$38

Komatsu 12V140E-7 Series Engine Shop Manual SEN06656-08 – PDF DOWNLOAD

Komatsu 12V140E-7 Series Engine Shop Manual SEN06656-08 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 12V140E-7 Series Engine Shop Manual SEN06656-08 – PDF DOWNLOAD

Language : English

Pages : 1080

Downloadable : Yes

File Type : PDF

Size: 56.3 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 12V140E-7 Series Engine Shop Manual SEN06656-08 – PDF DOWNLOAD

- The Komatsu 12V140E-7 Series Engine Shop Manual, identified by part number SEN06656-08, is a comprehensive guide that provides detailed information on the construction, operation, maintenance, and repair of the 12V140E-7 diesel engine produced by Komatsu, a leading manufacturer of construction and mining equipment based in Japan.

- The Komatsu 12V140E-7 engine is a turbocharged, air-to-air intercooled, four-stroke diesel engine with a displacement of 26.2 liters. It is a Tier 4 Final emission-compliant engine that is designed for heavy-duty applications in construction, mining, and industrial equipment.

- The Shop Manual is a technical document that provides detailed information on the different components of the 12V140E-7 engine, including the fuel system, turbocharger, cooling system, lubrication system, and air intake system. The manual is designed to be used by professional technicians and mechanics who work on these engines, as well as by owners and operators who want to learn more about the engine and its maintenance.

The manual is organized into several sections, each of which covers a specific aspect of the engine. These sections include:

- General Information: This section provides an overview of the engine and its specifications, including its dimensions, weight, performance data, and maintenance requirements.

- Structure and Function: This section provides a detailed explanation of the engine’s design and construction, including the operation of various systems and components.

- Testing and Adjusting: This section covers the procedures for testing and adjusting various engine components, such as the fuel system, turbocharger, intake and exhaust systems, and engine control system. The manual provides step-by-step instructions, illustrations, and specifications to help technicians perform these tasks accurately and safely.

- Disassembly and Assembly: This section provides detailed instructions for disassembling and assembling the engine, including the removal and installation of various components. The manual includes detailed illustrations and specifications to help technicians perform these tasks safely and efficiently.

- Maintenance: This section provides information on the routine maintenance tasks that are required to keep the engine in good working order, including oil and filter changes, inspections, and other maintenance procedures. The manual also includes a maintenance schedule and recommended service intervals.

- Troubleshooting: This section provides a comprehensive guide to identifying and diagnosing problems with the engine. The manual includes a list of symptoms, possible causes, and suggested remedies for each problem, as well as troubleshooting flowcharts and diagnostic procedures.

Overall, the Komatsu 12V140E-7 Series Engine Shop Manual SEN06656-08 is a valuable resource for anyone who works on or owns one of these engines. The manual provides detailed information on the construction, operation, maintenance, and repair of the engine, as well as important troubleshooting information that can help to identify and resolve problems quickly and efficiently. The manual is an essential tool for maintaining and repairing Komatsu engines, ensuring that they remain reliable and efficient over their long service life.

TABLE OF CONTENTS:

Komatsu 12V140E-7 Series Engine Shop Manual SEN06656-08 – PDF DOWNLOAD

COVER……………………………………………………………………………………………………………………………………………… 1

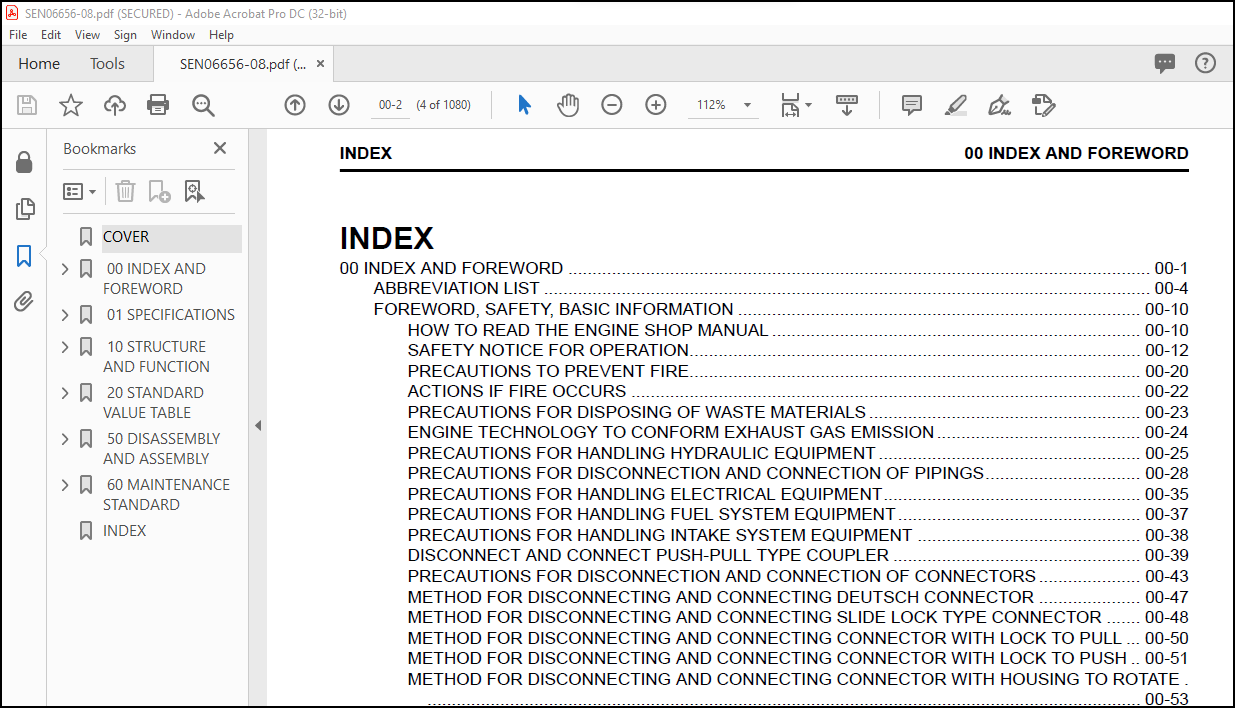

00 INDEX AND FOREWORD………………………………………………………………………………………………………………………………. 3

INDEX…………………………………………………………………………………………………………………………………………. 4

ABBREVIATION LIST………………………………………………………………………………………………………………………………. 6

FOREWORD, SAFETY, BASIC INFORMATION………………………………………………………………………………………………………………. 12

HOW TO READ THE ENGINE SHOP MANUAL……………………………………………………………………………………………………………. 12

SAFETY NOTICE FOR OPERATION………………………………………………………………………………………………………………….. 14

PRECAUTIONS TO PREVENT FIRE………………………………………………………………………………………………………………….. 22

ACTIONS IF FIRE OCCURS………………………………………………………………………………………………………………………. 24

PRECAUTIONS FOR DISPOSING OF WASTE MATERIALS…………………………………………………………………………………………………… 25

ENGINE TECHNOLOGY TO CONFORM EXHAUST GAS EMISSION………………………………………………………………………………………………. 26

PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT…………………………………………………………………………………………………… 27

