$30

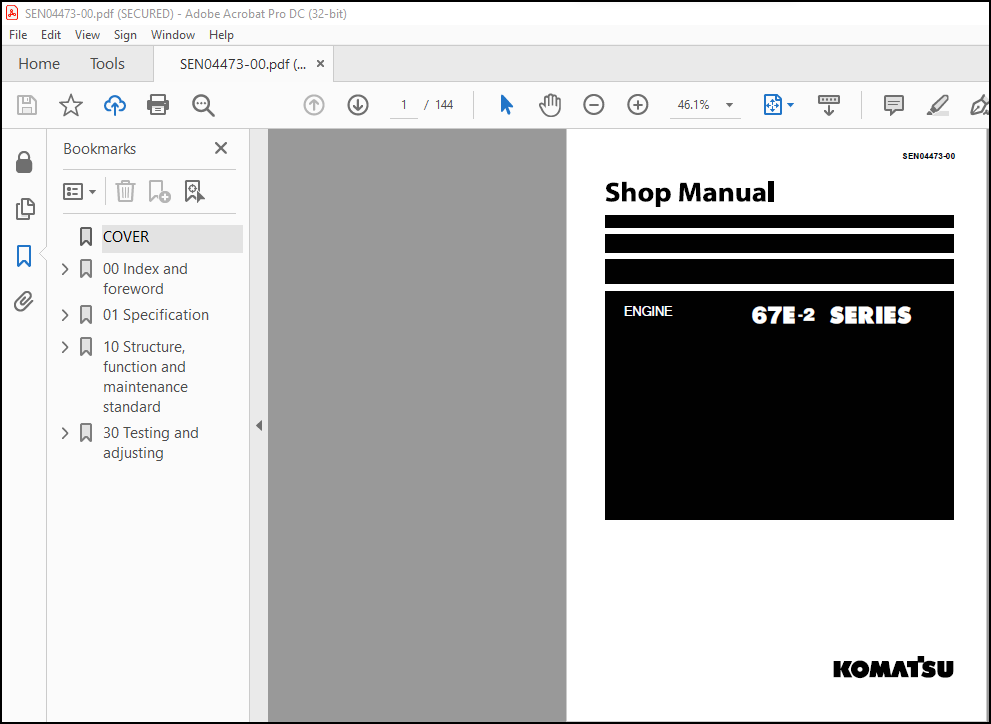

Komatsu 67E-2 Series Engine Shop Manual SEN04473-00 – PDF DOWNLOAD

Komatsu 67E-2 Series Engine Shop Manual SEN04473-00 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 67E-2 Series Engine Shop Manual SEN04473-00 – PDF DOWNLOAD

Language : English

Pages : 144

Downloadable : Yes

File Type : PDF

Size: 4.79 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 67E-2 Series Engine Shop Manual SEN04473-00 – PDF DOWNLOAD

TO THE READER:

This Shop Manual has been prepared to provide servicing personnel with information on the mechanism,

service and maintenance of 67E-2 series.

It is divided into three parts, “Specification”, “Structure, function and maintenance standard” and “Testing and

adjusting”.

■ Specification

Information on the engine specifications.

■ Structure, function and maintenance standard

Information on the construction and function are included. This part should be understood before

proceeding with troubleshooting, disassembling and servicing.

■ Testing and adjusting

• Information on the engine identification, the general precautions, maintenance check list, check and

maintenance and special tools are described.

• Information on the troubleshooting, servicing specification lists, tightening torque, checking and

adjusting, disassembling and assembling, and servicing which cover procedures, precautions, factory

specifications and allowable limits.

All information illustrations and specifications contained in this manual are based on the latest product

information available at the time of publication.

The right is reserved to make changes in all information at any time without notice.

Due to covering many models of this manual, information or picture being used have not been specified as

one model.

