin numbers…………………………………..247

T- branch box and T- branch adapter table……………………………………283

Troubleshooting of mechanical system (S-mode)……………………………………287

Method of using troubleshooting charts………………………………………289

S-1 Starting performance is poor……………………………………………292

S-2 Engine does not start………………………………………………….293

S-3 Engine does not pick up smoothly………………………………………..296

S-4 Engine stops during operations………………………………………….297

S-5 Engine does not rotate smoothly…………………………………………298

S-6 Engine lacks output (or lacks power)…………………………………….299

S-7 Exhaust smoke is black (incomplete combustion)……………………………301

S-8 Oil consumption is excessive (or exhaust smoke is blue)……………………302

S-9 Oil becomes contaminated quickly………………………………………..303

S-10 Fuel consumption is excessive………………………………………….304

S-11 Oil is in coolant (or coolant spurts back or coolant level goes down)………305

S-12 Oil pressure drops……………………………………………………306

S-13 Oil level rises (Entry of coolant or fuel)………………………………307

S-14 Coolant temperature becomes too high (overheating)……………………….308

S-15 Abnormal noise is made………………………………………………..309

S-16 Vibration is excessive………………………………………………..310

Troubleshooting of electrical system (E-mode), Part 1…………………………….313

E-1 Code [111/CA111] ECM Critical Internal Failure (LH bank)…………………..316

E-2 Code [111/CB111] ECM Critical Internal Failure (RH bank)…………………..318

E-3 Code [115/CA115] Eng. Ne and G (Bkup) Speed Sensor Error (LH bank)………….320

E-4 Code [115/CB115] Eng. Ne and G (Bkup) Speed Sensor Error (RH bank)………….321

E-5 Code [122/CA122] Charge Air Press. Sensor High Error (LH bank only)…………322

E-6 Code [123/CA123] Charge Air Press. Sensor Low Error (LH bank only)………….324

E-7 Code [131/CA131] Throttle Sensor High Error (LH bank only)…………………326

E-8 Code [132/CA132] Throttle Sensor Low Error (LH bank only)………………….327

E-9 Code [135/CA135] Oil Press. Sensor High Error (LH bank only)……………….328

E-10 Code [141/CA141] Oil Press. Sensor Low Error (LH bank only)……………….330

E-11 Code [144/CA144] Coolant Temp. Sensor High Error (LH bank only)……………332

E-12 Code [145/CA145] Coolant Temp. Sensor Low Error (LH bank only)…………….334

E-13 Code [153/CA153] Charge Air Temp. Sensor High Error (LH bank only)…………336

E-14 Code [154/CA154] Charge Air Temp. Sensor Low Error (LH bank only)………….338

E-15 Code [187/CA187] Sensor Sup. 2 Volt. Low Error (LH bank)………………….339

E-16 Code [187/CB187] Sensor Sup. 2 Volt. Low Error (RH bank)………………….339

E-17 Code [212/CA212] Eng. Oil Temp.Sensor High Error (LH bank only)……………340

E-18 Code [213/CA213] Eng. Oil Temp.Sensor Low Error (LH bank only)…………….342

E-19 Code [221/CA221] Ambient Air Press. Sensor High Error (LH bank only)……….344

E-20 Code [222/CA222] Ambient Air Press. Sensor Low Error (LH bank only)………..346

E-21 Code [227/CA227] Sensor Sup. 2 Volt. High Error (LH bank)…………………348

E-22 Code [227/CB227] Sensor Sup. 2 Volt. High Error (RH bank)…………………350

E-23 Code [234/CA234] Eng. Overspeed (LH bank only)…………………………..352

E-24 Code [238/CA238] Ne Speed Sensor Sup. Volt. Error (LH bank)……………….354

E-25 Code [238/CB238] Ne Speed Sensor Sup. Volt. Error (RH bank)……………….356

E-26 Code [263/CA263] Fuel Temp. Sensor High Error (LH bank)…………………..358

E-27 Code [263/CB263] Fuel Temp. Sensor High Error (RH bank)…………………..360

E-28 Code [265/CA265] Fuel Temp. Sensor Low Error (LH bank)……………………362

E-29 Code [265/CB265] Fuel Temp. Sensor Low Error (RH bank)……………………362

E-30 Code [271/CA271] PCV1 Short Error (LH bank)……………………………..364

E-31 Code [271/CB271] PCV1 Short Error (RH bank)……………………………..366

E-32 Code [272/CA272] PCV1 Open Error (LH bank)………………………………368

E-33 Code [272/CB272] PCV1 Open Error (RH bank)………………………………369

E-34 Code [273/CA273] PCV2 Short Error (LH bank)……………………………..370

E-35 Code [273/CB273] PCV2 Short Error (RH bank)……………………………..372

E-36 Code [274/CA274] PCV2 Open Error (LH bank)………………………………374

E-37 Code [274/CB274] PCV2 Open Error (RH bank)………………………………375

E-38 Code [322/CA322] Injector #1 (L/B #1) System Open/Short Error (LH bank)…….376

E-39 Code [323/CA323] Injector #5 (L/B #5) System Open/Short Error (LH bank)…….378

E-40 Code [324/CA324] Injector #3 (L/B #3) System Open/Short Error (LH bank)…….380

E-41 Code [325/CA325] Injector #6 (L/B #6) System Open/Short Error (LH bank)…….382

E-42 Code [331/CA331] Injector #2 (L/B #2) System Open/Short Error (LH bank)…….384

E-43 Code [332/CA332] Injector #4 (L/B #4) System Open/Short Error (LH bank)…….386

E-44 Code [342/CA342] Caribration Code Incompatibility (LH bank)……………….388

E-45 Code [342/CB342] Caribration Code Incompatibility (RH bank)……………….388

E-46 Code [351/CA351] INJ. Drive Circuit Error (LH bank)………………………390

E-47 Code [351/CB351] INJ. Drive Circuit Error (RH bank)………………………392

E-48 Code [352/CA352] Sensor Sup. 1 Volt. Low Error (LH bank)………………….394

E-49 Code [352/CB352] Sensor Sup. 1 Volt. Low Error (RH bank)………………….394

E-50 Code [386/CA386] Sensor Sup. 1 Volt. High Error (LH bank)…………………396

E-51 Code [386/CB386] Sensor Sup. 1 Volt. High Error (RH bank)…………………398

E-52 Code [441/CA441] Battery Voltage Low Error (LH bank)……………………..400

E-53 Code [441/CB441] Battery Voltage Low Error (RH bank)……………………..400

E-54 Code [442/CA442] Battery Voltage High Error (LH bank)…………………….401

E-55 Code [442/CB442] Battery Voltage High Error (RH bank)…………………….401

Troubleshooting of electrical system (E-mode), Part 2…………………………….403

E-56 Code [449/CA449] Rail Press. Very High Error (LH bank)……………………405

E-57 Code [449/CB449] Rail Press. Very High Error (RH bank)……………………405

E-58 Code [451/CA451] Rail Press. Sensor High Error (LH bank)………………….406

E-59 Code [451/CB451] Rail Press. Sensor High Error (RH bank)………………….408

E-60 Code [452/CA452] Rail Press. Sensor Low Error (LH bank)…………………..410

E-61 Code [452/CB452] Rail Press. Sensor Low Error (RH bank)…………………..410

E-62 Code [553/CA553] Rail Press. High Error 1 (LH bank)………………………411

E-63 Code [553/CB553] Rail Press. High Error 1 (RH bank)………………………412

E-64 Code [554/CA554] Rail Press. Sensor In Range Error (LH bank)………………413

E-65 Code [554/CB554] Rail Press. Sensor In Range Error (RH bank)………………413

E-66 Code [559/CA559] Rail Press. Low Error 1 (LH bank)……………………….414

E-67 Code [559/CB559] Rail Press. Low Error 1 (RH bank)……………………….418

E-68 Code [689/CA689] Eng. Ne Speed Sensor Error (LH bank)…………………….422

E-69 Code [689/CB689] Eng. Ne Speed Sensor Error (RH bank)…………………….424

E-70 Code [691/CA691] Intake Air Temp Sensor High Error (LH bank only)………….426

E-71 Code [692/CA692] Intake Air Temp Sensor Low Error (LH bank only)…………..428

E-72 Code [731/CA731] Eng. G (Bkup) Speed Sensor Phase Error (LH bank)………….429

E-73 Code [731/CB731] Eng. G (Bkup) Speed Sensor Phase Error (RH bank)………….429

E-74 Code [757/CA757] All Continuous Data Lost Error (LH bank)…………………430

E-75 Code [757/CB757] All Continuous Data Lost Error (RH bank)…………………430

E-76 Code [778/CA778] Eng. G (Bkup) Speed Sensor Error (LH bank)……………….432

E-77 Code [778/CB778] Eng. G (Bkup) Speed Sensor Error (RH bank)……………….434

E-78 Code [781/CA781] Inter Multi-controller Communication Error (LH bank)………436

E-79 Code [781/CB781] Inter Multi-controller Communication Error (RH bank)………438

E-80 Code [1117/CA1117] Persistent Data Lost Error (LH bank)…………………..439

E-81 Code [1117/CB1117] Persistent Data Lost Error (RH bank)…………………..439

E-82 Code [1257/CA1257] Harness Key error (LH bank)…………………………..440

E-83 Code [1257/CB1257] Harness Key error (RH bank)…………………………..441

E-84 Code [1548/CB1548] Injector #7 (R/B #1) System Open/Short Error (RH bank)…..442

E-85 Code [1549/CB1549] Injector #8 (R/B #2) System Open/Short Error (RH bank)…..444

