Starting from:

$36

Home

Komatsu

KOMATSU 155-4 SERIES DIESEL ENGINE SERVICE REPAIR MANUAL (SEBE6120A05) KOMATSU 155-4 – PDF DOWNLOAD

KOMATSU 155-4 SERIES DIESEL ENGINE SERVICE REPAIR MANUAL (SEBE6120A05) KOMATSU 155-4 – PDF DOWNLOAD

KOMATSU 155-4 SERIES DIESEL ENGINE SERVICE REPAIR MANUAL (SEBE6120A05) KOMATSU 155-4

IMAGE PREVIEW:

TABLE OF CONTENTS:

KOMATSU 155-4 SERIES DIESEL ENGINE SERVICE REPAIR MANUAL (SEBE6120A05) KOMATSU 155-4

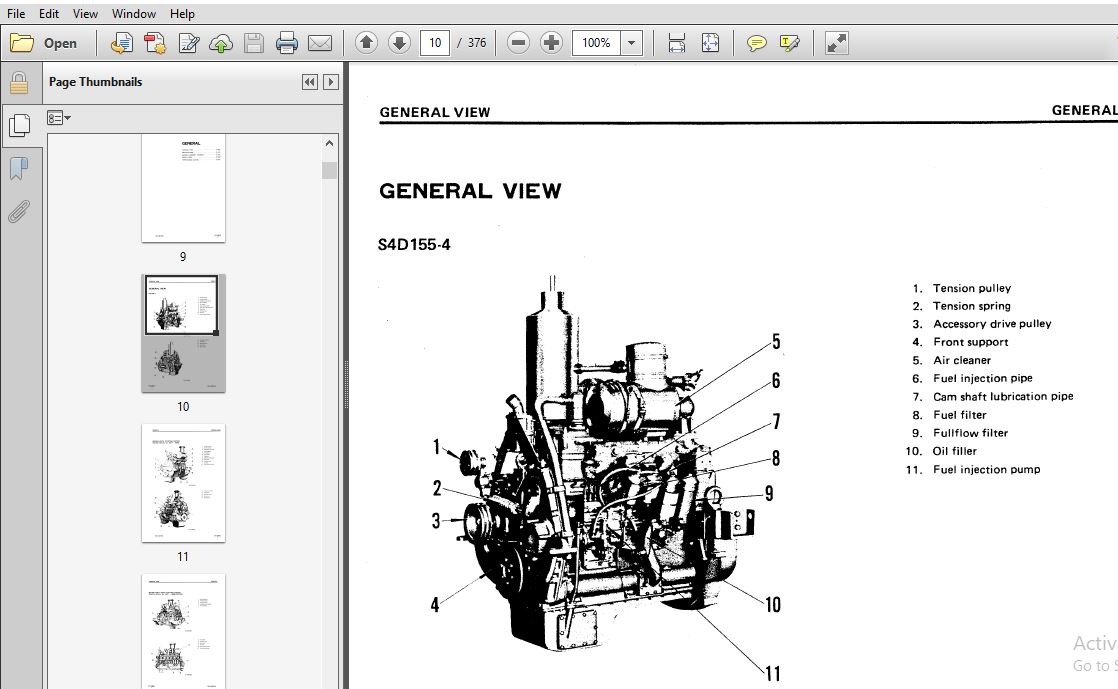

COVER.................................................... 1 CONTENTS................................................. 5 01 GENERAL............................................... 8 GENERAL.............................................. 9 GENERAL VIEW..................................... 10 SPECIFICATIONS................................... 17 GENERAL ASSEMBLY DRAWING......................... 25 WEIGHT TABLE..................................... 37 ENGINE PERFORMANCE CURVE......................... 38 11 STRUCTURE AND FUNCTION................................ 49 STRUCTURE AND FUNCTION............................... 50 GENERAL STRUCTURE ............................... 51 INTAKE AND EXHAUST SYSTEM........................ 55 TURBOCHARGER..................................... 59 AFTER COOLER..................................... 61 ENGINE BODY...................................... 62 CYLINDER HEAD................................ 62 ROCKER ARM................................... 64 VALVE SYSTEM................................. 65 CYLINDER BLOCK............................... 69 MAIN REVOLVING............................... 73 TIMING GEAR.................................. 77 BALANCER SHAFT............................... 79 P.T.O........................................ 80 LUBRICATION SYSTEM............................... 83 LUBRICATION SYSTEM CHART..................... 83 OIL PUMP..................................... 87 FULL FLOW OIL FILTER......................... 89 BY-PASS OIL FILTER........................... 94 OIL COOLER................................... 95 TORQUE CONVERTER OIL COOLER.................. 97 FUEL SYSTEM...................................... 98 FUEL SYSTEM CHART............................ 98 FUEL PIPING..................................100 FUEL INJECTION PUMP..........................103 FUEL INJECTION PUMP DRIVE....................120 FUEL INJECTION NOZZLE........................121 FUEL FILTER..................................123 COOLING SYSTEM...................................125 COOLING SYSTEM CHART.........................125 WATER PUMP...................................128 THERMOSTAT...................................132 CORROSION RESISTOR...........................133 ACCESSORY........................................134 ALTERNATOR...................................134 DYNAMO ......................................137 STARTING MOTOR...............................138 STARTING ENGINE..............................140 AIR COMPRESSOR...............................147 ENGINE STARTING AIDS.........................152 12 TESTING AND ADJUSTING................................. 0 TESTING AND ADJUSTING................................158 PREPARATION......................................159 ADJUSTING FUEL INJECTION TIMING..................162 PERFORMANCE TEST ON FEED PUMP....................164 FUEL INJECTION PUMP TABLE........................165 ENGINE PERFORMANCE TEST..........................167 STARTING ENGINE (2G84) PERFORMANCE TEST..........177 TESTING AND ADJUSTING TOOL LIST..................179 TESTING AND ADJUSTING DATA.......................180 13 DISASSEMBLY AND ASSEMBLY..............................188 DISASSEMBLY AND ASSEMBLY.............................189 GENERAL DISASSEMBLY OF ENGINE ASSEMBLY...........190 GENERAL ASSEMBLY OF ENGINE ASSEMBLY..............212 DISASSEMBLY OF WATER PUMP........................247 ASSEMBLY OF WATER PUMP...........................248 DISASSEMBLY OF TURBOCHARGER (KTR100,130).........250 ASSEMBLY OF TURBOCHARGER (KTR100,130)............254 DISASSEMBLY OF TURBOCHARGER (RH1521).............258 ASSEMBLY OF TURBOCHARGER (RH1521)................260 DISASSEMBLY OF STARTING ENGINE (2G84)............262 ASSEMBLY OF STARTING ENGINE (2G84)...............264 DISASSEMBLY OF 2G84 POWER TRAIN..................267 ASSEMBLY OF 2G84 POWER TRAIN.....................268 DISASSEMBLY OF FUEL INJECTION PUMP...............269 ASSEMBLY OF FUEL INJECTION PUMP..................280 14 MAINTENANCE STANDARD..................................284 MAINTENANCE STANDARD.................................285 TURBOCHARGER.....................................286 CYLINDER HEAD....................................290 VALVE,VALVE GUIDE................................292 CROSSHEAD,CROSSHEAD GUIDE........................293 ROCKER HOUSING...................................294 TAPPET,PUSH ROD..................................295 CYLINDER BLOCK...................................296 CYLINDER LINER...................................300 CRANKSHAFT.......................................302 CAMSHAFT.........................................304 BALANCER SHAFT...................................305 TIMING GEAR......................................306 PISTON,PISTON RING AND PISTON PIN................308 CONNECTING ROD...................................310 OIL PUMP.........................................312 RELIEF VALVE,REGULATOR VALVE AND SAFETY VALVE....314 PISTON COOLING VALVE,OIL COOLER BY-PASS VALVE....316 WATER PUMP.......................................318 STARTING ENGINE (2G84)...........................319 AIR COMPRESSOR...................................323 15 REPAIR AND REPLACEMENT................................328 REPAIR AND REPLACEMENT...............................329 CYLINDER HEAD SECTION............................330 CYLINDER BLOCK SECTION...........................345 PRESS FITTING OF BUSHING.........................372 REPLACING SHRINK-FITTED GEAR.....................375 OTHERS...........................................376

DESCRIPTION:

KOMATSU 155-4 SERIES DIESEL ENGINE SERVICE REPAIR MANUAL (SEBE6120A05) KOMATSU 155-4

- 1.Before carrying out any greasing or repairs, read all the precautions given on the decals which are fixed to the machine.

- 2.When carrying out any operation, always wear safety shoes and helmet. Do not wear loose work clothes, or clothes with buttons missing. Always wear safety glasses when hitting parts with a hammer. Always wear safety glasses when grinding parts with a grinder. etc.

- 3. If welding repalrs are needed. always have a trained, experienced welder carry out the work. When carrying out welding work. always wear welding gloves, apron. glasses, cap and other clothes suited for welding work.

- 4.When carrying out any operation with two or more workers, always agree on the operating procedure before starting. Always inform your fellow workers before starting any step of the operation. Before starting work, hang UNDER REPAIR signs on the controls in the operator’s compartment.

- 5.Keep all tools in good condition and learn the correct way to use them.

1 file (19.1MB)