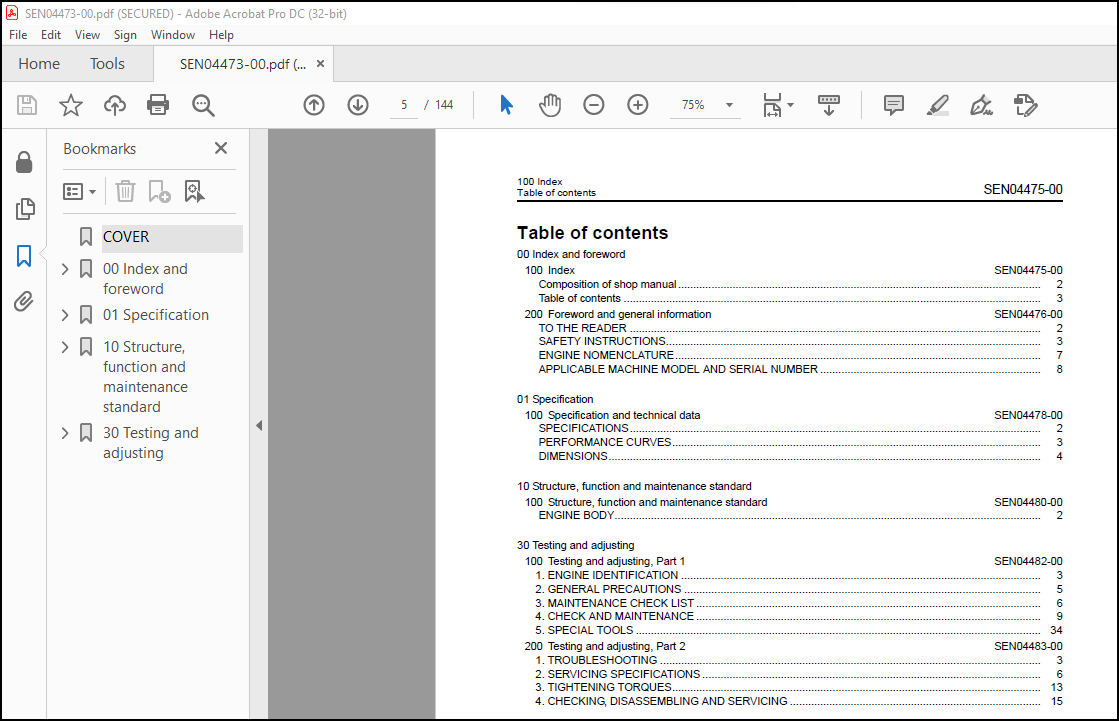

TABLE OF CONTENTS:

Komatsu 67E-2 Series Engine Shop Manual SEN04473-00 – PDF DOWNLOAD

COVER……………………………………………………………… 1

00 Index and foreword……………………………………………….. 0

100 Index………………………………………………………. 3

Composition of shop manual……………………………………. 4

Table of contents……………………………………………. 5

200 Foreword and general information………………………………. 7

TO THE READER……………………………………………….. 8

SAFETY INSTRUCTIONS………………………………………….. 9

ENGINE NOMENCLATURE………………………………………….. 13

APPLICABLE MACHINE MODEL AND SERIAL NUMBER……………………… 14

01 Specification……………………………………………………. 0

100 Specification and technical data………………………………. 17

SPECIFICATIONS………………………………………………. 18

PERFORMANCE CURVES…………………………………………… 19

DIMENSIONS………………………………………………….. 20

10 Structure, function and maintenance standard………………………… 0

100 Structure, function and maintenance standard……………………. 23

ENGINE BODY…………………………………………………. 24

[1] HALF-FLOATING HEAD COVER………………………………. 24

[2] CLOSED BREATHER………………………………………. 24

[3] PISTON………………………………………………. 25

30 Testing and adjusting…………………………………………….. 0

100 Testing and adjusting, Part 1…………………………………. 27

1. ENGINE IDENTIFICATION……………………………………… 29

[1] MODEL NAME AND ENGINE SERIAL NUMBER…………………….. 29

[2] 3D67E-2 ENGINE……………………………………….. 30

[3] CYLINDER NUMBER………………………………………. 30

2. GENERAL PRECAUTIONS……………………………………….. 31

3. MAINTENANCE CHECK LIST…………………………………….. 32

4. CHECK AND MAINTENANCE……………………………………… 35

[1] DAILY CHECK POINTS……………………………………. 35

[2] CHECK POINTS OF INITIAL 50 HOURS……………………….. 37

[3] CHECK POINT OF EVERY 50 HOURS………………………….. 39

[4] CHECK POINT OF EVERY 75 HOURS………………………….. 40

[5] CHECK POINTS OF EVERY 100 HOURS………………………… 41

[6] CHECK POINT OF EVERY 150 HOURS…………………………. 44

[7] CHECK POINTS OF EVERY 200 HOURS………………………… 44

[8] CHECK POINTS OF EVERY 400 HOURS………………………… 45

[9] CHECK POINTS OF EVERY 500 HOURS………………………… 46

[10] CHECK POINTS OF EVERY 1 OR 2 MONTHS……………………. 48

[11] CHECK POINT OF EVERY YEAR…………………………….. 50

[12] CHECK POINT OF EVERY 1000 HOURS……………………….. 51

[13] CHECK POINTS OF EVERY 1500 HOURS………………………. 52

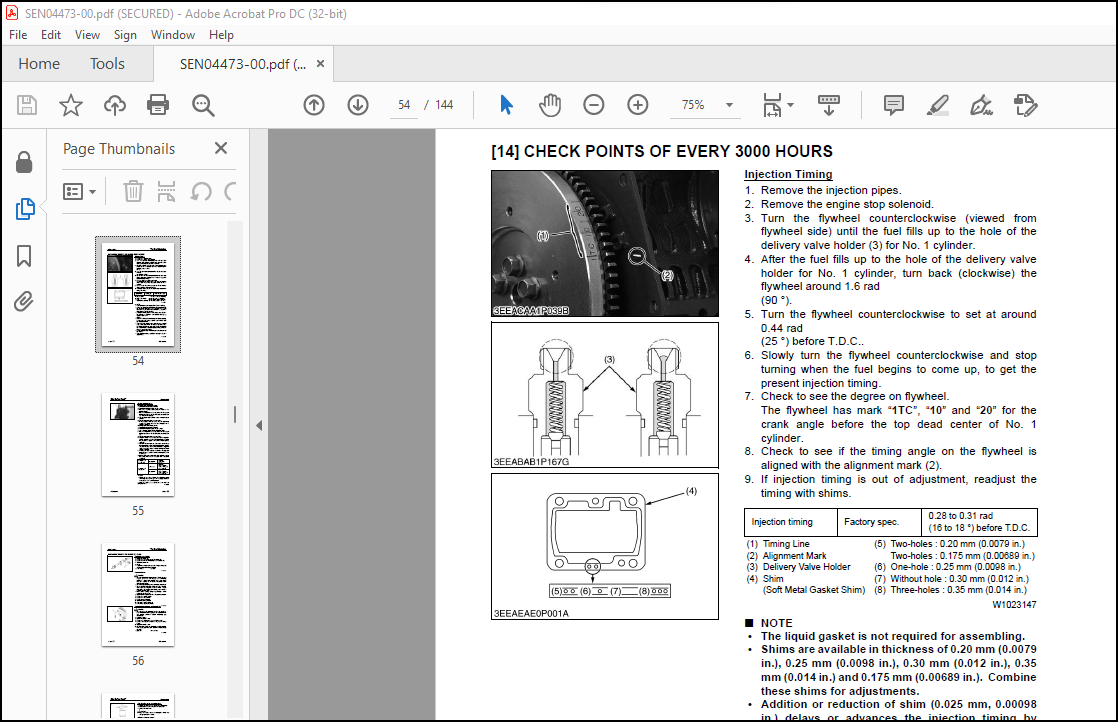

[14] CHECK POINTS OF EVERY 3000 HOURS………………………. 54

[15] CHECK POINTS OF EVERY 2 YEARS…………………………. 56

5. SPECIAL TOOLS…………………………………………….. 60

200 Testing and adjusting, Part 2…………………………………. 67

1. TROUBLESHOOTING…………………………………………… 69

2. SERVICING SPECIFICATIONS…………………………………… 72

3. TIGHTENING TORQUES………………………………………… 79

[1] TIGHTENING TORQUES FOR GENERAL USE SCREWS, BOLTS AND NUTS…. 79

[2] TIGHTENING TORQUES FOR SPECIAL USE SCREWS, BOLTS AND NUTS…. 80

4. CHECKING, DISASSEMBLING AND SERVICING……………………….. 81

[1] CHECKING AND ADJUSTING………………………………… 81

(1) Engine Body………………………………………. 81

(2) Lubricating System………………………………… 83

(3) Cooling System……………………………………. 83

(4) Fuel System………………………………………. 85

(5) Electrical System…………………………………. 89

[2] DISASSEMBLING AND ASSEMBLING…………………………… 96

(1) Draining Engine Oil and Coolant…………………….. 96

(2) External Components……………………………….. 97

(3) Cylinder Head, Valves and Oil Pan…………………… 97

(4) Gear Case and Timing Gears………………………….103

(5) Piston and Connecting Rod…………………………..110

(6) Flywheel and Crankshaft…………………………….113

(7) Starter…………………………………………..116

(8) Dynamo……………………………………………118

(9) Alternator………………………………………..119

[3] SERVICING…………………………………………….120

(1) Cylinder Head and Valves……………………………120

(2) Timing Gears………………………………………126

(3) Piston and Connecting Rod…………………………..128

(4) Crankshaft………………………………………..131

(5) Cylinder………………………………………….137

(6) Oil Pump………………………………………….138

(7) Starter…………………………………………..139

(8) Alternator………………………………………..142