$40

Komatsu 12V140E-7 Series Engine Shop Manual SEN06656-07 – PDF DOWNLOAD

Komatsu 12V140E-7 Series Engine Shop Manual SEN06656-07 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 12V140E-7 Series Engine Shop Manual SEN06656-07 – PDF DOWNLOAD

Language : English

Pages : 1080

Downloadable : Yes

File Type : PDF

Size: 56.6 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 12V140E-7 Series Engine Shop Manual SEN06656-07 – PDF DOWNLOAD

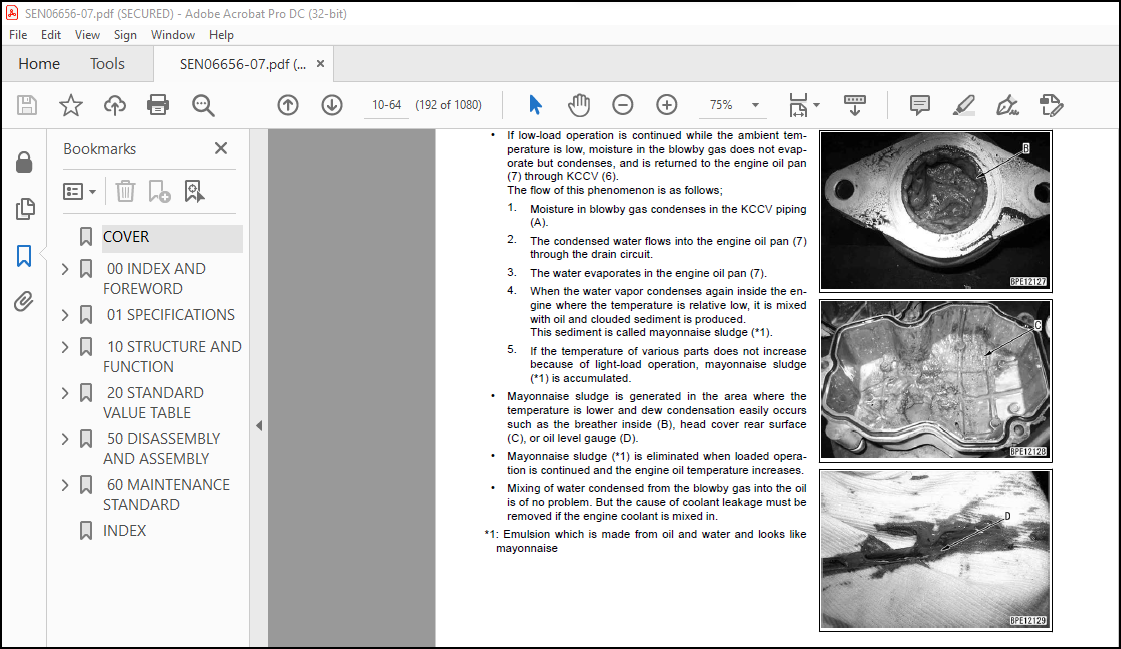

- The Komatsu 12V140E-7 Series Engine Shop Manual, identified by part number SEN06656-07, is a comprehensive technical guide for the 12V140E-7 diesel engine produced by Komatsu, a leading manufacturer of construction and mining equipment based in Japan. The manual is designed to provide detailed information on the construction, operation, maintenance, and repair of the engine to professional technicians and mechanics who work on these engines, as well as to owners and operators who want to learn more about the engine and its maintenance.

- The Komatsu 12V140E-7 engine is a four-stroke, turbocharged, air-to-air intercooled diesel engine with a displacement of 26.2 liters. It is a Tier 4 Final emission-compliant engine that is designed for use in heavy-duty applications in construction, mining, and industrial equipment.

The manual is organized into several sections, each of which covers a specific aspect of the engine. These sections include:

- General Information: This section provides an overview of the engine, including its specifications, dimensions, performance data, and maintenance requirements.

- Structure and Function: This section provides a detailed explanation of the engine’s design and construction, including the operation of various systems and components.

- Testing and Adjusting: This section covers the procedures for testing and adjusting various engine components, such as the fuel system, turbocharger, intake and exhaust systems, and engine control system. The manual provides step-by-step instructions, illustrations, and specifications to help technicians perform these tasks accurately and safely.

