$41

Komatsu 86E-7 – 98E-7 Series Engine (With common rail injection system) Shop Manual SEN06575-02 PDF

Komatsu 86E-7 – 98E-7 Series Engine (With common rail injection system) Shop Manual SEN06575-02 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 86E-7 – 98E-7 Series Engine (With common rail injection system) Shop Manual SEN06575-02 – PDF DOWNLOAD

Language : English

Pages : 716

Downloadable : Yes

File Type : PDF

Size: 40.3 MB

TABLE OF CONTENTS:

Komatsu 86E-7 – 98E-7 Series Engine (With common rail injection system) Shop Manual SEN06575-02 – PDF DOWNLOAD

COVER 1

Table of Contents 3

STRUCTURE AND FUNCTION,TESTING AND ADJUSTING,DISASSEMBLY AND ASSEMBLY,AND MAINTENANCE STANDARD

Introduction 7

APPLICABLE MACHINE 9

Safety 11

Safety Statements 13

Precautions for preparatory work 13

Precautions during work 13

Precautions for slinging work and making signals 14

Precautions for using mobile crane 15

Precautions for using overhead traveling crane 16

Selecting wire ropes 17

Precautions for disposing of waste materials 17

Drying wiring harness 18

Handling controller 19

Safety Precautions 20

During Operation and Maintenance 20

General Service Information 35

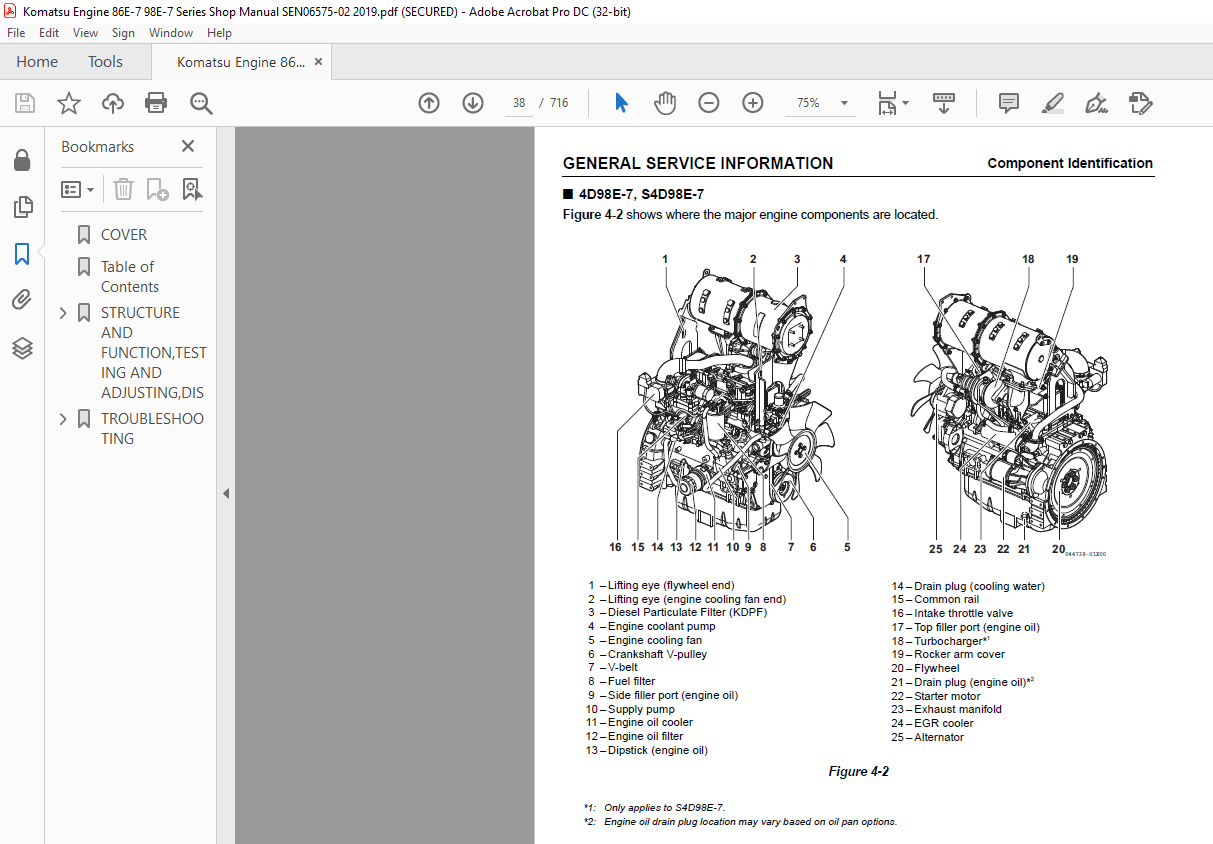

Component Identification 37

3D88E-7, S3D86E-7, 4D88E-7, S4D86E-7 37

4D98E-7, S4D98E-7 38

Function of Major Engine Components 39

Function of Cooling System Components 40

Main Electronic Control Components and Features 41

Installation Position of Sensors 43

Crank Rotation Sensor 44

Cam Speed Sensor 44

New Air Temperature Sensor 45

EGR Temperature Sensor 45

Intake Temperature Sensor 45

Fuel Temperature Sensor (equipped on supply pump) 46

Cooling Water Temperature Sensor 46

Diesel Particulate Filter (KDPF) Inside/Inlet, Exhaust Temperature Sensor 47

Rail Pressure Sensor 47

EGR Pressure Sensor 48

Diesel Particulate Filter (KDPF) Differential Pressure Sensor 49

EGR Valve 50

Intake Air Throttles 51

Acceleration Sensor (Example) 52

Diesel Fuel 53

Diesel Fuel Specifications 53

Additional technical fuel requirements 53

Precautions and concerns regarding the use of diesel fuel 53

Bio-diesel fuels 53

These B7 diesel fuels must meet certain requirements 54

Precautions and concerns regarding the use of bio-fuels: 54

Filling The Fuel Tank 54

Priming the Fuel System 55

Engine Oil 56

Engine Oil Specifications 56

Service categories 56

Definitions 56

Additional technical engine oil requirements: 56

Engine Oil Viscosity 56

Checking Engine Oil 57

Adding Engine Oil 57

Engine Oil Capacity (Typical) 57

Engine Coolant 58

Filling Radiator with Engine Coolant 59

Daily Check of the Cooling System 60

Engine Coolant Capacity (Typical) 60

Specifications 61

Description of Model Number 61

Engine General Specifications 61

Principal Engine Specifications 63

3D88E-7 63

S3D86E-7 64

4D88E-7 65

S4D86E-7 66

4D98E-7 67

S4D98E-7 68

Set Output Listed by Rotation 69

Engine Service Standards 70

Tightening Torques for Standard Bolts and Nuts 71

Abbreviations and Symbols 72

Abbreviations 72

Symbols 72

Unit Conversions 73

Unit prefixes 73

Units of length 73

Units of volume 73

Units of mass 73

Units of force 73

Units of torque 73

Units of pressure 73

Units of power 73

Units of temperature 73

Periodic Maintenance 75

Before You Begin Servicing 77

Introduction 78

The Importance of Periodic Maintenance 78

Performing Periodic Maintenance 78

Replacement Parts 78

Required EPA/ARB Maintenance USA Only 78

EPA/ARB Installation Requirements USA Only 78

Maximum exhaust gas restriction shall be: 78

Periodic Maintenance Schedule 79

Periodic Maintenance Procedures 80

Every 1000 Hours of Operation 80

Check and adjust intake/exhaust valve clearance 80

Every 1500 Hours of Operation 80

Inspect crankcase breather system 80

Every 2000 Hours of Operation 81

Lap the intake and exhaust valves 81

Every 3000 Hours of Operation 82

Inspect turbocharger (blower wash as necessary) 82

Inspect, clean and test EGR valve 82

Inspect and clean EGR lead valve 82

Check and clean of KDPF soot filter 82

Check and clean injector 82

Inspect and test intake throttle valve 82

Clean EGR cooler 83

Every 6000 Hours of Operation 83

Check and clean of KDPF soot filter 83

Engine 85

Before You Begin Servicing 87

Introduction 88

Cylinder Head Specifications 88

Adjustment Specifications 88

Cylinder Head 88

Intake/Exhaust Valve and Guide 89

Push Rod 90

Rocker Arm and Shaft 90

Valve Spring 90

Camshaft and Timing Gear Train Specifications 91

Camshaft 91

Idler Gear Shaft and Bushing 92

Timing Gear Backlash 92

Crankshaft and Piston Specifications 93

Crankshaft 93

Thrust Bearing 94

Piston 94

Piston Ring 95

Connecting Rod 98

Connecting rod small end 98

Connecting rod big end 98

Tappet 99

Cylinder Block Specifications 100

Cylinder Block 100

Special Torque Chart 101

Torque for Bolts and Nuts 101

Special Service Tools 104

Measuring Instruments 108

Cylinder Head 110

Cylinder Head Components 110

Disassembly of Cylinder Head 112

Removing the glow plugs 113

Removal of valve cover 113

Removal of rocker arm assembly 114

Disassembly of rocker arm assembly 114

Removal of cylinder head 115

Removal of intake/exhaust valves 116

Removal of valve guides 116

Cleaning of Cylinder Head Components 117

Inspection of Cylinder Head Components 117

Inspection of push rods 117

Push rod bend 117

Inspection of rocker arm assembly 118

Rocker arm shaft hole diameter 118

Rocker arm shaft outside diameter 118

Inspection of valve guides 118

Inspection of cylinder head 118

Cylinder head distortion 118

Inspection of intake and exhaust valves 119

Valve stem diameter 119

Valve stem bend 119

Valve recession 119

Valve face and valve seat 120

Inspection of valve springs 120

Fractures 120

Corrosion 120

Squareness 121

Free length 121

Reassembly of Cylinder Head 121

Reassembly of valve guides 121

Reassembly of intake and exhaust valves 122

Reassembly of cylinder head 123

Reassembly of rocker arm reassembly 123

