$37

Komatsu 6D170-2 Series Diesel Engine Shop Manual SEBM008107 – PDF DOWNLOAD

Komatsu 6D170-2 Series Diesel Engine Shop Manual SEBM008107 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 6D170-2 Series Diesel Engine Shop Manual SEBM008107 – PDF DOWNLOAD

Language : English

Pages : 341

Downloadable : Yes

File Type : PDF

Size: 15.6 MB

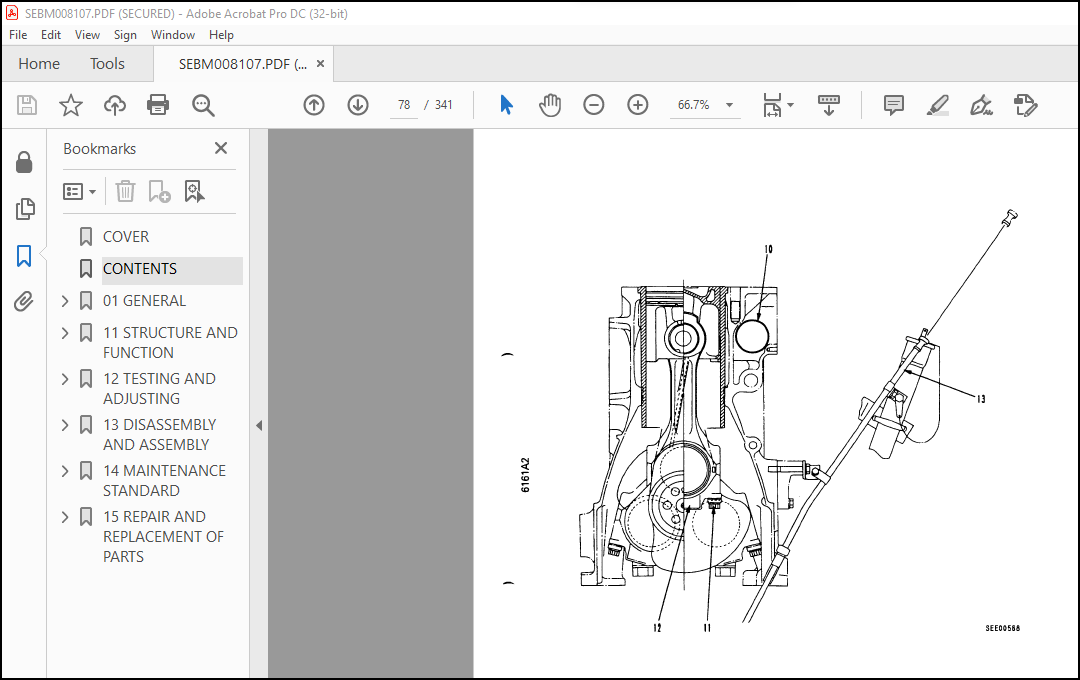

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 6D170-2 Series Diesel Engine Shop Manual SEBM008107 – PDF DOWNLOAD

The Komatsu 6D170-2 Series Diesel Engine Shop Manual is a comprehensive guide to servicing, maintaining, and repairing the Komatsu 6D170-2 diesel engine. This engine is commonly used in heavy-duty machinery, such as large excavators and bulldozers, as well as in marine applications.

The manual is published by Komatsu, a leading manufacturer of heavy equipment and diesel engines. It is designed to provide detailed information on the engine to qualified mechanics and technicians, enabling them to service and repair the engine to the highest standards.

The manual is divided into several sections, each of which provides specific information on different aspects of the engine. The sections include:

- General information: This section provides an overview of the engine, including its specifications, features, and operating principles. It also includes information on safety precautions, tools, and equipment needed for maintenance and repair.

- Inspection and adjustment: This section provides detailed instructions on how to inspect and adjust various components of the engine, including the cylinder head, valves, fuel system, and cooling system.

- Engine disassembly and assembly: This section provides step-by-step instructions on how to disassemble and assemble the engine. It includes detailed diagrams and illustrations to help users understand each step of the process.

- Troubleshooting: This section provides a comprehensive list of potential problems that may arise with the engine, along with diagnostic procedures to help identify and fix these issues.

- Maintenance: This section provides information on the regular maintenance tasks that should be performed on the engine, including oil changes, filter replacements, and other routine tasks.

- Reassembly and testing: This section provides detailed instructions on how to reassemble the engine after repairs have been made. It also includes information on how to test the engine to ensure that it is functioning properly.

- Service data: This section provides detailed technical data on the engine, including torque specifications, compression pressures, and other important information.

The manual is written in clear, concise language and is filled with detailed diagrams and illustrations to help users understand each step of the process. It is an essential tool for anyone who works with Komatsu diesel engines and can help to ensure that the engine is maintained and repaired to the highest standards.

However, it should be noted that the manual is designed for use by qualified mechanics and technicians and should not be used by individuals without the appropriate training and experience. The manual is also specifically for the Komatsu 6D170-2 engine and should not be used as a reference for other engines in the Komatsu lineup.

TABLE OF CONTENTS:

Komatsu 6D170-2 Series Diesel Engine Shop Manual SEBM008107 – PDF DOWNLOAD

COVER…………………………………………………………………………… 1

CONTENTS………………………………………………………………………… 2

01 GENERAL………………………………………………………………………. 25

APPLICABLE MACHINE……………………………………………………………. 26

SPECIFICATIONS……………………………………………………………….. 27

GENERAL ASSEMBLY DRAWING………………………………………………………. 31

WEIGHT TABLE…………………………………………………………………. 54

ENGINE PERFORMANCE CURVE………………………………………………………. 55

11 STRUCTURE AND FUNCTION…………………………………………………………. 64

INTAKE AND EXHAUST SYSTEM……………………………………………………… 65

AIR CLEANER………………………………………………………………. 65

TURBOCHARGER……………………………………………………………… 67

AFTERCOOLER………………………………………………………………. 71

ENGINE BODY………………………………………………………………….. 73

CYLINDER HEAD…………………………………………………………….. 73

VALVE SYSTEM……………………………………………………………… 75

CYLINDER BLOCK……………………………………………………………. 77

MAIN REVOLUTION…………………………………………………………… 79

TIMING GEAR………………………………………………………………. 81

FLYWHEEL AND FLYWHEEL HOUSING………………………………………………. 83

LUBRICATION SYSTEM……………………………………………………………. 84

OIL PUMP…………………………………………………………………. 85

OIL FILTER AND SAFETY VALVE………………………………………………… 86

BYPASS OIL FILTER…………………………………………………………. 87

OIL COOLER……………………………………………………………….. 88

OIL PUMP RELIEF VALVE……………………………………………………… 89

OIL COOLER BYPASS VALVE……………………………………………………. 89

PISTON COOLING VALVE………………………………………………………. 90

FUEL SYSTEM………………………………………………………………….. 91

FUEL INJECTION PUMP……………………………………………………….. 94

FUEL INJECTION PUMP……………………………………………………….. 97

FUEL INJECTION NOZZLE………………………………………………………100

FUEL INJECTION PUMP DRIVE…………………………………………………..101

FUEL FILTER……………………………………………………………….103

STARTING AID………………………………………………………………105

FUEL CUT SOLENOID………………………………………………………….106

ENGINE STOP MOTOR………………………………………………………….108

COOLING SYSTEM………………………………………………………………..113

WATER PUMP………………………………………………………………..114

COOLING FAN……………………………………………………………….115

CORROSION RESISTOR…………………………………………………………122

THERMOSTAT………………………………………………………………..123

ACCESSORY…………………………………………………………………….124

AIR COMPRESSOR MOUNTING…………………………………………………….124

FREON COMPRESSOR…………………………………………………………..126

AIR COMPRESSOR…………………………………………………………….127

EXHAUST BRAKE……………………………………………………………..129

ELECTRICAL SYSTEM……………………………………………………………..130

ALTERNATOR………………………………………………………………..130

ALTERNATOR WITH BUILT-IN REGULATOR…………………………………………..132

STARTING MOTOR…………………………………………………………….133

12 TESTING AND ADJUSTING…………………………………………………………..134

ENGINE BODY…………………………………………………………………..136

ADJUSTING VALVE CLEARANCE…………………………………………………..136

MEASURING COMPRESSION PRESSURE………………………………………………137

INSTALLING ENGINE SPEED SENSOR………………………………………………138

FUEL SYSTEM…………………………………………………………………..139

TESTING AND ADJUSTING FUEL INJECTION TIMING…………………………………..139

ADJUSTING FUEL INJECTION PRESSURE……………………………………………144

CALIBRATION DATA…………………………………………………………..146

REPLACE FAN BELT AND ADJUSTING AUTO TENSIONER…………………………………156

ELECTRICAL SYSTEM……………………………………………………………..157

TESTING AND ADJUSTING ALTERNATOR BELT TENSION…………………………………157

PERFORMANCE TEST………………………………………………………………158

RUNNING IN STANDARD………………………………………………………..158

PERFORMANCE TEST CRITERIA…………………………………………………..160

TROUBLESHOOTING……………………………………………………………….165

POINTS TO REMEMBER WHEN TROUBLESHOOTING………………………………………167

METHOD OF USING TROUBLESHOOTING CHART………………………………………..168

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)…………………..172

S-2 ENGINE DOES NOT START…………………………………………………..176

(1) ENGINE DOES NOT TURN………………………………………………..176

(2) ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT (FUEL IS NOT BEING INJECTED)….177

