$33

Komatsu 6D140-2 Series Diesel Engine Shop Manual SEBM008613 – PDF DOWNLOAD

Komatsu 6D140-2 Series Diesel Engine Shop Manual SEBM008613 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 6D140-2 Series Diesel Engine Shop Manual SEBM008613 – PDF DOWNLOAD

Language : English

Pages : 376

Downloadable : Yes

File Type : PDF

Size: 21.2 MB

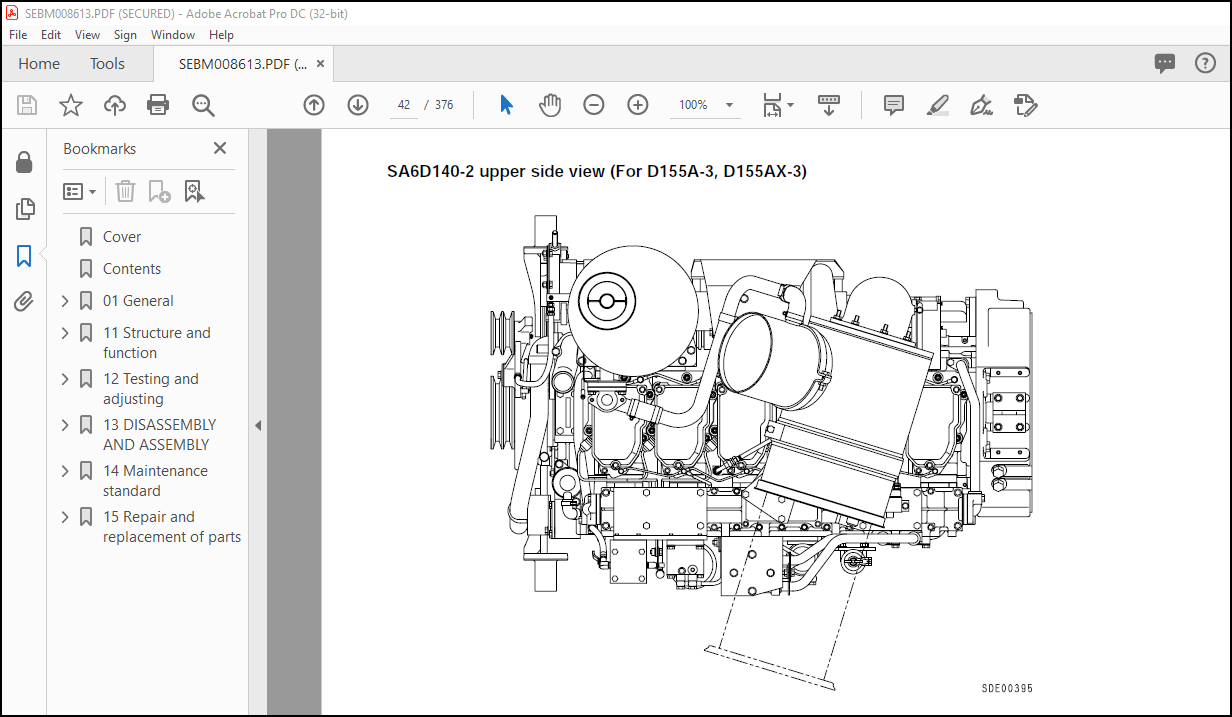

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 6D140-2 Series Diesel Engine Shop Manual SEBM008613 – PDF DOWNLOAD

The Komatsu 6D140-2 Series Diesel Engine Shop Manual SEBM008613 is a detailed guide that provides comprehensive information on the service, repair, and maintenance of the Komatsu 6D140-2 Series diesel engines. These engines are six-cylinder, turbocharged engines that are commonly used in heavy construction equipment, such as excavators and bulldozers.

The manual is published by Komatsu, a leading manufacturer of heavy equipment and construction machinery. The manual is designed to be used by mechanics and technicians who are responsible for maintaining and repairing Komatsu equipment. It is an essential tool for anyone who works with Komatsu engines.

The manual is divided into several sections, each of which provides specific information on different aspects of the engine. The sections include:

- General information: This section provides an overview of the engine, including its specifications, features, and operating principles. It also includes information on safety precautions, tools, and equipment needed for maintenance and repair.

- Inspection and adjustment: This section provides detailed instructions on how to inspect and adjust various components of the engine, including the cylinder head, valves, fuel system, and cooling system.

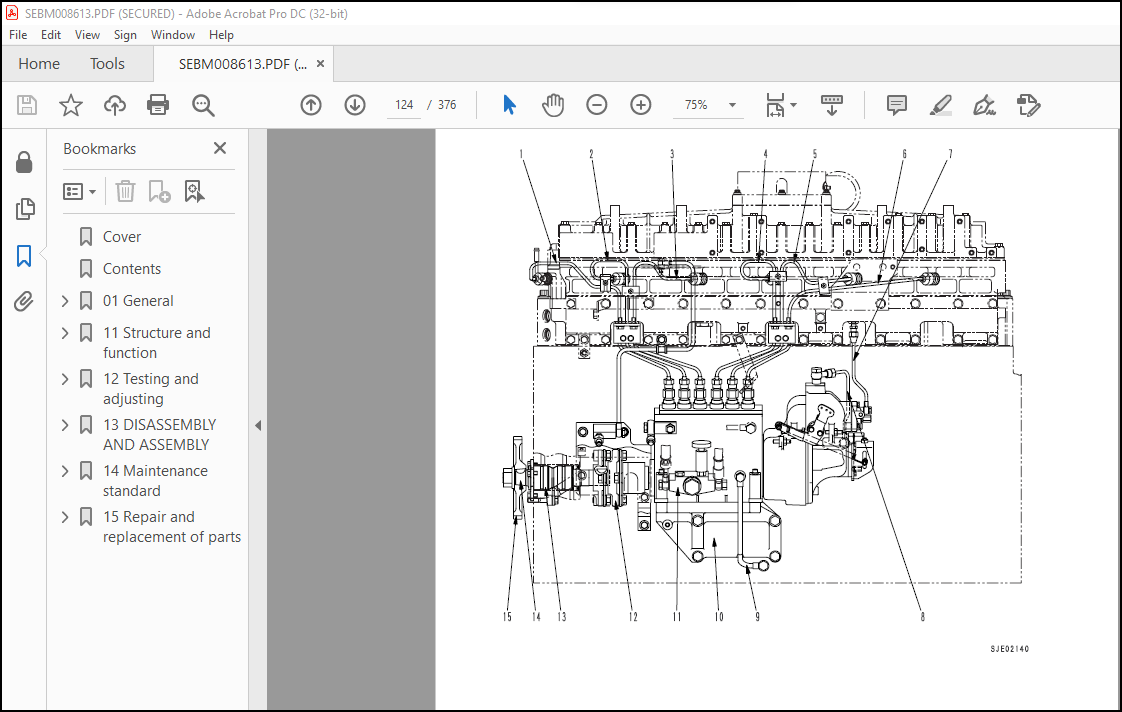

- Engine disassembly and assembly: This section provides step-by-step instructions on how to disassemble and assemble the engine. It includes detailed diagrams and illustrations to help users understand each step of the process.

- Troubleshooting: This section provides a comprehensive list of potential problems that may arise with the engine, along with diagnostic procedures to help identify and fix these issues.

- Maintenance: This section provides information on the regular maintenance tasks that should be performed on the engine, including oil changes, filter replacements, and other routine tasks.

- Reassembly and testing: This section provides detailed instructions on how to reassemble the engine after repairs have been made. It also includes information on how to test the engine to ensure that it is functioning properly.

- Service data: This section provides detailed technical data on the engine, including torque specifications, compression pressures, and other important information.

The manual is written in clear, concise language, and is filled with detailed diagrams and illustrations to help users understand each step of the process. It is an essential tool for anyone who works with Komatsu engines, and can help to ensure that the engine is maintained and repaired to the highest standards. It is important to note that the manual is designed for use by qualified mechanics and technicians, and should not be used by individuals without the appropriate training and experience.

TABLE OF CONTENTS:

Komatsu 6D140-2 Series Diesel Engine Shop Manual SEBM008613 – PDF DOWNLOAD

Cover……………………………………………………………………….. 1

Contents…………………………………………………………………….. 2

01 General…………………………………………………………………… 27

Applicable machine………………………………………………………… 28

Specifications……………………………………………………………. 30

General assembly drawing…………………………………………………… 38

Weight table……………………………………………………………… 54

Engine performance curve…………………………………………………… 57

11 Structure and function……………………………………………………… 69

Intake and exhaust system………………………………………………….. 70

Intake and exhaust system………………………………………………. 70

Air cleaner…………………………………………………………… 83

Turbocharger………………………………………………………….. 86

Aftercooler…………………………………………………………… 88

Engine body………………………………………………………………. 92

Cylinder head…………………………………………………………. 92

Cylinder block………………………………………………………… 94

Main circulation system………………………………………………… 96

Vibration damper………………………………………………………. 98

Timing gear……………………………………………………………100

Valve system…………………………………………………………..102

Flywheel and flywheel housing……………………………………………104

Lubrication system…………………………………………………………106

Lubrication system chart………………………………………………..106

Oil pump………………………………………………………………108

Regulator valve and piston cooling valve………………………………….109

Oil filter…………………………………………………………….110

Oil cooler…………………………………………………………….114

Fuel system……………………………………………………………….116

Fuel system chart………………………………………………………116

Fuel injection pump…………………………………………………….118

Feed pump……………………………………………………………..126

Fuel injection nozzle…………………………………………………..127

Fuel filter……………………………………………………………128

Engine stop motor………………………………………………………129

Cooling system…………………………………………………………….134

Cooling system chart……………………………………………………134

Water pump…………………………………………………………….138

Thermostat…………………………………………………………….144

Corrosion resistor……………………………………………………..145

Corrosion resistor mounting……………………………………………..146

Cooling fan drive………………………………………………………147

Accessory…………………………………………………………………156

Air compressor…………………………………………………………156

Exhaust brake………………………………………………………….161

Electrical system………………………………………………………….165

Alternator…………………………………………………………….165

Starting motor…………………………………………………………172

Electrical intake air heater…………………………………………….177

Front PTO mounting……………………………………………………..178

Front PTO assembly……………………………………………………..179

Front PTO drive gear assembly……………………………………………180

12 Testing and adjusting……………………………………………………….181

Mounting (adjusting) methodof engine speed sensor……………………………..182

Engine body……………………………………………………………….183

Adjusting valve clearance……………………………………………….183

Measuring compressionpressure……………………………………………184

Fuel system……………………………………………………………….185

Testing and adjusting fuelinjection timing………………………………..185

Adjusting fuel injectionpressure…………………………………………186

Procedure for adjustingengine stop motor cable…………………………….187

Cooling system…………………………………………………………….189

Checking and adjusting fan belt tension…………………………………..189

Fuel injection pump calibration data…………………………………………190

Performance test…………………………………………………………..206

Run-in standard………………………………………………………..206

Performance test criteria……………………………………………….212

Troubleshooting……………………………………………………………221

Points to remember when troubleshooting…………………………………..223

Method of using troubleshooting charts……………………………………224

S-1 Starting performance is poor (starting always takes time)……………….228

S-2 Engine does not start……………………………………………….229

S-3 Engine does not pick up smoothly (follow-up is poor)……………………232

S-4 Engine stops during operations……………………………………….233

S-5 Engine does not rotate smoothly (hunting)……………………………..234

S-6 Engine lacks output (no power)……………………………………….235

S-7 Exhaust smoke is black (incomplete combustion)…………………………236

S-8 Oil consumption is excessive (or exhaust smoke is blue)…………………237

S-9 Oil becomes contaminated quickly……………………………………..238

S-10 Fuel consumption is excessive……………………………………….239

S-11 Oil is in cooling water, or water spurts back, or water level goes down….240

