$34

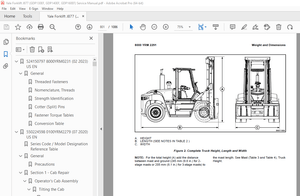

Komatsu 140-3 Series Diesel Engine Shop Manual SEBM022213 – PDF DOWNLOAD

Komatsu 140-3 Series Diesel Engine Shop Manual SEBM022213 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 140-3 Series Diesel Engine Shop Manual SEBM022213 – PDF DOWNLOAD

Language : English

Pages : 357

Downloadable : Yes

File Type : PDF

Size: 26.1 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 140-3 Series Diesel Engine Shop Manual SEBM022213 – PDF DOWNLOAD

The Komatsu 140-3 Series Diesel Engine Shop Manual SEBM022213 is a comprehensive technical reference guide for maintaining, repairing, and overhauling the Komatsu 140-3 series diesel engine. This engine is widely used in heavy-duty applications, such as construction equipment, mining vehicles, and marine vessels. The manual is an essential resource for mechanics, technicians, and service personnel responsible for servicing and maintaining these engines.

The shop manual is organized into several sections, each of which covers a specific aspect of the engine. These sections include:

- General Information: This section provides an overview of the engine, including specifications, operating guidelines, and maintenance intervals.

- Inspection and Adjustment: This section provides detailed instructions for inspecting and adjusting engine components, including the fuel injection system, valves, and timing belt.

- Engine Assembly: This section covers the removal and installation of major engine components, such as the cylinder head, crankshaft, and pistons. The manual includes detailed illustrations and specifications to help technicians perform these tasks safely and efficiently.

- Lubrication System: This section provides information on the engine’s lubrication system, including oil pump removal and installation, oil filter replacement, and oil pressure testing.

- Cooling System: This section provides information on the engine’s cooling system, including water pump removal and installation, radiator removal and installation, and thermostat replacement.

- Fuel System: This section covers the engine’s fuel system, including fuel pump removal and installation, fuel injector replacement, and fuel system troubleshooting.

- Air Intake and Exhaust System: This section provides information on the engine’s air intake and exhaust system, including air filter replacement, turbocharger removal and installation, and exhaust manifold removal and installation.

- Electrical System: This section provides information on the engine’s electrical system, including alternator and starter motor removal and installation, as well as troubleshooting procedures for electrical faults.

- Special Tools: This section lists the special tools required for servicing the engine, including part numbers and illustrations.

The Komatsu 140-3 Series Diesel Engine Shop Manual SEBM022213 is an essential resource for maintaining and repairing these engines. It provides a comprehensive guide to servicing the engine and includes detailed instructions, specifications, and illustrations to help technicians perform tasks accurately and safely. The manual is a valuable tool for ensuring that the Komatsu 140-3 series diesel engine continues to operate at peak performance, with maximum efficiency and reliability over its long service life.

TABLE OF CONTENTS:

Komatsu 140-3 Series Diesel Engine Shop Manual SEBM022213 – PDF DOWNLOAD

COVER…………………………………………………………………………………………………………………………… 1

CONTENTS………………………………………………………………………………………………………………………… 2

01 GENERAL………………………………………………………………………………………………………………………. 27

OUTLINE……………………………………………………………………………………………………………………… 28

SPECIFICATIONS……………………………………………………………………………………………………………….. 31

OVERALL DRAWING………………………………………………………………………………………………………………. 36

WEIGHT TABLE…………………………………………………………………………………………………………………. 43

ENGINE PERFORMANCE CURVE………………………………………………………………………………………………………. 45

11 STRUCTURE AND FUNCTION,MAINTENANCE STANDARD………………………………………………………………………………………. 55

INTAKE,EXHAUST SYSTEM…………………………………………………………………………………………………………. 56

INTAKE,EXHAUST EQUIPMENT…………………………………………………………………………………………………… 56

AIR CLEANER………………………………………………………………………………………………………………. 68

TURBOCHARGER……………………………………………………………………………………………………………… 71

AFTERCOOLER………………………………………………………………………………………………………………. 75

ENGINE………………………………………………………………………………………………………………………. 77

CYLINDER HEAD…………………………………………………………………………………………………………….. 77

CYLINDER BLOCK……………………………………………………………………………………………………………. 80

CYLINDER LINER……………………………………………………………………………………………………………. 83

MAIN MOVING PARTS…………………………………………………………………………………………………………. 84

CRANKSHAFT……………………………………………………………………………………………………………….. 86

CAMSHAFT…………………………………………………………………………………………………………………. 87

CAM FOLLOWER AND PUSH ROD………………………………………………………………………………………………….. 88

PISTON・PISTON RING・PISTON PIN………………………………………………………………………………………………. 89

CONNECTING ROD……………………………………………………………………………………………………………. 91

FLYWHEEL,FLYWHEEL HOUSING………………………………………………………………………………………………….. 92

VIBRATION DAMPER………………………………………………………………………………………………………….. 94

TIMING GEAR………………………………………………………………………………………………………………. 95

VALVE SYSTEM……………………………………………………………………………………………………………… 99

VALVE,VALVE GUIDE………………………………………………………………………………………………………….101

ROCKER ARM AND SHAFT……………………………………………………………………………………………………….103

CROSSHEAD AND GUIDE………………………………………………………………………………………………………..104

LUBRICATION SYSTEM…………………………………………………………………………………………………………….105

LUBRICATION SYSTEM DIAGRAM………………………………………………………………………………………………….105

OIL PUMP………………………………………………………………………………………………………………….106

OIL FILTER………………………………………………………………………………………………………………..109

OIL COOLER………………………………………………………………………………………………………………..110

FUEL SYSTEM…………………………………………………………………………………………………………………..112

FUEL SYSTEM DIAGRAM………………………………………………………………………………………………………..112

OUTLINE OF CRI SYSTEM………………………………………………………………………………………………………113

FUEL PIPING……………………………………………………………………………………………………………….126

FUEL COOLER……………………………………………………………………………………………………………….128

FUEL FILTER……………………………………………………………………………………………………………….129

COOLANT SYSTEM………………………………………………………………………………………………………………..130

COOLING SYSTEM DIAGRAM……………………………………………………………………………………………………..130

WATER PUMP………………………………………………………………………………………………………………..133

THERMOSTAT………………………………………………………………………………………………………………..136

CORROSION RESISTOR…………………………………………………………………………………………………………138

COOLING FAN DRIVE………………………………………………………………………………………………………….140

ACCESSORIES…………………………………………………………………………………………………………………..151

FRONT PTO…………………………………………………………………………………………………………………151

AIR COMPRESSOR…………………………………………………………………………………………………………….154

EXHAUST BRAKE……………………………………………………………………………………………………………..157

ELECTRICAL COMPONENTS………………………………………………………………………………………………………….161

ALTERNATOR………………………………………………………………………………………………………………..161

STARTING MOTOR…………………………………………………………………………………………………………….168

STARTING AID………………………………………………………………………………………………………………170

12 TESTING AND ADJUSTING…………………………………………………………………………………………………………..172

STANDARD VALUE TABLE FOR TESTING,ADJUSTING,AND TROUBLESHOOTING……………………………………………………………………..173

STANDARD VALUE TABLE FOR ELECTRICAL RELATED PARTS…………………………………………………………………………………178

TOOLS FOR TESTING,ADJUSTING,AND TROUBLESHOOTING…………………………………………………………………………………..180

MEASURING INTAKE AIR PRESSURE(BOOST PRESSURE)…………………………………………………………………………………….181

MEASURING EXHAUST TEMPERATURE…………………………………………………………………………………………………..181

ADJUSTING VALVE CLEARANCE………………………………………………………………………………………………………182

MEASURING COMPRESSION PRESSURE………………………………………………………………………………………………….183

MEASURING BLOW-BY PRESSURE……………………………………………………………………………………………………..184

MEASURING OIL PRESSURE…………………………………………………………………………………………………………185

HANDLING EQUIPMENT IN FUEL CIRCUIT………………………………………………………………………………………………185

RELEASING REMAINING PRESSURE IN FUEL SYSTEM………………………………………………………………………………………186

MEASURING FUEL PRESSURE………………………………………………………………………………………………………..186

REDUCED CYLINDER MODE OPERATION…………………………………………………………………………………………………187

BLEEDING AIR FROM FUEL SYSTEM…………………………………………………………………………………………………..188

CHECK FOR LEAKAGE IN FUEL SYSTEM………………………………………………………………………………………………..190

ADJUSTING SPEED SENSOR…………………………………………………………………………………………………………191

TESTING AND ADJUSTING ALTERNATOR BELT TENSION…………………………………………………………………………………….191

TESTING AND ADJUSTING FAN BELT TENSION…………………………………………………………………………………………..192

HANDLING CONTROLLER HIGH VOLTAGE CIRCUIT…………………………………………………………………………………………194

RUN-IN STANDARD……………………………………………………………………………………………………………….195

PERFORMANCE TEST STANDARDS……………………………………………………………………………………………………..197

TROUBLESHOOTING OF ENGINE SYSTEM(S MODE)…………………………………………………………………………………………203

POINTS TO REMEMBER WHEN TROUBLESHOOTING………………………………………………………………………………………204

METHOD OF USING TROUBLESHOOTING CHARTS……………………………………………………………………………………….205

S-1 STARTING PERFORMANCE IS POOR(STARTING ALWAYS TAKES TIME)……………………………………………………………………208

S-2 ENGINE DOES NOT START…………………………………………………………………………………………………..209

S-3 ENGINE DOES NOT PICK UP SMOOTHLY(FOLLOW-UP IS POOR)………………………………………………………………………..212

S-4 ENGINE STOPS DURING OPERATIONS…………………………………………………………………………………………..213

S-5 ENGINE DOES NOT ROTATE SMOOTHLY(HUNTING)………………………………………………………………………………….214

S-6 ENGINE LACKS OUTPUT(OR LACKS POWER)………………………………………………………………………………………215

S-7 EXHAUST SMOKE IS BLACK(INCOMPLETE COMBUSTION)……………………………………………………………………………..216

S-8 OIL CONSUMPTION IS EXCESSIVE(OR EXHAUST SMOKE IS BLUE)……………………………………………………………………..217

S-9 OIL BECOMES CONTAMINATED QUICKLY…………………………………………………………………………………………218

S-10 FUEL CONSUMPTION IS EXCESSIVE…………………………………………………………………………………………..219

S-11 OIL IS IN COOLING WATER(OR WATER SPURTS BACK,OR WATER LEVEL GOES DOWN)………………………………………………………220

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP(DROP IN OIL PRESSURE)………………………………………………………………….221

S-13 OIL LEVEL RISES(WATER,FUEL IN OIL)………………………………………………………………………………………222

S-14 WATER TEMPERATURE BECOMES TOO HIGH(OVERHEATING)…………………………………………………………………………..223

S-15 ABNORMAL NOISE IS MADE…………………………………………………………………………………………………224

S-16 VIBRATION IS EXCESSIVE…………………………………………………………………………………………………225

TROUBLESHOOTING OF ELECTRICAL SYSTEM(E MODE)……………………………………………………………………………………..226

POINTS TO REMEMBER WHEN TROUBLESHOOTING………………………………………………………………………………………228

METHOD OF USING TROUBLESHOOTING FLOWCHART…………………………………………………………………………………….229

ERROR CODE DISPLAYS AND POINTS TO REMEMBER WHEN TROUBLESHOOTING…………………………………………………………………230

ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ERROR CODE IS DISPLAYED………………………………………………….233

E-1 ERROR CODE [E-1b] [ABNORMALITY IN NE REVOLUTION SENSOR SYSTEM]………………………………………………………………241

E-2 ERROR CODE [E-1C] [ABNORMALITY IN G REVOLUTION SENSOR SYSTEM]……………………………………………………………….242

E-3 ERROR CODE [E-20] [ABNORMALITY IN MODEL SELECTION SYSTEM]…………………………………………………………………..243

E-4 ERROR CODE [E-22] [OVERRUN]……………………………………………………………………………………………..244

E-5 ERROR CODE [E-23] [OVERHEAT]…………………………………………………………………………………………….244

E-6 ERROR CODE [E-24] [DROP IN OIL PRESSURE]………………………………………………………………………………….245

E-7 ERROR CODE [E-30] [ABNORMALITY IN IDLING VALIDATION SIGNAL SYSTEM]…………………………………………………………..246

E-8 ERROR CODE [E-31] [ABNORMALITY IN THROTTLE SENSOR SYSTEM]…………………………………………………………………..248

E-9 ERROR CODE [E-34] [ABNORMALITY IN WATER TEMPERATURE HIGH-TEMPERATURE SENSOR SYSTEM]……………………………………………251

E-10 ERROR CODE [E-36] [ABNORMALITY IN OIL PRESSURE SWITCH SYSTEM]………………………………………………………………252

E-11 ERROR CODE [E-3C] [ABNORMALITY IN BOOST PRESSURE SENSOR SYSTEM]…………………………………………………………….254

E-12 ERROR CODE [E-3D] [ABNORMALITY IN FUEL TEMPERATURE SENSOR SYSTEM]…………………………………………………………..255

E-13 ERROR CODE [E-50] [ABNORMALITY IN PREHEATING RELAY CONNECTING POINT SYSTEM]………………………………………………….256

E-14 ERROR CODE [E-51] [ABNORMALITY IN PREHEAT RELAY COIL SYSTEM]……………………………………………………………….257

E-15 ERROR CODE [E-54] [SHORT CIRCUIT IN STARTING SWITCH C SYSTEM]………………………………………………………………258

E-16 ERROR CODE [E-56] [POWER SOURCE SYSTEM ABNORMALITY 1]……………………………………………………………………..259

E-17 ERROR CODE [E-57] [POWER SOURCE SYSTEM ABNORMALITY 2]……………………………………………………………………..261

E-18 ERROR CODE [E-5A] [ABNORMALITY IN FUEL INJECTION QUANTITY CONTROL SWITCH SIGNAL]……………………………………………..262

E-19 ERROR CODE [E-6A] [ABNORMALITY IN WATER TEMPERATURE LOW-TEMPERATURE SENSOR SYSTEM]……………………………………………263

E-20 ERROR CODE [E-70] [EXCESS CURRENT IN FUEL SUPPLY PUMP PCV1 SYSTEM]………………………………………………………….264

E-21 ERROR CODE [E-71] [EXCESS CURRENT IN FUEL SUPPLY PUMP PCV2 SYSTEM]………………………………………………………….265

E-22 ERROR CODE [E-74] [DISCONNECTION IN FUEL SUPPLY PUMP PCV1 SYSTEM]…………………………………………………………..266

E-23 ERROR CODE [E-75] [DISCONNECTION IN FUEL SUPPLY PUMP PCV2 SYSTEM]…………………………………………………………..267

E-24 ERROR CODE [E-77] [ABNORMALITY IN COMMON RAIL FUEL PRESSURE SENSOR SYSTEM]…………………………………………………..268

E-25 ERROR CODE [E-79] [COMMON RAIL FUEL HIGH PRESSURE ABNORMALITY 1];ERROR CODE [E-7A] [COMMON RAIL FUEL HIGH PRESSURE ABNORMALITY 2]….269

E-26 ERROR CODE [E-7b] [FUEL SUPPLY PUMP NON-FORCE FEED 1];ERROR CODE [E-7C] [FUEL SUPPLY PUMP NON-FORCE FEED 2]……………………..270

E-27 ERROR CODE [E-7d] [ABNORMALITY IN COMMON RAIL FUEL PRESSURE]……………………………………………………………….272

E-28 ERROR CODE [E-80] [DEFECTIVE CONTROLLER]…………………………………………………………………………………272

E-29 ERROR CODE [E-81] [DISCONNECTION IN NO.1 FUEL INJECTOR SYSTEM]……………………………………………………………..273

E-30 ERROR CODE [E-82] [DISCONNECTION IN NO.2 FUEL INJECTOR SYSTEM]……………………………………………………………..274

E-31 ERROR CODE [E-83] [DISCONNECTION IN NO.3 FUEL INJECTOR SYSTEM]……………………………………………………………..275

E-32 ERROR CODE [E-84] [DISCONNECTION IN NO.4 FUEL INJECTOR SYSTEM]……………………………………………………………..276

E-33 ERROR CODE [E-85] [DISCONNECTION IN NO.5 FUEL INJECTOR SYSTEM]……………………………………………………………..277

E-34 ERROR CODE [E-86] [DISCONNECTION IN NO.6 FUEL INJECTOR SYSTEM]……………………………………………………………..278

E-35 ERROR CODE [E-8A] [SHORT CIRCUIT IN NO.1,NO.2,NO.3 FUEL INJECTOR SYSTEM]…………………………………………………….279

E-36 ERROR CODE [E-8b] [SHORT CIRCUIT IN NO.4,NO.5,NO.6 FUEL INJECTOR SYSTEM]…………………………………………………….282

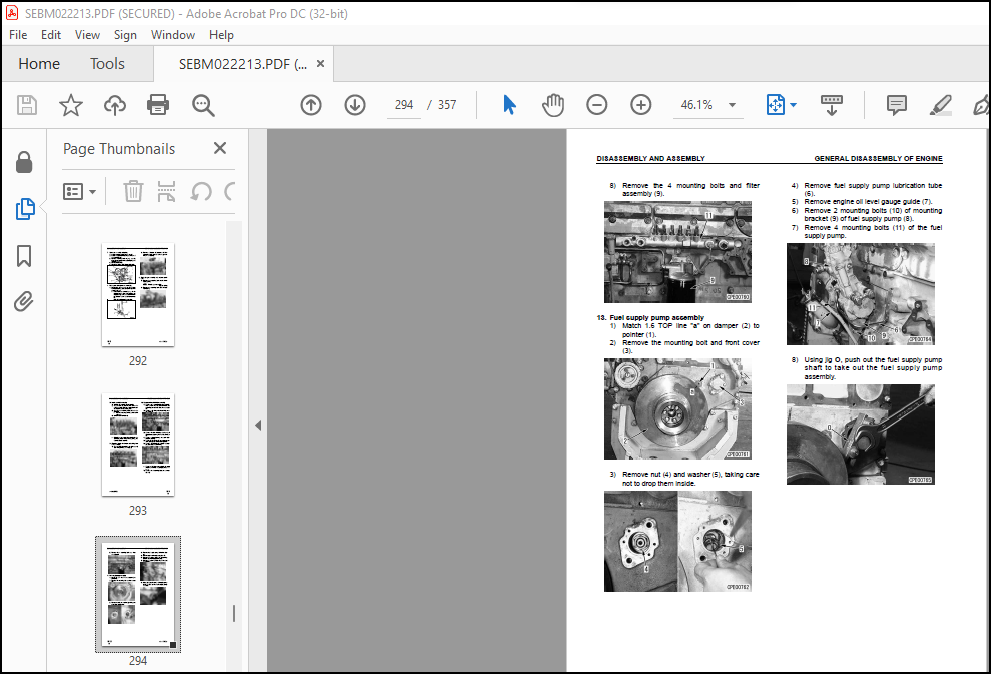

13 DISASSEMBLY AND ASSEMBLY………………………………………………………………………………………………………..285

METHOD OF USING MANUAL…………………………………………………………………………………………………………286

PRECAUTIONS WHEN CARRYING OUT OPERATION………………………………………………………………………………………….287

SPECIAL TOOL LIST……………………………………………………………………………………………………………..289

GENERAL DISASSEMBLY OF ENGINE…………………………………………………………………………………………………..290

GENERAL ASSEMBLY OF ENGINE……………………………………………………………………………………………………..306

PROCEDURE FOR REMOVING AND INSTALLING FUEL SUPPLY PUMP UNIT………………………………………………………………………..338

15 REPAIR AND REPLACEMENT OF PARTS………………………………………………………………………………………………….340

CYLINDER HEAD…………………………………………………………………………………………………………………341

GRINDING OF FITTING FACE OF CYLINDER HEAD…………………………………………………………………………………….341

REPLACING VALVE SEAT INSERT…………………………………………………………………………………………………342

PRESSURE TEST……………………………………………………………………………………………………………..347

REPLACING VALVE GUIDE………………………………………………………………………………………………………348

REPLACING CROSSHEAD GUIDE…………………………………………………………………………………………………..349

GRINDING VALVE…………………………………………………………………………………………………………….350

CYLINDER BLOCK………………………………………………………………………………………………………………..351

REPLACING CAM BUSHING………………………………………………………………………………………………………351

REPLACING CRANKSHAFT GEAR…………………………………………………………………………………………………..354

REPLACING CAM GEAR…………………………………………………………………………………………………………355

REPLACING FLYWHEEL RING GEAR………………………………………………………………………………………………..356

REPLACING CONNECTING ROD SMALL END BUSHING……………………………………………………………………………………357