$39

Komatsu 170E-7 Series Engine Shop Manual SEN06580-06 – PDF DOWNLOAD

Komatsu 170E-7 Series Engine Shop Manual SEN06580-06 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 170E-7 Series Engine Shop Manual SEN06580-06 – PDF DOWNLOAD

Language : English

Pages : 588

Downloadable : Yes

File Type : PDF

Size: 22.6 MB

TABLE OF CONTENTS:

Komatsu 170E-7 Series Engine Shop Manual SEN06580-06 – PDF DOWNLOAD

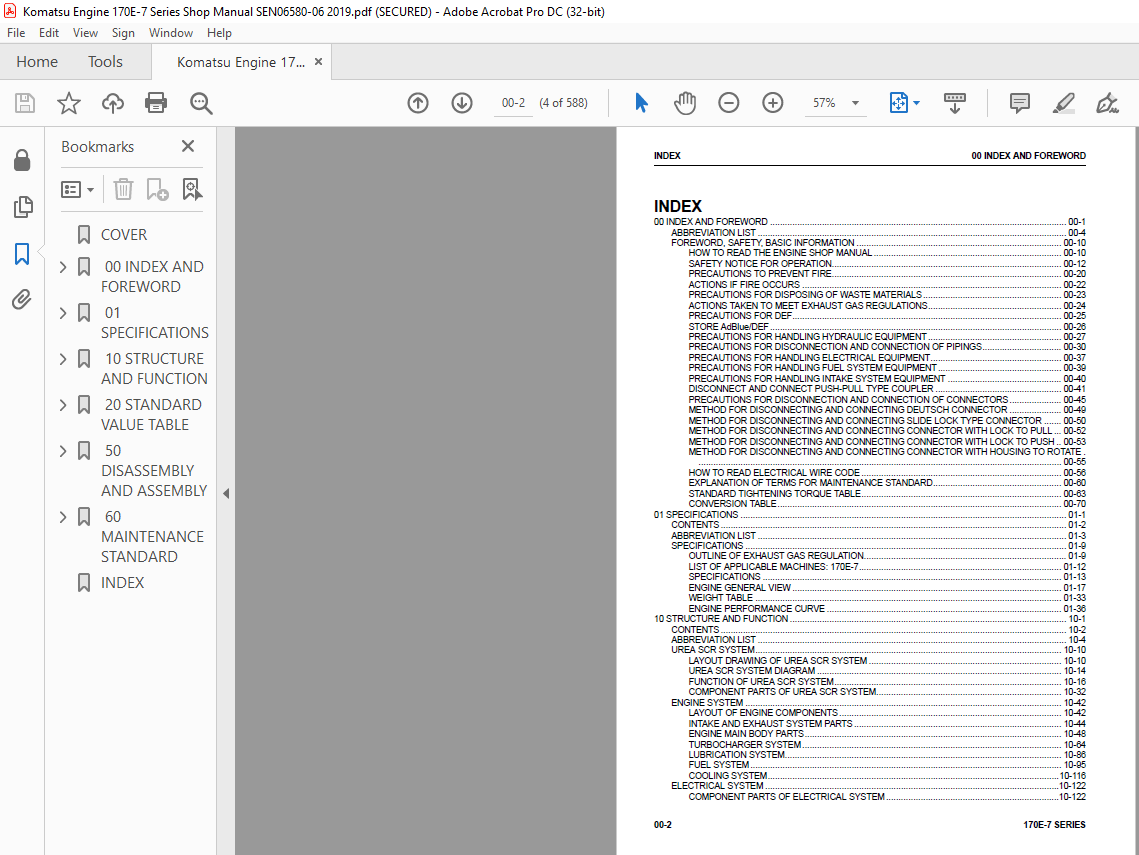

00 INDEX AND FOREWORD 00-1

ABBREVIATION LIST 00-4

FOREWORD, SAFETY, BASIC INFORMATION 00-10

HOW TO READ THE ENGINE SHOP MANUAL 00-10

SAFETY NOTICE FOR OPERATION 00-12

PRECAUTIONS TO PREVENT FIRE 00-20

ACTIONS IF FIRE OCCURS 00-22

PRECAUTIONS FOR DISPOSING OF WASTE MATERIALS 00-23

ACTIONS TAKEN TO MEET EXHAUST GAS REGULATIONS 00-24

PRECAUTIONS FOR DEF 00-25

STORE AdBlue/DEF 00-26

PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT 00-27

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF PIPINGS 00-30

PRECAUTIONS FOR HANDLING ELECTRICAL EQUIPMENT 00-37

PRECAUTIONS FOR HANDLING FUEL SYSTEM EQUIPMENT 00-39

PRECAUTIONS FOR HANDLING INTAKE SYSTEM EQUIPMENT 00-40

DISCONNECT AND CONNECT PUSH-PULL TYPE COUPLER 00-41

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF CONNECTORS 00-45

METHOD FOR DISCONNECTING AND CONNECTING DEUTSCH CONNECTOR 00-49

METHOD FOR DISCONNECTING AND CONNECTING SLIDE LOCK TYPE CONNECTOR 00-50

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PULL 00-52

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PUSH 00-53

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH HOUSING TO ROTATE

00-55

HOW TO READ ELECTRICAL WIRE CODE 00-56

EXPLANATION OF TERMS FOR MAINTENANCE STANDARD 00-60

STANDARD TIGHTENING TORQUE TABLE 00-63

CONVERSION TABLE 00-70

01 SPECIFICATIONS 01-1

CONTENTS 01-2

ABBREVIATION LIST 01-3

SPECIFICATIONS 01-9

OUTLINE OF EXHAUST GAS REGULATION 01-9

LIST OF APPLICABLE MACHINES: 170E-7 01-12

SPECIFICATIONS 01-13

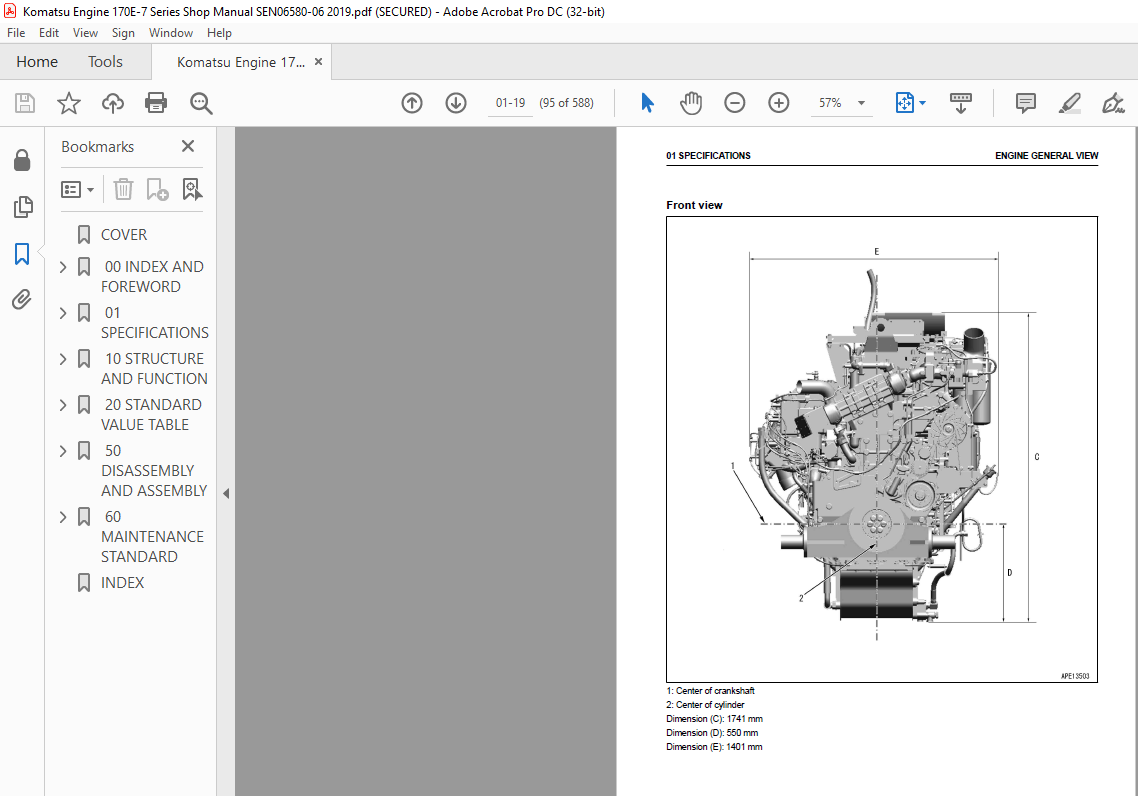

ENGINE GENERAL VIEW 01-17

WEIGHT TABLE 01-33

ENGINE PERFORMANCE CURVE 01-36

10 STRUCTURE AND FUNCTION 10-1

CONTENTS 10-2

ABBREVIATION LIST 10-4

UREA SCR SYSTEM 10-10

