$37

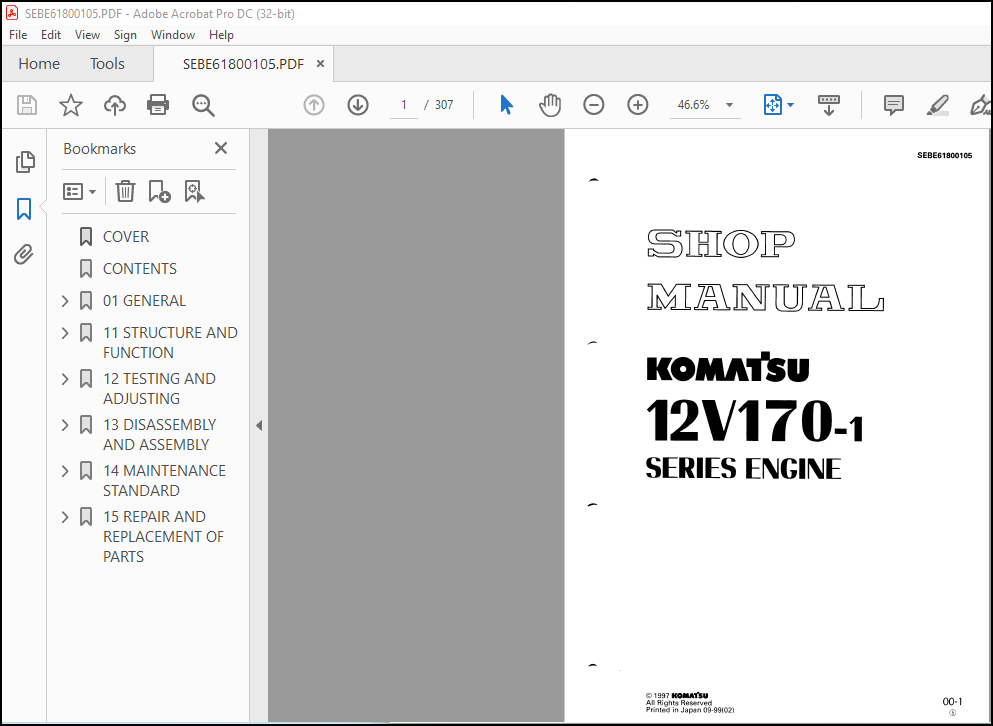

Komatsu 12v170-1 Series Engine Shop Manual SEBEB61800105 – PDF DOWNLOAD

Komatsu 12v170-1 Series Engine Shop Manual SEBEB61800105 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 12v170-1 Series Engine Shop Manual SEBEB61800105 – PDF DOWNLOAD

