$45

Komatsu 140-3 Series Diesel Engine Shop Manual PDF DOWNLOAD

Komatsu 140-3 Series Diesel Engine Shop Manual

DESCRIPTION:

Komatsu 140-3 Series Diesel Engine Shop Manual

FOREWORD:

GENERAL:

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity. This shop manual mainly contains the necessary technical information for operations performed in a service workshop. For ease of understanding, the manual is divided into the following chapters; these chapters are further divided into the each main group of components.

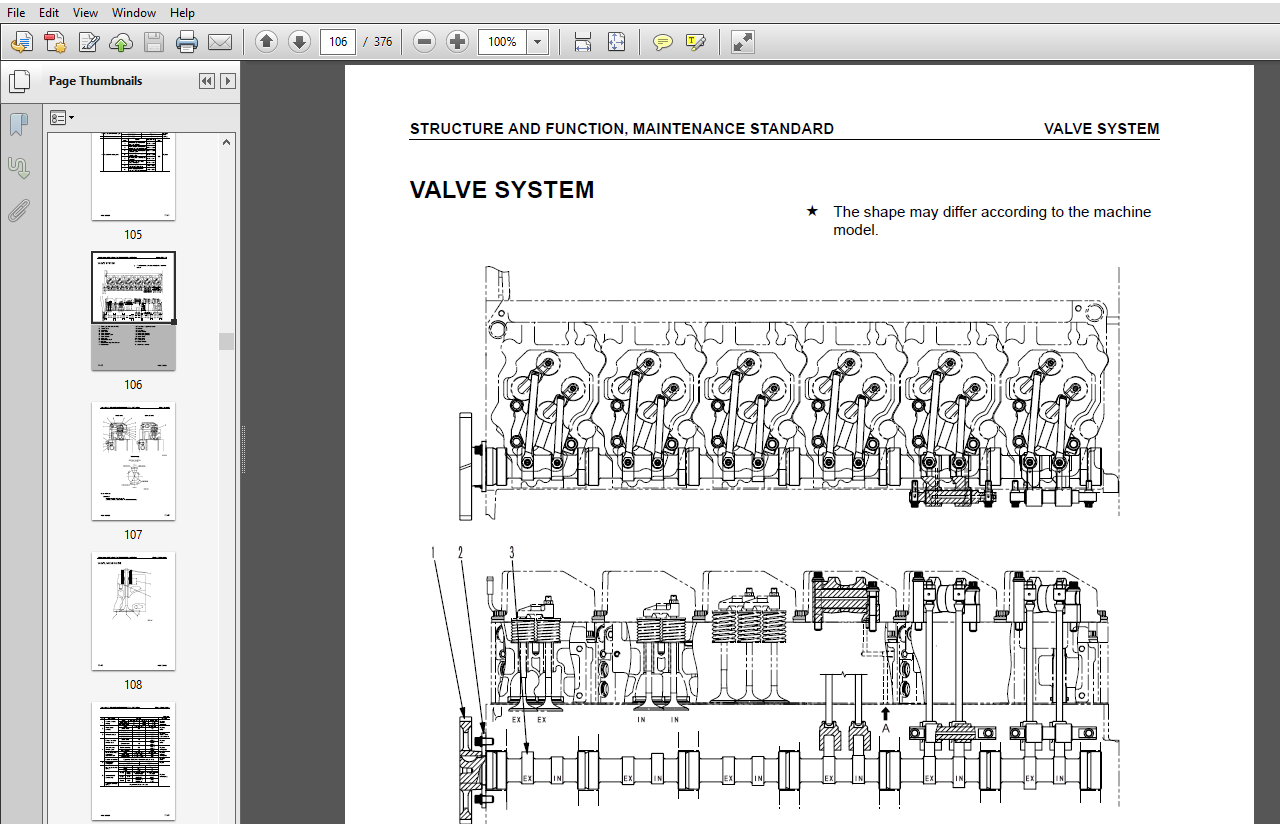

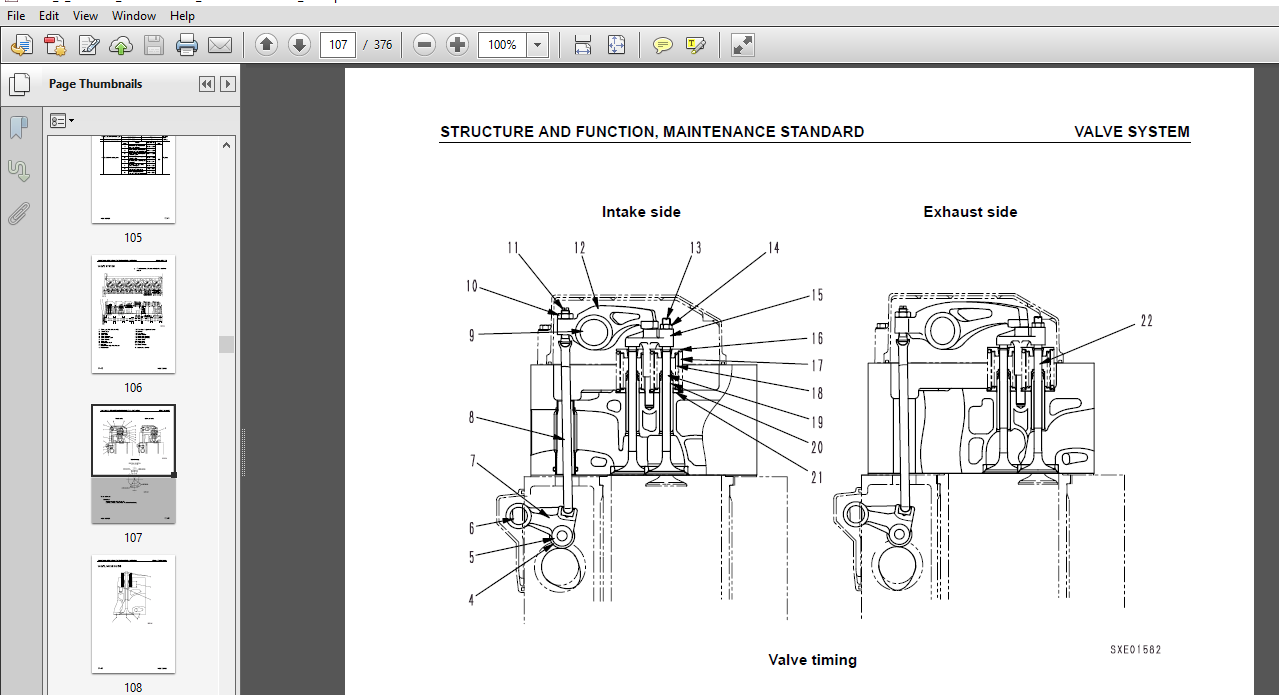

STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting.

In addition, this section may contain hydraulic circuit diagrams, electric circuit diagrams, and maintenance standards.

TESTING AND ADJUSTING

This section explains checks to be made before and after performing repairs, as well as adjustments to be made at completion of the checks and repairs. Troubleshooting charts correlating “Problems” with “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY

This section explains the procedures for removing, installing, disassembling and assembling each component, as well as precautions for them.

MAINTENANCE STANDARD

This section gives the judgment standards for inspection of disassembled parts. The contents of this section may be described in STRUCTURE AND FUNCTION.

OTHERS

This section mainly gives hydraulic circuit diagrams and electric circuit diagrams. In addition, this section may give the specifications of attachments and options together.