LAYOUT DRAWING OF UREA SCR SYSTEM 10-10

UREA SCR SYSTEM DIAGRAM 10-14

FUNCTION OF UREA SCR SYSTEM 10-16

COMPONENT PARTS OF UREA SCR SYSTEM 10-32

ENGINE SYSTEM 10-42

LAYOUT OF ENGINE COMPONENTS 10-42

INTAKE AND EXHAUST SYSTEM PARTS 10-44

ENGINE MAIN BODY PARTS 10-48

TURBOCHARGER SYSTEM 10-64

LUBRICATION SYSTEM 10-86

FUEL SYSTEM 10-95

COOLING SYSTEM 10-116

ELECTRICAL SYSTEM 10-122

COMPONENT PARTS OF ELECTRICAL SYSTEM 10-122

INDEX 00 INDEX AND FOREWORD

00-2 170E-7 SERIES

SENSOR 10-151

20 STANDARD VALUE TABLE 20-1

CONTENTS 20-2

ABBREVIATION LIST 20-3

STANDARD VALUE TABLE FOR ENGINE 20-9

STANDARD VALUE TABLE FOR ENGINE: SAA6D170E-7 (D375A-8, D375A-8E0, D375AI-8,

D375AI-8E0) 20-9

STANDARD VALUE TABLE FOR ENGINE: SAA6D170E-7(HD465-8, HD465-8E0, HD605-8,

HD605-8E0) 20-11

STANDARD VALUE TABLE FOR ENGINE: SAA6D170E-7(PC1250-11, PC1250-11E0, PC1250LC-11,

PC1250SP-11, PC1250SP-11E0) 20-13

STANDARD VALUE TABLE FOR ENGINE: SAA6D170E-7 (WA600-8, WA600-8E0) 20-15

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD 20-17

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D170E-7 (D375A-8,

D375A-8E0, D375AI-8, D375AI-8E0) 20-17

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D170E-7(HD465-8,

HD465-8E0, HD605-8, HD605-8E0) 20-19

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D170E-7(PC1250-11,

PC1250-11E0, PC1250LC-11, PC1250SP-11, PC1250SP-11E0) 20-21

RUNNING-IN STANDARD AND PERFORMANCE TEST STANDARD: SAA6D170E-7 (WA600-8,

WA600-8E0) 20-23

50 DISASSEMBLY AND ASSEMBLY 50-1

CONTENTS 50-2

ABBREVIATION LIST 50-3

RELATED INFORMATION ON DISASSEMBLY AND ASSEMBLY 50-9

HOW TO READ THIS MANUAL 50-9

COATING MATERIALS LIST 50-11

SPECIAL TOOLS LIST 50-15

SKETCHES OF SPECIAL TOOLS 50-17

ENGINE SYSTEM 50-18

DISASSEMBLE AND ASSEMBLE ENGINE GENERALLY 50-18

REMOVE AND INSTALL SUPPLY PUMP ASSEMBLY 50-197

REMOVE AND INSTALL ENGINE FRONT OIL SEAL 50-220

REMOVE AND INSTALL ENGINE REAR OIL SEAL 50-223

60 MAINTENANCE STANDARD 60-1

CONTENTS 60-2

ABBREVIATION LIST 60-3

ENGINE SYSTEM 60-9

INTAKE AND EXHAUST SYSTEM PARTS 60-9

ENGINE MAIN BODY PARTS 60-10

LUBRICATION SYSTEM 60-35

COOLING SYSTEM 60-40

INDEX 1

DESCRIPTION:

Komatsu 170E-7 Series Engine Shop Manual SEN06580-06 – PDF DOWNLOAD

FOREWORD, SAFETY, BASIC INFORMATION

HOW TO READ THE ENGINE SHOP MANUAL

• Some of the attachments and options described in this shop manual may not be available in some areas. If

they are required, consult your Komatsu distributor.

• The materials and specifications are subject to change without notice.

• Shop manuals are available for “machine part” and “engine part”. For the engine unit, see the shop manual

for the machine which has the same engine model.

• Actual machine may differ from the images which are contained in this manual. A typical model is shown in

the illustrations of this shop manual.

Composition of the shop manual

This shop manual contains technical information necessary to perform services in workshops. It is divided into

the following chapters for the ease of use.

00 INDEX AND FOREWORD

This section describes the index, foreword, safety, and basic information.

01 SPECIFICATIONS

This section describes the specifications of the machine.

10 STRUCTURE AND FUNCTION

This section describes the structure and operation of each component with respect to each system. “STRUCTURE

AND FUNCTION” is helpful in not only understanding the structure of each component but performing

troubleshooting.

20 STANDARD VALUE TABLE

This section describes the standard values for new machine and failure criteria for testing and adjusting, and

troubleshooting. Use the standard values table to check the standard values for testing and adjusting, and judge

troubles in troubleshooting.

50 DISASSEMBLY AND ASSEMBLY

This section describes the special tools, work procedures, and safety precautions necessary for removal, installation,

disassembly, and assembly of the components and parts. In addition, tightening torques, quantity, and

weight of the coating materials, lubricants, and coolant necessary to these works are shown.

60 MAINTENANCE STANDARD

This section describes the maintenance standard value of each component. The maintenance standard shows

the criteria and remedies for disassembly and assembly.

IMAGES PREVIEW OF THE MANUAL: