$38

Komatsu 4TNV98C-S5 Engine Shop Manual WENBM00180 – PDF DOWNLOAD

Komatsu 4TNV98C-S5 Engine Shop Manual WENBM00180 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 4TNV98C-S5 Engine Shop Manual WENBM00180 – PDF DOWNLOAD

Language : English

Pages : 782

Downloadable : Yes

File Type : PDF

Size: 83.6 MB

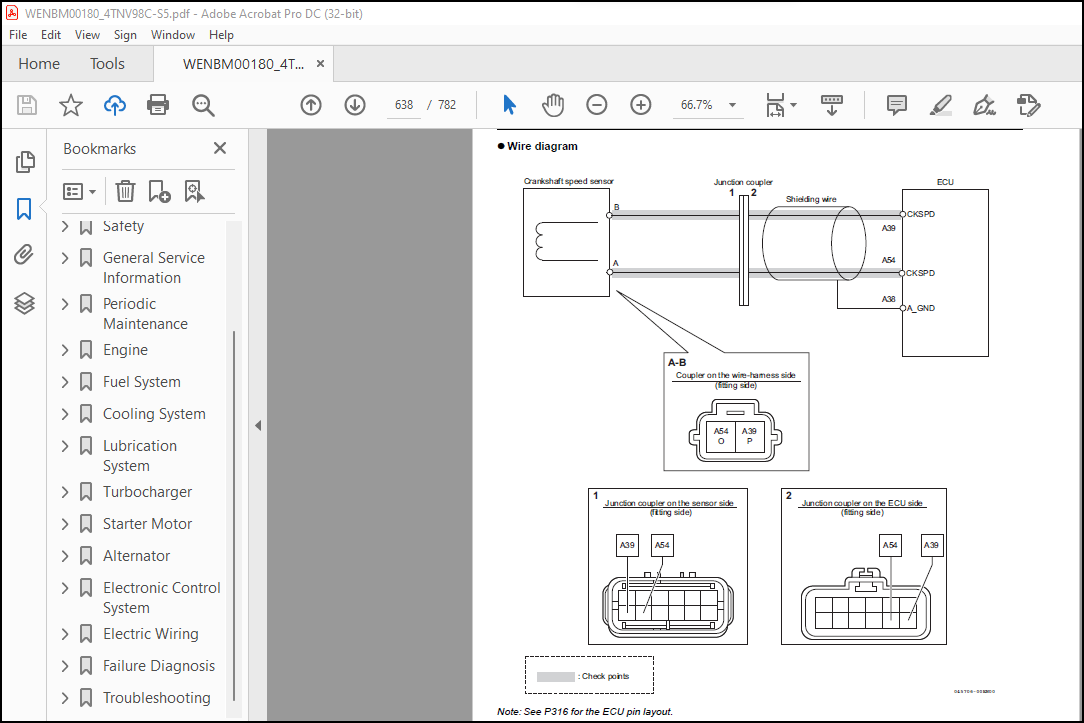

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 4TNV98C-S5 Engine Shop Manual WENBM00180 – PDF DOWNLOAD

The Komatsu 4TNV98C-S5 Engine Shop Manual WENBM00180 is a comprehensive guide that provides detailed information on the service, repair, and maintenance of the 4TNV98C-S5 engine. This engine is a diesel engine that is commonly used in construction equipment, such as excavators, bulldozers, and loaders.

The manual is published by Komatsu, a leading manufacturer of heavy equipment and construction machinery. The manual is designed to be used by mechanics and technicians who are responsible for maintaining and repairing Komatsu equipment. It is an essential tool for anyone who works with Komatsu engines.

The manual is divided into several sections, each of which provides specific information on different aspects of the engine. The sections include:

- General information: This section provides an overview of the engine, including its specifications, features, and operating principles. It also includes information on safety precautions, tools, and equipment needed for maintenance and repair.

- Inspection and adjustment: This section provides detailed instructions on how to inspect and adjust various components of the engine, including the cylinder head, valves, fuel system, and cooling system.

- Engine disassembly and assembly: This section provides step-by-step instructions on how to disassemble and assemble the engine. It includes detailed diagrams and illustrations to help users understand each step of the process.

- Troubleshooting: This section provides a comprehensive list of potential problems that may arise with the engine, along with diagnostic procedures to help identify and fix these issues.

- Maintenance: This section provides information on the regular maintenance tasks that should be performed on the engine, including oil changes, filter replacements, and other routine tasks.

- Reassembly and testing: This section provides detailed instructions on how to reassemble the engine after repairs have been made. It also includes information on how to test the engine to ensure that it is functioning properly.

The manual is written in clear, concise language, and is filled with detailed diagrams and illustrations to help users understand each step of the process. It is an essential tool for anyone who works with Komatsu engines, and can help to ensure that the engine is maintained and repaired to the highest standards.

TABLE OF CONTENTS:

Komatsu 4TNV98C-S5 Engine Shop Manual WENBM00180 – PDF DOWNLOAD

Cover………………………………………………………………………………….. 0

Table of Contents……………………………………………………………………….. 3

Introduction……………………………………………………………………………. 5

Safety…………………………………………………………………………………. 7

Safety Statements……………………………………………………………………. 9

Safety Precautions…………………………………………………………………… 10

During Operation and Maintenance…………………………………………………… 10

General Service Information………………………………………………………………. 23

Component Identification……………………………………………………………… 25

3TNV88C, 3TNV86CT, 3TNV86CHT, 4TNV88C, 4TNV86CT, 4TNV86CHT……………………………. 25

Location of Labels…………………………………………………………………… 27

Location of labels/nameplates on common rail system engine……………………………. 27

Engine Nameplate (Typical)………………………………………………………… 28

Emission Control Regulations………………………………………………………….. 28

EPA/ARB Regulations – USA Only…………………………………………………….. 28

Emission Control Labels………………………………………………………………. 28

EPA/ARB labels (Typical)………………………………………………………….. 28

EPA…………………………………………………………………………. 28

EPA and ARB………………………………………………………………….. 28

The 97/68/EC Directive Certified Engines……………………………………………. 29

Engine Family……………………………………………………………………….. 29

Function of Major Engine Components……………………………………………………. 30

Function of Cooling System Components………………………………………………….. 31

Main Electronic Control Components and Features…………………………………………. 32

Installation Position of Sensors………………………………………………………. 34

Cam Speed Sensor…………………………………………………………………. 35

New Air Temperature Sensor………………………………………………………… 36

EGR Temperature Sensor……………………………………………………………. 36

Intake Temperature Sensor…………………………………………………………. 36

Cooling Water Temperature Sensor…………………………………………………… 37

Exhaust Temperature Sensor………………………………………………………… 38

Diesel Particulate Filter (DPF) Inside/Inlet Temperature Sensor……………………….. 38

Rail Pressure Sensor……………………………………………………………… 38

EGR Pressure Sensor………………………………………………………………. 39

EGR Valve……………………………………………………………………….. 41

Intake Air Throttles……………………………………………………………… 42

Exhaust Air Throttles…………………………………………………………….. 43

Diesel Fuel…………………………………………………………………………. 45

Diesel Fuel Specifications………………………………………………………… 45

Additional technical fuel requirements………………………………………….. 45

Precautions and concerns regarding the use of diesel fuel…………………………. 45

Biodiesel fuels………………………………………………………………. 45

Kit component for B20 (TNV Tier4 CR)……………………………………………. 48

Filling The Fuel Tank…………………………………………………………….. 49

Priming the Fuel System…………………………………………………………… 50

Engine Lubricating Oil……………………………………………………………….. 51

Engine Lubricating Oil Specifications………………………………………………. 51

Service categories……………………………………………………………. 51

Definitions………………………………………………………………….. 51

Additional technical engine lubricating oil requirements:…………………………. 51