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF PIPINGS…………………………………………………………………………………………. 30

PRECAUTIONS FOR HANDLING ELECTRICAL EQUIPMENT………………………………………………………………………………………………….. 37

PRECAUTIONS FOR HANDLING FUEL SYSTEM EQUIPMENT…………………………………………………………………………………………………. 39

PRECAUTIONS FOR HANDLING INTAKE SYSTEM EQUIPMENT……………………………………………………………………………………………….. 40

DISCONNECT AND CONNECT PUSH-PULL TYPE COUPLER………………………………………………………………………………………………….. 41

METHOD FOR DISCONNECTING AND CONNECTING TYPE 1 PUSH-PULL TYPE COUPLER…………………………………………………………………………. 41

METHOD FOR DISCONNECTING AND CONNECTING TYPE 2 PUSH-PULL TYPE COUPLER…………………………………………………………………………. 42

METHOD FOR DISCONNECTING AND CONNECTING TYPE 3 PUSH-PULL TYPE COUPLER…………………………………………………………………………. 43

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF CONNECTORS………………………………………………………………………………………. 45

METHOD FOR DISCONNECTING AND CONNECTING DEUTSCH CONNECTOR……………………………………………………………………………………….. 49

METHOD FOR DISCONNECTING AND CONNECTING SLIDE LOCK TYPE CONNECTOR………………………………………………………………………………… 50

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PULL………………………………………………………………………………. 52

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PUSH………………………………………………………………………………. 53

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH HOUSING TO ROTATE………………………………………………………………………….. 55

HOW TO READ ELECTRICAL WIRE CODE……………………………………………………………………………………………………………… 56

EXPLANATION OF TERMS FOR MAINTENANCE STANDARD………………………………………………………………………………………………….. 60

STANDARD TIGHTENING TORQUE TABLE……………………………………………………………………………………………………………… 63

CONVERSION TABLE……………………………………………………………………………………………………………………………. 70

01 SPECIFICATIONS………………………………………………………………………………………………………………………………….. 75

CONTENTS………………………………………………………………………………………………………………………………………. 76

ABBREVIATION LIST………………………………………………………………………………………………………………………………. 77

SPECIFICATIONS…………………………………………………………………………………………………………………………………. 83

OUTLINE OF EXHAUST GAS REGULATION…………………………………………………………………………………………………………….. 83

SYSTEM DIAGRAM OF ENGINE COMPLIED WITH TIER 4 AND EU STAGE V REGULATION……………………………………………………………………….. 84

IMPROVED POINTS OF ENGINE COMPLIED WITH TIER 4 AND EU STAGE V REGULATION AGAINST TIER3 REGULATION………………………………………………… 85

SYSTEM DIAGRAM OF ENGINE OTHER THAN ENGINE COMPLIED WITH TIER 4 AND EU STAGE V REGULATION……………………………………………………….. 86

LIST OF APPLICABLE MACHINES: 12V140E-7………………………………………………………………………………………………………… 87

SPECIFICATIONS……………………………………………………………………………………………………………………………… 88

SPECIFICATIONS: SAA12V140E-7 (D475A-8, D475A-8E0)…………………………………………………………………………………………… 88

SPECIFICATIONS: SAA12V140E-7 (HD785-8, HD785-8E0)…………………………………………………………………………………………… 89

SPECIFICATIONS: SAA12V140E-7 (PC2000-11, PC2000-11E0)……………………………………………………………………………………….. 90

SPECIFICATIONS: SAA12V140E-7 (PC2000-11R)………………………………………………………………………………………………….. 91

SPECIFICATIONS: SAA12V140E-7 (WA800-8, WA800-8E0)…………………………………………………………………………………………… 92

SPECIFICATIONS: SAA12V140E-7 (WA900-8, WA900-8E0)…………………………………………………………………………………………… 93

SPECIFICATIONS: SAA12V140E-7 (WA900-8R)……………………………………………………………………………………………………. 94

ENGINE GENERAL VIEW…………………………………………………………………………………………………………………………. 95

ENGINE GENERAL VIEW: SAA12V140E-7 (D475A-8, D475A-8E0)………………………………………………………………………………………. 95

ENGINE GENERAL VIEW: SAA12V140E-7 (HD785-8, HD785-8E0)………………………………………………………………………………………. 99

ENGINE GENERAL VIEW: SAA12V140E-7 (PC2000-11, PC2000-11E0)…………………………………………………………………………………… 103

ENGINE GENERAL VIEW: SAA12V140E-7 (PC2000-11R)……………………………………………………………………………………………… 107

ENGINE GENERAL VIEW: SAA12V140E-7 (WA800-8, WA800-8E0, WA900-8, WA900-8E0)…………………………………………………………………….. 111

ENGINE GENERAL VIEW: SAA12V140E-7 (WA900-8R)……………………………………………………………………………………………….. 115

WEIGHT TABLE……………………………………………………………………………………………………………………………….. 119

WEIGHT TABLE: 12V140E-7………………………………………………………………………………………………………………….. 119

ENGINE PERFORMANCE CURVE…………………………………………………………………………………………………………………….. 123

ENGINE PERFORMANCE CURVE: SAA12V140E-7 (D475A-8, D475A-8E0)………………………………………………………………………………….. 123

ENGINE PERFORMANCE CURVE: SAA12V140E-7 (HD785-8, HD785-8E0)………………………………………………………………………………….. 124

ENGINE PERFORMANCE CURVE: SAA12V140E-7 (PC2000-11, PC2000-11E0, PC2000-11R)……………………………………………………………………. 125

ENGINE PERFORMANCE CURVE: SAA12V140E-7 (WA800-8, WA800-8E0)………………………………………………………………………………….. 126

ENGINE PERFORMANCE CURVE: SAA12V140E-7 (WA900-8, WA900-8E0, WA900-8R)…………………………………………………………………………. 127

10 STRUCTURE AND FUNCTION…………………………………………………………………………………………………………………………… 129

CONTENTS………………………………………………………………………………………………………………………………………. 130

ABBREVIATION LIST………………………………………………………………………………………………………………………………. 133

ENGINE SYSTEM………………………………………………………………………………………………………………………………….. 139

LAYOUT OF ENGINE COMPONENTS………………………………………………………………………………………………………………….. 139

LAYOUT DRAWING OF COMPONENT PARTS OF ENGINE………………………………………………………………………………………………… 139

INTAKE AND EXHAUST SYSTEM PARTS………………………………………………………………………………………………………………. 141

LAYOUT DRAWING OF AIR INTAKE AND EXHAUST SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………………………………. 141