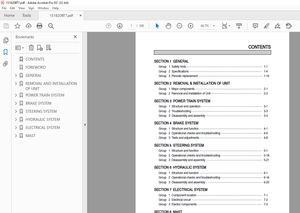

TABLE OF CONTENTS:

Komatsu 140-3 Series Diesel Engine Shop Manual

MAIN MENU.......................................................................................... 1 COVER.............................................................................................. 1 CONTENTS........................................................................................... 2 00 FOREWARD........................................................................................ 7 SAFETY......................................................................................... 7 FOREWARD....................................................................................... 9 HOW TO READ THIS MANUAL........................................................................ 10 HOISTING INSTRUCTIONS.......................................................................... 11 METHOD OF DISASSEMBLING, CONNECTING, PUSH-PULL TYPE COUPLER.................................... 12 COATING MATERIALS.............................................................................. 14 STANDARD TIGHTENING TORQUE..................................................................... 16 ELECTRIC WIRE CODE............................................................................. 19 COVERSION TABLE................................................................................ 20 UNITS.......................................................................................... 26 01 GENERAL......................................................................................... 27 OUTLINE........................................................................................ 28 SPECIFICATIONS................................................................................. 32 OVERALL DRAWING................................................................................ 34 WEIGHT TABLE................................................................................... 0 ENGINE PERFORMANCE CURVE....................................................................... 0 11 STRUCTURE AND FUNCTION, MAINTENANCE STANDARD.................................................... 59 INTAKE, EXHAUST SYSTEM......................................................................... 60 INTAKE, EXHAUST EQUIPMENT.................................................................. 60 AIR CLEANER................................................................................ 72 TURBOCHARGER............................................................................... 76 AFTERCOOLER................................................................................ 80 ENGINE......................................................................................... 82 CYLINDER HEAD.............................................................................. 82 CYLINDER BLOCK............................................................................. 86 CYLINDER LINER............................................................................. 89 MAIN MOVING PARTS.......................................................................... 90 CRANKSHAFT................................................................................. 92 CAMSHAFT................................................................................... 93 CAM FOLLOWER AND PUSH ROD.................................................................. 94 PISTON PISTON RING PISTON PIN.............................................................. 96 CONNECTING ROD............................................................................. 98 FLYWHEEL, FLYWHEEL HOUSING................................................................. 99 VIBRATION DAMPER...........................................................................101 TIMING GEAR................................................................................102 VALVE SYSTEM...............................................................................106 VALVE, VALVE GUIDE.........................................................................108 ROCKER ARM AND SHAFT.......................................................................110 CROSSHEAD AND GUIDE........................................................................111 LUBRICATION SYSTEM.............................................................................112 LUBRICATION SYSTEM DIAGRAM.................................................................112 OIL PUMP...................................................................................113 OIL FILTER.................................................................................116 OIL COOLER.................................................................................117 FUEL SYSTEM....................................................................................120 FUEL SYSTEM DIAGRAM........................................................................120 OUTLINE OF CRI SYSTEM......................................................................121 FUEL PIPING................................................................................134 FUEL