$36.95

Komatsu 3D95E-1 Series Diesel Engine Shop Manual SEN06834-02 – PDF DOWNLOAD

Komatsu 3D95E-1 Series Diesel Engine Shop Manual SEN06834-02 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 3D95E-1 Series Diesel Engine Shop Manual SEN06834-02 – PDF DOWNLOAD

Language : English

Pages : 386

Downloadable : Yes

File Type : PDF

Size: 20.2 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 3D95E-1 Series Diesel Engine Shop Manual SEN06834-02 – PDF DOWNLOAD

The Komatsu 3D95E-1 Series Diesel Engine Shop Manual SEN06834-02 is a comprehensive guide that provides detailed information on the construction, operation, and maintenance of the 3D95E-1 series diesel engine. The manual is designed to help mechanics and technicians with repair and maintenance procedures and is an essential resource for anyone responsible for the upkeep of these engines.

- The manual begins with an introduction to the 3D95E-1 series diesel engine, which provides information on the engine’s specifications, performance characteristics, and construction features. The manual also outlines the engine’s maintenance schedule and recommended service intervals.

- The manual then provides detailed instructions on the disassembly, inspection, repair, and reassembly of various engine components. The manual covers topics such as the cylinder block, cylinder head, crankshaft, pistons, connecting rods, camshaft, and timing gears.

- The cylinder block section provides detailed instructions on the removal and installation of the cylinder block, as well as instructions for inspection, repair, and reassembly of various cylinder block components, such as the cylinder liners and main bearings. The cylinder head section covers the inspection, repair, and replacement of various cylinder head components, such as valves, springs, and guides. The crankshaft section provides instructions on the inspection, repair, and replacement of various crankshaft components, such as the main and connecting rod bearings. The piston section covers the inspection, repair, and replacement of various piston components, such as rings and wrist pins. The connecting rod section provides instructions on the inspection, repair, and replacement of various connecting rod components, such as bearings and bolts. The camshaft and timing gears section covers the inspection, repair, and replacement of various camshaft and timing gear components, such as bearings, gears, and chains.

- The manual also includes sections on the fuel injection system, lubrication system, and cooling system. These sections provide detailed instructions on the repair and maintenance of these critical engine systems. The fuel injection section covers topics such as the injection pump, fuel injectors, and fuel lines. The lubrication system section covers topics such as the oil pump, oil filter, and oil cooler. The cooling system section covers topics such as the radiator, water pump, and thermostat.

- In addition to these repair and maintenance procedures, the manual includes a section on troubleshooting. This section provides detailed instructions on how to diagnose and fix common problems that may occur during the operation of the engine. This section includes a list of common symptoms, possible causes, and recommended solutions for each problem.

- Overall, the Komatsu 3D95E-1 Series Diesel Engine Shop Manual SEN06834-02 is an essential resource for mechanics and technicians who are responsible for the repair and maintenance of the 3D95E-1 series diesel engine. It provides detailed information on how to disassemble, inspect, repair, and reassemble the engine’s various components, as well as important safety information to help prevent accidents and injuries. The manual is a must-have for anyone who needs to perform repairs or maintenance on these engines.

TABLE OF CONTENTS:

Komatsu 3D95E-1 Series Diesel Engine Shop Manual SEN06834-02 – PDF DOWNLOAD

COVER……………………………………………………………………………………………………………………………………. 1

00 INDEX AND FOREWORD…………………………………………………………………………………………………………………….. 3

INDEX……………………………………………………………………………………………………………………………….. 4

FOREWORD, SAFETY, BASIC INFORMATION…………………………………………………………………………………………………….. 6

HOW TO READ THE ENGINE SHOP MANUAL………………………………………………………………………………………………….. 6

SAFETY NOTICE FOR OPERATION………………………………………………………………………………………………………… 8

PRECAUTIONS TO PREVENT FIRE………………………………………………………………………………………………………… 16

ACTIONS IF FIRE OCCURS…………………………………………………………………………………………………………….. 18

PRECAUTIONS WHEN YOU DISPOSE OF WASTE MATERIALS………………………………………………………………………………………. 19

ENGINE TECHNOLOGY TO CONFORM EXHAUST GAS EMISSION…………………………………………………………………………………….. 20

PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT…………………………………………………………………………………………. 21

PRECAUTIONS WHEN YOU DISCONNECT AND CONNECT PIPINGS…………………………………………………………………………………… 24

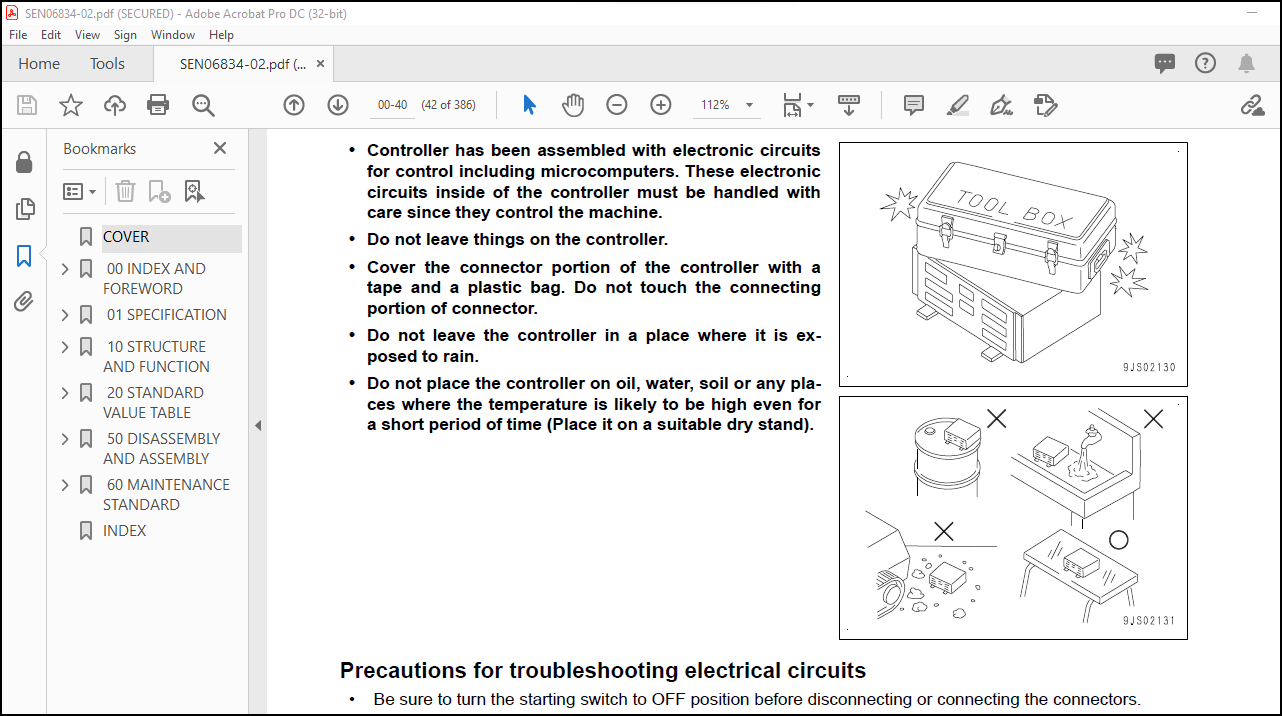

PRECAUTIONS WHEN YOU HANDLE ELECTRICAL EQUIPMENT……………………………………………………………………………………… 31

PRECAUTIONS FOR HANDLING FUEL SYSTEM EQUIPMENT……………………………………………………………………………………….. 33

PRECAUTIONS FOR HANDLING INTAKE SYSTEM EQUIPMENT……………………………………………………………………………………… 34

DISCONNECT AND CONNECT PUSH-PULL TYPE COUPLER………………………………………………………………………………………… 35

METHOD FOR DISCONNECTING AND CONNECTING TYPE 1 PUSH-PULL TYPE COUPLER……………………………………………………………….. 35

METHOD FOR DISCONNECTING AND CONNECTING TYPE 2 PUSH-PULL TYPE COUPLER……………………………………………………………….. 36

METHOD FOR DISCONNECTING AND CONNECTING TYPE 3 PUSH-PULL TYPE COUPLER……………………………………………………………….. 37

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF CONNECTORS…………………………………………………………………………….. 39

METHOD FOR DISCONNECTING AND CONNECTING DEUTSCH CONNECTOR……………………………………………………………………………… 43

METHOD FOR DISCONNECTING AND CONNECTING SLIDE LOCK TYPE CONNECTOR………………………………………………………………………. 44

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PULL…………………………………………………………………….. 46

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PUSH…………………………………………………………………….. 47

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH HOUSING TO ROTATE………………………………………………………………… 49

STANDARD TIGHTENING TORQUE TABLE……………………………………………………………………………………………………. 50

CONVERSION TABLE………………………………………………………………………………………………………………….. 57

ABBREVIATION LIST…………………………………………………………………………………………………………………. 62

01 SPECIFICATION…………………………………………………………………………………………………………………………. 65

CONTENTS…………………………………………………………………………………………………………………………….. 66

SPECIFICATIONS……………………………………………………………………………………………………………………….. 67

OUTLINE OF EXHAUST GAS REGULATION…………………………………………………………………………………………………… 67

SYSTEM DIAGRAM OF ENGINE CONFORMED TO TIER4 REGULATION…………………………………………………………………………….. 68

LIST OF APPLICABLE MACHINES: 3D95E-1………………………………………………………………………………………………… 70

SPECIFICATIONS……………………………………………………………………………………………………………………. 71

SPECIFICATIONS: SAA3D95E-1(PC78US-11, PC78US-11E0, PC88MR-11, PC88MR-11E0)…………………………………………………………… 71

ENGINE GENERAL VIEW……………………………………………………………………………………………………………….. 72

ENGINE GENERAL VIEW: SAA3D95E-1(PC78US-11, PC78US-11E0, PC88MR-11, PC88MR-11E0)………………………………………………………. 72

WEIGHT TABLE……………………………………………………………………………………………………………………… 80

WEIGHT TABLE: 3D95E-1………………………………………………………………………………………………………….. 80

ENGINE PERFORMANCE CURVE…………………………………………………………………………………………………………… 81

ENGINE PERFORMANCE CURVE: SAA3D95E-1 (PC78US-11, PC78US-11E0, PC88MR-11, PC88MR-11E0)…………………………………………………. 81

10 STRUCTURE AND FUNCTION…………………………………………………………………………………………………………………. 83

CONTENTS…………………………………………………………………………………………………………………………….. 84

ENGINE SYSTEM………………………………………………………………………………………………………………………… 86

LAYOUT OF ENGINE COMPONENTS………………………………………………………………………………………………………… 86

LAYOUT DRAWING OF ENGINE COMPONENTS……………………………………………………………………………………………… 86

INTAKE AND EXHAUST SYSTEM PARTS…………………………………………………………………………………………………….. 89

LAYOUT DRAWING OF INTAKE AND EXHAUST SYSTEM………………………………………………………………………………………. 89

INTAKE AND EXHAUST SYSTEM CIRCUIT DIAGRAM………………………………………………………………………………………… 90

FUNCTION OF INTAKE AND EXHAUST SYSTEM……………………………………………………………………………………………. 90

AIR CLEANER…………………………………………………………………………………………………………………… 92

INTAKE AIR HEATER……………………………………………………………………………………………………………… 94

ENGINE MAIN BODY PARTS…………………………………………………………………………………………………………….. 95

CYLINDER HEAD…………………………………………………………………………………………………………………. 95

CYLINDER BLOCK………………………………………………………………………………………………………………… 98

MAIN DRIVE PARTS……………………………………………………………………………………………………………….100

TIMING GEAR……………………………………………………………………………………………………………………103

FRONT COVER……………………………………………………………………………………………………………………104

VALVE SYSTEM…………………………………………………………………………………………………………………..105

FLYWHEEL AND FLYWHEEL HOUSING……………………………………………………………………………………………………107

TURBOCHARGER SYSTEM………………………………………………………………………………………………………………..108

TURBOCHARGER…………………………………………………………………………………………………………………..108

EGR SYSTEM…………………………………………………………………………………………………………………….111

EGR VALVE……………………………………………………………………………………………………………………..114

EGR COOLER…………………………………………………………………………………………………………………….116

HIGH EFFICIENCY BREATHER SYSTEM………………………………………………………………………………………………….117

HIGH EFFICIENCY BREATHER………………………………………………………………………………………………………..118

EXHAUST THROTTLE VALVE………………………………………………………………………………………………………….120

KDOC………………………………………………………………………………………………………………………….121

KDPF………………………………………………………………………………………………………………………….123

LUBRICATION SYSTEM…………………………………………………………………………………………………………………127

LAYOUT DRAWING OF LUBRICATION SYSTEM PARTS………………………………………………………………………………………..127

LUBRICATION SYSTEM CIRCUIT DIAGRAM……………………………………………………………………………………………….128

ENGINE OIL PUMP………………………………………………………………………………………………………………..129

ENGINE OIL FILTER………………………………………………………………………………………………………………131

ENGINE OIL COOLER………………………………………………………………………………………………………………132

ENGINE OIL PAN…………………………………………………………………………………………………………………133

FUEL SYSTEM……………………………………………………………………………………………………………………….134

LAYOUT DRAWING OF FUEL SYSTEM PARTS………………………………………………………………………………………………134

FUEL SYSTEM CIRCUIT DIAGRAM……………………………………………………………………………………………………..135

CRI SYSTEM…………………………………………………………………………………………………………………….136

SUPPLY PUMP……………………………………………………………………………………………………………………140

COMMON RAIL……………………………………………………………………………………………………………………141

INJECTOR………………………………………………………………………………………………………………………143

FUEL PREFILTER…………………………………………………………………………………………………………………148

FUEL MAIN FILTER……………………………………………………………………………………………………………….149

COOLING SYSTEM…………………………………………………………………………………………………………………….150

LAYOUT DRAWING OF COOLING SYSTEM PARTS……………………………………………………………………………………………150

COOLING SYSTEM CIRCUIT DIAGRAM…………………………………………………………………………………………………..151

DRIVE PULLEY…………………………………………………………………………………………………………………..152

WATER PUMP…………………………………………………………………………………………………………………….153

THERMOSTAT…………………………………………………………………………………………………………………….154

ELECTRICAL SYSTEM……………………………………………………………………………………………………………………..158

COMPONENT PARTS OF ELECTRICAL SYSTEM…………………………………………………………………………………………………158

ALTERNATOR…………………………………………………………………………………………………………………….158

STARTING MOTOR…………………………………………………………………………………………………………………161

ENGINE WIRING HARNESS…………………………………………………………………………………………………………..163

ENGINE CONTROLLER………………………………………………………………………………………………………………165

SENSOR……………………………………………………………………………………………………………………………172

LAYOUT DRAWING OF ENGINE SENSOR………………………………………………………………………………………………….172

STRUCTURE OF AMBIENT PRESSURE SENSOR……………………………………………………………………………………………..174

FUNCTION OF AMBIENT PRESSURE SENSOR………………………………………………………………………………………………174

STRUCTURE OF ENGINE OIL PRESSURE SWITCH…………………………………………………………………………………………..175

FUNCTION OF ENGINE OIL PRESSURE SWITCH……………………………………………………………………………………………175

STRUCTURE OF CHARGE (BOOST) PRESSURE AND TEMPERATURE SENSOR…………………………………………………………………………176

FUNCTION OF CHARGE (BOOST) PRESSURE AND TEMPERATURE SENSOR………………………………………………………………………….176

STRUCTURE OF COOLANT TEMPERATURE SENSOR…………………………………………………………………………………………..177

FUNCTION OF COOLANT TEMPERATURE SENSOR……………………………………………………………………………………………177

STRUCTURE OF NE (CRANKSHAFT) SPEED SENSOR…………………………………………………………………………………………178

FUNCTION OF NE (CRANKSHAFT) SPEED SENSOR………………………………………………………………………………………….178

STRUCTURE OF Bkup (CAM) SPEED SENSOR……………………………………………………………………………………………..179

FUNCTION OF Bkup (CAM) SPEED SENSOR………………………………………………………………………………………………179

STRUCTURE OF COMMON RAIL PRESSURE SENSOR………………………………………………………………………………………….180

FUNCTION OF COMMON RAIL PRESSURE SENSOR…………………………………………………………………………………………..180

STRUCTURE OF MASS AIR FLOW AND TEMPERATURE SENSOR………………………………………………………………………………….181

FUNCTION OF MASS AIR FLOW AND TEMPERATURE SENSOR…………………………………………………………………………………..181

STRUCTURE OF AIR CLEANER CLOGGING SENSOR………………………………………………………………………………………….182

FUNCTION OF AIR CLEANER CLOGGING SENSOR…………………………………………………………………………………………..182

STRUCTURE OF EGR VALVE (WITH BUILT-IN POSITION SENSOR)……………………………………………………………………………..183

FUNCTION OF EGR VALVE (WITH BUILT-IN POSITION SENSOR)………………………………………………………………………………183

STRUCTURE OF EXHAUST THROTTLE VALVE (WITH BUILT-IN POSITION SENSOR)………………………………………………………………….184

FUNCTION OF EXHAUST THROTTLE VALVE (WITH BUILT-IN POSITION SENSOR)…………………………………………………………………..184

20 STANDARD VALUE TABLE……………………………………………………………………………………………………………………185

CONTENTS……………………………………………………………………………………………………………………………..186

STANDARD VALUE TABLE FOR ENGINE…………………………………………………………………………………………………………187

STANDARD VALUE TABLE FOR ENGINE: SAA3D95E-1 (PC78US-11, PC78US-11E0, PC88MR-11, PC88MR-11E0)……………………………………………….187

PERFORMANCE TEST STANDARD AND STANDARD FOR OPERATION OF ENGINE FOR BREAK IN PERIOD……………………………………………………………189

PERFORMANCE TEST STANDARD AND STANDARD FOR OPERATION OF ENGINE FOR BREAK IN PERIOD: SAA3D95E-1 (PC78US-11, PC78US-11E0, PC88MR-11, PC88MR-11E0)….189

50 DISASSEMBLY AND ASSEMBLY………………………………………………………………………………………………………………..191

CONTENTS……………………………………………………………………………………………………………………………..192

RELATED INFORMATION ON DISASSEMBLY AND ASSEMBLY…………………………………………………………………………………………..193

HOW TO READ THIS MANUAL…………………………………………………………………………………………………………….193

COATING MATERIALS LIST……………………………………………………………………………………………………………..195

SPECIAL TOOLS LIST…………………………………………………………………………………………………………………199

SKETCHES OF SPECIAL TOOLS…………………………………………………………………………………………………………..201

ENGINE RELATED………………………………………………………………………………………………………………………..202

DISASSEMBLE AND ASSEMBLE ENGINE GENERALLY…………………………………………………………………………………………….202

DISASSEMBLE ENGINE GENERALLY…………………………………………………………………………………………………….206

ASSEMBLE ENGINE GENERALLY……………………………………………………………………………………………………….254

REMOVE AND INSTALL SUPPLY PUMP ASSEMBLY………………………………………………………………………………………………332

REMOVE SUPPLY PUMP ASSEMBLY……………………………………………………………………………………………………..333

INSTALL SUPPLY PUMP ASSEMBLY…………………………………………………………………………………………………….340

REMOVE AND INSTALL ENGINE FRONT OIL SEAL……………………………………………………………………………………………..349

REMOVE ENGINE FRONT OIL SEAL…………………………………………………………………………………………………….349

INSTALL ENGINE FRONT OIL SEAL……………………………………………………………………………………………………351

60 MAINTENANCE STANDARD……………………………………………………………………………………………………………………355

CONTENTS……………………………………………………………………………………………………………………………..356

EXPLANATION OF TERMS FOR MAINTENANCE STANDARD…………………………………………………………………………………………….357

ENGINE SYSTEM…………………………………………………………………………………………………………………………359

INTAKE AND EXHAUST SYSTEM PARTS……………………………………………………………………………………………………..359

MAINTENANCE STANDARD OF TURBOCHARGER……………………………………………………………………………………………..359

ENGINE MAIN BODY PARTS……………………………………………………………………………………………………………..360

MAINTENANCE STANDARD OF CYLINDER HEAD…………………………………………………………………………………………….360

MAINTENANCE STANDARD OF CYLINDER BLOCK……………………………………………………………………………………………362

MAINTENANCE STANDARD OF CRANKSHAFT……………………………………………………………………………………………….365

MAINTENANCE STANDARD OF PISTON…………………………………………………………………………………………………..367

MAINTENANCE STANDARD OF CONNECTING ROD……………………………………………………………………………………………369

MAINTENANCE STANDARD OF TIMING GEAR………………………………………………………………………………………………371

MAINTENANCE STANDARD OF CAMSHAFT…………………………………………………………………………………………………372

MAINTENANCE STANDARD OF VALVE AND VALVE GUIDE……………………………………………………………………………………..374

MAINTENANCE STANDARD OF ROCKER ARM……………………………………………………………………………………………….376

MAINTENANCE STANDARD OF TAPPET…………………………………………………………………………………………………..378

MAINTENANCE STANDARD OF FLYWHEEL…………………………………………………………………………………………………379

LUBRICATION SYSTEM…………………………………………………………………………………………………………………381

MAINTENANCE STANDARD OF ENGINE OIL PUMP…………………………………………………………………………………………..381

INDEX…………………………………………………………………………………………………………………………………….383