Engine Lubricating Oil Viscosity…………………………………………………… 51

Checking Engine Lubricating Oil……………………………………………………. 52

Adding Engine Lubricating Oil……………………………………………………… 52

Engine Oil Capacity (Typical)……………………………………………………… 52

Engine Coolant………………………………………………………………………. 53

Engine Coolant Specifications……………………………………………………… 54

Alternative engine coolant…………………………………………………….. 54

Filling Radiator with Engine Coolant……………………………………………….. 54

Daily Check of the Cooling System………………………………………………….. 55

Engine Coolant Capacity (Typical)………………………………………………….. 55

Specifications………………………………………………………………………. 56

Description of Model Number……………………………………………………….. 56

Engine General Specifications……………………………………………………… 56

Principal Engine Specifications……………………………………………………….. 57

3TNV88C…………………………………………………………………………. 57

Engine Service Standards……………………………………………………………… 66

Tightening Torques for Standard Bolts and Nuts………………………………………….. 67

Abbreviations and Symbols…………………………………………………………….. 68

Abbreviations……………………………………………………………………. 68

Symbols…………………………………………………………………………. 68

Unit Conversions…………………………………………………………………….. 69

Unit prefixes……………………………………………………………………. 69

Units of length………………………………………………………………….. 69

Units of volume………………………………………………………………….. 69

Units of mass……………………………………………………………………. 69

Units of force…………………………………………………………………… 69

Units of torque………………………………………………………………….. 69

Units of pressure………………………………………………………………… 69

Units of power…………………………………………………………………… 69

Units of temperature……………………………………………………………… 69

Periodic Maintenance…………………………………………………………………….. 71

Before You Begin Servicing……………………………………………………………. 73

Introduction………………………………………………………………………… 74

The Importance of Periodic Maintenance……………………………………………… 74

Performing Periodic Maintenance……………………………………………………. 74

YANMAR Replacement Parts………………………………………………………….. 74

Required EPA/ARB Maintenance USA Only………………………………………………. 74

EPA/ARB Installation Requirements USA Only………………………………………….. 74

Maximum exhaust gas restriction shall be:……………………………………….. 74

Periodic Maintenance Schedule…………………………………………………………. 75

Periodic Maintenance Procedures……………………………………………………….. 77

After Initial 50 Hours of Operation………………………………………………… 77

Check and adjust cooling fan V-belt…………………………………………….. 77

Every 50 Hours of Operation……………………………………………………….. 78

Drain water separator…………………………………………………………. 78

Check battery………………………………………………………………… 80

Every 250 Hours of Operation………………………………………………………. 81

Drain fuel tank………………………………………………………………. 81

Check and clean radiator fins………………………………………………….. 82

Check and adjust cooling fan V-belt…………………………………………….. 82

Clean air cleaner element……………………………………………………… 82

Every 500 Hours of Operation………………………………………………………. 83

Replace air cleaner element……………………………………………………. 83

Replace fuel filter…………………………………………………………… 84

Replace water separator element………………………………………………… 85

Replace engine lubricating oil and oil filter……………………………………. 86

Every 1000 Hours of Operation……………………………………………………… 88

Check and adjust intake/exhaust valve clearance………………………………….. 88

Every 1500 Hours of Operation……………………………………………………… 88

Inspect crankcase breather system………………………………………………. 88

Every 2000 Hours of Operation……………………………………………………… 89

Inspect and replace fuel line, coolant line, lubricating oil line, and breather hose…. 89

Lap the intake and exhaust valves………………………………………………. 89

Replace engine coolant………………………………………………………… 89

Every 3000 Hours of Operation……………………………………………………… 91

Inspect ECU and related sensors and actuators……………………………………. 91

Inspect turbocharger (blower wash as necessary)………………………………….. 91

Inspect, clean and test EGR valve (except for engines with turbochargers)…………… 91

Cleaning the EGR cooler (water side/exhaust passage blower)……………………….. 91

Inspect DPF DOC………………………………………………………………. 92

Inspect and test intake throttle valve………………………………………….. 92

Check the operation of exhaust throttle valve (optional)………………………….. 92

Check and clean injector………………………………………………………. 92

At 6000 Hours of Operation………………………………………………………… 92

Check and clean of DPF soot filter……………………………………………… 92

Engine…………………………………………………………………………………. 93

Before You Begin Servicing……………………………………………………………. 95

INTRODUCTION………………………………………………………………………… 95

Cylinder Head Specifications………………………………………………………….. 96

Adjustment Specifications…………………………………………………………. 96

Cylinder Head……………………………………………………………………. 96

Rocker Arm and Shaft……………………………………………………………… 98

Valve Spring…………………………………………………………………….. 98

Camshaft and Timing Gear Train Specifications…………………………………………… 99

Camshaft………………………………………………………………………… 99

Timing Gear Backlash………………………………………………………………100

Crankshaft and Piston Specifications……………………………………………………101

Crankshaft……………………………………………………………………….101

Piston…………………………………………………………………………..102

Connecting rod small end……………………………………………………….106

Connecting rod big end…………………………………………………………106

Tappet…………………………………………………………………………..106

Cylinder Block Specifications………………………………………………………….107

Cylinder Block……………………………………………………………………107

Special Torque Chart………………………………………………………………….108

Torque for Bolts and Nuts………………………………………………………….108

Special Service Tools…………………………………………………………………111

Measuring Instruments…………………………………………………………………114

Cylinder Head………………………………………………………………………..116

Cylinder Head Components…………………………………………………………..116

Disassembly of Cylinder Head……………………………………………………….117

Removing the Glow Plugs……………………………………………………………120

Removal of Cylinder Head Cover……………………………………………………..120

Removal of Rocker Arm Assembly……………………………………………………..120

Disassembly of Rocker Arm Assembly………………………………………………….121

Removal of Cylinder Head…………………………………………………………..121

Removal of Intake/exhaust Valves……………………………………………………122

Removal of Valve Guides……………………………………………………………122

Cleaning of Cylinder Head Components………………………………………………..122

Inspection of Cylinder Head Components………………………………………………123

Inspection of Push Rods……………………………………………………………123

Push rod bend…………………………………………………………………123

Inspection of Rocker Arm Assembly…………………………………………………..123

Rocker arm shaft hole diameter………………………………………………….123

Rocker arm shaft outside diameter……………………………………………….123

Inspection of Valve Guides…………………………………………………………124

Inspection of Cylinder Head………………………………………………………..124

Cylinder head distortion……………………………………………………….124

Inspection of Intake and Exhaust Valves……………………………………………..124

Valve stem diameter……………………………………………………………124

Valve stem bend……………………………………………………………….124

Valve recession……………………………………………………………….125

Valve face and valve seat………………………………………………………125

Inspection of Valve Springs………………………………………………………..126

Fractures…………………………………………………………………….126

Corrosion…………………………………………………………………….126

Squareness……………………………………………………………………126

Free length…………………………………………………………………..126

Reassembly of Cylinder Head………………………………………………………..127

Reassembly of valve guides……………………………………………………..127

Reassembly of intake and exhaust valves………………………………………….127

Reassembly of cylinder head…………………………………………………….128

Reassembly of rocker arm reassembly……………………………………………..129

Assembling the parts around the cylinder head…………………………………….129

Measuring and Adjusting Valve Clearance…………………………………………………131

3-cylinder engines………………………………………………………………..131

4-cylinder engines………………………………………………………………..131

Crankshaft and Camshaft Components……………………………………………………..133

Disassembly of Engine……………………………………………………………..134

Disassembly of Camshaft and Timing Components………………………………………..135

Removal of timing gear case cover……………………………………………….135

Checking timing gear backlash…………………………………………………..135

Measuring idler gear-to-crankshaft gear backlash………………………………….136

Measuring idler gear-to-camshaft gear backlash……………………………………136

Removal of timing gears………………………………………………………..136

Removal of oil pan…………………………………………………………….137

Removal of camshaft……………………………………………………………137

Removal of gear case…………………………………………………………..138

Disassembly of Crankshaft and Piston Components………………………………………139

Removal of pistons…………………………………………………………….139