E-86 Code [1551/CB1551] Injector #10 (R/B #4) System Open/Short Error (RH bank)….446

E-87 Code [1552/CB1552] Injector #11 (R/B #5) System Open/Short Error (RH bank)….448

E-88 Code [1553/CB1553] Injector #12 (R/B #6) System Open/Short Error (RH bank)….450

E-89 Code [1622/CB1622] Injector #9 (R/B #3) System Open/Short Error (RH bank)…..452

E-90 Code [1633/CA1633] KOMNET Datalink Timeout Error (LH bank)………………..454

E-91 Code [2185/CA2185] Throttle Sens. Sup. Volt. High Error (LH bank only)……..456

E-92 Code [2186/CA2186] Throttle Sens. Sup. Volt. Low Error (LH bank only)………458

E-93 Code [2249/CA2249] Rail Press. Very Low Error (LH bank)…………………..459

E-94 Code [2249/CB2249] Rail Press. Very Low Error (RH bank)…………………..459

E-95 Code [- -*1/-] Eng. Overheat (LH bank only)……………………………..460

E-96 Code [- -*2/-] Eng. Oil Press. Low Speed Derate (LH bank only)…………….460

E-97 Code [- -*3/-] Press. Low Torque Derate (LH bank only)……………………461

50 Disassembly and assembly………………………………………………………. 0

General information on disassembly and assembly………………………………….463

How to read this manual……………………………………………………464

Coating materials list…………………………………………………….466

Special tool list…………………………………………………………469

Sketches of special tools………………………………………………….471

Disassembly and assembly, Part 1……………………………………………….475

Disassembly and assembly, Part 1……………………………………………476

General disassembly of engine…………………………………………..476

Disassembly and assembly, Part 2……………………………………………….495

General assembly of engine…………………………………………………496

Disassembly and assembly, Part 3……………………………………………….535

Removal and installation fuel supply pump unit……………………………….536

Removal and installation oil seal unit………………………………………539

90 Repair and replacement of parts………………………………………………… 0

Information related to repair and replacement……………………………………547

Flowchart ……………………………………………………………….548

Special tool table………………………………………………………..550

Parts related to cylinder head…………………………………………………553

Part names related to cylinder head…………………………………………554

Testing and inspection of cylinder head……………………………………..555

Pressure test of cylinder head……………………………………………..557

Replacement of valve guide…………………………………………………557

Replacement of valve seat insert……………………………………………558

Replacement of crosshead guide……………………………………………..565

Repair of cylinder head mounting face by grinding…………………………….566

Repair of valve by grinding………………………………………………..567

Parts related to cylinder block………………………………………………..569

Part names related to cylinder block………………………………………..571

Testing and inspection of cylinder block…………………………………….572

Part names related to crankshaft……………………………………………575

Testing and inspection of crankshaft………………………………………..576

Part names related to connecting rod………………………………………..577

Testing and inspection of connecting rod…………………………………….578

Replacement of flywheel ring gear…………………………………………..579

Replacement of crankshaft gear……………………………………………..580

Replacement of camshaft gear……………………………………………….581

Replacement of main bearing metal cap……………………………………….582

Replacement of connecting rod small end bushing………………………………584

Replacement of cam bushing…………………………………………………585

Repair of cylinder block top by grinding…………………………………….587

Repair of counterbore by grinding…………………………………………..588

Check and identification after repair by grinding…………………………….590

Gasket sealant application procedure………………………………………..591

Repair standard for cylinder liner O-ring……………………………………593

Repair of crankshaft by grinding……………………………………………594

Improvement of surface roughness of crankshaft journal………………………..600