Reassembly of the valve cover 124

Measuring and Adjusting Valve Clearance 126

3-cylinder engines 126

4-cylinder engines 126

Crankshaft and Camshaft Components 128

Disassembly of Engine 129

Disassembly of Camshaft and Timing Components 130

Removal of timing gear case cover 130

Checking timing gear backlash 130

Measuring idler gear-to-crankshaft gear backlash 131

Measuring idler gear-to-camshaft gear backlash 131

Removal of timing gears 131

Removal of oil pan 132

Removal of camshaft 132

Removal of gear case or front plate 133

Disassembly of Crankshaft and Piston Components 134

Removal of pistons 134

Removal of crankshaft 136

Inspection of Crankshaft and Camshaft Components 137

Replacement of crankshaft oil seals 138

Measure crankshaft bearing oil clearance 138

Inspection of cylinder block 138

Inspection of pistons, piston rings and wrist pin 138

Inspection of connecting rod 140

Inspection of tappets 141

Inspection of crankshaft 141

Inspection of camshaft 142

Inspection of camshaft bushing and bores 143

Inspection of idler gear and shaft 143

Inspection of flywheel 143

Honing and Boring 144

Reassembly of Crankshaft and Piston Components 145

Reassembly of pistons 145

Installation of crankshaft 147

Installation of pistons 148

Reassembly of Camshaft and Timing Components 150

Installation of gear case 150

Installation of camshaft 150

Installation of timing gears 151

Installation of gear case cover 151

Installation of oil pan 152

Final Reassembly of Engine 153

EGR System 154

EGR System (Typical Model) 154

Typical Model for Turbocharger Model 155

Disassembly of Supply Pump 156

Engine without turbocharger (3D88E-7, 4D88E-7, 4D98E-7) 158

Engine with turbocharger (S3D86E-7, S4D86E-7, S4D98E-7) 158

EGR active control 158

Cleaning the EGR Valves 159

Exit the EGR active control 159

Precautions for cleaning 159

Clean Lead Valves 160

Precautions for Installation 160

Clean EGR Cooler 160

EGR Pipe and Other Connecting Elbows 161

Installing EGR Related Components/Parts 161

Intake Throttle 162

Precautions for Handling the Intake Throttle 162

Fuel System 163

Before You Begin Servicing 165

System Structure 166

Supply pump 166

Rail 166

Injector 166

Crank rotation sensor and gear speed sensor 167

ECU 167

Fuel System Specifications 168

Torque Chart for Major Bolts and Nuts 168

Fuel System Diagram 169

Fuel System Components 170

Removal of Common Rail 171

Reassembly of Common Rail 172

Removal of Injector 173

Reassembly of injector 174

Removal of Supply Pump 175

Reassembly of Supply Pump 176

Cooling System 179

Before You Begin Servicing 181

Introduction 182

Cooling System Diagram 182

Engine Coolant Pump Components 183

Engine Coolant System Check 184

Engine Coolant Pump 184

Removal of Engine Coolant Pump 184

Disassembly of Engine Coolant Pump 185

Cleaning and Inspection 186

Temperature switch 186

Water temperature sensor 186

Thermostat 187

Radiator cap 187

Reassembly of Engine Coolant Pump 187

