$37

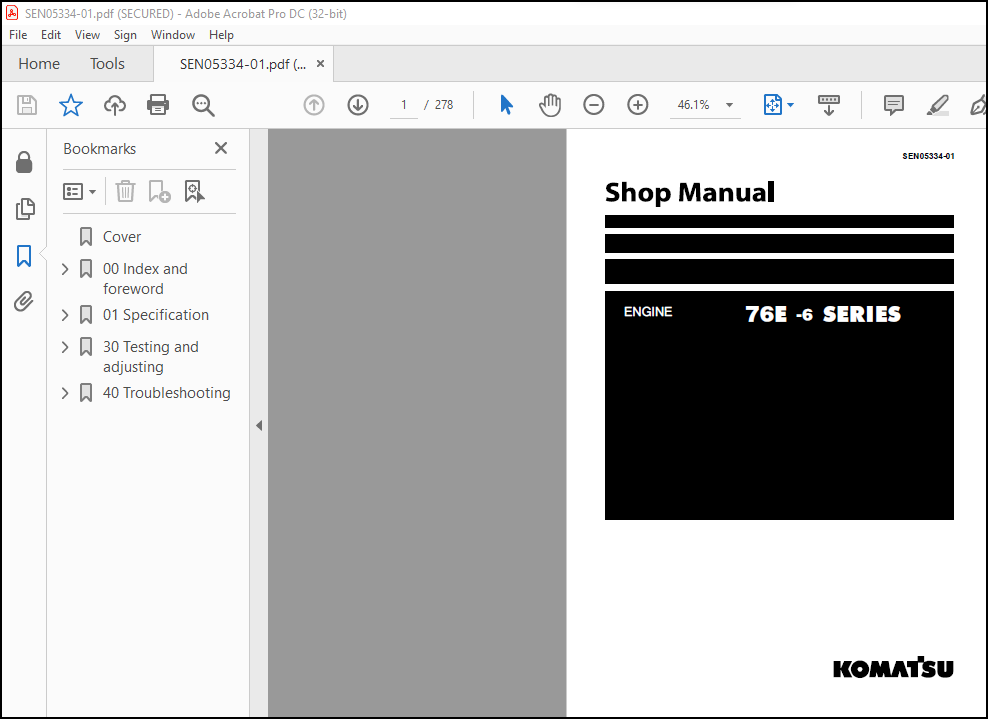

Komatsu 76E-6 Series Engine Shop Manual SEN05334-01 – PDF DOWNLOAD

Komatsu 76E-6 Series Engine Shop Manual SEN05334-01 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 76E-6 Series Engine Shop Manual SEN05334-01 – PDF DOWNLOAD

Language : English

Pages : 278

Downloadable : Yes

File Type : PDF

Size: 13.4 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 76E-6 Series Engine Shop Manual SEN05334-01 – PDF DOWNLOAD

Introduction:

This manual describes the maintenance procedure for 76E-6 Series engines (swirl chamber type).

The contents of this manual shall be used as materials for correct, quick and safe maintenance of the above

engines.

Since this manual explains the maintenance procedure for the standard engine, the specifications and component

parts shown below are partly different from those of the engine mounted on each work equipment

(generator, pump, compressor, etc.)

This shop manual consists of volumes.

Some volumes titled “Testing and adjusting” [Testing and adjusting, Part 1 – Part 8] contain descriptions

related to disassembly and assembly.

For the contents of description, see the general contents or the contents of each volume.

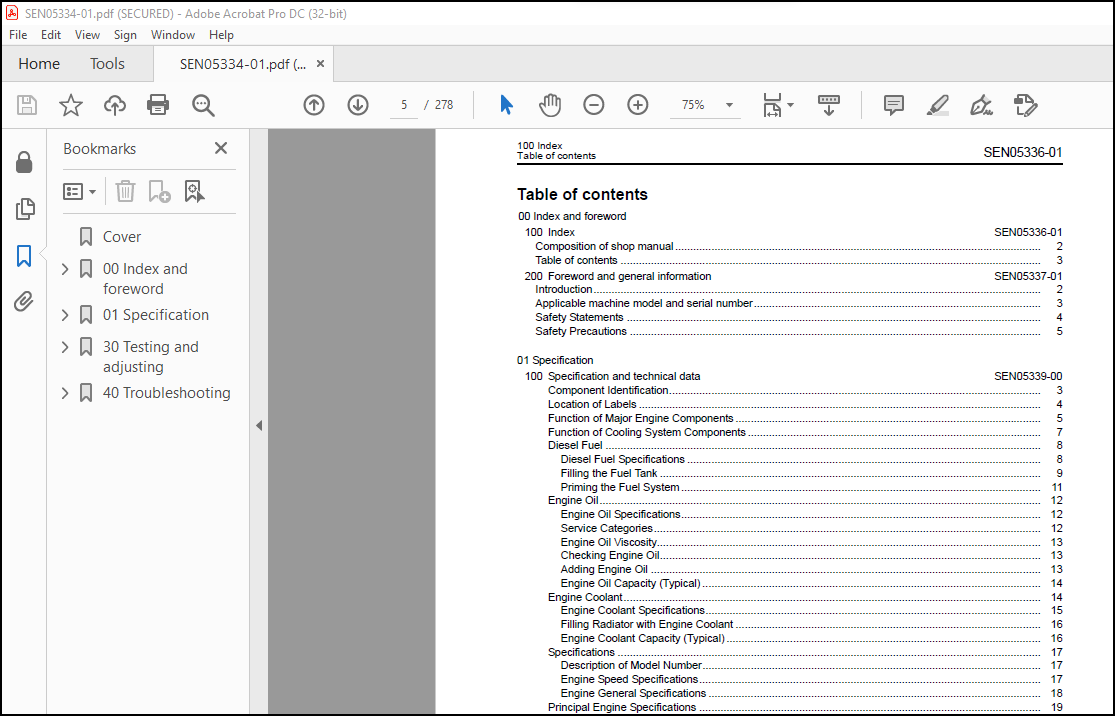

TABLE OF CONTENTS:

Komatsu 76E-6 Series Engine Shop Manual SEN05334-01 – PDF DOWNLOAD

Cover………………………………………………………….. 1

00 Index and foreword……………………………………………. 0

100 Index…………………………………………………… 3

Composition of shop manual………………………………… 4

Table of contents………………………………………… 5

200 Foreword and general information…………………………… 11

Introduction…………………………………………….. 12

Applicable machine model and serial number………………….. 13

Safety Statements………………………………………… 14

Safety Precautions……………………………………….. 15

01 Specification………………………………………………… 33

100 Specification and technical data…………………………… 33

Component Identification………………………………….. 35

Location of Labels……………………………………….. 36

Function of Major Engine Components………………………… 37

Function of Cooling System Components………………………. 39

Diesel Fuel……………………………………………… 40

Diesel Fuel Specifications…………………………….. 40

Filling the Fuel Tank…………………………………. 41

Priming the Fuel System……………………………….. 43

Engine Oil………………………………………………. 44

Engine Oil Specifications……………………………… 44

Service Categories……………………………………. 44

Engine Oil Viscosity………………………………….. 45

Checking Engine Oil…………………………………… 45

Adding Engine Oil…………………………………….. 45

Engine Oil Capacity (Typical)………………………….. 46

Engine Coolant…………………………………………… 46

Engine Coolant Specifications………………………….. 47

Filling Radiator with Engine Coolant……………………. 48

Engine Coolant Capacity (Typical)………………………. 48

Specifications…………………………………………… 49

Description of Model Number……………………………. 49

Engine Speed Specifications……………………………. 49

Engine General Specifications………………………….. 50

Principal Engine Specifications……………………………. 51

Engine Service Information………………………………… 52

Tightening Torques for Standard Bolts and Nuts………………. 53

Abbreviations and Symbols…………………………………. 55

Abbreviations………………………………………… 55

Symbols……………………………………………… 55

Unit Conversions…………………………………………. 56

Unit Prefixes………………………………………… 56

Units of Length………………………………………. 56

Units of Volume………………………………………. 56

Units of Mass………………………………………… 56

Units of Force……………………………………….. 56

Units of Torque………………………………………. 56

Units of Pressure…………………………………….. 56

Units of Power……………………………………….. 56

Units of Temperature………………………………….. 56

30 Testing and adjusting…………………………………………. 59

101 Testing and adjusting, Part 1……………………………… 59

Introduction…………………………………………….. 60

Precautions……………………………………………… 72

The Importance of Periodic Maintenance………………….. 72

Performing Periodic Maintenance………………………… 72

Komatsu Replacement Parts……………………………… 73

Periodic Maintenance Schedule……………………………… 73

Periodic Maintenance Procedures……………………………. 75

After Initial 50 Hours of Operation…………………….. 75

Every 50 Hours of Operation……………………………. 78

Every 250 Hours of Operation…………………………… 81

Every 500 Hours of Operation…………………………… 86

Every 1000 Hours of Operation………………………….. 89

Every 1500 Hours of Operation………………………….. 91

Every 2000 Hours of Operation………………………….. 93

102 Testing and adjusting, Part 2……………………………… 95

Before You Begin Servicing………………………………… 97

Introduction…………………………………………….. 99

Cylinder Head Specifications………………………………. 99

Adjustment Specifications……………………………… 99

Cylinder Head………………………………………… 99

Intake / Exhaust Valve and Guide………………………..100

Push Rod……………………………………………..100

Valve Spring………………………………………….100

Rocker Arm and Shaft…………………………………..100

Camshaft and Timing Gear Train Specifications………………..101

Camshaft……………………………………………..101

Idler Gear Shaft and Bushing……………………………101

Timing Gear Backlash…………………………………..101

Crankshaft and Pistons Specifications……………………….102

Crankshaft……………………………………………102

Crankshaft Reconditioning………………………………102

Thrust Bearing………………………………………..102

Piston……………………………………………….103

Piston Ring…………………………………………..103

Connecting Rod………………………………………..104

Tappet……………………………………………….104

Cylinder Block Specifications………………………………105

Cylinder Block………………………………………..105

Special Torque Chart………………………………………105

Torque for Bolts and Nuts………………………………105

Special Service Tools……………………………………..106

Measuring Instruments……………………………………..108

Cylinder Head…………………………………………….110

Cylinder Head Components……………………………….110

Disassembly of Cylinder Head……………………………111

Cleaning of Cylinder Head Components…………………….115

Inspection of Cylinder Head Components…………………..115

Reassembly of Cylinder Head…………………………….119

Measuring and Adjusting Valve Clearance………………….123

Cylinder Block……………………………………………126

Crankshaft and Camshaft Components………………………126

Disassembly of Cylinder Block Components…………………127

Disassembly of Camshaft and Timing Components…………….128

Disassembly of Crankshaft and Piston Components…………..132

Inspection of Crankshaft and Camshaft Components………….136

Reconditioning the Crankshaft…………………………..141

Honing and Boring……………………………………..142

Reassembly of Crankshaft and Piston Components……………143

Reassembly of Camshaft and Timing Components……………..149

103 Testing and adjusting, Part 3………………………………153

Before You Begin Servicing…………………………………155

Introduction……………………………………………..157

Fuel Injection Pump……………………………………157

Stop Solenoid…………………………………………158

Fuel System Specifications…………………………………159

Special Torque Chart…………………………………..159

Test and Adjustment Specifications………………………159

Special Service Tools……………………………………..160

Measuring Instruments……………………………………..160

Fuel System Diagram……………………………………….161

Fuel System Components…………………………………….162

Fuel Injection Lines………………………………………163

Removal of High-Pressure Fuel Injection Lines…………….163

Installation of High-Pressure Fuel Injection Lines………..163

Removal of Fuel Return Line…………………………….164

Installation of Fuel Return Line………………………..164

Fuel Injection Pump……………………………………….165

Removal of Fuel Injection Pump………………………….165

Installation of Fuel Injection Pump……………………..168

Checking and Adjusting Fuel Injection Timing…………………171

Checking Fuel Injection Timing………………………….171

Adjusting Fuel Injection Timing…………………………174

Fuel Injectors……………………………………………175

Removal of Fuel Injectors………………………………175

Testing of Fuel Injectors………………………………175

Disassembly and Inspection of Fuel Injectors……………..178

Adjusting Fuel Injector Pressure………………………..179

Reassembly of Fuel Injectors……………………………180

Installation of the Fuel Injectors………………………180

104 Testing and adjusting, Part 4………………………………183

Before You Begin Servicing…………………………………184

Introduction……………………………………………..186

Cooling System Diagram…………………………………….186

Engine Coolant Pump Components……………………………..187

Engine Coolant System Check………………………………..188

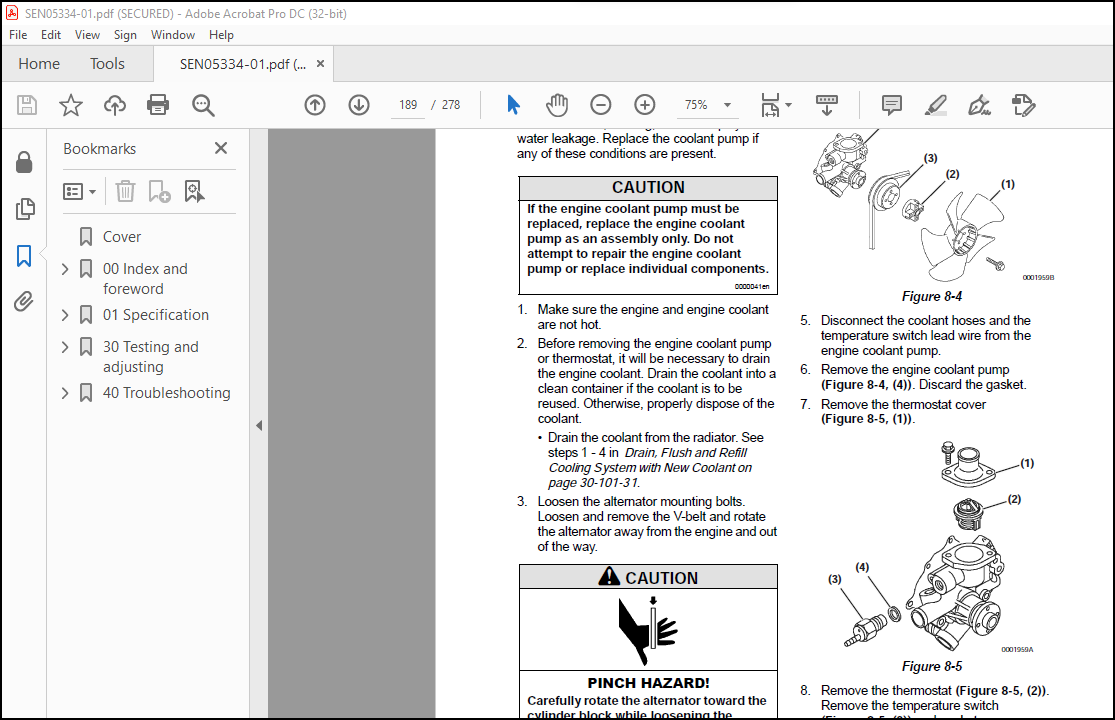

Engine Coolant Pump……………………………………….189

Disassembly of Engine Coolant Pump………………………189

Cleaning and Inspection………………………………..190

Reassembly of Engine Coolant Pump……………………….191

105 Testing and adjusting, Part 5………………………………195

Before You Begin Servicing…………………………………196

Introduction……………………………………………..198

Oil Pump Service Information……………………………….198

Engine Oil Pressure……………………………………198

Outer Rotor Outside Clearance…………………………..198

Outer Rotor Side Clearance……………………………..198

Outer Rotor to Inner Rotor Tip Clearance…………………198

Inner Rotor and Gear Boss Clearance……………………..198

Lubrication System Diagram…………………………………199

Checking Engine Oil Pressure……………………………….200

Trochoid Oil Pump…………………………………………201

Oil Pump Components……………………………………201

Disassembly of Oil Pump………………………………..201

Cleaning and Inspection………………………………..202

Reassembly of Oil Pump…………………………………204

106 Testing and adjusting, Part 6………………………………207

Before You Begin Servicing…………………………………208

Introduction……………………………………………..210

Starter Motor Information………………………………….210

Starter Motor Specifications……………………………….211

Starter Motor Troubleshooting………………………………212

Starter Motor Components…………………………………..213

Starter Motor…………………………………………….214

Removal of Starter Motor……………………………….214

Disassembly of Starter Motor……………………………214

Cleaning and Inspection………………………………..217

Reassembly of Starter Motor…………………………….221

Check Pinion Projection Length………………………….223

No-Load Test………………………………………….224

Installation of Starter Motor…………………………..225

107 Testing and adjusting, Part 7………………………………227

Before You Begin Servicing…………………………………229

Introduction……………………………………………..232

Standard and Optional Alternator Information…………………232

Alternator Specifications………………………………….232

Alternator Troubleshooting…………………………………233

Alternator Components……………………………………..234

Alternator Wiring Diagram………………………………….235

Alternator Standard Output…………………………………236

Alternator……………………………………………….237

Removal of Alternator………………………………….237

Disassembly of Alternator………………………………238

Reassembly of Alternator……………………………….240

Installation of Alternator……………………………..242

Dynamo Component Location………………………………….243

Dynamo Wiring Diagram……………………………………..244

Operation of Dynamo……………………………………….244

Dynamo Standard Output…………………………………….245

Testing of Dynamo…………………………………………246

Testing Stator Coil Continuity………………………….246

Testing Stator Coil Short-to-Ground……………………..246

Testing Dynamo Regulated Output…………………………246

Dynamo…………………………………………………..247

Removal of Dynamo……………………………………..247

Disassembly of Dynamo………………………………….247

Reassembly of Dynamo…………………………………..248

Installation of Dynamo…………………………………249

108 Testing and adjusting, Part 8………………………………251

Electric Wiring Precautions………………………………..252

Electric Wire Resistance…………………………………..253

Battery Cable Resistance…………………………………..254

Electrical Wire Sizes – Voltage Drop………………………..255

Conversion of AWG to European Standards……………………..256

40 Troubleshooting……………………………………………….259

100 Troubleshooting of mechanical system………………………..259

Special Service Tools……………………………………..261

Troubleshooting By Measuring Compression Pressure…………….262

Compression Pressure Measurement Method………………….262

Standard Compression Pressure…………………………..263

Engine Speed and Compression Pressure (Use for Reference)….263

Measured Value and Troubleshooting………………………263

Quick Reference Table For Troubleshooting……………………264

Troubleshooting Charts…………………………………265

Electric Wiring…………………………………………..275