CIRCUIT DIAGRAM OF AIR INTAKE AND EXHAUST SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………… 143

FUNCTION OF INTAKE AND EXHAUST SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………………….. 144

LAYOUT DRAWING OF AIR INTAKE AND EXHAUST SYSTEM (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………… 145

CIRCUIT DIAGRAM OF AIR INTAKE AND EXHAUST SYSTEM (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………….. 147

FUNCTION OF INTAKE AND EXHAUST SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………………….. 148

AIR CLEANER (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………………………………………………………………. 149

AIR CLEANER (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………………………… 150

ENGINE MAIN BODY PARTS………………………………………………………………………………………………………………………. 151

CYLINDER HEAD…………………………………………………………………………………………………………………………… 151

CYLINDER BLOCK………………………………………………………………………………………………………………………….. 154

MAIN MOVING PARTS……………………………………………………………………………………………………………………….. 157

VIBRATION DAMPER………………………………………………………………………………………………………………………… 160

TIMING GEAR…………………………………………………………………………………………………………………………….. 161

FRONT COVER…………………………………………………………………………………………………………………………….. 162

VALVE SYSTEM……………………………………………………………………………………………………………………………. 163

FLYWHEEL AND FLYWHEEL HOUSING…………………………………………………………………………………………………………….. 167

TURBOCHARGER SYSTEM…………………………………………………………………………………………………………………………. 168

CIRCUIT DIAGRAM OF TURBOCHARGER SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………………………………………. 168

FUNCTION OF TURBOCHRGER SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………………………… 169

CIRCUIT DIAGRAM OF TURBOCHARGER SYSTEM (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………… 171

FUNCTION OF TURBOCHRGER SYSTEM (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………………………….. 172

VGT (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………………………………………………… 174

TURBOCHARGER (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………………………………………….. 178

EGR SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………………………………………….. 180

EGR VALVE (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………………………………………………………………… 184

EGR COOLER (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………………………………………….. 186

MIXING CONNECTOR (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………………………………………………………….. 187

KCCV SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………………………………………………………………. 189

KCCV…………………………………………………………………………………………………………………………………… 194

KDPF (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………………………………………………………………….. 197

MUFFLER (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………………………………………………. 201

LUBRICATION SYSTEM………………………………………………………………………………………………………………………….. 202

LAYOUT DRAWING OF COMPONENT PARTS OF LUBRICATION SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………….. 202

CIRCUIT DIAGRAM OF LUBRICATION SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………………….. 203

LAYOUT DRAWING OF COMPONENT PARTS OF LUBRICATION SYSTEM (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………. 204

CIRCUIT DIAGRAM OF LUBRICATION SYSTEM (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………………………. 205

ENGINE OIL PUMP…………………………………………………………………………………………………………………………. 206

ENGINE BOOST OIL PUMP (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………………………………… 208

ENGINE OIL FILTER……………………………………………………………………………………………………………………….. 210

ENGINE OIL COOLER……………………………………………………………………………………………………………………….. 211

ENGINE OIL PAN………………………………………………………………………………………………………………………….. 213

FUEL SYSTEM………………………………………………………………………………………………………………………………… 214

LAYOUT DRAWING OF COMPONENT PARTS OF FUEL SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………… 214

CIRCUIT DIAGRAM OF FUEL SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………………………… 216

FUNCTION OF FUEL SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………………………………. 217

OPERATION OF FUEL SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………………………………………………… 217

LAYOUT DRAWING OF COMPONENT PARTS OF FUEL SYSTEM (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………….. 218

CIRCUIT DIAGRAM OF FUEL SYSTEM (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………………………….. 219

FUNCTION OF FUEL SYSTEM (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………………………………… 220

OPERATION OF FUEL SYSTEM (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………………………………….. 220

CRI SYSTEM……………………………………………………………………………………………………………………………… 220

SUPPLY PUMP…………………………………………………………………………………………………………………………….. 226

COMMON RAIL…………………………………………………………………………………………………………………………….. 229

INJECTOR……………………………………………………………………………………………………………………………….. 232

FUEL DOSING SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………………………………………………………… 235

FUEL PREFILTER………………………………………………………………………………………………………………………….. 238

FUEL MAIN FILTER………………………………………………………………………………………………………………………… 240

COOLING SYSTEM……………………………………………………………………………………………………………………………… 241

LAYOUT DRAWING OF COMPONENT PARTS OF COOLING SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………………………… 241

CIRCUIT DIAGRAM OF COOLING SYSTEM (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………………………………………… 242

LAYOUT DRAWING OF COMPONENT PARTS OF COOLING SYSTEM (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………….. 243

CIRCUIT DIAGRAM OF COOLING SYSTEM (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………………………….. 244

COOLANT FILTER (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………………………………………… 245

WATER PUMP……………………………………………………………………………………………………………………………… 246

THERMOSTAT CASE…………………………………………………………………………………………………………………………. 247

THERMOSTAT……………………………………………………………………………………………………………………………… 250

ELECTRICAL SYSTEM………………………………………………………………………………………………………………………………. 252

COMPONENT PARTS OF ELECTRICAL SYSTEM………………………………………………………………………………………………………….. 252

ALTERNATOR……………………………………………………………………………………………………………………………… 252

ALTERNATOR MOUNTING……………………………………………………………………………………………………………………… 256

STARTING MOTOR………………………………………………………………………………………………………………………….. 258

ENGINE CONTROLLER (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………………………………………………………. 260

ENGINE CONTROLLER (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………………………………………… 275

FUEL FEED PUMP (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………………………………………. 290

ELECTRIC FUEL PRIMER PUMP (FOR ENGINES OTHER THAN ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………………………………. 291

ELECTRIC FUEL PRIMER PUMP………………………………………………………………………………………………………………… 291

FUEL FEED PUMP SWITCH……………………………………………………………………………………………………………………. 292

ELECTRIC FUEL PRIMER PUMP SWITCH………………………………………………………………………………………………………….. 292

SENSOR…………………………………………………………………………………………………………………………………….. 295

STRUCTURE OF AMBIENT PRESSURE SENSOR………………………………………………………………………………………………………. 295

FUNCTION OF AMBIENT PRESSURE SENSOR……………………………………………………………………………………………………….. 295

STRUCTURE OF ENGINE OIL PRESSURE SENSOR……………………………………………………………………………………………………. 296

FUNCTION OF ENGINE OIL PRESSURE SENSOR…………………………………………………………………………………………………….. 296

STRUCTURE OF CHARGE PRESSURE SENSOR……………………………………………………………………………………………………….. 297

FUNCTION OF CHARGE PRESSURE SENSOR………………………………………………………………………………………………………… 297

STRUCTURE OF CHARGE TEMPERATURE SENSOR…………………………………………………………………………………………………….. 298

FUNCTION OF CHARGE TEMPERATURE SENSOR……………………………………………………………………………………………………… 298

STRUCTURE OF COOLANT TEMPERATURE SENSOR……………………………………………………………………………………………………. 299

FUNCTION OF COOLANT TEMPERATURE SENSOR…………………………………………………………………………………………………….. 299

STRUCTURE OF NE (CRANKSHAFT) SPEED SENSOR………………………………………………………………………………………………….. 300

FUNCTION OF NE (CRANKSHAFT) SPEED SENSOR…………………………………………………………………………………………………… 300

STRUCTURE OF Bkup (CAMSHAFT) SPEED SENSOR………………………………………………………………………………………………….. 301

FUNCTION OF Bkup (CAMSHAFT) SPEED SENSOR…………………………………………………………………………………………………… 301

STRUCTURE OF COMMON RAIL PRESSURE SENSOR…………………………………………………………………………………………………… 302

FUNCTION OF COMMON RAIL PRESSURE SENSOR……………………………………………………………………………………………………. 302

STRUCTURE OF EGR VALVE LIFT SENSOR (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………………………………………….. 303

FUNCTION OF EGR VALVE LIFT SENSOR…………………………………………………………………………………………………………. 303

STRUCTURE OF VGT SPEED SENSOR (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)………………………………………………………. 304

FUNCTION OF VGT SPEED SENSOR……………………………………………………………………………………………………………… 304

STRUCTURE OF VGT POSITION SENSOR (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………………………. 305

FUNCTION OF VGT POSITION SENSOR…………………………………………………………………………………………………………… 305

STRUCTURE OF MASS AIR FLOW AND TEMPERATURE SENSOR (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………………………….. 306

FUNCTION OF MASS AIR FLOW AND TEMPERATURE SENSOR……………………………………………………………………………………………. 306

STRUCTURE OF DOSER FUEL PRESSURE SENSOR (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………………………………… 307

FUNCTION OF DOSING FUEL PRESSURE SENSOR……………………………………………………………………………………………………. 307

STRUCTURE OF KDPF DIFFERENTIAL PRESSURE AND OUTLET PRESSURE SENSOR (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)……………………… 308

FUNCTION OF KDPF DIFFERENTIAL PRESSURE AND OUTLET PRESSURE SENSOR…………………………………………………………………………….. 308

STRUCTURE OF CRANKCASE PRESSURE SENSOR…………………………………………………………………………………………………….. 309

FUNCTION OF CRANKCASE PRESSURE SENSOR……………………………………………………………………………………………………… 309

STRUCTURE OF ENGINE OIL LEVEL SENSOR………………………………………………………………………………………………………. 310

FUNCTION OF ENGINE OIL LEVEL SENSOR……………………………………………………………………………………………………….. 310

STRUCTURE OF AIR CLEANER CLOGGING SENSOR…………………………………………………………………………………………………… 311

FUNCTION OF AIR CLEANER CLOGGING SENSOR……………………………………………………………………………………………………. 311

20 STANDARD VALUE TABLE…………………………………………………………………………………………………………………………….. 313

CONTENTS………………………………………………………………………………………………………………………………………. 314

ABBREVIATION LIST………………………………………………………………………………………………………………………………. 315

STANDARD VALUE TABLE FOR ENGINE………………………………………………………………………………………………………………….. 321

STANDARD VALUE TABLE FOR ENGINE: SAA12V140E-7 (D475A-8, D475A-8E0)……………………………………………………………………………….. 321

STANDARD VALUE TABLE FOR ENGINE: SAA12V140E-7 (HD785-8, HD785-8E0)……………………………………………………………………………….. 323

STANDARD VALUE TABLE FOR ENGINE: SAA12V140E-7 (PC2000-11, PC2000-11E0)……………………………………………………………………………. 325

STANDARD VALUE TABLE FOR ENGINE: SAA12V140E-7 (PC2000-11R)………………………………………………………………………………………. 327

STANDARD VALUE TABLE FOR ENGINE: SAA12V140E-7 (WA800-8, WA800-8E0, WA900-8, WA900-8E0)……………………………………………………………… 329

STANDARD VALUE TABLE FOR ENGINE: SAA12V140E-7 (WA900-8R)………………………………………………………………………………………… 331

MACHINE POSTURE AND PROCEDURE FOR MEASURING PERFORMANCE…………………………………………………………………………………………. 333

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD………………………………………………………………………………………………….. 334

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA12V140E-7 (D475A-8, D475A-8E0)……………………………………………………………….. 334

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA12V140E-7 (HD785-8, HD785-8E0)……………………………………………………………….. 336

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA12V140E-7 (PC2000-11, PC2000-11E0)……………………………………………………………. 338

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA12V140E-7 (PC2000-11R)………………………………………………………………………. 340

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA12V140E-7 (WA800-8, WA800-8E0)……………………………………………………………….. 342

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA12V140E-7 (WA900-8, WA900-8E0)……………………………………………………………….. 344

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA12V140E-7 (WA900-8R)………………………………………………………………………… 346