Language : English

Pages : 307

Downloadable : Yes

File Type : PDF

Size: 18 MB

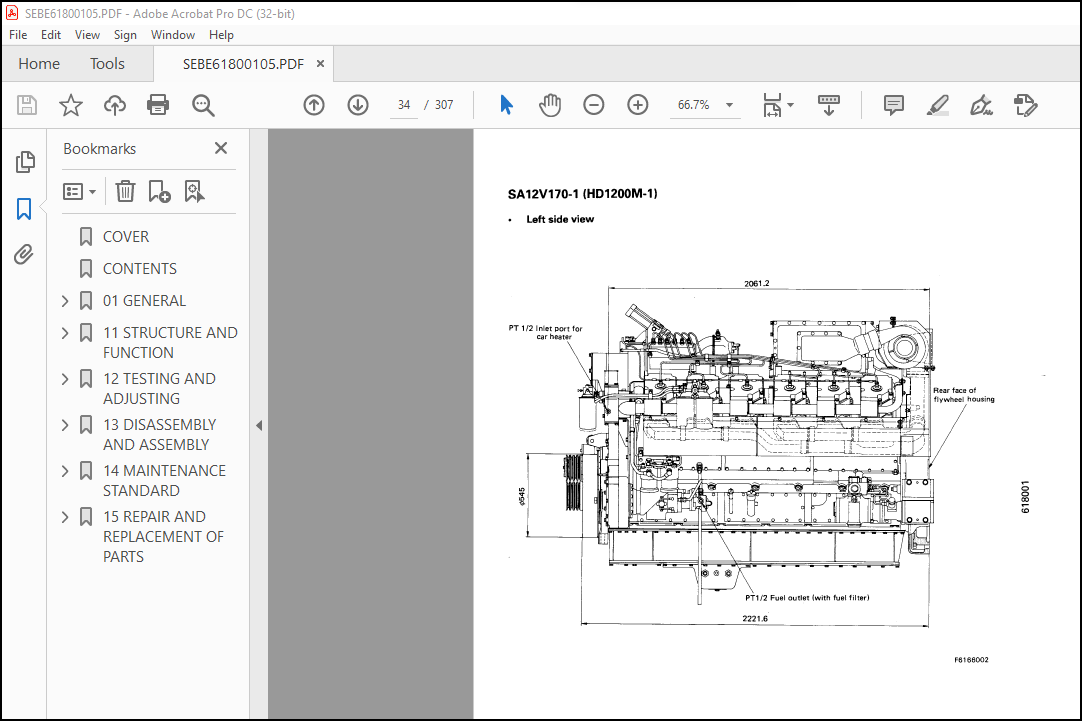

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 12v170-1 Series Engine Shop Manual SEBEB61800105 – PDF DOWNLOAD

The Komatsu 12v170-1 Series Engine Shop Manual SEBEB61800105 is a comprehensive guide that provides detailed information on the maintenance, repair, and overhaul of the 12v170-1 series engine. This engine is used in a variety of Komatsu equipment, including large construction machinery and mining equipment.

- The manual is organized into several sections, each covering a different aspect of the engine. The first section provides an overview of the engine, including its specifications and performance data. This section also includes a table of contents, a list of illustrations, and a list of symbols and abbreviations used throughout the manual.

- The second section of the manual covers engine inspection and measurement procedures. This section provides step-by-step instructions for checking and measuring various components of the engine, including the cylinder block, crankshaft, and connecting rods. The manual includes detailed illustrations to help the reader understand the procedures.

- The third section covers engine disassembly and assembly procedures. This section provides instructions for removing and installing various components of the engine, including the cylinder head, pistons, and crankshaft. The manual also includes torque specifications for each component.

- The fourth section covers engine testing and adjusting procedures. This section provides instructions for testing and adjusting various components of the engine, including the fuel injection system, the turbocharger, and the valve clearance. The manual includes detailed illustrations to help the reader understand the procedures.

- The fifth section covers engine maintenance procedures, including routine maintenance and inspections. This section provides instructions for maintaining the engine to ensure its continued performance and longevity.

- The sixth section covers engine troubleshooting and diagnosis procedures. This section provides instructions for diagnosing and troubleshooting various engine problems, including starting problems, low power output, and excessive smoke. The manual includes a troubleshooting chart and detailed illustrations to help the reader diagnose and fix the problem.

- Overall, the Komatsu 12v170-1 Series Engine Shop Manual SEBEB61800105 is an essential tool for anyone working on or maintaining this engine. The manual is available in print or digital formats, making it a convenient and accessible resource for mechanics and technicians. It is designed to be user-friendly and easy to understand, with clear instructions and detailed illustrations. With this manual, you can ensure that your Komatsu equipment is operating at its best and avoid costly repairs and downtime.

TABLE OF CONTENTS:

Komatsu 12v170-1 Series Engine Shop Manual SEBEB61800105 – PDF DOWNLOAD

COVER…………………………………………………………………………….. 1

CONTENTS………………………………………………………………………….. 2

01 GENERAL………………………………………………………………………… 25

SPECIFICATIONS…………………………………………………………………. 26

ENGINE PERFORMANCE CURVE………………………………………………………… 30

WEIGHT TABLE…………………………………………………………………… 41

11 STRUCTURE AND FUNCTION…………………………………………………………… 43

GENERAL STRUCTURE………………………………………………………………. 44

INTAKE AND EXHAUST SYSTEM……………………………………………………….. 46

AFTER-COOLER……………………………………………………………….. 46

TURBOCHARGER……………………………………………………………….. 47

ENGINE BODY……………………………………………………………………. 50

CYLINDER HEAD………………………………………………………………. 50

VALVE SYSTEM……………………………………………………………….. 51

CYLINDER BLOCK……………………………………………………………… 53

MAIN REVOLVING PART…………………………………………………………. 54

TIMING GEAR………………………………………………………………… 55

FLYWHEEL AND FLYWHEEL HOUSING………………………………………………… 57

LUBRICATION SYSTEM……………………………………………………………… 58

LUBRICATION SYSTEM CHART…………………………………………………….. 58

OIL PUMP…………………………………………………………………… 60

OIL FILTER…………………………………………………………………. 61

OIL COOLER…………………………………………………………………. 63

OIL COOLER BYPASS VALVE……………………………………………………… 64

PISTON COOLING VALVE………………………………………………………… 64

MECHANICAL PUMP…………………………………………………………….. 65

FUEL SYSTEM……………………………………………………………………. 66

FUEL SYSTEM CHART…………………………………………………………… 66

FUEL INJECTION PUMP…………………………………………………………. 69

FEED PUMP………………………………………………………………….. 70

FUEL INJECTION NOZZLE……………………………………………………….. 71

FUEL INJECTION PUMP DRIVE……………………………………………………. 72

FUEL FILTER………………………………………………………………… 74

INJECTION PUMP RACK CONTROLLER……………………………………………….. 75

AUTOMATIC TIMER…………………………………………………………….. 77

FUEL SOLENOID………………………………………………………………. 78

ENGINE STOP MOTOR…………………………………………………………… 79

COOLING SYSTEM…………………………………………………………………. 84

COOLING SYSTEM CHART………………………………………………………… 84

WATER PUMP…………………………………………………………………. 86

WATER PUMP DRIVE……………………………………………………………. 88

FAN DRIVE AND TENSION PULLEY…………………………………………………. 89

CORROSION RESISTOR………………………………………………………….. 92

THERMOSTAT…………………………………………………………………. 93

ACCESSORY……………………………………………………………………… 94

AIR COMPRESSOR MOUNTING……………………………………………………… 94

AIR COMPRESSOR……………………………………………………………… 95

ALTERNATOR WITH REGULATOR……………………………………………………. 96

STARTING MOTOR……………………………………………………………… 97

AIR STARTING MOTOR………………………………………………………….. 98

12 TESTING AND ADJUSTING……………………………………………………………. 99

COOLING SYSTEM………………………………………………………………….100

CHECKING AND ADJUSTING FAN BELT TENSION………………………………………..100

CHECKING AND ADJUSTING ALTERNATOR BELT TENSION………………………………….101

ENGINE BODY…………………………………………………………………….102

ADJUSTING VALVE CLEARANCE…………………………………………………….102

MEASURING COMPRESSION PRESSURE………………………………………………..103

MEASURING BLOW-BY……………………………………………………………104

FUEL SYSTEM…………………………………………………………………….105

TESTING AND ADJUSTING FUEL INJECTION TIMING…………………………………….105

ADJUSTING FUEL INJECTION PUMP RACK LINKAGE……………………………………..107

ADJUSTING ENGINE STOP MOTOR…………………………………………………..108

ADJUSTING ENGINE SPEED SENSOR…………………………………………………109

ADJUSTING FUEL INJECTION PRESSURE (VALVE CRACKING PRESSURE)………………………110

FUEL INJECTION PUMP CALIBRATION DATA…………………………………………..112

PERFORMANCE TEST………………………………………………………………..119

RUN-IN STANDARD……………………………………………………………..119

PERFORMANCE TEST CRITERIA…………………………………………………….121

TESTING AND ADJUSTING DATA……………………………………………………125

TESTING AND ADJUSTING TOOL LIST……………………………………………….129

TROUBLESHOOTING…………………………………………………………………131

POINTS TO REMEMBER WHEN TROUBLESHOOTING………………………………………..132

METHOD OF USING TROUBLESHOOTING CHART………………………………………….133

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)…………………….137

S-2 ENGINE DOES NOT START…………………………………………………….138

(1) ENGINE DOES NOT TURN………………………………………………….138

(2) ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT (FUEL IS NOT BEING INJECTED)……139

(3) EXHAUST SMOKE COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)….140

S-3 ENGINE DOES NOT PICK-UP SMOOTHLY (FOLLOW-UP IS POOR)…………………………141

S-4 ENGINE STOPS DURING OPERATIONS…………………………………………….142

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)…………………………………..143

S-6 ENGINE LACKS OUTPUT (NO POWER)…………………………………………….144

S-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION)………………………………145

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE)………………………146

S-9 OIL BECOMES CONTAMINATED QUICKLY…………………………………………..147

S-10 FUEL CONSUMPTION IS EXCESSIVE…………………………………………….148

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN……….149

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE)…………………..150

S-13 OIL LEVEL RISES…………………………………………………………151

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)……………………………152

S-15 ABNORMAL NOISE IS MADE…………………………………………………..153

S-16 VIBRATION IS EXCESSIVE…………………………………………………..154

13 DISASSEMBLY AND ASSEMBLY………………………………………………………….155

GENERAL DISASSEMBLY CONTENTS……………………………………………………..156

DISASSEMBLY…………………………………………………………………….157

1. WASHING………………………………………………………………….157

2. SETTING ENGINE STAND………………………………………………………157

3. ENGINE COOLING WATER AND ENGINE OIL…………………………………………157

4. BY-PASS FILTER (D575A-2,575A-2SD)…………………………………………..158

5. AIR CLEANER AND MUFFLER ASSEMBLY……………………………………………158

6. TUBE FOR OIL FILTER……………………………………………………….159

7. OIL FILTER……………………………………………………………….159

8. CORROSION RESISTOR………………………………………………………..159

9. FUEL TUBE………………………………………………………………..159

10. FILTER BRACKET…………………………………………………………..159

11. EXHAUST MANIFOLD COVER……………………………………………………160

12. TURBOCHARGER ASSEMBLY…………………………………………………….160

13. EXHAUST CONNECTOR………………………………………………………..162

14. WATER TUBE,TURBOCHARGER LUBRICATION TUBE,EXHAUST TUBE ……………………….162

15. BRACKET,OIL CONNECTOR,BREATHER…………………………………………….162

16. WATER TUBE………………………………………………………………163

17. AFTER-COOLER ASSEMBLY…………………………………………………….163

18. PLATE,CASE………………………………………………………………164

19. FUEL INJECTION PIPES,SPILL TUBES…………………………………………..164

20. FUEL TUBES………………………………………………………………165

21. LUBRICATION HOSES,BOOST COMPENSATOR HOSE……………………………………166

22. LUBRICATION TUBES (D575A-2,D575A-2SD)………………………………………167

22A. MECHANICAL PUMP ASSEMBLY (EXCEPT D575A-2,D575A-2SD)…………………………167

23. FUEL INJCTION PUMP ASSEMBLY……………………………………………….167

24. EXHAUST MANIFOLD…………………………………………………………169

25. ALTERNAOR ASSEMBLY (EXCEPT D575A-2,D575A-2SD)……………………………….169

26. WATER PUMP ASSEMBLY………………………………………………………169

27. AIR COMPRESSOR ASSEMBLY (EXCEPT D575A-2,D575A-2SD)…………………………..169

28. OIL COOLER ASSEMBLY………………………………………………………170

29. OIL PAN…………………………………………………………………171

30. AIR VENT TUBE……………………………………………………………171

31. THERMOSTAT ASSEMBLY………………………………………………………171

32. CYLINDER HEAD COVERS……………………………………………………..172

33. NOZZLE HOLDERS…………………………………………………………..172

34. ROCKER ARM HOUSING ASSEMBLY……………………………………………….173

35. PUSH RODS……………………………………………………………….173

36. CROSSHEADS………………………………………………………………173

37. CYLINDER HEAD ASSEMBLY……………………………………………………173

38. OIL PUMP ASSEMBLY………………………………………………………..174

39. STARTING MOTOR ASSEMBLY…………………………………………………..175

40. FLYWHEEL………………………………………………………………..175

41. FLYWHEEL HOUSING…………………………………………………………176

42. CRANKSHAFT PULLEY,VIBRATION DAMPER…………………………………………176

43. DRIVE CASE ASSEMBLY………………………………………………………176

44. RETAINER,FRONT SUPPORT……………………………………………………176

45. GEAR CASE COVER,TIMER CASE COVER…………………………………………..177

46. TIMER ASSEMBLY…………………………………………………………..177

47. FUEL INJECTION PUMP DRIVE CASE…………………………………………….177

48. INTAKE MANIFOLD………………………………………………………….177

49. CAM FOLLOWER…………………………………………………………….178

50. GEAR TRAIN………………………………………………………………178

51. CAMSHAFT ASSEMBLY………………………………………………………..178

52. GEAR CASE……………………………………………………………….179

53. MAIN GALLERY PLUG,OIL PLUG,COOLING VALVE……………………………………179

54. SIDE COVER………………………………………………………………179

55. PISTON COOLING NOZZLE…………………………………………………….180

56. CHANGING POSITION OF ENGINE……………………………………………….180

57. PISTON AND CONNECTING ROD ASSEMBLY…………………………………………180

58. CRANKSHAFT………………………………………………………………181

59. CYLINDER LINER…………………………………………………………..182

GENERAL ASSEMBLY CONTENTS………………………………………………………..183

ASSEMBLY……………………………………………………………………….185

1. CYLINDER LINER……………………………………………………………186

2. CRANKSHAFT……………………………………………………………….188

3. PISTON,CONNECTING ROD ASSEMBLY……………………………………………..192

4. CHANGING POSITION OF ENGINE………………………………………………..197

5. PISTON COOLING NOZZLE……………………………………………………..197

6. SIDE COVER……………………………………………………………….197

7. MAIN GALLERY PLUG,OIL PLUG,COOLING VALVE…………………………………….197

8. GEAR CASE………………………………………………………………..197

9. CAMSHAFT ASSEMBLY…………………………………………………………199

10. GEAR TRAIN………………………………………………………………200

11. CAM FOLLOWER…………………………………………………………….202

12. INTAKE MANIFOLD………………………………………………………….202

13. PUMP DRIVE CASE………………………………………………………….203

14. AUTO TIMER ASSEMBLY………………………………………………………203

15. FRONT SHAFT……………………………………………………………..205

16. GEAR CASE COVER………………………………………………………….205

17. TIMER COVER……………………………………………………………..206

18. WATER PUMP DRIVE CASE…………………………………………………….206

19. COMPRESSOR DRIVE CASE…………………………………………………….208

20. BREATHER CONNECTOR……………………………………………………….208

21. FRONT SEAL………………………………………………………………209

22. FRONT SUPPORT……………………………………………………………209

23. VIBRATION DAMPER…………………………………………………………209

24. PISTON COOLING VALVE……………………………………………………..211

25. OIL COOLER ASSEMBLY………………………………………………………211

26. WATER PUMP ASSEMBLY………………………………………………………213

27. FLYWHEEL HOUSING ASSEMBLY…………………………………………………214

28. REAR SEAL……………………………………………………………….215

29. FLYWHEEL………………………………………………………………..216

30. STARTING MOTOR ASSEMBLIES…………………………………………………217

31. CYLINDER HEAD ASSEMBLY……………………………………………………217

32. CROSSHEAD……………………………………………………………….220

33. ROCKER HOUSING…………………………………………………………..220

34. PUSH ROD………………………………………………………………..221

35. ROCKER ARM ASSEMBLY………………………………………………………221

36. INJECTION NOZZLE ASSEMBLY…………………………………………………223

37. AFTERCOOLER ASSEMBLY……………………………………………………..223

38. WATER TUBES……………………………………………………………..224

39. HEAD COVER………………………………………………………………224

40. THERMOSTAT CASE ASSEMBLIES………………………………………………..225

41. FUEL INJECTION PUMP ASSEMBLY………………………………………………226

42. AIR VENT TUBE……………………………………………………………228

43. MUFFLER BRACKET………………………………………………………….228

44. SPILL HOSES……………………………………………………………..229

45. LUBRICATION TUBES………………………………………………………..229

46. BOOST COMPENSATOR HOSE……………………………………………………229

47. FUEL AIR VENT HOSES………………………………………………………229

48. INJECTION PUMP LUBRICATION PIPING………………………………………….230

49. FUEL SUPPLY,OVERFLOW PIPES………………………………………………..230

50. FUEL INJECTION TUBES……………………………………………………..230

51. BRAKET,OIL CONNECTOR……………………………………………………..230

52. EXHAUST MANIFOLD…………………………………………………………231

53. TURBOCHARGER LUBRICATION PIPING,COOLANT WATER PIPING…………………………232

54. EXHAUST CONNECTOR………………………………………………………..232

55. TURBOCHARGER ASSEMBLY…………………………………………………….233

56. EXHAUST MANIFOLD COVER……………………………………………………234

57. OIL FILLER………………………………………………………………234

58. BYPASS TUBE……………………………………………………………..235

59. BLOWBY HOSE……………………………………………………………..235

60. OIL PUMP ASSEMBLY………………………………………………………..235

61. OIL PAN…………………………………………………………………236

62. OIL LEVEL SENSOR,DRAIN VALVE………………………………………………236

63. FILTER BRACKET…………………………………………………………..237

64. FUEL TUBE……………………………………………………………….237

65. CORROSION RESISTOR……………………………………………………….237

66. OIL FILTER………………………………………………………………237

67. TUBE FOR OIL FILTER………………………………………………………237

68. INTAKE PIPES…………………………………………………………….237

69. AIR CLEANER,MUFFLER ASSEMBLY………………………………………………238

70. BYPASS FILTER ASSEMBLY……………………………………………………238

14 MAINTENANCE STANDARD……………………………………………………………..239

INTAKE AND EXHAUST SYSTEM………………………………………………………..240

TURBOCHARGER………………………………………………………………..240

ENGINE BODY…………………………………………………………………….242

CYLINDER HEAD……………………………………………………………….242

VALVES AND VALVE GUIDE……………………………………………………….243

CROSSHEAD AND CROSSHEAD GUIDE…………………………………………………244

ROCKER ARM SHAFT…………………………………………………………….245

PUSH ROD AND CAM FOLLOWER…………………………………………………….246

CYLINDER BLOCK………………………………………………………………247

CYLINDER LINER………………………………………………………………249

CAMSHFT…………………………………………………………………….250

CRANKSHAFT………………………………………………………………….251

PISTON……………………………………………………………………..253

CONNECTING ROD………………………………………………………………254

TIMING GEAR…………………………………………………………………255

FLYWHEEL, FLYWHEEL HOUSING……………………………………………………256

LUBRICATION SYSTEM………………………………………………………………257

OIL PUMP……………………………………………………………………257

MAIN RELIEF VALVE, PISTON COOLING VALVE AND OIL COOLER BYPASS VALVE……………….258

COOLING SYSTEM………………………………………………………………….259

WATER PUMP………………………………………………………………….259

15 REPAIR AND REPLACEMENT OF PARTS……………………………………………………260

CYLINDER HEAD…………………………………………………………………..261

TESTING AND INSPECTING……………………………………………………….262

REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING…………………………….264

REPLACING VALVE SEAT INSERTS………………………………………………….265

REPLACING NOZZLE HOLDER SLEEVE………………………………………………..270

REPLACING VALVE GUIDE………………………………………………………..274

REPLACING CROSS HEAD GUIDE……………………………………………………275

GRINDING THE VALVE…………………………………………………………..276

CYLINDER BLOCK………………………………………………………………….277

TESTING AND INSPECTING……………………………………………………….278

GRINDING THE TOP SURFACE OF CYLINDER BLOCK……………………………………..280

REPLACING MAIN METAL CAP……………………………………………………..285

REPLACING CAM BUSHING………………………………………………………..287

CRANKSHAFT………………………………………………………………….288

REPLACING THE CRANKSHAFT……………………………………………………..295

CONNECTING ROD………………………………………………………………303

REPLACING CAM GEAR…………………………………………………………..307

REPLACING FLYWHEEL RING GEAR………………………………………………….307