S-12 Oil pressure caution lamp lights up (drop in oil pressure)……………..241

S-13 Oil level rises (water, fuel in oil)…………………………………242

S-14 Water temperature becomes too high (overheating)………………………243

S-15 Abnormal noise is made……………………………………………..244

S-16 Vibration is excessive……………………………………………..245

Testing and adjusting tool list………………………………………….247

Testing and adjusting dataa……………………………………………..248

13 DISASSEMBLY AND ASSEMBLY…………………………………………………….257

GENERAL DISASSEMBLY………………………………………………………..257

Air cleaner・muffler…………………………………………………….258

Starting motor…………………………………………………………258

Turbocharger drain tube…………………………………………………259

Setting engine in engine overhaul stand…………………………………..259

Corrosion resistor, air compressor suction tube……………………………259

Bracket……………………………………………………………….259

Connector……………………………………………………………..260

Tension pulley assembly…………………………………………………260

Fan pulley assembly…………………………………………………….260

Alternator assembly・pulley………………………………………………260

Dipstick guide, air compressor…………………………………………..261

Fuel hose……………………………………………………………..261

Turbocharger…………………………………………………………..261

Exhaust manifold……………………………………………………….261

After-cooler assembly (Intake manifold assembly)…………………………..261

Fuel injection tube…………………………………………………….261

Fuel injection pump assembly…………………………………………….262

Tube, bracket, PTO case…………………………………………………262

Fuel filter・fuel filter bracket………………………………………….262

Oil filter・oil regulator………………………………………………..262

Oil pan……………………………………………………………….263

Suction pipe, under frame……………………………………………….263

Flywheel………………………………………………………………263

Rear seal……………………………………………………………..263

Flywheel housing……………………………………………………….264

Air vent tube, spill pipe, rocker arm housing cover………………………..264

Nozzle holder, inlet connector…………………………………………..265

Rocker arm…………………………………………………………….265

Push rod………………………………………………………………266

Crosshead……………………………………………………………..266

Rocker arm housing……………………………………………………..266

Cylinder head assembly………………………………………………….266

Vibration damper・crankshaft pulley assembly……………………………….267

Front support………………………………………………………….267

Thermostat housing……………………………………………………..267

Water pump assembly…………………………………………………….267

Oil cooler assembly…………………………………………………….267

Cam follower…………………………………………………………..268

Gear case cover………………………………………………………..268

Injection pump drive gear……………………………………………….268

Camshaft………………………………………………………………268

Oil pump assembly, oil pump idler gear……………………………………269

Main idler gear, injection pump drive shaft……………………………….269

Piston cooling nozzle…………………………………………………..269

Piston and connecting rod assembly……………………………………….269

Crankshaft…………………………………………………………….271

Cylinder liner…………………………………………………………272

GENERAL ASSEMBLY…………………………………………………………..273

Tightening bolts by the plastic range turning angle method………………….274

Drawing of special tool…………………………………………………275

Preparatory work……………………………………………………….276

Cylinder liner…………………………………………………………277

Crankshaft…………………………………………………………….279

Piston and connecting rod assembly……………………………………….282

Piston cooling nozzle…………………………………………………..284

Main idler gear, fuel injection pump drive shaft…………………………..285

Oil pump idler gear, oil pump assembly……………………………………286

Camshaft………………………………………………………………286

Fuel injection pump drive gear…………………………………………..286

Fuel injection pump drive shaft oil seal………………………………….287

Gear case cover………………………………………………………..288

Breather………………………………………………………………288

Front seal…………………………………………………………….289

Cam follower…………………………………………………………..290

Oil cooler assembly…………………………………………………….290

Water pump assembly…………………………………………………….291

Thermostat housing……………………………………………………..291

Front support………………………………………………………….291

Vibration damper, crankshaft pulley assembly………………………………291

Cylinder head assembly………………………………………………….292

Crosshead……………………………………………………………..294

Rocker arm housing……………………………………………………..294

Push rod………………………………………………………………294

Rocker arm…………………………………………………………….295

Adjusting valve clearance……………………………………………….295

Nozzle holder, inlet connector…………………………………………..296

Rocker arm housing cover, spill pipe, air vent tube………………………..297

Flywheel housing……………………………………………………….297

Rear seal……………………………………………………………..298

Flywheel………………………………………………………………301

Suction pipe…………………………………………………………..302

Oil pan……………………………………………………………….302

Oil filter assembly, oil regulator……………………………………….302

Fuel filter assembly・fuel filter bracket………………………………….302

PTO case tube, bracket………………………………………………….303

Fuel injection pump assembly…………………………………………….303

Adjusting fuel injection pump……………………………………………304

Fuel injection tube…………………………………………………….306

After-cooler assembly (Intake manifold assembly)…………………………..306

Exhaust manifold……………………………………………………….306

Turbocharger…………………………………………………………..307

Fuel hose……………………………………………………………..307

Dipstick guide, air compressor…………………………………………..307

Alternator assembly, pulley……………………………………………..307

Fan pulley assembly…………………………………………………….308

Tension pulley assembly…………………………………………………308

Intake connector……………………………………………………….308

Muffler bracket, air cleaner bracket……………………………………..308

Corrosion resistor……………………………………………………..309

Resetting engine in engine stand…………………………………………309

Turbocharger drain tube…………………………………………………309

Starting motor…………………………………………………………309

Air cleaner, muffler……………………………………………………310

Refilling with oil……………………………………………………..310

14 Maintenance standard………………………………………………………..311

Intake and exhaust system…………………………………………………..312

Turbocharger…………………………………………………………..312

Engine body……………………………………………………………….316

Cylinder head………………………………………………………….316

Valve, valve guide……………………………………………………..318

Rocker arm and shaft……………………………………………………320

Crosshead and guide…………………………………………………….321

Cylinder block…………………………………………………………322

Cylinder liner…………………………………………………………323

Crankshaft…………………………………………………………….324

Camshaft………………………………………………………………325

Cam follower and push rod……………………………………………….326

Timing gear……………………………………………………………328

Piston………………………………………………………………..330

Connecting rod…………………………………………………………332

Flywheel and flywheel housing……………………………………………333

Lubrication system…………………………………………………………334

Oil pump………………………………………………………………334

Regulator valve, piston cooling valve and safety valve……………………..336

Oil cooler…………………………………………………………….337

Cooling system…………………………………………………………….338

Water pump…………………………………………………………….338

Thermostat…………………………………………………………….341

15 Repair and replacement of parts………………………………………………343

Table of special tools……………………………………………………..344

Cylinder head……………………………………………………………..345

Grinding of fitting face ofcylinder head………………………………….345

Replacing valve seat insert……………………………………………..346

Pressure test………………………………………………………….351

Replacing valve guide…………………………………………………..352

Replacing crosshead guide……………………………………………….353

Grinding valve…………………………………………………………354

Cylinder block…………………………………………………………….355

Replacing cam bushing…………………………………………………..355

Replacing crankshaft gear……………………………………………….358

Replacing cam gear……………………………………………………..359

Replacing flywheel ring gear…………………………………………….360

Replacing connecting rodsmall end bushing…………………………………361

Cylinder block parts……………………………………………………362

Testing and inspecting cylinder block…………………………………….363

Correcting cylinder block top surface, counterbore…………………………366

Replacing main bearing cap………………………………………………374