$31

Komatsu 4D94LE, 4D98E FACTORY MANUAL DIESEL ENGINE 4D94E17-BRU2 – PDF DOWNLOAD (Russian)

Komatsu 4D94LE, 4D98E FACTORY MANUAL DIESEL ENGINE 4D94E17-BRU2 – PDF DOWNLOAD (Russian)

FILE DETAILS:

Komatsu 4D94LE, 4D98E FACTORY MANUAL DIESEL ENGINE 4D94E17-BRU2 – PDF DOWNLOAD (Russian)

Language : Russian

Pages : 161

Downloadable : Yes

File Type : PDF

Size: 12.5 MB

IMAGES PREVIEW OF THE MANUAL:

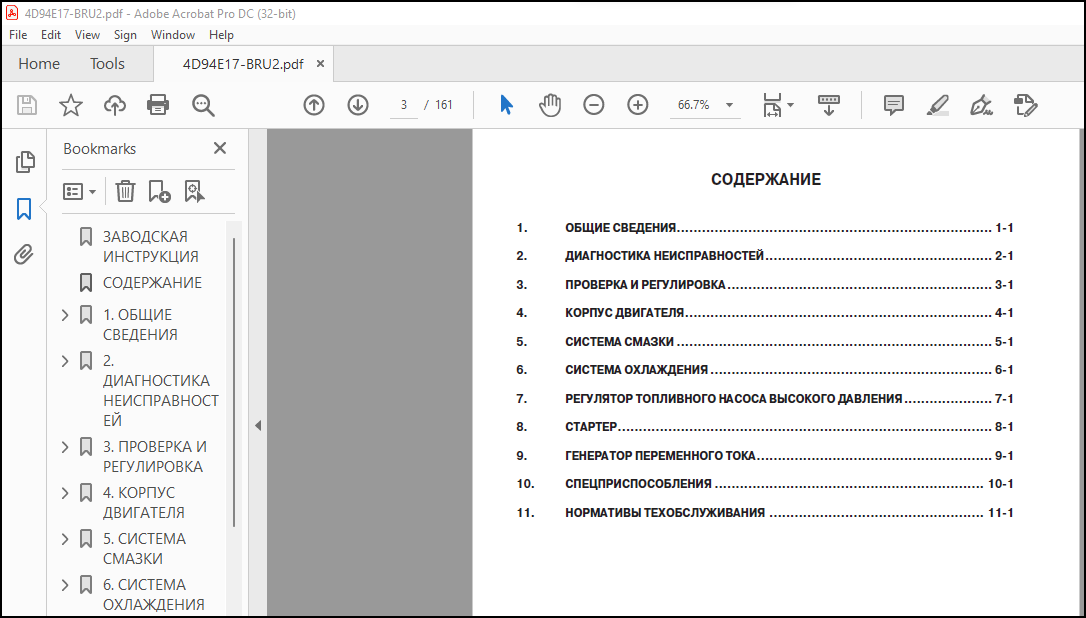

TABLE OF CONTENTS:

Komatsu 4D94LE, 4D98E FACTORY MANUAL DIESEL ENGINE 4D94E17-BRU2 – PDF DOWNLOAD (Russian)

SHOP MANUAL………………………………………………………………………… 2

CONTENTS…………………………………………………………………………. 3

1. GENERAL INFORMATION…………………………………………………………………… 4

1-1 Technical Specifications……………………………………………………. 5

1-2 Diesel Fuel, Lubricating Oil, and Coolant………………………… 6

1-3 Engine Performance Curve…………………………………………. 7

1-4 Engine External Appearance Pictures……………………………………………. 9

1-5 Structural Description…………………………………………………. 11

1-6 How to Use This Manual……………………………………………. 13

1-7 Precautions for Maintenance Work……………………….. 15

1-8 Tightening Torques of Standard Bolts and Nuts………………………………. 16

2. TROUBLE DIAGNOSIS………………………………………………………… 18

2-1 Troubleshooting Reference Table……………………………….. 19

2-2 Troubleshooting by Measuring Compression Pressure……………………….. 23

3. CHECKING AND ADJUSTING……………………………………………………………. 26

3-1 Checking for Coolant Leakage from Cooling System and Radiator……………….. 27

3-2 Checking and Adjusting Fan Belt Tension………………………………. 28

3-3 Adjusting Valve Clearance………………………………………………. 29

3-4 Checking Injector Injection Pressure and Fuel Spray Pattern……………….. 30

3-5 Checking and Adjusting Fuel Injection Timing……………………………….. 34

3-6 Checking Sensors…………………………………………………………………. 35

3-7 Checking the Battery………………………………………………………….. 36

3-8 Performing Adjustments……………………………………………………….. 38

3-9 Preservation…………………………………………………………………. 38

3-10 Periodic Maintenance Schedule…………………………………………. 39

4. ENGINE BODY…………………………………………………………………. 40

4-1 Introduction……………………………………………………………………. 41

4-2 Cylinder Head………………………………………………………. 42

4-3 Gear Block and Camshaft……………………………………………………. 51

4-4 Cylinder Block………………………………………………………. 57

5. LUBRICATION SYSTEM…………………………………………………………… 72

5-1 Lubrication System Diagram………………………………………………. 73

5-2 Trochoid Pump Components…………………………………………………. 73

5-3 Disassembly (Reverse the assembly procedure for the following procedure)…………….. 74

5-4 Maintenance Items………………………………………………………….. 74

5-5 Checking and Measuring Parts………………………………………………….. 75

6. COOLING SYSTEM……………………………………………………………….. 76

6-1 Cooling Water System…………………………………………………… 77

6-2 Cooling Pump Components………………………………………………… 78

6-3 Disassembly (Reverse the assembly procedure for the following procedure)…………….. 78

6-4 Maintenance Items………………………………………………………….. 78

7. HIGH-PRESSURE FUEL PUMP REGULATOR………………………………………….. 80

7-1 Technical characteristics……………………………………………………. 81

7-2 Design details…………………………………………………………… 82

7-3 High-pressure fuel pump diagram………………………………. 83

7-4 Removing and installing the high-pressure fuel pump…………………………… 84

7-5 Fuel system……………………………………………………………. 85

7-6 Pump Design and Operation…………………………………………………… 87

7-7 Plunger Operation……………………………………………………………… 91

7-8 All-Mode Regulator………………………………………………………… 97

7-9 Timer Design and Operation…………………………………………………..105

7-10 Solenoid Valve………………………………………………………107

7-11 Improving Starting Performance at Very Low Temperatures (4D94LE Engine)…..108

7-12 Cold Spark Plug (CSD) (4D98E Engine)………………………………………..109

8. STARTER………………………………………………………………………….112

8-1 Specifications…………………………………………………………….113

8-2 Design………………………………………………………………….114

8-3 Diagnostics

8-4 Part Names and Disassembly Procedure…………………………………………..116

8-5 Inspection and Maintenance……………………………………………….120

8-6 Assembly………………………………………………………………126

8-7 Performance Check………………………………………………………129

9. AC GENERATOR………………………………………………………………130

9-1 Sectional View……………………………………………………………….131

9-2 Troubleshooting……………………………………………………….132

9-3 Part Names and Disassembly Procedure……………………………….133 9-4 Inspection and Maintenance ………………………………………………

.136

9-5 Assembly………………………………………………………………140

9-6 Performance Check ………………………………………………………148 characteristics………………………………………………………143

10. SPECIAL TOOLS FOR MAINTENANCE………………………………………………………..146

10-1 Special tools………………………………………………………………………..147

10-2 Measuring instruments………………………………………………………..149

11. MAINTENANCE STANDARDS………………………………………………………………152

11-1 Engine adjustment………………………………………………………………..153

11-2 Engine housing…………………………………………………………………….154

11-3 Lubrication system (trochoid pump)……………………………………………..158

11-4 Tightening torques for main parts………………………………………………..159