50 DISASSEMBLY AND ASSEMBLY…………………………………………………………………………………………………………………………. 349

CONTENTS………………………………………………………………………………………………………………………………………. 350

ABBREVIATION LIST………………………………………………………………………………………………………………………………. 354

RELATED INFORMATION ON DISASSEMBLY AND ASSEMBLY……………………………………………………………………………………………………. 360

HOW TO READ THIS MANUAL……………………………………………………………………………………………………………………… 360

COATING MATERIALS LIST………………………………………………………………………………………………………………………. 362

SPECIAL TOOLS LIST………………………………………………………………………………………………………………………….. 366

SKETCHES OF SPECIAL TOOLS……………………………………………………………………………………………………………………. 369

ENGINE SYSTEM………………………………………………………………………………………………………………………………….. 371

METHOD FOR DISASSEMBLING ENGINE GENERALLY……………………………………………………………………………………………………… 371

METHOD FOR REMOVING FUEL MAIN FILTER AND OIL FILTER…………………………………………………………………………………………. 379

METHOD FOR REMOVING ALTERNATOR WIRING HARNESS………………………………………………………………………………………………. 381

METHOD FOR REMOVING ENGINE WIRING HARNESS CLAMP AND BAND (LEFT BANK)………………………………………………………………………….. 384

METHOD FOR REMOVING ENGINE WIRING HARNESS (LEFT BANK) AND WIRING HARNESS BRACKET (LEFT BANK)…………………………………………………….. 389

METHOD FOR REMOVING ENGINE WIRING HARNESS CLAMP AND BAND (RIGHT BANK)…………………………………………………………………………. 395

METHOD FOR REMOVING ENGINE WIRING HARNESS (RIGHT BANK) AND WIRING HARNESS BRACKET (RIGHT BANK)…………………………………………………… 400

METHOD FOR REMOVING ALTERNATOR……………………………………………………………………………………………………………. 406

METHOD FOR REMOVING HEAT INSULATION COVER………………………………………………………………………………………………….. 411

METHOD FOR REMOVING BOOST TUBE……………………………………………………………………………………………………………. 415

METHOD FOR REMOVING EGR COOLER AIR VENT TUBE (LEFT BANK) AND VGT AIR VENT TUBE (LEFT BANK)………………………………………………………. 418

METHOD FOR REMOVING EGR COOLER AIR VENT TUBE (RIGHT BANK) AND VGT AIR VENT TUBE (RIGHT BANK)…………………………………………………….. 421

METHOD FOR REMOVING ENGINE OIL FILTER HEAD, TUBE, AND HOSE…………………………………………………………………………………… 424

METHOD FOR REMOVING COOLING PLATE HOSE (LEFT BANK)………………………………………………………………………………………….. 427

METHOD FOR REMOVING COOLING PLATE HOSE (RIGHT BANK)…………………………………………………………………………………………. 429

METHOD FOR REMOVING FUEL MAIN FILTER HEAD AND TUBE………………………………………………………………………………………….. 431

METHOD FOR REMOVING EXHAUST TEMPERATURE SENSOR……………………………………………………………………………………………… 436

METHOD FOR REMOVING KCCV (LEFT BANK)………………………………………………………………………………………………………. 439

METHOD FOR REMOVING KCCV (RIGHT BANK)……………………………………………………………………………………………………… 445

METHOD FOR REMOVING ENGINE CONTROLLER (LEFT BANK)…………………………………………………………………………………………… 451

METHOD FOR REMOVING ENGINE CONTROLLER (RIGHT BANK)………………………………………………………………………………………….. 454

METHOD FOR REMOVING OIL FILLER TUBE, OIL LEVEL GAUGE, AND OIL LEVEL SENSOR…………………………………………………………………….. 457

METHOD FOR REMOVING WATER PUMP BYPASS TUBE…………………………………………………………………………………………………. 461

METHOD FOR REMOVING FUEL DOSER WIRING HARNESS (LEFT BANK) AND VGT WIRING HARNESS (LEFT BANK)…………………………………………………….. 465

METHOD FOR REMOVING FUEL DOSER WIRING HARNESS (RIGHT BANK) AND VGT WIRING HARNESS (RIGHT BANK)…………………………………………………… 468

METHOD FOR REMOVING VGT HYDRAULIC PRESSURE TUBE (LEFT BANK) AND EGR VALVE HYDRAULIC PRESSURE TUBE (LEFT BANK)……………………………………… 471

METHOD FOR REMOVING VGT HYDRAULIC PRESSURE TUBE (RIGHT BANK) AND EGR VALVE HYDRAULIC PRESSURE TUBE (RIGHT BANK)……………………………………. 476

METHOD FOR REMOVING EGR COOLER (LEFT BANK) AND EGR VALVE (LEFT BANK)………………………………………………………………………….. 481

METHOD FOR REMOVING EGR COOLER (RIGHT BANK) AND EGR VALVE (RIGHT BANK)………………………………………………………………………… 492

METHOD FOR REMOVING FUEL FEED PUMP (LEFT BANK) AND FUEL DOSER SOLENOID VALVE (LEFT BANK)………………………………………………………… 503

METHOD FOR REMOVING FUEL FEED PUMP (RIGHT BANK) AND FUEL DOSER SOLENOID VALVE (RIGHT BANK)………………………………………………………. 511

METHOD FOR REMOVING BLOWER CONNECTOR………………………………………………………………………………………………………. 518

METHOD FOR REMOVING FUEL DOSER (LEFT BANK), FUEL DOSER WATER TUBE (LEFT BANK), AND EXHAUST CONNECTOR (LEFT BANK)…………………………………… 520

METHOD FOR REMOVING FUEL DOSER (RIGHT BANK), FUEL DOSER WATER TUBE (RIGHT BANK), AND EXHAUST CONNECTOR (RIGHT BANK)………………………………… 524

METHOD FOR REMOVING AIR INTALE CONNECTOR (LEFT BANK) AND MIXING CONNECTOR (LEFT BANK)…………………………………………………………… 528

METHOD FOR REMOVING AIR INTALE CONNECTOR (RIGHT BANK) AND MIXING CONNECTOR (RIGHT BANK)…………………………………………………………. 531

METHOD FOR REMOVING FUEL HIGH-PRESSURE PIPING CLAMPS (LEFT BANK), FUEL INJECTION PIPING CLAMPS (LEFT BANK), AND INJECTOR WIRING HARNESS (LEFT BANK)……. 534

METHOD FOR REMOVING FUEL HIGH-PRESSURE PIPING CLAMPS (RIGHT BANK), FUEL INJECTION PIPING CLAMPS (RIGHT BANK), AND INJECTOR WIRING HARNESS (RIGHT BANK)…. 538

METHOD FOR REMOVING AIR INTAKE MANIFOLD……………………………………………………………………………………………………. 542

METHOD FOR REMOVING BREATHER……………………………………………………………………………………………………………… 547

METHOD FOR REMOVING VGT (LEFT BANK) AND VGT WATER TUBE (LEFT BANK)……………………………………………………………………………. 551

METHOD FOR REMOVING VGT (RIGHT BANK) AND VGT WATER TUBE (RIGHT BANK)………………………………………………………………………….. 556

METHOD FOR REMOVING ALTERNATOR DRIVE AND ENGINE BOOST OIL PUMP……………………………………………………………………………….. 561

METHOD FOR REMOVING CYLINDER HEAD COVER, ROCKER ARM HOUSING, AND INJECTOR WIRING HARNESS………………………………………………………… 564

METHOD FOR REMOVING VGT OIL TUBE (LEFT BANK), FUEL HIGH-PRESSURE PIPE (LEFT BANK), AND FUEL INJECTION PIPE (LEFT BANK)……………………………… 568

METHOD FOR REMOVING VGT OIL TUBE (RIGHT BANK), FUEL HIGH-PRESSURE PIPE (RIGHT BANK), AND FUEL INJECTION PIPE (RIGHT BANK)…………………………… 573

METHOD FOR REMOVING SUPPLY PUMP (LEFT BANK), COMMON RAIL (LEFT BANK), AND KCCV OIL DRAIN CHECK VALVE (LEFT BANK)…………………………………… 578

METHOD FOR REMOVING SUPPLY PUMP (RIGHT BANK) AND COMMON RAIL (RIGHT BANK)……………………………………………………………………… 583

METHOD FOR REMOVING KCCV OIL DRAIN CHECK VALVE (RIGHT BANK) AND REGULATOR VALVE………………………………………………………………… 586

METHOD FOR REMOVING INJECTOR AND CAM FOLLOWER………………………………………………………………………………………………. 589

METHOD FOR REMOVING CYLINDER HEAD AIR VENT TUBE…………………………………………………………………………………………….. 594

METHOD FOR REMOVING EXHAUST MANIFOLD………………………………………………………………………………………………………. 597

METHOD FOR REMOVING CYLINDER HEAD…………………………………………………………………………………………………………. 600

METHOD FOR REMOVING CRANK PULLEY, AND VIBRATION DAMPER………………………………………………………………………………………. 604

METHOD FOR REMOVING STARTING MOTOR………………………………………………………………………………………………………… 607

METHOD FOR REMOVING BARRING DEVICE AND Ne (CRANKSHAFT) SPEED SENSOR…………………………………………………………………………… 609

METHOD FOR REMOVING FLYWHEEL AND WATER MANIFOLD COVER……………………………………………………………………………………….. 611

METHOD FOR REMOVING ENGINE OIL PAN AND RELIEF VALVE…………………………………………………………………………………………. 614

METHOD FOR REMOVING FRONT COVER…………………………………………………………………………………………………………… 618

METHOD FOR REMOVING FLYWHEEL HOUSING………………………………………………………………………………………………………. 621

METHOD FOR REMOVING TIMING GEAR, OIL PUMP, GEAR CASE, AND WATER PUMP………………………………………………………………………….. 624

METHOD FOR REMOVING ENGINE OIL COOLER……………………………………………………………………………………………………… 631

METHOD FOR REMOVING FRONT HANGER AND THERMOSTAT HOUSING……………………………………………………………………………………… 634

METHOD FOR REMOVING REAR HANGER AND EGR WATER DIVIDER CONNECTOR………………………………………………………………………………. 637

METHOD FOR REMOVING PISTON AND CONNECTING ROD………………………………………………………………………………………………. 639

METHOD FOR REMOVING CRANKSHAFT……………………………………………………………………………………………………………. 643

METHOD FOR REMOVING CYLINDER LINER………………………………………………………………………………………………………… 646

METHOD FOR ASSEMBLING ENGINE GENERALLY………………………………………………………………………………………………………… 649

METHOD FOR INSTALLING CYLINDER LINER………………………………………………………………………………………………………. 657

METHOD FOR INSTALLING CRANKSHAFT………………………………………………………………………………………………………….. 662

METHOD FOR INSTALLING PISTON AND CONNECTING ROD…………………………………………………………………………………………….. 666

METHOD FOR INSTALLING REAR HANGER AND EGR WATER DIVIDER CONNECTOR…………………………………………………………………………….. 675

METHOD FOR INSTALLING FRONT HANGER AND THERMOSTAT HOUSING……………………………………………………………………………………. 677

METHOD FOR INSTALLING ENGINE OIL COOLER……………………………………………………………………………………………………. 680

METHOD FOR INSTALLING TIMING GEAR, OIL PUMP, GEAR CASE, AND WATER PUMP………………………………………………………………………… 684

METHOD FOR INSTALLING FLYWHEEL HOUSING…………………………………………………………………………………………………….. 696

METHOD FOR INSTALLING FRONT COVER…………………………………………………………………………………………………………. 700

METHOD FOR INSTALLING ENGINE OIL PAN AND RELIEF VALVE……………………………………………………………………………………….. 703

METHOD FOR INSTALLING FLYWHEEL AND WATER MANIFOLD COVER……………………………………………………………………………………… 708

METHOD FOR INSTALLING BARRING DEVICE AND Ne (CRANKSHAFT) SPEED SENSOR…………………………………………………………………………. 713

METHOD FOR INSTALLING STARTING MOTOR………………………………………………………………………………………………………. 715

METHOD FOR INSTALLING CRANK PULLEY AND VIBRATION DAMPER……………………………………………………………………………………… 718

METHOD FOR INSTALLING CYLINDER HEAD……………………………………………………………………………………………………….. 722

METHOD FOR INSTALLING EXHAUST MANIFOLD…………………………………………………………………………………………………….. 727

METHOD FOR INSTALLING CYLINDER HEAD AIR VENT TUBE…………………………………………………………………………………………… 731

METHOD FOR INSTALLING INJECTOR AND CAM FOLLOWER…………………………………………………………………………………………….. 734

METHOD FOR INSTALLING KCCV OIL DRAIN CHECK VALVE (RIGHT BANK) AND REGULATOR VALVE………………………………………………………………. 740

METHOD FOR INSTALLING SUPPLY PUMP (RIGHT BANK) AND COMMON RAIL (RIGHT BANK)……………………………………………………………………. 744

METHOD FOR INSTALLING SUPPLY PUMP (LEFT BANK), COMMON RAIL (LEFT BANK), AND KCCV OIL DRAIN CHECK VALVE (LEFT BANK)…………………………………. 748

METHOD FOR INSTALLING VGT OIL TUBE (RIGHT BANK), FUEL HIGH-PRESSURE PIPE (RIGHT BANK), AND FUEL INJECTION PIPE (RIGHT BANK)…………………………. 755

METHOD FOR INSTALLING VGT OIL TUBE (LEFT BANK), FUEL HIGH-PRESSURE PIPE (LEFT BANK), AND FUEL INJECTION PIPE (LEFT BANK)……………………………. 763

METHOD FOR INSTALLING CYLINDER HEAD COVER, ROCKER ARM HOUSING, AND INJECTOR WIRING HARNESS………………………………………………………. 771

METHOD FOR INSTALLING ALTERNATOR DRIVE AND ENGINE BOOST OIL PUMP……………………………………………………………………………… 777

METHOD FOR INSTALLING VGT (RIGHT BANK) AND VGT WATER TUBE (RIGHT BANK)………………………………………………………………………… 780

METHOD FOR INSTALLING VGT (LEFT BANK) AND VGT WATER TUBE (LEFT BANK)………………………………………………………………………….. 787

METHOD FOR INSTALLING BREATHER……………………………………………………………………………………………………………. 794

METHOD FOR INSTALLING AIR INTAKE MANIFOLD………………………………………………………………………………………………….. 798

METHOD FOR INSTALLING FUEL HIGH-PRESSURE PIPING CLAMPS (RIGHT BANK), FUEL INJECTOR CLAMPS (RIGHT BANK), AND INJECTOR WIRING HARNESS (RIGHT BANK)………. 804

METHOD FOR INSTALLING FUEL HIGH-PRESSURE PIPING CLAMPS (LEFT BANK), FUEL INJECTOR CLAMPS (LEFT BANK), AND INJECTOR WIRING HARNESS (LEFT BANK)…………. 811

METHOD FOR INSTALLING AIR INTAKE CONNECTOR (RIGHT BANK) AND MIXING CONNECTOR (RIGHT BANK)……………………………………………………….. 817

METHOD FOR INSTALLING AIR INTAKE CONNECTOR (LEFT BANK) AND MIXING CONNECTOR (LEFT BANK)…………………………………………………………. 820

METHOD FOR INSTALLING FUEL DOSER (RIGHT BANK), FUEL DOSER WATER TUBE (RIGHT BANK), AND EXHAUST CONNECTOR (RIGHT BANK)………………………………. 823

METHOD FOR INSTALLING FUEL DOSER (LEFT BANK), FUEL DOSER WATER TUBE (LEFT BANK), AND EXHAUST CONNECTOR (LEFT BANK)…………………………………. 831

METHOD FOR INSTALLING BLOWER CONNECTOR…………………………………………………………………………………………………….. 839

METHOD FOR INSTALLING FUEL FEED PUMP (RIGHT BANK) AND FUEL DOSER SOLENOID VALVE (RIGHT BANK)…………………………………………………….. 842

METHOD FOR INSTALLING FUEL FEED PUMP (LEFT BANK) AND FUEL DOSER SOLENOID VALVE (LEFT BANK)………………………………………………………. 853

METHOD FOR INSTALLING EGR COOLER (RIGHT BANK) AND EGR VALVE (RIGHT BANK)………………………………………………………………………. 867

METHOD FOR INSTALLING EGR COOLER (LEFT BANK) AND EGR VALVE (LEFT BANK)………………………………………………………………………… 883

METHOD FOR INSTALLING VGT HYDRAULIC PRESSURE TUBE (RIGHT BANK) AND EGR VALVE HYDRAULIC PRESSURE TUBE (RIGHT BANK)………………………………….. 899

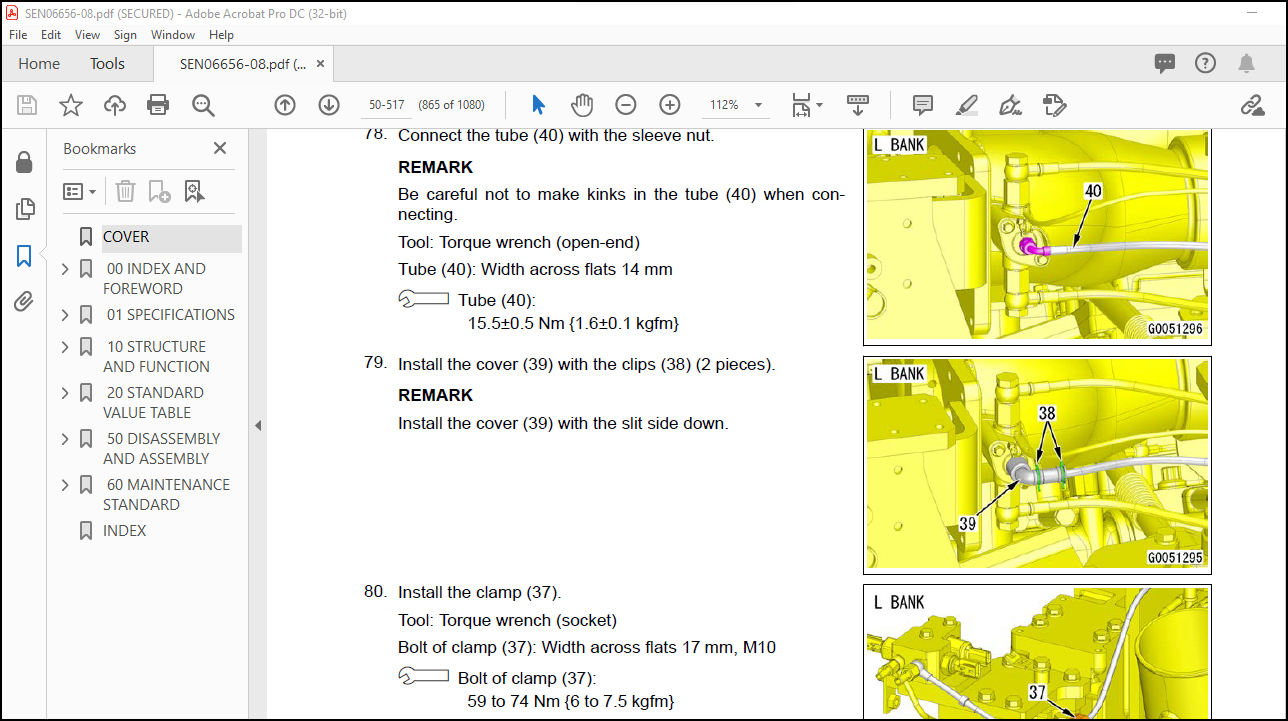

METHOD FOR INSTALLING VGT HYDRAULIC PRESSURE TUBE (LEFT BANK) AND EGR VALVE HYDRAULIC PRESSURE TUBE (LEFT BANK)……………………………………. 906