Removal of crankshaft………………………………………………………….140

Inspection of Crankshaft and Camshaft Components……………………………………..142

Replacement of crankshaft oil seals……………………………………………..142

Measure crankshaft bearing oil clearance…………………………………………143

Inspection of cylinder block……………………………………………………143

Inspection of pistons, piston rings and wrist pin…………………………………143

Inspection of connecting rod……………………………………………………145

Inspection of tappets………………………………………………………….145

Inspection of crankshaft……………………………………………………….146

Inspection of camshaft…………………………………………………………146

Inspection of camshaft bushing and bores…………………………………………147

Inspection of idler gear and shaft………………………………………………147

Inspection of flywheel…………………………………………………………147

Honing and Boring…………………………………………………………………148

Reassembly of Crankshaft and Piston Components……………………………………….149

Reassembly of pistons………………………………………………………….149

Installation of crankshaft……………………………………………………..151

Installation of pistons………………………………………………………..152

Reassembly of Camshaft and Timing Components…………………………………………153

Installation of gear case………………………………………………………153

Installation of camshaft……………………………………………………….154

Installation of timing gears……………………………………………………154

Installation of gear case cover…………………………………………………155

Installation of oil pan………………………………………………………..156

Final Reassembly of Engine…………………………………………………………156

EGR System…………………………………………………………………………..157

EGR System Configuration…………………………………………………………..157

Engine without turbocharger…………………………………………………….157

Engine with turbocharger……………………………………………………….158

EGR valve…………………………………………………………………….159

EGR lead valve………………………………………………………………..159

EGR cooler……………………………………………………………………159

Disassembly of EGR System………………………………………………………….159

EGR cooler……………………………………………………………………160

EGR valve/Lead valve…………………………………………………………..160

Cleaning the EGR Cooler (Water Side/Exhaust Passage Blower)……………………………161

Cleaning the EGR Pipe and Other Connecting Elbows…………………………………….161

Check, Clean, and Test EGR Valve……………………………………………………161

EGR active control…………………………………………………………….162

Cleaning the EGR valves………………………………………………………..163

Exit the EGR active control…………………………………………………….163

Precautions for cleaning……………………………………………………….163

Cleaning the EGR Lead Valves……………………………………………………….164

Precautions for installation……………………………………………………164

Assembling around the EGR Valve…………………………………………………….164

Intake Throttle………………………………………………………………………165

Precautions for Handling the Intake Throttle…………………………………………165

Exhaust Throttle……………………………………………………………………..166

Checking the Operation of Exhaust Throttle…………………………………………..166

Fuel System……………………………………………………………………………..167

Before You Begin Servicing…………………………………………………………….169

System Structure……………………………………………………………………..170

Supply pump………………………………………………………………………170

Rail…………………………………………………………………………….170

Injector…………………………………………………………………………170

ECU……………………………………………………………………………..171

Fuel System Specifications…………………………………………………………….172

Torque Chart for Major Bolts and Nuts……………………………………………….172

Fuel System Diagram…………………………………………………………………..173

Fuel System Components………………………………………………………………..174

Removal of Injector……………………………………………………………….175

Reassembly of injector…………………………………………………………….176

Removal of Common Rail…………………………………………………………….177

Reassembly of Common Rail………………………………………………………….178

Removal of Supply Pump…………………………………………………………….179

Reassembly of Supply Pump………………………………………………………….180

Cooling System…………………………………………………………………………..183

Before You Begin Servicing…………………………………………………………….185

INTRODUCTION…………………………………………………………………………185

Cooling System Diagram………………………………………………………………..186

Engine Coolant Pump Components…………………………………………………………187

Engine Coolant System Check……………………………………………………………188

Engine Coolant Pump…………………………………………………………………..188

Removal of Engine Coolant Pump……………………………………………………..188

Disassembly of Engine Coolant Pump………………………………………………….189

Cleaning and Inspection……………………………………………………………190

Temperature switch…………………………………………………………….190

Water temperature sensor……………………………………………………….190

Thermostat……………………………………………………………………191

Radiator cap………………………………………………………………….191

Reassembly of Engine Coolant Pump…………………………………………………..191

Installation of Engine Coolant Pump…………………………………………………192

Lubrication System……………………………………………………………………….193

Before You Begin Servicing…………………………………………………………….195

Introduction…………………………………………………………………………195

Oil Pump Service Information…………………………………………………………..196

Engine lubricating oil pressure…………………………………………………….196

Outer rotor outside clearance………………………………………………………196

Outer rotor side clearance…………………………………………………………196

Outer rotor to inner rotor tip clearance…………………………………………….196

Rotor shaft clearance……………………………………………………………..197

Lubrication System Diagram…………………………………………………………….198

Checking Engine Lubricating Oil Pressure………………………………………………..199

Oil Pump Components…………………………………………………………………..199

3TNV88C, 3TNV86CT, 3TNV86CHT, 4TNV88C, 4TNV86CT, 4TNV86CHT…………………………….199

Disassembly of Oil Pump……………………………………………………………199

Cleaning and Inspection……………………………………………………………200

Check outer rotor outside clearance……………………………………………..200

Outer rotor to inner rotor tip clearance…………………………………………200

Check outer rotor side clearance………………………………………………..201

Check rotor shaft clearance…………………………………………………….201

Reassembly of Oil Pump…………………………………………………………….201

4TNV98C, 4TNV98CT (Trochoid Oil Pump)……………………………………………….202

Disassembly of Oil Pump……………………………………………………………202

Cleaning and Inspection……………………………………………………………203

Check outer rotor outside clearance……………………………………………..203

Outer rotor to inner rotor tip clearance…………………………………………203

Check outer rotor side clearance………………………………………………..203

Check rotor shaft clearance…………………………………………………….204

Reassembly of Oil Pump…………………………………………………………….204

Turbocharger…………………………………………………………………………….205

Before You Begin Servicing…………………………………………………………….207

Introduction…………………………………………………………………………207

Specifications……………………………………………………………………….207

Turbocharger Service Information……………………………………………………207

Troubleshooting………………………………………………………………………208

Excessive exhaust smoke……………………………………………………………208

Sudden oil decrease……………………………………………………………….209

Decrease in output………………………………………………………………..209

Poor (slow) response (starting) of turbocharger………………………………………209

Abnormal sound or vibration………………………………………………………..209

Turbocharger Components……………………………………………………………….210

Turbocharger Component Functions……………………………………………………….211

Structure of Turbocharger………………………………………………………….211

Turbine………………………………………………………………………211

Compressor……………………………………………………………………211

Bearings……………………………………………………………………..212

Compressor side sealing mechanism……………………………………………….212

Role of Waste Gate………………………………………………………………..212

Periodic Inspection…………………………………………………………………..213

Visual Inspection…………………………………………………………………213

Inspection of Rotor Rotation……………………………………………………….213

Checking Rotor Play……………………………………………………………….213

To check rotor end play:……………………………………………………….213

To check rotor run-out:………………………………………………………..213

Waste Gate Valve Test……………………………………………………………..214

Waste Gate Actuator Leak Test………………………………………………………214

Removal and Installation of turbocharger………………………………………………..215

Removal of Turbocharger……………………………………………………………215

Installation of Turbocharger……………………………………………………….215

Cleaning Procedure……………………………………………………………………216

Starter Motor……………………………………………………………………………217

Before You Begin Servicing…………………………………………………………….219

INTRODUCTION…………………………………………………………………………219

Starter Motor Information……………………………………………………………..220

3TNV88C to 4TNV86CHT – Standard and Optional…………………………………………220

4TNV98C and 4TNV98CT – Standard and Optional…………………………………………220

Starter Motor Specifications…………………………………………………………..221

Starter Motor Troubleshooting………………………………………………………….222

Starter Motor Components………………………………………………………………223

Starter Motor………………………………………………………………………..224

Removal of Starter Motor…………………………………………………………..224

Disassembly of Starter Motor……………………………………………………….224

Cleaning and Inspection……………………………………………………………226

Armature……………………………………………………………………..226

Field coil……………………………………………………………………227

Magnetic switch……………………………………………………………….228

Pinion clutch assembly…………………………………………………………229

Reassembly of Starter Motor………………………………………………………..229

Check Pinion Projection Length……………………………………………………..231

No-Load Test……………………………………………………………………..231

Installation of Starter Motor………………………………………………………232

Alternator………………………………………………………………………………233

Before You Begin Servicing…………………………………………………………….235

Introduction…………………………………………………………………………236

Dynamo and Alternator Information………………………………………………………236

3TNV88C to 4TNV98CT – Standard and Optional Dynamos…………………………………..236

3TNV88C to 4TNV98CT – Standard and Optional Alternators……………………………….236

Alternator Specifications……………………………………………………………..237

Dynamo Specifications…………………………………………………………………237

Alternator Troubleshooting…………………………………………………………….238

Alternator Components…………………………………………………………………239

Alternator Wiring Diagram……………………………………………………………..240

Alternator Standard Output…………………………………………………………….241

Alternator…………………………………………………………………………..242

Removal of Alternator……………………………………………………………..242

Disassembly of Alternator………………………………………………………….243

Reassembly of Alternator…………………………………………………………..244

Installation of Alternator…………………………………………………………246

Dynamo Component Location……………………………………………………………..248

Dynamo Wiring Diagram…………………………………………………………………249

Operation of Dynamo…………………………………………………………………..249

Dynamo Standard Output………………………………………………………………..250

Testing of Dynamo…………………………………………………………………….251

Testing Stator Coil Continuity……………………………………………………..251

Testing Stator Coil Short-to-Ground…………………………………………………251

Testing Dynamo Regulated Output…………………………………………………….251

Dynamo………………………………………………………………………………251

Removal of Dynamo…………………………………………………………………251

Disassembly of Dynamo……………………………………………………………..252

Reassembly of Dynamo………………………………………………………………252

Installation of Dynamo…………………………………………………………….253

Electronic Control System…………………………………………………………………255

Before You Begin Servicing…………………………………………………………….257

Introduction…………………………………………………………………………257

System Structure……………………………………………………………………..258

Diesel Particulate Filter (DPF)…………………………………………………….259

Overview of Diesel Particulate Filter (DPF) regeneration control……………………260

Self-regeneration……………………………………………………………..260

Assisted regeneration………………………………………………………….260

Reset regeneration…………………………………………………………….260

Stationary regeneration………………………………………………………..261

Operation procedures of stationary regeneration…………………………………..261

Precautions for stationary regeneration………………………………………….261

Recovery regeneration (optional)………………………………………………..262

Precautions for recovery regeneration……………………………………………262

Diesel Particulate Filter (DPF) service………………………………………….263

Procedures for servicing the Diesel Particulate Filter (DPF)……………………….263

HOW TO REMOVE AND REATTACH THE DIESEL PARTICULATE FILTER (DPF)…………………………….264

How to remove the soot filter (SF) case……………………………………………..264

How to reattach the SF case………………………………………………………..267

How to remove the DPF unit…………………………………………………………269

How to reattach the DPF……………………………………………………………271

SF and DPF Maintenance Kit…………………………………………………………….274

Troubleshooting of Electronic Control System…………………………………………….276

Fault Detection Capability…………………………………………………………276

SMARTASSIST-DIRECT (SA-D)………………………………………………………….277

About SA-D use………………………………………………………………..278

Replacement of Components……………………………………………………………..279

Processing the DPF regeneration after the parts replacement……………………………279

Processing after the ECU replacement (when it is impossible to inherit from the old ECU)….280

Required processing at the CR-related parts replacement……………………………….281

Electronic Control Harness Connections………………………………………………….282

Electric Wiring………………………………………………………………………….289

Electric Wiring Precautions……………………………………………………………291

Electrical Wire Resistance…………………………………………………………….292

Battery Cable Resistance………………………………………………………………293

Electrical Wire Sizes – Voltage Drop……………………………………………………294

Conversion of AWG to European Standards…………………………………………………295

Failure Diagnosis………………………………………………………………………..297

Special Service Tools…………………………………………………………………299

Troubleshooting by Measuring Compression Pressure………………………………………..300

Compression Pressure Inspection Procedures…………………………………………..300

Attaching the Injector…………………………………………………………….301

Engine Speed and Compression Pressure (Use for Reference)……………………………..302

Measured Value and Troubleshooting……………………………………………………..303

Quick Reference Table for Troubleshooting……………………………………………….304

Failure Diagnostic List……………………………………………………………305

Troubleshooting………………………………………………………………………….309

CONTENTS…………………………………………………………………………….311

TROUBLESHOOTING………………………………………………………………………319

DTC (Diagnostic Trouble Codes) General Description……………………………………….319

Method and Procedure of Failure Diagnosis……………………………………………….633