- Disassembly and Assembly: This section provides detailed instructions for disassembling and assembling the engine, including the removal and installation of various components. The manual includes detailed illustrations and specifications to help technicians perform these tasks safely and efficiently.

- Maintenance: This section provides information on the routine maintenance tasks that are required to keep the engine in good working order, including oil and filter changes, inspections, and other maintenance procedures. The manual also includes a maintenance schedule and recommended service intervals.

- Troubleshooting: This section provides a comprehensive guide to identifying and diagnosing problems with the engine. The manual includes a list of symptoms, possible causes, and suggested remedies for each problem, as well as troubleshooting flowcharts and diagnostic procedures.

The Komatsu 12V140E-7 Series Engine Shop Manual SEN06656-07 is an essential tool for maintaining and repairing these engines. The manual provides comprehensive and detailed information on the construction, operation, maintenance, and repair of the engine, as well as important troubleshooting information that can help to identify and resolve problems quickly and efficiently. The manual is an essential resource for ensuring that Komatsu engines remain reliable and efficient over their long service life.

TABLE OF CONTENTS:

Komatsu 12V140E-7 Series Engine Shop Manual SEN06656-07 – PDF DOWNLOAD

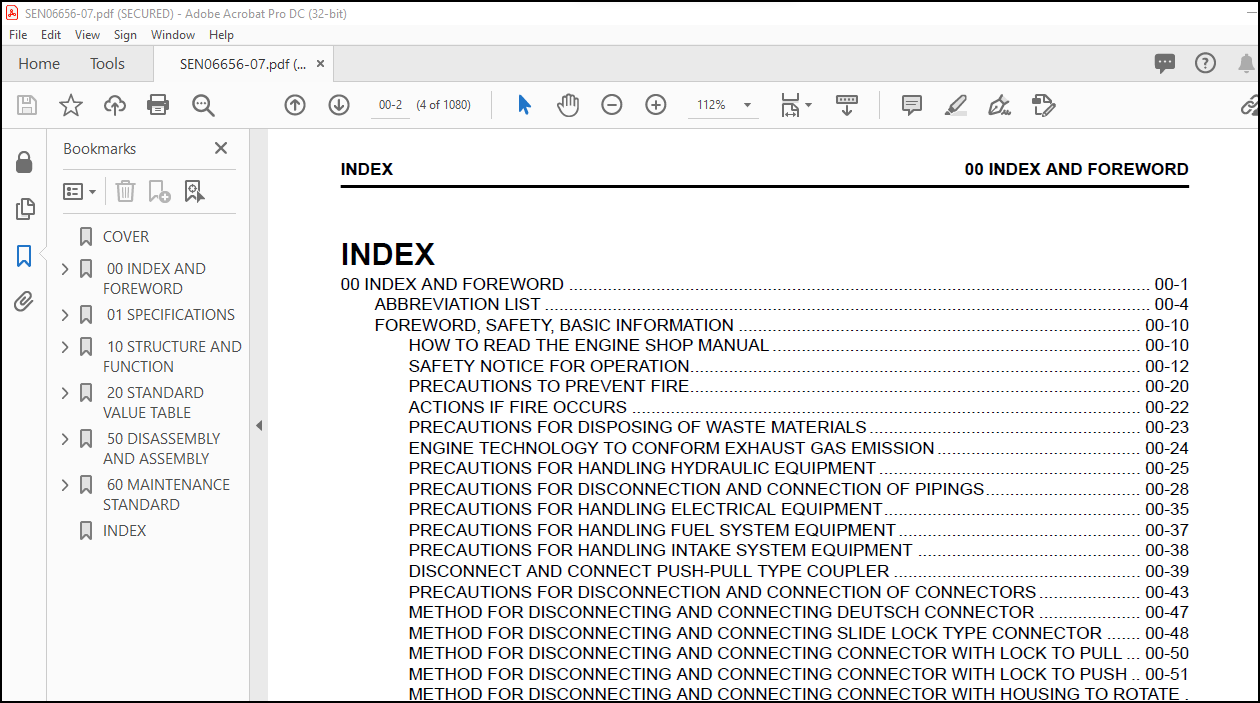

00 INDEX AND FOREWORD ………………………………………………………………………………………………………… 00-1

ABBREVIATION LIST …………………………………………………………………………………………………………….. 00-4

FOREWORD, SAFETY, BASIC INFORMATION ……………………………………………………………………….. 00-10

HOW TO READ THE ENGINE SHOP MANUAL …………………………………………………………………. 00-10

SAFETY NOTICE FOR OPERATION………………………………………………………………………………… 00-12

PRECAUTIONS TO PREVENT FIRE………………………………………………………………………………… 00-20

ACTIONS IF FIRE OCCURS …………………………………………………………………………………………… 00-22

PRECAUTIONS FOR DISPOSING OF WASTE MATERIALS ……………………………………………….. 00-23

ENGINE TECHNOLOGY TO CONFORM EXHAUST GAS EMISSION …………………………………… 00-24

PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT ……………………………………………… 00-25

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF PIPINGS………………………….. 00-28

PRECAUTIONS FOR HANDLING ELECTRICAL EQUIPMENT…………………………………………….. 00-35

PRECAUTIONS FOR HANDLING FUEL SYSTEM EQUIPMENT ………………………………………….. 00-37

PRECAUTIONS FOR HANDLING INTAKE SYSTEM EQUIPMENT ………………………………………. 00-38

DISCONNECT AND CONNECT PUSH-PULL TYPE COUPLER …………………………………………… 00-39

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF CONNECTORS ………………… 00-43

METHOD FOR DISCONNECTING AND CONNECTING DEUTSCH CONNECTOR ………………… 00-47

METHOD FOR DISCONNECTING AND CONNECTING SLIDE LOCK TYPE CONNECTOR ……. 00-48

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PULL … 00-50

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PUSH .. 00-51

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH HOUSING TO ROTATE .

………………………………………………………………………………………………………………………………… 00-53

HOW TO READ ELECTRICAL WIRE CODE ……………………………………………………………………… 00-54

EXPLANATION OF TERMS FOR MAINTENANCE STANDARD……………………………………………. 00-58

STANDARD TIGHTENING TORQUE TABLE……………………………………………………………………… 00-61

CONVERSION TABLE……………………………………………………………………………………………………. 00-68

01 SPECIFICATIONS …………………………………………………………………………………………………………………… 01-1

CONTENTS ………………………………………………………………………………………………………………………….. 01-2

ABBREVIATION LIST …………………………………………………………………………………………………………….. 01-3

SPECIFICATIONS …………………………………………………………………………………………………………………. 01-9

OUTLINE OF EXHAUST GAS REGULATION………………………………………………………………………. 01-9

LIST OF APPLICABLE MACHINES: 12V140E-7 ………………………………………………………………… 01-13

SPECIFICATIONS …………………………………………………………………………………………………………. 01-14

ENGINE GENERAL VIEW ………………………………………………………………………………………………. 01-21

WEIGHT TABLE ……………………………………………………………………………………………………………. 01-45

ENGINE PERFORMANCE CURVE ………………………………………………………………………………….. 01-49

10 STRUCTURE AND FUNCTION …………………………………………………………………………………………………. 10-1

CONTENTS ………………………………………………………………………………………………………………………….. 10-2

ABBREVIATION LIST …………………………………………………………………………………………………………….. 10-5

ENGINE SYSTEM …………………………………………………………………………………………………………………10-11

LAYOUT OF ENGINE COMPONENTS ……………………………………………………………………………….10-11

INTAKE AND EXHAUST SYSTEM PARTS ………………………………………………………………………… 10-13

ENGINE MAIN BODY PARTS………………………………………………………………………………………….. 10-23

TURBOCHARGER SYSTEM …………………………………………………………………………………………… 10-40

LUBRICATION SYSTEM…………………………………………………………………………………………………. 10-74

FUEL SYSTEM ……………………………………………………………………………………………………………… 10-86

COOLING SYSTEM……………………………………………………………………………………………………….10-113

ELECTRICAL SYSTEM ………………………………………………………………………………………………………..10-124

COMPONENT PARTS OF ELECTRICAL SYSTEM …………………………………………………………….10-124

SENSOR………………………………………………………………………………………………………………………10-167

20 STANDARD VALUE TABLE ………………………………………………………………………………………………………. 20-1

CONTENTS ………………………………………………………………………………………………………………………….. 20-2

ABBREVIATION LIST …………………………………………………………………………………………………………….. 20-3

STANDARD VALUE TABLE FOR ENGINE ………………………………………………………………………………… 20-9

STANDARD VALUE TABLE FOR ENGINE: SAA12V140E-7 (D475A-8, D475A-8E0) …………………. 20-9

STANDARD VALUE TABLE FOR ENGINE: SAA12V140E-7 (HD785-8, HD785-8E0)…………………20-11

INDEX 00 INDEX AND FOREWORD

00-2 12V140E-7 SERIES

STANDARD VALUE TABLE FOR ENGINE: SAA12V140E-7 (PC2000-11, PC2000-11E0)…………. 20-13

STANDARD VALUE TABLE FOR ENGINE: SAA12V140E-7 (PC2000-11R) ……………………………. 20-15

STANDARD VALUE TABLE FOR ENGINE: SAA12V140E-7 (WA800-8, WA800-8E0, WA900-8,

WA900-8E0) ………………………………………………………………………………………………………………. 20-17

STANDARD VALUE TABLE FOR ENGINE: SAA12V140E-7 (WA900-8R) ………………………………. 20-19

MACHINE POSTURE AND PROCEDURE FOR MEASURING PERFORMANCE ……………………. 20-21

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD …………………………………………. 20-22

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA12V140E-7 (D475A-8,

D475A-8E0)……………………………………………………………………………………………………………….. 20-22

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA12V140E-7 (HD785-8,

HD785-8E0) ………………………………………………………………………………………………………………. 20-24

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA12V140E-7 (PC2000-11,

PC2000-11E0) ……………………………………………………………………………………………………………. 20-26

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA12V140E-7 (PC2000-11R) ..

………………………………………………………………………………………………………………………………… 20-28

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA12V140E-7 (WA800-8,

WA800-8E0) ……………………………………………………………………………………………………………… 20-30

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA12V140E-7 (WA900-8,

WA900-8E0) ………………………………………………………………………………………………………………. 20-32

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA12V140E-7 (WA900-8R) …..

………………………………………………………………………………………………………………………………… 20-34

50 DISASSEMBLY AND ASSEMBLY………………………………………………………………………………………………. 50-1

CONTENTS ………………………………………………………………………………………………………………………….. 50-2

ABBREVIATION LIST …………………………………………………………………………………………………………….. 50-6

RELATED INFORMATION ON DISASSEMBLY AND ASSEMBLY ……………………………………………….. 50-12

HOW TO READ THIS MANUAL……………………………………………………………………………………….. 50-12

COATING MATERIALS LIST……………………………………………………………………………………………. 50-14

SPECIAL TOOLS LIST …………………………………………………………………………………………………… 50-18

SKETCHES OF SPECIAL TOOLS……………………………………………………………………………………. 50-21

ENGINE SYSTEM ……………………………………………………………………………………………………………….. 50-23

METHOD FOR DISASSEMBLING ENGINE GENERALLY……………………………………………………. 50-23

METHOD FOR ASSEMBLING ENGINE GENERALLY ………………………………………………………..50-301

60 MAINTENANCE STANDARD…………………………………………………………………………………………………….. 60-1

CONTENTS ………………………………………………………………………………………………………………………….. 60-2

ABBREVIATION LIST …………………………………………………………………………………………………………….. 60-3

ENGINE SYSTEM …………………………………………………………………………………………………………………. 60-9

INTAKE AND EXHAUST SYSTEM PARTS ………………………………………………………………………….. 60-9

ENGINE MAIN BODY PARTS………………………………………………………………………………………….. 60-12

LUBRICATION SYSTEM…………………………………………………………………………………………………. 60-38

COOLING SYSTEM……………………………………………………………………………………………………….. 60-43

INDEX………………………………………………………………………………………………………………………………………………1