Installation of Engine Coolant Pump 188

Lubrication System 189

Before You Begin Servicing 191

Introduction 191

Oil Pump Service Information 192

Engine oil pressure 192

Outer rotor outside clearance 192

Outer rotor side clearance 192

Outer rotor to inner rotor tip clearance 192

Rotor shaft clearance 193

Lubrication System Diagram 194

Checking Engine Oil Pressure 195

Oil Pump Components 195

3D88E-7, S3D86E-7, 4D88E-7, S4D86E-7 195

Disassembly of Oil Pump 195

Cleaning and Inspection 196

Check outer rotor outside clearance 196

Outer rotor to inner rotor tip clearance 196

Check outer rotor side clearance 197

Check rotor shaft clearance 197

Reassembly of Oil Pump 197

4D98E-7, S4D98E-7 (Trochoid Oil Pump) 198

Disassembly of Oil Pump 198

Cleaning and Inspection 199

Check outer rotor outside clearance 199

Outer rotor to inner rotor tip clearance 199

Check outer rotor side clearance 199

Check rotor shaft clearance 200

Reassembly of Oil Pump 200

Turbocharger 201

Before You Begin Servicing 203

Introduction 204

Specifications 204

Turbocharger Service Information 204

Troubleshooting 205

Excessive exhaust smoke 205

Generates white smoke 206

Sudden oil decrease 206

Decrease in output 206

Poor (slow) response (starting) of turbocharger 206

Abnormal sound or vibration 206

Turbocharger Components 207

Turbocharger Component Functions 208

Theory of Operation 209

Turbine 209

Compressor 209

Bearings 209

Thrust bearing 209

Radial bearing 209

Lubrication 209

Compressor Side Sealing Mechanism 209

Waste Gate Modulation 209

Waste gate control 209

Washing Procedure 210

Periodic Inspection 211

Visual Inspection 211

Inspection of Rotor Rotation 211

Inspection of Rotor Play 211

Removal of Turbocharger 211

Checking Rotor Play 212

To check rotor end play: 212

To check rotor run-out: 212

Waste Gate Valve Test 213

Waste Gate Actuator Leak Test 213

Installation of Turbocharger 213

Starter Motor 215

Before You Begin Servicing 217

Introduction 218

Starter Motor Information 218

3D88E-7 to S4D86E-7 – Standard and Optional 218

4D98E-7 and S4D98E-7 – Standard and Optional 218

Starter Motor Specifications 219

Starter Motor Troubleshooting 220

Starter Motor Components 221

Starter Motor 222

Removal of Starter Motor 222

Disassembly of Starter Motor 222

Cleaning and Inspection 224

Armature 224

Commutator surface inspection 224

Measure commutator outside diameter 224

Measure commutator insulation depth 225

Armature coil continuity test 225

Armature coil insulation test 225

Measure armature and commutator run-outs 225

Field coil 226

Field coil continuity test 226

Field coil insulation test 226

Measure brush length 226

Magnetic switch 226

Shunt coil continuity test 226

Series coil continuity test 227

Coil resistance test 227

Contact continuity test 227

Pinion clutch assembly 227

Pinion clutch assembly inspection 227

Ball bearing inspection 227

Reassembly of Starter Motor 228

Check Pinion Projection Length 229

No-Load Test 230

