$34

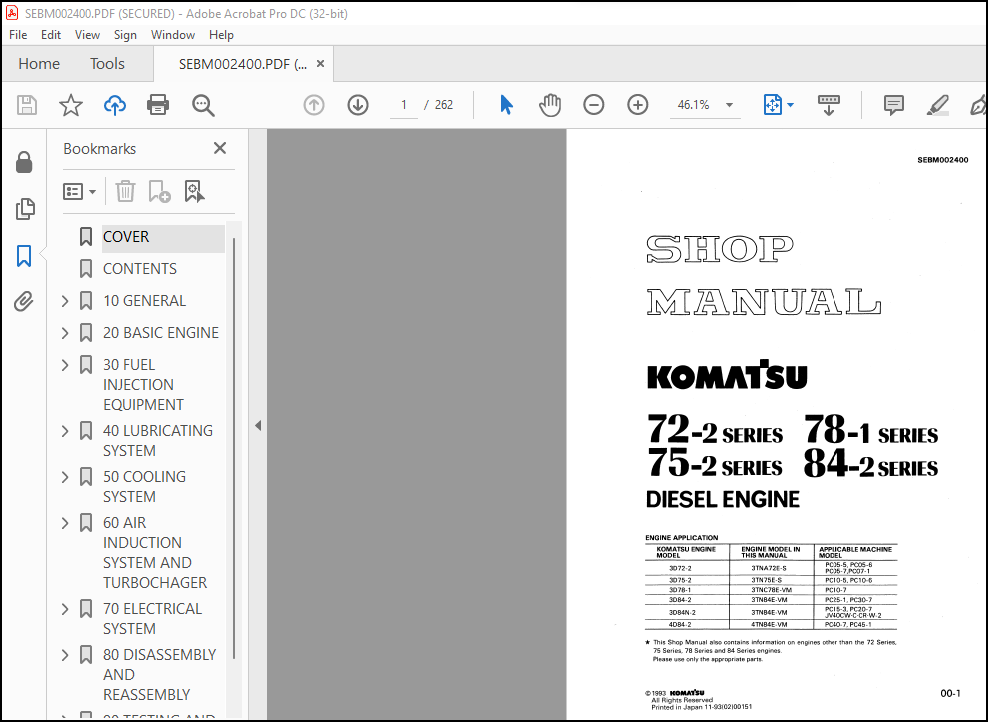

Komatsu 72-2 Series 78-1 Series 75-2 Series 84-2 Series Diesel Engine Shop Manual SEBM002400 – PDF

Komatsu 72-2 Series 78-1 Series 75-2 Series 84-2 Series Diesel Engine Shop Manual SEBM002400 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 72-2 Series 78-1 Series 75-2 Series 84-2 Series Diesel Engine Shop Manual SEBM002400 – PDF DOWNLOAD

Language : English

Pages : 262

Downloadable : Yes

File Type : PDF

Size: 15.2 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 72-2 Series 78-1 Series 75-2 Series 84-2 Series Diesel Engine Shop Manual SEBM002400 – PDF DOWNLOAD

The Komatsu 72-2 Series, 78-1 Series, 75-2 Series, and 84-2 Series Diesel Engine Shop Manual SEBM002400 is a comprehensive guide for mechanics and technicians who are responsible for the repair and maintenance of these engines. The manual provides detailed information on the construction, operation, and maintenance of the engines, as well as step-by-step instructions for disassembly, inspection, repair, and reassembly of various engine components.

- The manual begins with an overview of the engine’s design features, specifications, and performance characteristics. This section provides a detailed description of the engine’s construction and operation, as well as an overview of the various components that make up the engine. It also includes information on the engine’s maintenance schedule and recommended service intervals.

- The manual then provides detailed instructions on the disassembly, inspection, repair, and reassembly of the various components of the engine. This section covers topics such as the cylinder block, cylinder head, crankshaft, pistons, connecting rods, camshaft, and timing gears.

- The cylinder block section provides detailed instructions on the removal and installation of the cylinder block, as well as instructions for inspection, repair, and reassembly of various cylinder block components, such as the cylinder liners and main bearings. The cylinder head section covers the inspection, repair, and replacement of various cylinder head components, such as valves, springs, and guides. The crankshaft section provides instructions on the inspection, repair, and replacement of various crankshaft components, such as the main and connecting rod bearings. The piston section covers the inspection, repair, and replacement of various piston components, such as rings and wrist pins. The connecting rod section provides instructions on the inspection, repair, and replacement of various connecting rod components, such as bearings and bolts. The camshaft and timing gears section covers the inspection, repair, and replacement of various camshaft and timing gear components, such as bearings, gears, and chains.

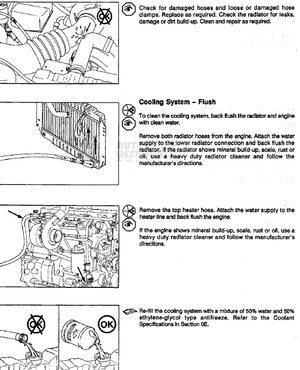

- The manual also includes sections on fuel injection systems, lubrication systems, and cooling systems, which provide detailed instructions on the repair and maintenance of these critical engine systems. The fuel injection section covers topics such as the injection pump, fuel injectors, and fuel lines. The lubrication system section covers topics such as the oil pump, oil filter, and oil cooler. The cooling system section covers topics such as the radiator, water pump, and thermostat.

- In addition to these repair and maintenance procedures, the manual includes a section on troubleshooting, which provides detailed instructions on how to diagnose and fix common problems that may occur during the operation of the engine. This section includes a list of common symptoms, possible causes, and recommended solutions for each problem.

- Overall, the Komatsu 72-2 Series, 78-1 Series, 75-2 Series, and 84-2 Series Diesel Engine Shop Manual SEBM002400 is an essential resource for mechanics and technicians who are responsible for the repair and maintenance of these engines. It provides detailed information on how to disassemble, inspect, repair, and reassemble the engine’s various components, as well as important safety information to help prevent accidents and injuries. The manual is a must-have for anyone who needs to perform repairs or maintenance on these engines.

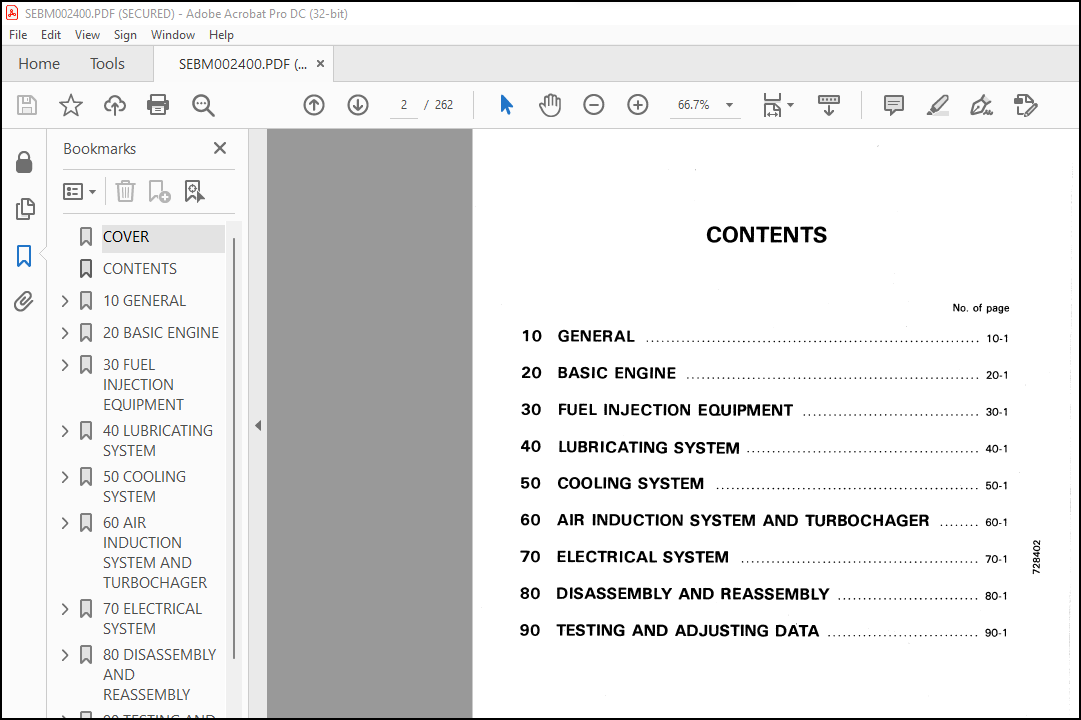

TABLE OF CONTENTS:

Komatsu 72-2 Series 78-1 Series 75-2 Series 84-2 Series Diesel Engine Shop Manual SEBM002400 – PDF DOWNLOAD

COVER…………………………………………………………. 1

CONTENTS………………………………………………………. 2

10 GENERAL…………………………………………………….. 17

1. EXTERNAL VIEWS…………………………………………… 18

2. SPECIFICATIONS…………………………………………… 19

3. CROSS SECTIONAL VIEWS…………………………………….. 23

4. DIMENSIONS………………………………………………. 25

20 BASIC ENGINE………………………………………………… 34

1. CYLINDER BLOCK…………………………………………… 35

2. CYLINDER HEAD……………………………………………. 40

3. PISTON AND PISTON PINS……………………………………. 47

4. CONNECTING ROD…………………………………………… 51

5. CRANKSHAFT AND MAIN BEARING……………………………….. 54

6. CAMSHAFT AND TAPPETS……………………………………… 57

7. TIMING GEAR……………………………………………… 60

8. FLYWHEEL………………………………………………… 62

9. SERVICE DATA…………………………………………….. 64

10. OVER-SIZE AND UNDER-SIZE PARTS……………………………. 72

30 FUEL INJECTION EQUIPMENT……………………………………… 73

1. FUEL SUPPLY SYSTEM……………………………………….. 74

2. DISASSEMBLY, REASSEMBLY AND INSPECTION OF GOVERNOR…………… 86

3. DISASSEMBLY, REASSEMBLY AND INSPECTION OF FUEL INJECTION PUMP…. 96

4. ADJUSTMENT OF FUEL INJECTION PUMP AND GOVERNOR……………….111

5. FUEL FEED PUMP……………………………………………120

6. FUEL INJECTION NOZZLE……………………………………..122

7. TROUBLESHOOTING…………………………………………..128

8. TOOLS……………………………………………………130

9. FUEL FILTER………………………………………………132

10. AIR VENTING SYSTEM……………………………………….132

11. SERVICE DATA…………………………………………….133

40 LUBRICATING SYSTEM……………………………………………140

1. LUBRICATION SYSTEM………………………………………..141

2. LUBE OIL PUMP…………………………………………….143

3. LUBE OIL FILTER & OIL PRESSURE CONTROL VALVE…………………146

4. OIL COOLER……………………………………………….148

5. PISTON COOLING NOZZLE……………………………………..149

6. SERVICE DATA……………………………………………..150

50 COOLING SYSTEM……………………………………………….152

1. COOLING SYSTEM……………………………………………153

2. RADIATOR…………………………………………………153

3. RADIATOR FAN BELT…………………………………………154

4. THERMOSTAT……………………………………………….155

5. COOLING WATER PUMP………………………………………..156

6. SERVICE DATA……………………………………………..158

60 AIR INDUCTION SYSTEM AND TURBOCHAGER……………………………160

1. AIR CLEANER………………………………………………161

2. TURBOCHARGER……………………………………………..163

70 ELECTRICAL SYSTEM…………………………………………….177

1. WIRING DIAGRAM……………………………………………178

2. STARTER MOTOR…………………………………………….191

3. CHARGING EQUIPMENT………………………………………..206

4. STARTING AIDS…………………………………………….217

5. BATTERY………………………………………………….219

6. SERVICE DATA……………………………………………..222

80 DISASSEMBLY AND REASSEMBLY…………………………………….224

1. DISASSEMBLY AND REASSEMBLY PRECAUTIONS………………………225

2. DISASSEMBLY AND REASSEMBLY TOOLS……………………………226

3. DISASSEMBLY AND REASSEMBLY…………………………………233

4. BOLT/NUT TIGHTENING TORQUE…………………………………246

5. TROUBLESHOOTING…………………………………………..247

6. IDENTIFICATION OF PARTS FOR EACH APPLICATION…………………253

7. CONVERSION TABLE………………………………………….254

90 TESTING AND ADJUSTING DATA…………………………………….256

TESTING AND ADJUSTING DATA……………………………………257

FUEL INJECTION SPECIFICATIONS…………………………………262