(3) EXHAUST GAS COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)….179

S-3 ENGINE DOES NOT PICK-UP SMOOTHLY (FOLLOW-UP IS POOR)……………………….180

S-4 ENGINE STOPS DURING OPERATIONS…………………………………………..181

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)…………………………………184

S-6 ENGINE LACKS OUTPUT (NO POWER)…………………………………………..186

S-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION)…………………………….188

S-8 OIL COMSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE)…………………….190

S-9 OIL BECOMES CONTAMINATED QUICKLY…………………………………………191

S-10 FUEL CONSUMPTION IS EXCESSIVE…………………………………………..192

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVER GOES DOWN……..194

S-12 OIL PRESSURE LAMP LIGHTS UP (DROP IN OIL PRESSURE)………………………..195

S-13 OIL LEVEL RISES……………………………………………………….196

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)………………………….197

S-15 ABNORMAL NOISE IS MADE…………………………………………………198

S-16 VIBRATION IS EXCESSIVE…………………………………………………199

TOOL LIST…………………………………………………………………200

TESTING AND ADJUSTING DATA………………………………………………….201

13 DISASSEMBLY AND ASSEMBLY………………………………………………………..205

SPECIAL TOOL LIST……………………………………………………………..206

DISASSEMBLY…………………………………………………………………..207

WASHING………………………………………………………………………225

WASHING CYLINDER BLOCK…………………………………………………………225

WASHING CRANKSHAFT…………………………………………………………….225

MEASURING PARTS……………………………………………………………….226

ASSEMBLY……………………………………………………………………..232

14 MAINTENANCE STANDARD……………………………………………………………269

TURBOCHARGER………………………………………………………………….270

CYLINDER HEAD…………………………………………………………………274

VALVES AND VALVE GUIDE…………………………………………………………275

CROSSHEAD AND CROSSHEAD GUIDE…………………………………………………..276

PUSH ROD AND CAM FOLLOWER………………………………………………………277

CYLINDER BLOCK………………………………………………………………..278

CYLINDER LINER………………………………………………………………..280

CRANKSHAFT……………………………………………………………………281

CAMSHAFT……………………………………………………………………..282

TIMING GEAR…………………………………………………………………..283

PISTON……………………………………………………………………….285

CONNECTING ROD………………………………………………………………..286

OIL PUMP……………………………………………………………………..287

OIL PUMP RELIEF VALVE, PISTON COOLING VALVE AND OIL COOLER BY-PASS VALVE…………….288

WATER PUMP……………………………………………………………………289

15 REPAIR AND REPLACEMENT OF PARTS………………………………………………….290

TABLE OF SPECIAL TOOLS…………………………………………………………291

CYLINDER HEAD…………………………………………………………………292

TESTING AND INSPECTING…………………………………………………………293

REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING………………………………295

REPLACING VALVE SEAT INSERTS……………………………………………………296

REPLACING NOZZLE HOLDER SLEEVE………………………………………………….302

PRESSURE TEST METHOD…………………………………………………………..305

REPLACING VALVE GUIDE………………………………………………………….306

REPLACING CROSS HEAD GUIDE……………………………………………………..307

GRINDING THE VALVE…………………………………………………………….308

CYLINDER BLOCK………………………………………………………………..309

TESTING AND INSPECTING…………………………………………………………310

GRINDING THE TOP SURFACE OF CYLINDER BLOCK……………………………………….312

REPLACING MAIN BEARING CAP……………………………………………………..318

REPLACING CAM BUSHING………………………………………………………….320

CRANKSHAFT……………………………………………………………………322

REPAIRING THE CRANKSHAFT……………………………………………………….329

CONNECTING ROD………………………………………………………………..337

REPLACING CRANKSHAFT GEAR………………………………………………………339

REPLACING CAMSHAFT GEAR………………………………………………………..340

REPLACING FLYWHEEL RING GEAR……………………………………………………341