METHOD FOR INSTALLING FUEL DOSER WIRING HARNESS (RIGHT BANK) AND VGT WIRING HARNESS (RIGHT BANK)…………………………………………………. 914

METHOD FOR INSTALLING FUEL DOSER WIRING HARNESS (LEFT BANK) AND VGT WIRING HARNESS (LEFT BANK)…………………………………………………… 918

METHOD FOR INSTALLING WATER PUMP BYPASS TUBE……………………………………………………………………………………………….. 922

METHOD FOR INSTALLING OIL FILLER TUBE, OIL LEVEL GAUGE, AND OIL LEVEL SENSOR…………………………………………………………………… 928

METHOD FOR INSTALLING ENGINE CONTROLLER (RIGHT BANK)………………………………………………………………………………………… 933

METHOD FOR INSTALLING ENGINE CONTROLLER (LEFT BANK)…………………………………………………………………………………………. 936

METHOD FOR INSTALLING KCCV (RIGHT BANK)……………………………………………………………………………………………………. 939

METHOD FOR INSTALLING KCCV (LEFT BANK)…………………………………………………………………………………………………….. 946

METHOD FOR INSTALLING EXHAUST TEMPERATURE SENSOR……………………………………………………………………………………………. 954

METHOD FOR INSTALLING FUEL MAIN FILTER HEAD AND TUBE………………………………………………………………………………………… 959

METHOD FOR INSTALLING COOLING PLATE HOSE (RIGHT BANK)……………………………………………………………………………………….. 967

METHOD FOR INSTALLING COOLING PLATE HOSE (LEFT BANK)………………………………………………………………………………………… 970

METHOD FOR INSTALLING ENGINE OIL FILTER HEAD, TUBE, AND HOSE…………………………………………………………………………………. 973

METHOD FOR INSTALLING EGR COOLER AIR VENT TUBE (RIGHT BANK) AND VGT AIR VENT TUBE (RIGHT BANK)…………………………………………………… 977

METHOD FOR INSTALLING EGR COOLER AIR VENT TUBE (LEFT BANK) AND VGT AIR VENT TUBE (LEFT BANK)…………………………………………………….. 981

METHOD FOR INSTALLING BOOST TUBE………………………………………………………………………………………………………….. 984

METHOD FOR INSTALLING HEAT INSULATION COVER………………………………………………………………………………………………… 987

METHOD FOR INSTALLING ALTERNATOR………………………………………………………………………………………………………….. 991

METHOD FOR INSTALLING ENGINE WIRING HARNESS (LEFT BANK) AND WIRING HARNESS BRACKET (LEFT BANK)…………………………………………………… 999

METHOD FOR INSTALLING ENGINE WIRING HARNESS CLAMP AND BAND (RIGHT BANK)………………………………………………………………………..1005

METHOD FOR INSTALLING ENGINE WIRING HARNESS (LEFT BANK) AND WIRING HARNESS BRACKET (LEFT BANK)……………………………………………………1010

METHOD FOR INSTALLING ENGINE WIRING HARNESS CLAMP AND BAND (LEFT BANK)…………………………………………………………………………1017

METHOD FOR INSTALLING ALTERNATOR WIRING HARNESS……………………………………………………………………………………………..1022

METHOD FOR INSTALLING FUEL MAIN FILTER AND OIL FILTER………………………………………………………………………………………..1027

60 MAINTENANCE STANDARD……………………………………………………………………………………………………………………………..1029

CONTENTS……………………………………………………………………………………………………………………………………….1030

ABBREVIATION LIST……………………………………………………………………………………………………………………………….1031

ENGINE SYSTEM…………………………………………………………………………………………………………………………………..1037

INTAKE AND EXHAUST SYSTEM PARTS……………………………………………………………………………………………………………….1037

MAINTENANCE STANDARD OF VGT……………………………………………………………………………………………………………….1037

MAINTENANCE STANDARD OF TARBO CHARGER………………………………………………………………………………………………………1038

ENGINE MAIN BODY PARTS……………………………………………………………………………………………………………………….1040

MAINTENANCE STANDARD OF CYLINDER HEAD………………………………………………………………………………………………………1040

MAINTENANCE STANDARD OF CYLINDER BLOCK……………………………………………………………………………………………………..1042

MAINTENANCE STANDARD OF CYLINDER LINER……………………………………………………………………………………………………..1044

MAINTENANCE STANDARD OF CRANKSHAFT…………………………………………………………………………………………………………1046

MAINTENANCE STANDARD OF CAM FOLLOWER AND PUSH ROD……………………………………………………………………………………………1048

MAINTENANCE STANDARD OF PISTON…………………………………………………………………………………………………………….1050

MAINTENANCE STANDARD OF CONROD…………………………………………………………………………………………………………….1052

MAINTENANCE STANDARD OF VIBRATION DAMPER……………………………………………………………………………………………………1054

MAINTENANCE STANDARD OF TIMING GEAR………………………………………………………………………………………………………..1056

MAINTENANCE STANDARD OF CAMSHAFT…………………………………………………………………………………………………………..1058

MAINTENANCE STANDARD OF VALVE AND VALVE GUIDE……………………………………………………………………………………………….1059

MAINTENANCE STANDARD OF ROCKER ARM…………………………………………………………………………………………………………1062

MAINTENANCE STANDARD OF CROSSHEAD AND GUIDE…………………………………………………………………………………………………1063

MAINTENANCE STANDARD OF FLYWHEEL…………………………………………………………………………………………………………..1064

LUBRICATION SYSTEM…………………………………………………………………………………………………………………………..1066

MAINTENANCE STANDARD OF RELIEF VALVE OF ENGINE OIL PUMP………………………………………………………………………………………1066

MAINTENANCE STANDARD OF RELIEF VALVE OF ENGINE BOOST OIL PUMP (FOR ENGINES COMPLIED WITH TIER 4 AND EU STAGE V REGULATION)…………………………..1068

MAINTENANCE STANDARD OF SAFETY VALVE OF ENGINE OIL FILTER…………………………………………………………………………………….1069

MAINTENANCE STANDARD OF OIL COOLER BYPASS VALVE AND REGULATOR VALVE……………………………………………………………………………1070

COOLING SYSTEM………………………………………………………………………………………………………………………………1071

MAINTENANCE STANDARD OF WATER PUMP…………………………………………………………………………………………………………1071

MAINTENANCE STANDARD OF THERMOSTAT…………………………………………………………………………………………………………1072

INDEX………………………………………………………………………………………………………………………………………………1073