$28

Komatsu 67E-1 Series Diesel Engine Workshop Manual SEBM038300 – PDF DOWNLOAD

Komatsu 67E-1 Series Diesel Engine Workshop Manual SEBM038300 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 67E-1 Series Diesel Engine Workshop Manual SEBM038300 – PDF DOWNLOAD

Language : English

Pages : 114

Downloadable : Yes

File Type : PDF

Size: 7.97 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 67E-1 Series Diesel Engine Workshop Manual SEBM038300 – PDF DOWNLOAD

The Komatsu 67E-1 Series Diesel Engine Workshop Manual SEBM038300 is a comprehensive guide for mechanics and technicians who are responsible for the repair and maintenance of these engines. The manual provides detailed information on the construction, operation, and maintenance of the engines, as well as step-by-step instructions for disassembly, inspection, repair, and reassembly of various engine components.

- The manual begins with an overview of the engine’s design features, specifications, and performance characteristics. This section provides a detailed description of the engine’s construction and operation, as well as an overview of the various components that make up the engine. It also includes information on the engine’s maintenance schedule and recommended service intervals.

- The manual then provides detailed instructions on the disassembly, inspection, repair, and reassembly of the various components of the engine. This section covers topics such as the cylinder block, cylinder head, crankshaft, pistons, connecting rods, camshaft, and timing gears.

- The cylinder block section provides detailed instructions on the removal and installation of the cylinder block, as well as instructions for inspection, repair, and reassembly of various cylinder block components, such as the cylinder liners and main bearings. The cylinder head section covers the inspection, repair, and replacement of various cylinder head components, such as valves, springs, and guides. The crankshaft section provides instructions on the inspection, repair, and replacement of various crankshaft components, such as the main and connecting rod bearings. The piston section covers the inspection, repair, and replacement of various piston components, such as rings and wrist pins. The connecting rod section provides instructions on the inspection, repair, and replacement of various connecting rod components, such as bearings and bolts. The camshaft and timing gears section covers the inspection, repair, and replacement of various camshaft and timing gear components, such as bearings, gears, and chains.

- The manual also includes sections on fuel injection systems, lubrication systems, and cooling systems, which provide detailed instructions on the repair and maintenance of these critical engine systems. The fuel injection section covers topics such as the injection pump, fuel injectors, and fuel lines. The lubrication system section covers topics such as the oil pump, oil filter, and oil cooler. The cooling system section covers topics such as the radiator, water pump, and thermostat.

- In addition to these repair and maintenance procedures, the manual includes a section on troubleshooting, which provides detailed instructions on how to diagnose and fix common problems that may occur during the operation of the engine. This section includes a list of common symptoms, possible causes, and recommended solutions for each problem.

- Overall, the Komatsu 67E-1 Series Diesel Engine Workshop Manual SEBM038300 is an essential resource for mechanics and technicians who are responsible for the repair and maintenance of these engines. It provides detailed information on how to disassemble, inspect, repair, and reassemble the engine’s various components, as well as important safety information to help prevent accidents and injuries. The manual is a must-have for anyone who needs to perform repairs or maintenance on these engines.

TABLE OF CONTENTS:

Komatsu 67E-1 Series Diesel Engine Workshop Manual SEBM038300 – PDF DOWNLOAD

COVER………………………………………………………………………… 1

CONTENTS……………………………………………………………………… 2

1. GENERAL…………………………………………………………………….10

SPECIFICATIONS……………………………………………………………..11

PERFORMANCE CURVES………………………………………………………….12

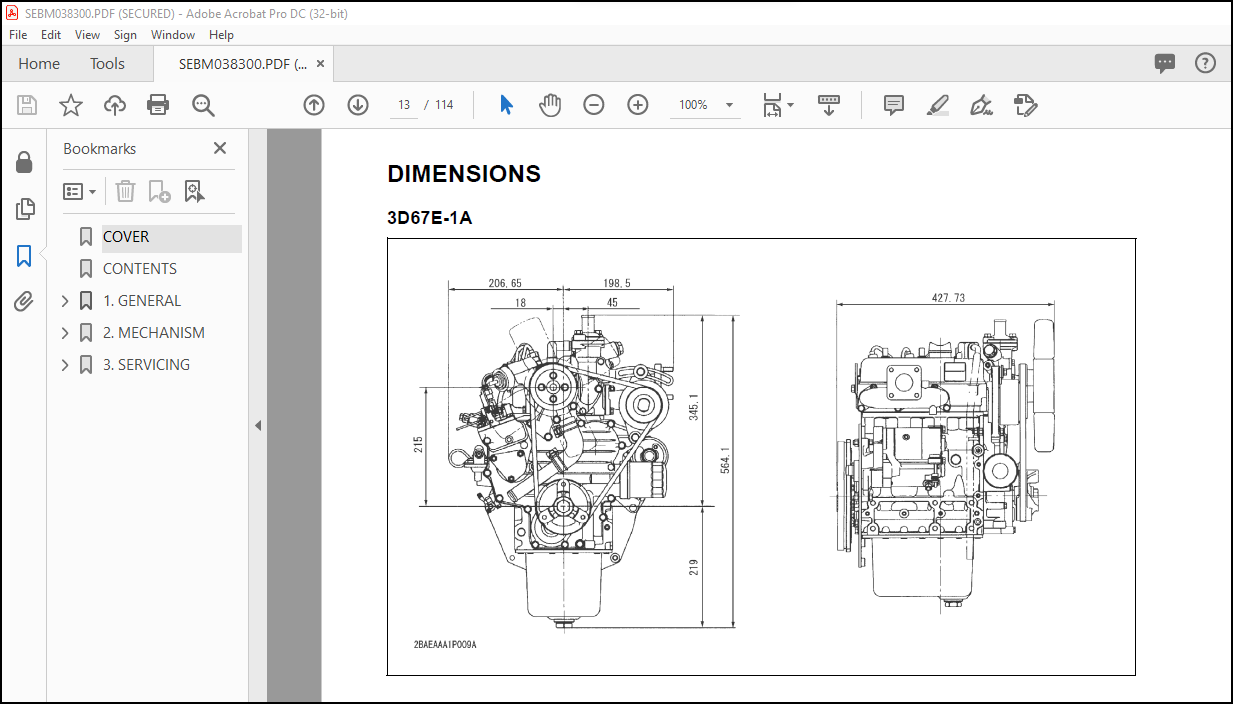

DIMENSIONS…………………………………………………………………13

ENGINE IDENTIFICATION……………………………………………………….14

1. CYLINDER NUMBER………………………………………………………14

GENERAL PRECAUTION………………………………………………………….14

MAINTENANCE CHECK LIST………………………………………………………15

CHECK AND MAINTENANCE……………………………………………………….17

1. DAILY CHECK POINTS……………………………………………………17

2. CHECK POINTS OF EVERY 50 HOURS…………………………………………19

3. CHECK POINTS OF EVERY 100 HOURS………………………………………..20

4. CHECK POINTS OF EVERY 200 HOURS………………………………………..21

5. CHECK POINTS OF EVERY 400 HOURS………………………………………..23

6. CHECK POINTS OF EVERY 500 HOURS………………………………………..24

7. CHECK POINTS OF EVERY YEAR OR EVERY SIXTH CLEANINGS OF AIR CLEANER ELEMENT….25

8. CHECK POINTS OF EVERY 800 HOURS………………………………………..26

9. CHECK POINTS OF EVERY 1500 HOURS……………………………………….27

10. CHECK POINTS OF EVERY 3000 HOURS………………………………………27

11. CHECK POINTS OF EVERY 2 YEARS…………………………………………27

SPECIAL TOOLS………………………………………………………………28

2. MECHANISM…………………………………………………………………..34

ENGINE BODY………………………………………………………………..35

1. HALF-FLOATING HEAD COVER………………………………………………35

2. CLOSED BREATHER………………………………………………………35

3. PISTON………………………………………………………………36

4. OIL PAN……………………………………………………………..36

3. SERVICING…………………………………………………………………..37

TROUBLESHOOTING…………………………………………………………….38

SERVICING SPECIFICATION……………………………………………………..42

TIGHTENING TORQUES………………………………………………………….47

1. TIGHTENING TORQUES FOR SPECIAL USE SCREWS,BOLTS AND NUTS………………….47

2. TIGHTENING TORQUES FOR GENERAL USE SCREWS,BOLTS AND NUTS………………….48

CHECKING,DISASSEMBLING AND SERVICING………………………………………….49

1. CHECKING AND ADJUSTING………………………………………………..49

2. DISASSEMBLING AND ASSEMBLING…………………………………………..65

3. SERVICING……………………………………………………………89