COOLER................................................................................136 FUEL FILTER................................................................................137 COOLANT SYSTEM.................................................................................138 COOLING SYSTEM DIAGRAM.....................................................................138 WATER PUMP.................................................................................142 THERMOSTAT.................................................................................145 CORROSION RESISTOR.........................................................................147 COOLING FAN DRIVE..........................................................................149 ACCESSORIES....................................................................................162 FRONT PRO..................................................................................162 AIR COMPRESSOR.............................................................................165 EXHAUST BRAKE..............................................................................168 ELECTRICAL COMPONENTS..........................................................................173 ALTERNATOR.................................................................................173 STARTING MOTOR.............................................................................180 STARTING AID...............................................................................182 12 TESTING AND ADJUSTING...........................................................................185 STANDARD VALUE TABLE FOR TESTING, ADJUSTING, AND TROUBLESHOOTING..............................186 STANDARD VALUE TABLE FOR ELECTRICAL RELATED PARTS..............................................192 TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING..............................................194 MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE).................................................195 MEASURING EXHAUST TEMPERATURE..................................................................195 ADJUSTING VALVE CLEARENCE......................................................................196 MEASURING COMPRESSION PRESSURE.................................................................197 MEASURING BLOW-BY PRESSURE.....................................................................198 MEASURING OIL PRESSURE.........................................................................199 HANDLING EQUIPMENT IN FUEL CIRCUIT.............................................................199 RELEASING REMAINING PRESSURE IN FUEL SYSTEM....................................................200 MEASURING FUEL PRESSURE........................................................................200 REDUCED CYLINDER MODE OPERATION................................................................201 BLEEDING AIR FROM FUEL SYSTEM..................................................................202 CHECK FOR LEAKAGE IN FUEL SYSTEM...............................................................205 ADJUSTING SPEED SENSOR.........................................................................206 TESTING AND ADJUSTING ALTERNATOR BELT TENSION..................................................206 TESTING AND ADJUSTING FAN BELT TENSION.........................................................207 HANDLING CONTROLLER HIGH VOLTAGE CIRCUIT.......................................................209 RUN-IN STANDARD................................................................................210 PERFORMANCE TEST STANDARDS..................................................................... 0 TROUBLESHOOTING OF ENGINE SYSTEM (S MODE)......................................................219 POINTS TO REMEMBER WHEN TROUBLESHOOTING....................................................220 METHOD OF USING TROUBLESHOOTING CHARTS.....................................................222 S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)..............................225 S-2 ENGINE DOES NOT START..................................................................226 S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)...................................229 S-4 ENGINE STOPS DURING OPERATIONS.........................................................230 S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)..............................................231 S-6 ENGINE LACKS OUTPUT (OR LACKS POWER)...................................................232 S-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION).........................................233 S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE)................................234 S-9 OIL BECOMES CONTAMINATED QUICKLY.......................................................235 S-10 FUEL CONSUMPTION IS EXCESSIVE.........................................................236 S-11 OIL IS IN COOLING WATER (OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN)..............237 S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE)............................238 S-13 OIL LEVEL RISES (WATER, FUEL IN OIL)..................................................239 S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)......................................240 S-15 ABNORMAL NOISE IS MADE................................................................241 S-16 VIBRATION IS EXCESSIVE................................................................242 TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)..................................................243 POINTS TO REMEMBER WHEN TROUBLESHOOTING....................................................245 METHOD OF USING TROUBLESHOOTING FLOWCHART..................................................247 ERROR CODE DISPLAYS AND POINTS TO REMEMBER WHEN TROUBLESHOOTING............................248 ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ERROR CODE IS DISPLAYED...........251 E-1 ERROR CODE [E-1B] [ABNORMALITY IN NE REVOLUTION SENOR SYSTEM]..........................259 E-2 ERROR CODE [E-1C] [ABNORMALITY IN G REVOLUTION SENOR SYSTEM]...........................260 E-3 ERROR CODE [E-20] [ABNORMALITY IN MODEL SELECTION SYSTEM]..............................261 E-4 ERROR CODE [E-22] [OVERRUN]............................................................262 E-5 ERROR CODE [E-23] [OVERHEAT]...........................................................262 E-6 ERROR CODE [E-24] [DROP IN OIL PRESSURE]...............................................263 E-7 ERROR CODE [E-30] [ABNORMALITY IN IDLING VALIDATION SIGNAL SYSTEM].....................264 E-8 ERROR CODE [E-31B] [ABNORMALITY IN NE REVOLUTION SENOR SYSTEM].........................266 E-9 ERROR CODE [E-34] [ABNORMALITY IN WATER TEMPERATURE HIGH-TEMPERATURE SENSOR SYSTEM]....269 E-10 ERROR CODE [E-36] [ABNORMALITY IN OIL PRESSURE SYSTEM.................................270 E-11 ERROR CODE [E-3C] [ABNORMALITY IN BOOST PRESSURE SENSOR SYSTEM........................272 E-12 ERROR CODE [E-3D] [ABNORMALITY IN FUEL TEMPERATURE SENSOR SYSTEM].....................273 E-13 ERROR CODE [E-50] [ABNORMALITY IN PREHEATING RELAY CONNECTING POINT SYSTEM]...........274 E-14 ERROR CODE [E-51] [ABNORMALITY IN PREHEAT RELY COIL SYSTEM]...........................275 E-15 ERROR CODE [E-54] [ SHORT CURCUIT IN STARTING SWITCH C SYSTEM.........................276 E-16 ERROR CODE [E-56] [POWER SOURCE SYSTEM ABNORMALITY 1].................................277 E-17 ERROR CODE [E-57] [POWER SOURCE SYSTEM ABNORMALITY 2].................................279 E-18 ERROR CODE [E-5A] ABNORMALITY IN FUEL INJECTION QUANTITY CONTROL SWITCH SIGNAL].......280 E-19 ERROR CODE [E-6A] [ABNORMALITY IN WATER TEMPERATURE LOW-TEMPERATURE SENSOR SYSTEM]....281 E-20 ERROR CODE [E-70] [EXCESS CURRENT IN FUEL SUPPLY PUMP PCV1 SYSTEM.....................282 E-21 ERROR CODE [E-71] EXCESS CURRENT IN FUEL SUPPLY PUMP PCV2 SYSTEM......................283 E-22 ERROR CODE [E-71] DISCONNECTION CURRENT IN FUEL SUPPLY PUMP PCV1 SYSTEM...............284 E-23 ERROR CODE [E-71] DISCONNECTION CURRENT IN FUEL SUPPLY PUMP PCV2 SYSTEM...............285 E-24 ERROR CODE [E-77] [ABNORMALITY IN COMMON RAIL FUEL PRESSURE SENSOR SYSTEM.............286 E-25 ERROR CODE [E-79] [COMMON RAIL FUEL HIGH PRESSURE ABNORMALITY 1]......................287 ERROR CODE [E-7A] [COMMON RAIL FUEL HIGH PRESSURE ABNORMALITY 2].......................287 E-26 ERROR CODE [E-7B] [FUEL SUPPLY PUMP NON-FORCE FEED 1].................................288 ERROR CODE [E-7C] [FUEL SUPPLY PUMP NON-FORCE FEED 2]..................................288 E-27 ERROR CODE [E-7D] [ABNORMALITY IN COMMON RAIL FUEL PRESSURE]..........................290 E-28 ERROR CODE [E-80] [DEFECTIVE CONTROLLER]..............................................290 E-29 ERROR CODE [E-81] [DISCONNECTION IN NO. 1 FUEL INJECTOR SYSTEM].......................291 E-30 ERROR CODE [E-82] [DISCONNECTION IN NO.2 FUEL INJECTOR SYSTEM]........................292 E-31 ERROR CODE [E-83] [DISCONNECTION IN NO. 3 FUEL INJECTOR SYSTEM].......................293 E-32 ERROR CODE [E-84] [DISCONNECTION IN NO. 4 FUEL INJECTOR SYSTEM].......................294 E-33 ERROR CODE [E-85] [DISCONNECTION IN NO. 5 FUEL INJECTOR SYSTEM].......................295 E-34 ERROR CODE [E-86] [DISCONNECTION IN NO.6 FUEL INJECTOR SYSTEM]........................296 E-35 ERROR CODE [E-8A] [SHORT CIRCUIT IN NO. 1, NO.2, NO.3 FUEL INJECTOR SYSTEM] ..........297 E-36 ERROR CODE [E-8B] [SHORT CIRCUIT IN NO.3, NO.4, NO.5 FUEL INJECTOR SYSTEM] ...........300 13 DIASSEMBLY AND ASSEMBLY.........................................................................303 METHOD OF USING MANUAL.........................................................................304 PRECAUTIONS WHEN CARRYING OUT OPERATION........................................................305 SPECIAL TOOL LIST..............................................................................307 GENERAL DISASSEMBLY OF ENGINE..................................................................308 GENERAL ASSEMBLY OF ENGINE.....................................................................324 PROCEDURE FOR REMOVING AND INSTALLING FUEL SUPPLY PUMP UNIT....................................356

IMAGES PREVIEW OF THE MANUAL: