$33

Komatsu 4D130-1 Series Diesel Engine Shop Manual SEBE6114Z00 – PDF DOWNLOAD

Komatsu 4D130-1 Series Diesel Engine Shop Manual SEBE6114Z00 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 4D130-1 Series Diesel Engine Shop Manual SEBE6114Z00 – PDF DOWNLOAD

Language : English

Pages : 220

Downloadable : Yes

File Type : PDF

Size: 17.3 MB

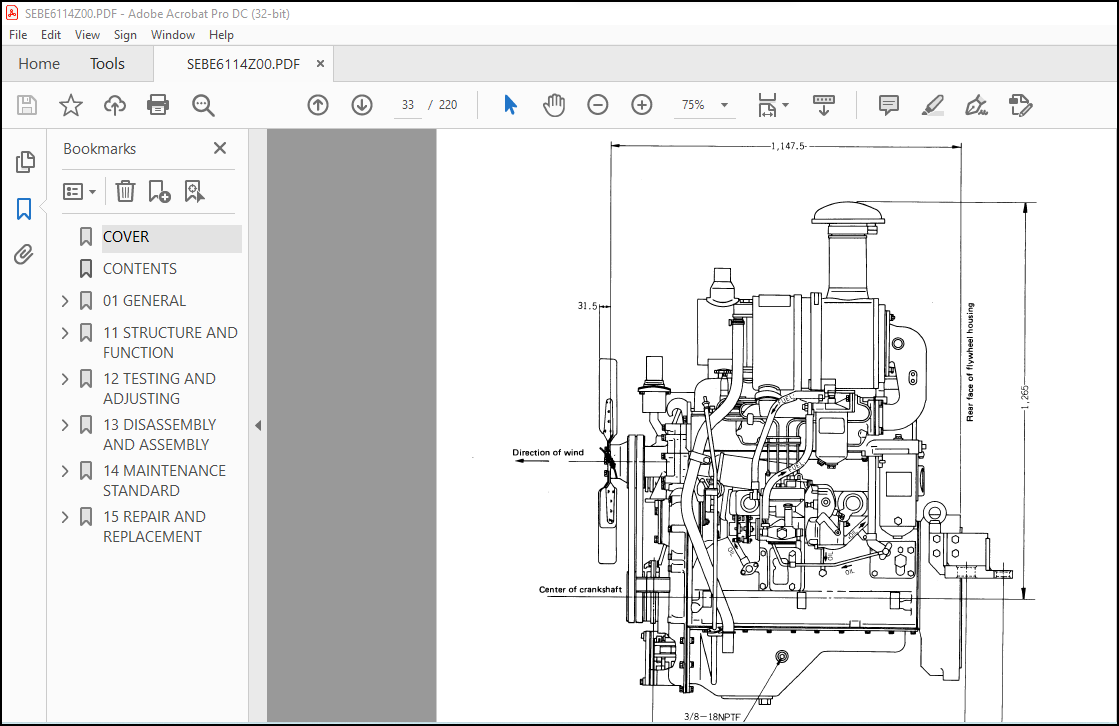

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 4D130-1 Series Diesel Engine Shop Manual SEBE6114Z00 – PDF DOWNLOAD

The Komatsu 4D130-1 Series Diesel Engine Shop Manual SEBE6114Z00 is a comprehensive guidebook that provides detailed technical information and instructions on how to operate, maintain, and repair the Komatsu 4D130-1 series diesel engines. These engines are commonly used in a variety of heavy equipment, such as excavators, bulldozers, and other construction machinery.

- The manual is organized into several sections, each providing detailed information on specific topics. These sections include specifications, structure and function, testing and adjusting, disassembly and assembly, maintenance, and troubleshooting.

- The specifications section of the manual provides detailed information on the engine’s physical and operational characteristics, including its dimensions, weight, performance, and power output. It also provides information on the engine’s cooling system, fuel system, and lubrication system.

- The structure and function section of the manual provides an overview of the engine’s internal components and their functions. This section includes detailed diagrams and descriptions of the engine’s various components, such as the cylinder block, cylinder head, crankshaft, pistons, and valves.

- The testing and adjusting section of the manual provides instructions on how to test and adjust the engine’s various components to ensure they are functioning correctly. This section includes detailed procedures for testing and adjusting the engine’s fuel injection system, valve clearances, and oil pressure.

- The disassembly and assembly section of the manual provides step-by-step instructions on how to disassemble and reassemble the engine’s various components. This section includes detailed diagrams and photographs to guide the user through the process.

- The maintenance section of the manual provides information on routine maintenance tasks that should be performed to keep the engine in good working condition. This section includes instructions on how to perform tasks such as changing the engine oil and replacing the air filter.

- The troubleshooting section of the manual provides guidance on how to diagnose and resolve common issues that may arise with the engine. This section includes a list of common symptoms and their likely causes, as well as step-by-step instructions for troubleshooting and resolving each issue.

TABLE OF CONTENTS:

Komatsu 4D130-1 Series Diesel Engine Shop Manual SEBE6114Z00 – PDF DOWNLOAD

COVER………………………………………… 1

CONTENTS……………………………………… 2

01 GENERAL……………………………………. 32

GENERAL ASSEMBLY DRAWING……………………. 33

SPECIFICATIONS…………………………….. 37

ENGINE PERFORMANCE CURVE……………………. 38

WEIGHT TABLE………………………………. 39

11 STRUCTURE AND FUNCTION………………………. 40

GENERAL STRUCTURE………………………….. 41

INTAKE AND EXHAUST UNIT…………………….. 43

CYLINDER HEAD……………………………… 44

CYLINDER BLOCK…………………………….. 47

TIMING GEAR……………………………….. 49

PISTON AND CONNECTING ROD…………………… 51

FLYWHEEL………………………………….. 52

BALANCER SHAFT…………………………….. 53

OIL PUMP………………………………….. 54

REGULATOR VALVE……………………………. 55

OIL FITER(CARTRIDGE TYPE)…………………… 56

OIL COOLER………………………………… 57

FUEL SYSTEM……………………………….. 58

FUEL INJECTION PUMP………………………… 59

GOVERNOR………………………………….. 63

FEED PUMP…………………………………. 67

INJECTION PUMP DRIVE CASE…………………… 69

FUEL INJECTION NOZZLE………………………. 70

FUEL FILTER(CARTRIDGE TYPE)…………………. 71

COOLING SYSTEM…………………………….. 72

WATER PUMP………………………………… 73

THERMOSTAT………………………………… 74

RADIATOR………………………………….. 75

CORROSION RESISTOR…………………………. 76

ELECTRICAL SYSTEM………………………….. 77

ALTERNATOR………………………………… 78

STARTING MOTOR…………………………….. 79

12 TESTING AND ADJUSTING……………………….. 80

GENERAL INSTRUCTION FOR TESTING AND ADJUSTING…. 81

INTAKE AND EXHAUST SYSTEM…………………… 82

ENGINE BODY……………………………….. 86

LUBRICATION SYSTEM…………………………. 88

FUEL SYSTEM……………………………….. 91

COOLING SYSTEM……………………………..108

PERFORMANCE TEST……………………………111

RUN-IN STANDARD…………………………….114

PERFORMANCE TEST STANDARD TABLE………………114

STANDARD FOR TESTING AND ADJUSTING……………115

TOOLS FOR TESTING AND ADJUSTING ……………..116

13 DISASSEMBLY AND ASSEMBLY……………………..117

DISASSEMBLY………………………………..118

ASSEMBLY…………………………………..142

14 MAINTENANCE STANDARD…………………………180

CYLINDER HEAD,PRECOMBUSTION CHAMBER…………..181

VALVE,VALVE GUIDE…………………………..182

ROCKER ARM,TAPPET…………………………..183

CYLINDER BLOCK……………………………..184

CYLINDER LINER……………………………..185

CRANKSHAFT…………………………………186

CAMSHAFT…………………………………..187

TIMING GEAR………………………………..188

PISTON,PISTON RING,PISTON PIN………………..189

CONNECTING ROD……………………………..190

FLYWHEEL,FLYWHEEL HOUSING……………………191

OIL PUMP…………………………………..192

REGULATOR VALVE,SAFETY VALVE…………………193

FUEL INJECTION PUMP…………………………194

GOVERNOR…………………………………..196

FEED PUMP………………………………….197

WATER PUMP,THERMOSTAT……………………….198

15 REPAIR AND REPLACEMENT……………………….199

CYLINDER HEAD SECTION……………………….200

CYLINDER BLOCK SECTION………………………205