$35

Komatsu 12V170-2 Series Engine Shop Manual SEBM036601 – PDF DOWNLOAD

Komatsu 12V170-2 Series Engine Shop Manual SEBM036601 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 12V170-2 Series Engine Shop Manual SEBM036601 – PDF DOWNLOAD

Language : English

Pages : 333

Downloadable : Yes

File Type : PDF

Size: 11.5 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 12V170-2 Series Engine Shop Manual SEBM036601 – PDF DOWNLOAD

- The Komatsu 12V170-2 Series Engine Shop Manual SEBM036601 is a comprehensive guidebook that provides detailed technical information and instructions on how to operate, maintain, and repair the Komatsu 12V170-2 series diesel engines. These engines are commonly used in large mining trucks, generators, and other heavy equipment.

- The manual is organized into several sections, each providing detailed information on specific topics. These sections include specifications, structure and function, testing and adjusting, disassembly and assembly, maintenance, and troubleshooting.

- The specifications section of the manual provides detailed information on the engine’s physical and operational characteristics, including its dimensions, weight, performance, and power output. It also provides information on the engine’s cooling system, fuel system, and lubrication system.

- The structure and function section of the manual provides an overview of the engine’s internal components and their functions. This section includes detailed diagrams and descriptions of the engine’s various components, such as the cylinder block, cylinder head, crankshaft, pistons, and valves.

- The testing and adjusting section of the manual provides instructions on how to test and adjust the engine’s various components to ensure they are functioning correctly. This section includes detailed procedures for testing and adjusting the engine’s fuel injection system, valve clearances, and oil pressure.

- The disassembly and assembly section of the manual provides step-by-step instructions on how to disassemble and reassemble the engine’s various components. This section includes detailed diagrams and photographs to guide the user through the process.

- The maintenance section of the manual provides information on routine maintenance tasks that should be performed to keep the engine in good working condition. This section includes instructions on how to perform tasks such as changing the engine oil and replacing the air filter.

- The troubleshooting section of the manual provides guidance on how to diagnose and resolve common issues that may arise with the engine. This section includes a list of common symptoms and their likely causes, as well as step-by-step instructions for troubleshooting and resolving each issue.

- Overall, the Komatsu 12V170-2 Series Engine Shop Manual SEBM036601 is an essential resource for anyone who operates, maintains, or repairs these powerful diesel engines. With its detailed technical information and comprehensive instructions, this manual is an invaluable tool for ensuring the efficient and reliable operation of Komatsu 12V170-2 series engines in heavy equipment applications.

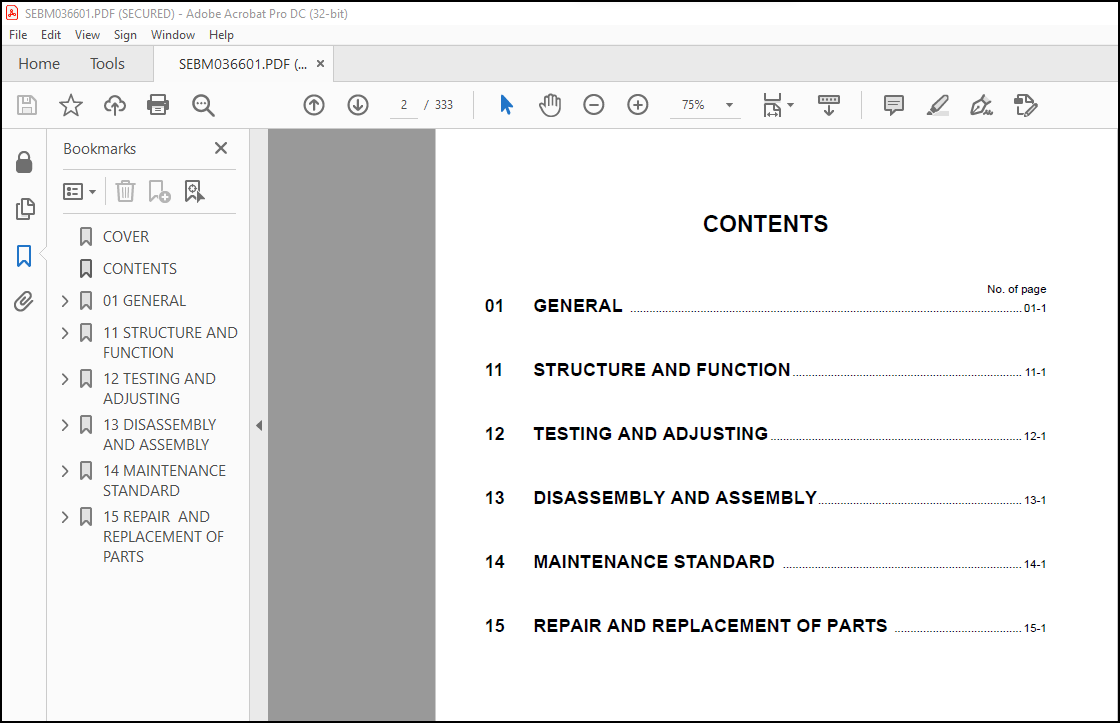

TABLE OF CONTENTS:

Komatsu 12V170-2 Series Engine Shop Manual SEBM036601 – PDF DOWNLOAD

COVER………………………………………………………………………………………… 1

CONTENTS……………………………………………………………………………………… 2

01 GENERAL……………………………………………………………………………………. 25

APPLICABLE MACHINE…………………………………………………………………………. 26

SPECIFICATIONS…………………………………………………………………………….. 27

GENERAL ASSEMBLY DRAWING……………………………………………………………………. 28

WEIGHT TABLE………………………………………………………………………………. 33

ENGINE PERFORMANCE CURVE……………………………………………………………………. 34

11 STRUCTURE AND FUNCTION………………………………………………………………………. 37

GENERAL STRUCTURE………………………………………………………………………….. 38

AIR CLEANER……………………………………………………………………………….. 40

TURBOCHARGER………………………………………………………………………………. 41

AFTER-COOLER………………………………………………………………………………. 42

CYLINDER HEAD……………………………………………………………………………… 43

CYLINDER BLOCK…………………………………………………………………………….. 45

MAIN REVOLVING PART………………………………………………………………………… 47

VALVE SYSTEM………………………………………………………………………………. 49

TIMING GEAR……………………………………………………………………………….. 51

FLYWHEEL AND FLYWHEEL HOUSING……………………………………………………………….. 53

LUBRICATION SYSTEM CHART……………………………………………………………………. 54

OIL PUMP …………………………………………………………………………………. 55

OIL FILTER, SAFETY VALVE……………………………………………………………………. 56

BYPASS FILTER……………………………………………………………………………… 57

OIL COOLER………………………………………………………………………………… 58

OIL COOLER BYPASS VALVE…………………………………………………………………….. 59

PISTON COOLING VALVE……………………………………………………………………….. 59

FUEL SYSTEM CHART………………………………………………………………………….. 60

FUEL INJECTION PUMP………………………………………………………………………… 61

FUEL PIPING……………………………………………………………………………….. 63

FUEL INJECTION PUMP DRIVE…………………………………………………………………… 65

FUEL INJECTION NOZZLE………………………………………………………………………. 66

FUEL FILTER……………………………………………………………………………….. 67

COOLING SYSTEM CHART……………………………………………………………………….. 68

WATER PUMP………………………………………………………………………………… 70

WATER PUMP DRIVE…………………………………………………………………………… 71

THERMOSTAT………………………………………………………………………………… 72

CORROSION RESISTOR…………………………………………………………………………. 73

FAN DRIVE AND TENSION PULLEY………………………………………………………………… 74

ALTERNATOR………………………………………………………………………………… 75

STARTING MOTOR…………………………………………………………………………….. 76

STARTING AID………………………………………………………………………………. 78

12 TESTING AND ADJUSTING……………………………………………………………………….. 79

STANDARD VALUE TABLE FOR TESTING,ADJUST AND TROUBLESHOOTING…………………………………….. 80

TESTING AND ADJUSTING TOOL LIST……………………………………………………………… 82

ADJUSTING VALVE CLEARANCE…………………………………………………………………… 83

TESTING AND ADJUSTING OF FUEL INJECTION TIMING(WITH KOMATSU ELECTRONICAL GOVERNOR)………………… 85

MEASURING COMPRESSION PRESSURE………………………………………………………………. 88

MEASURING BLOW-BY………………………………………………………………………….. 89

ADJUSTING FUEL INJECTION PRESSURE (VALVE CRACKING PRESSURE)…………………………………….. 90

INSTALLING ENGINE SPEED SENSOR (WITH ELECTRONIC GOVERNOR)………………………………………. 91

TESTING AND ADJUSTING ALTERNATOR BELT AND FAN BELT ……………………………………………. 92

DATA FOR FUEL INJECTION PRESSURE ADJUSTMENT SHIMS……………………………………………… 93

FUEL INJECTION PUMP CALIBRATION DATA…………………………………………………………. 94

PERFORMANCE TEST…………………………………………………………………………… 97

PERFORMANCE TEST CRITERIA…………………………………………………………………… 98

TROUBLESHOOTING OF ENGINE CONTROLLER SYSTEM(E MODE)…………………………………………….100

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE…………………….101

E-1 [E0401] ABNORMALITY IN ENGINE CONTROLLER POWER SOURCE VOLTAGE IS DISPLAYED…………………109

E-3 [E0403] MISTAKEN CONNECTION IN ENGINE CONTROLLER IS DISPLAYED…………………………….110

E-4 [E0405] ABNORMALITY IN FUEL CONTROL DIAL SYSTEM IS DISPLAYED……………………………..111

E-5 [E0406] ABNORMALITY IN DECELERATION POTENTIOMETER IS DISPLAYED……………………………113

E-6 [E0407] ABNORMALITY IN SHOE SLIP CONTROL COMMAND VALUE IS DISPLAYED……………………….115

E-7 [E0409] ABNORMALITY IN ENGINE SPEED SENSOR A SYSTEM IS DISPLAYED………………………….116

E-8 [E0410] ABNORMALITY IN ENGINE SPEED SENSOR B SYSTEM IS DISPLAYED………………………….117

E-9 [E0411] ABNORMALITY IN RIGHT RACK SENSOR SYSTEM IS DISPLAYED……………………………..118

E-10 [E0412] ABNORMALITY IN LEFT RACK SENSOR SYSTEM IS DISPLAYED …………………………….119

E-11 [E0413] ABNORMALITY IN RACK SENSOR POWER SOURCE SYSTEM IS DISPLAYED………………………120

E-12 [E0421] SHORT CIRCUIT IN RIGHT GOVERNOR SOLENOID SYSTEM IS DISPLAYED……………………..121

E-13 [E0422] DISCONNECTION IN RIGHT GOVERNOR SOLENOID SYSTEM IS DISPLAYED……………………..122

E-14 [E0423] SHORT CIRCUIT IN LEFT GOVERNOR SOLENOID SYSTEM IS DISPLAYED………………………123

E-15 [E0424] DISCONNECTION IN LEFT GOVERNOR SOLENOID SYSTEM IS DISPLAYED………………………124

E-16 [E0425] SHORT CIRCUIT IN RIGHT GOVERNOR CUT RELAY SYSTEM IS DISPLAYED……………………125

E-17 [E0426] DISCONNECTION IN LEFT GOVERNOR CUT RELAY SYSTEM IS DISPLAYED……………………..126

E-18 [E0427] SHORT CIRCUIT IN LEFT GOVERNOR CUT RELAY SYSTEM IS DISPLAYED……………………..127

E-19 [E0428] DISCONNECTION IN LEFT GOVERNOR CUT RELAY SYSTEM IS DISPLAYED……………………..128

E-20 [E0433] SHORT CIRCUIT IN LEFT PRE-STROKE SOLENOID SYSTEM IS DISPLAYED…………………….129

E-21 [E0434] DISCONNECTION IN LEFT PRE-STROKE SOLENOID SYSTEM IS DISPLAYED…………………….130

E-22 [E0435] ABNORMALITY IN ENGINE WATER TEMPERATURE SENSOR SYSTEM IS DISPLAYED………………..131

E-23 [E0437] ABNORMALITY IN RIGHT GOVERNOR SERVO IS DISPLAYED………………………………..132

E-24 [E0438] ABNORMALITY IN LEFT GOVERNOR SERVO IS DISPLAYED ………………………………..133

E-25 [E0440] DISCONNECTION SOLENOID POWER SOURCE 1 SYSTEM IS DISPLAYED………………………..134

E-26 [E0441] DISCONNECTION IN POWER SUPPLY SYSTEM 2 OF SOLENOID IS DISPLAYED…………………..134

E-27 [E0442] ABNORMALITY IN ENGINE CONTROLLER BACKUP POWER SOURCE SYSTEM IS DISPLAYED…………..135

E-28 [E0443] ABNORMALITY IN ENGINE CONTROLLER SWITCH POWER SOURCE SYSTEM IS DISPLAYED…………..136

E-29 [E0455] ENGINE OVERHEATING IS DISPLAYED……………………………………………….137

E-30 [E0456] SHORT CIRCUIT IN RIGHT PRE-STROKE SOLENOID SYSTEM IS DISPLAYED……………………138

E-31 [E0457] DISCONNECTION IN RIGHT PRE-STROKE SOLENOID SYSTEM IS DISPLAYED……………………139

E-32 ENGINE DOES NOT ROTATE WHEN STARTING SWITCH IS TURNED TO ON POSITION……………………..140

E-33 ENGINE DOES NOT STOP WHEN STARTING SWITCH IS TURNED TO OFF POSITION………………………143

TROUBLESHOOTING (S-MODE)…………………………………………………………………….144

POINTS TO REMEMBER WHEN TROUBLESHOOTING……………………………………………………145

METHOD OF USING TROUBLESHOOTING CHARTS…………………………………………………….146

S-1 STARTING PERFORMANCE IS POOR(STARTING ALWAYS TAKES TIME)…………………………………150

S-2 ENGINE DOES NOT START………………………………………………………………..151

(1) ENGINE DOES NOT TURN……………………………………………………………..151

(2) ENGINE TURNS BUT NO EXHAUST GAS COMES OUT (FUEL IS NOT BEING INJECTED)…………………152

(3) EXHAUST SMOKE COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)……………..153

S-3 ENGINE DOES NOT PICK-UP SMOOTHLY(FOLLOW-UP IS POOR)……………………………………..154

S-4 ENGINE STOPS DURING OPERATIONS(WITH ELECTRONICAL GOVERNOR)……………………………….155

S-5 ENGINE DOES NOT ROTATE SMOOTHLY(HUNTING)(WITH ELECTRONICAL GOVERNOR)………………………156

S-6 ENGINE LACKS OUTPUT (NOT POWER)(WITH ELECTRONICAL GOVERNOR)………………………………157

S-7 EXHAUST GAS IS BLACK(INCOMPLETE COMBUSTION)(WITH ELECTRONICAL GOVERNOR)……………………158

S-8 OIL CONSUMPTION IS EXCESSIVE(OR EXHAUST SMOKE IS BLUE)…………………………………..159

S-9 OIL BECOMES CONTAMINATED QUICKLY………………………………………………………160

S-10 FUEL CONSUMPTION IS EXCESSIVE(WITH ELECTRONICAL GOVERNOR)……………………………….161

S-11 OIL IS COOLING WATER,OR WATER SPURTS BACK,OR WATER LEVEL GOES DOWN……………………….162

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE)………………………………163

S-13 OIL LEVEL RISES…………………………………………………………………….164

S-14 WATER TEMPERATURE BECOMES TOO HIGH(OVERHEATING)………………………………………..165

S-15 ABNORMAL NOISE IS MADE………………………………………………………………166

S-16 VIBRATION IS EXCESSIVE………………………………………………………………167

S-17 ABNORMALITY IN GOVERNOR SERVO SYSTEM IS DISPLAYED IN TROUBLESHOOTING FOR ENGINE CONTROLLER….168

13 DISASSEMBLY AND ASSEMBLY……………………………………………………………………..170

METHOD OF USING MANUAL………………………………………………………………………172

PRECAUTIONS WHEN CARRYING OUT OPERATION……………………………………………………….173

SPECIAL TOOL LIST ………………………………………………………………………….175

GENERAL DISASSEMBLY…………………………………………………………………………176

1.CLEANING……………………………………………………………………………..176

2.SETTING ENGINE STAND…………………………………………………………………..176

3.COOLANT AND ENGINE OIL…………………………………………………………………176

4.AIR CLEANER AND MUFFLER ASSEMBLY………………………………………………………..176

5.OIL FILTER TUBES………………………………………………………………………177

6.OIL FILTER …………………………………………………………………………..177

7.FUEL TUBE…………………………………………………………………………….177

8.FILTER BACKET ………………………………………………………………………..178

9.EXHAUST MANIFOLD COVER (RIGHT SIDE IS SHOWN IN FIGURE)…………………………………….178

10.TURBOCHARGER ASSEMBLY…………………………………………………………………178

11.EXHAUST CONNECTOR…………………………………………………………………….180

12.COOLANT TUBE,TURBOCHARGER PIPE,AND EXHAUST TUBE………………………………………….180

13.AFTERCOOLER ASSEMBLY………………………………………………………………….180

14.PLATE AND CASE……………………………………………………………………….181

15.FUEL INJECTION PIPE AND SPILL TUBE……………………………………………………..181

16.FUEL PIPING …………………………………………………………………………182

17.LUBRICATION TUBES…………………………………………………………………….182

18.FUEL INJECTION PUMP ASSEMBLY…………………………………………………………..183

19.EXHAUST MANIFOLDS…………………………………………………………………….183

20.WATER PUMP ASSEMBLY…………………………………………………………………..184

21.OIL COOLER ASSEMBLY…………………………………………………………………..184

22.OIL PAN …………………………………………………………………………….185

23.AIR VENT TUBES……………………………………………………………………….185

24.THERMOSTAT ASSEMBLY…………………………………………………………………..186

25.CYLINDER HEAD COVERS………………………………………………………………….186

26.NOZZLE HOLDERS……………………………………………………………………….187

27.ROCKER ARM HOUSING ASSEMBLY……………………………………………………………187

28.PUSH ROD…………………………………………………………………………….187

29.CROSS HEAD…………………………………………………………………………..187

30.CYLINDER HEAD ASSEMBLY………………………………………………………………..187

31.OIL PUMP ASSEMBLY…………………………………………………………………….189

32.STARTING MOTOR ASSEMBLY……………………………………………………………….189

33.FLYWHEEL ……………………………………………………………………………190

34.FLYWHEEL HOUSING……………………………………………………………………..190

35.VIBRATION DAMPER …………………………………………………………………….190

36.DRIVE CASE ASSEMBLY…………………………………………………………………..190

37.RETAINER AND FRONT SUPPORT…………………………………………………………….191

38.GEAR CASE COVER AND TIMER CASE COVER……………………………………………………191

39.FUEL INJECTION PUMP DRIVE CASE…………………………………………………………191

40.AIR INTAKE MANIFOLD…………………………………………………………………..191

41.CAM FOLLOWER ………………………………………………………………………..192

42.GEAR TRAIN…………………………………………………………………………..192

43.CAMSHAFT ASSEMBLIES…………………………………………………………………..192

44.GEAR CASE …………………………………………………………………………..193

45.MAIN GALLERY PLUG,OIL PLUG,AND COOLING VALVE…………………………………………….193

46.SIDE COVERS………………………………………………………………………….193

47.PISTON COOLING NOZZLES………………………………………………………………..193

48.ENGINE SET…………………………………………………………………………..194

49.PISTONS AND CONNECTING ROD ASSEMBLIES…………………………………………………..194

50.CRANKSHAFT…………………………………………………………………………..195

51.CYLINDER LINER……………………………………………………………………….196

CLEANING…………………………………………………………………………………..197

MEASURING PARTS…………………………………………………………………………….198

GENERAL ASSEMBLY……………………………………………………………………………203

1.CYLINDER LINER………………………………………………………………………..205

2.CRANKSHAFT……………………………………………………………………………208

3.PISTON AND CONNECTING ROD ASSEMBLY………………………………………………………212

4.SETTING ENGINE STAND…………………………………………………………………..217

5.PISTON COOLING NOZZLES…………………………………………………………………217

6.SIDE COVERS…………………………………………………………………………..217

7.MAIN GALLERY PLUG,OIL PLUG,AND COOLING PLUG………………………………………………217

8.GEAR CASE…………………………………………………………………………….217

9.CAMSHAFT ASSEMBLY……………………………………………………………………..219

10.GEAR TRAIN ………………………………………………………………………….220

11.CAM FOLLOWER…………………………………………………………………………222

12.AIR INTAKE MANIFOLD…………………………………………………………………..223

13.PUMP DRIVE CASE………………………………………………………………………224

14.BACKLASH AND END PLAY OF GEARS…………………………………………………………225

15.FRONT SHAFT …………………………………………………………………………226

16.GEAR CASE COVER………………………………………………………………………226

17.TIMER COVER………………………………………………………………………….227

18.WATER PUMP DRIVE CASE…………………………………………………………………227

19.COMPRESSOR DRIVE CASE…………………………………………………………………228

20.BREATHER CONNECTOR……………………………………………………………………229

21.FRONT SEAL ………………………………………………………………………….229

22.FRONT SUPPORT………………………………………………………………………..229

23.VIBRATION DAMPER……………………………………………………………………..230

24.PISTON COOLING VALVE………………………………………………………………….231

25.OIL COOLER ASSEMBLY…………………………………………………………………..232

26.WATER PUMP ASSEMBLY…………………………………………………………………..233

27.FLYWHEEL HOUSING ASSEMBLY……………………………………………………………..234

28.REAR SEAL …………………………………………………………………………..235

29.FLYWHEEL…………………………………………………………………………….235

30.STARTING MOTOR ASSEMBLIES……………………………………………………………..237

31.CYLINDER HEAD ASSEMBLY………………………………………………………………..237

32.CROSS HEAD…………………………………………………………………………..241

33.ROCKER HOUSING……………………………………………………………………….241

34.INJECTION NOZZLE ASSEMBLY……………………………………………………………..242

35.PUSH ROD…………………………………………………………………………….242

36.ROCKER ARM ASSEMBLY…………………………………………………………………..243

37.ADJUSTING VALVE CLEARANCE……………………………………………………………..243

38.AFTERCOOLER ASSEMBLY………………………………………………………………….244

39.WATER TUBES………………………………………………………………………….244

40.HEAD COVER…………………………………………………………………………..245

41.THERMOSTAT CASE ASSEMBLY………………………………………………………………245

42.FUEL INJECTION PUMP ASSEMBLY…………………………………………………………..246

43.AIR VENT TUBES……………………………………………………………………….247

44.MUFFLER BRACKET………………………………………………………………………248

45.SPILL HOSES………………………………………………………………………….248

46.FUEL INJECTION PUMP LUBRICATION TUBES…………………………………………………..248

47.FUEL SUPPLY AND OVERFLOW PIPE………………………………………………………….249

48.FUEL INJECTION TUBES………………………………………………………………….249

49.EXHAUST MANIFOLD……………………………………………………………………..250

50.WATER TUBE AND TURBOCHARGER PIPING……………………………………………………..251

51.EXHAUST CONNECTOR…………………………………………………………………….251

52.TURBOCHARGER ASSEMBLY…………………………………………………………………252

53.EXHAUST MANIFOLD COVER(RIGHT ONE IS SHOWN IN THE FIGURE)………………………………….253

54.OIL FILLER…………………………………………………………………………..253

55.BYPASS TUBE………………………………………………………………………….254

56.BLOW-BY HOSE…………………………………………………………………………254

57.OIL PUMP ASSEMBLY…………………………………………………………………….254

58.OIL PAN …………………………………………………………………………….255

59.OIL LEVEL SENSOR AND DRAIN VALVE……………………………………………………….255

60.FILTER BRACKET……………………………………………………………………….255

61.FUEL TUBE……………………………………………………………………………256

62.OIL FILTER…………………………………………………………………………..256

63.OIL FILTER TUBE………………………………………………………………………256

64.AIR INTAKE PIPE………………………………………………………………………256

65.AIR CLEANER AND MUFFLER ASSEMBLY……………………………………………………….257

14 MAINTENANCE STANDARD…………………………………………………………………………258

TURBOCHARGER……………………………………………………………………………….259

CYLINDER HEAD………………………………………………………………………………261

VALVES AND VALVE GUIDE………………………………………………………………………262

CROSSHEAD AND CROSSHEAD GUIDE………………………………………………………………..263

ROCKER ARM SHAFT……………………………………………………………………………264

PUSH ROD AND CAM FOLLOWER……………………………………………………………………265

CYLINDER BLOCK……………………………………………………………………………..266

CYLINDER LINER……………………………………………………………………………..268

CAMSHAFT…………………………………………………………………………………..269

CRANKSHAFT…………………………………………………………………………………270

TIMING GEAR………………………………………………………………………………..272

POSTON…………………………………………………………………………………….273

CONNECTING ROD……………………………………………………………………………..274

FLYWHEEL,FLYWHEEL HOUSING …………………………………………………………………..275

OIL PUMP…………………………………………………………………………………..276

OIL PUMP RELIEF VALVE,PISTON COOLING VALVE,OIL COOLER BYPASS VALVE AND OIL FILTER SAFETY VALVE………277

WATER PUMP…………………………………………………………………………………279

THERMOSTAT…………………………………………………………………………………280

15 REPAIR AND REPLACEMENT OF PARTS………………………………………………………………281

TABLE OF SPECIAL TOOLS………………………………………………………………………282

TESTING AND INSPECTING CYLINDER HEAD………………………………………………………….283

REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING……………………………………………286

REPLACING VALVE SEAT INSERTS…………………………………………………………………287

REPLACING NOZZLE HOLDER SLEEVE……………………………………………………………….293

CYLINDER HEAD PRESSURE TEST METHOD……………………………………………………………296

REPLACING VALVE GUIDE……………………………………………………………………….297

REPLACING CROSS HEAD GUIDE…………………………………………………………………..298

GRINDING VALVE……………………………………………………………………………..299

TESTING AND INSPECTING CYLINDER BLOCK…………………………………………………………300

GRINDING TOP SURFACE OF CYLINDING BLOCK……………………………………………………….303

REPLACING MAIN BEARING CAP…………………………………………………………………..309

REPLACING CAM BUSHING……………………………………………………………………….311

TESTING CRANKSHAFT………………………………………………………………………….313

CORRECTING SURFACE ROUGHNESS OF CRANKSHAFT JOURNAL PORTION………………………………………315

GRINDING CRANKSHAFT…………………………………………………………………………320

TESTING AND INSPECTING CONNECTING ROD…………………………………………………………329

REPLACING CONNECTING ROD SMALL END BUSHING…………………………………………………….331

REPLACING CAMSHAFT GEAR……………………………………………………………………..332

REPLACING FLYWHEEL RING GEAR ………………………………………………………………..333