Installation of Starter Motor 231

Alternator 233

Before You Begin Servicing 235

Introduction 236

Dynamo and Alternator Information 236

3D88E-7 to S4D98E-7 – Standard and Optional Dynamos 236

3D88E-7 to S4D98E-7 – Standard and Optional Alternators 236

Alternator Specifications 237

Dynamo Specifications 237

Alternator Troubleshooting 238

Alternator Components 239

Alternator Wiring Diagram 240

Alternator Standard Output 241

Alternator 242

Removal of Alternator 242

Disassembly of Alternator 242

Reassembly of Alternator 244

Installation of Alternator 246

Dynamo Component Location 247

Dynamo Wiring Diagram 248

Operation of Dynamo 248

Dynamo Standard Output 249

Testing of Dynamo 250

Testing Stator Coil Continuity 250

Testing Stator Coil Short-to-Ground 250

Testing Dynamo Regulated Output 250

Dynamo 250

Removal of Dynamo 250

Disassembly of Dynamo 251

Reassembly of Dynamo 251

Installation of Dynamo 252

Electronic Control System 253

Before You Begin Servicing 255

System Structure 256

Electronic Engine Speed Control 257

Speed control 257

Engine speed curves 257

Droop control 257

Isochronous control 257

Other engine speed control 257

Low-idling speed up 257

High-idling speed down 257

Auto deceleration (optional) 258

Others 258

Diesel Particulate Filter (KDPF) 259

Outline of Diesel Particulate Filter (KDPF) 259

Overview of Diesel Particulate Filter (KDPF) regeneration control 260

Self-regeneration (passive regeneration) 260

Assisted regeneration (passive regeneration) 260

Reset regeneration (automatic regeneration) 260

Stationary regeneration (manual stationary regeneration) 260

Operation procedures of stationary regeneration 261

Precautions for stationary regeneration 261

Recovery regeneration (optional) 261

Precautions for recovery regeneration 261

KDPF service 262

Procedures for servicing the Diesel Particulate Filter (KDPF) 262

How to Remove and Reattach the Diesel Particulate Filter (KDPF) 263

How to remove the soot filter (SF) 263

KDPF flywheel housing-mounted type 263

KDPF exhaust manifold-mounted type 264

How to reattach the soot filter (SF) 266

KDPF flywheel housing-mounted type 266

KDPF exhaust manifold-mounted type 266

How to remove the KDPF unit 267

KDPF flywheel housing-mounted type 267

KDPF exhaust manifold-mounted type 268

How to reattach the KDPF 269

KDPF flywheel housing-mounted type 269

KDPF exhaust manifold-mounted type 270

SF and KDPF Maintenance Kit 272

Troubleshooting of Electronic Control System 274

Fault Detection Capability 274

SMARTASSIST DIRECT (SA-D) 276

Replacement of Components 277

Processing the KDPF regeneration after the parts replacement 277

Calculation of PM sediment amount in KDPF 278

Processing after the ECU replacement (when it is impossible to inherit from the old ECU) 278

Required processing at the CR-related parts replacement 279

Electric Wiring 281

Electric Wiring Precautions 283

Electrical Wire Resistance 284

Battery Cable Resistance 285

Electrical Wire Sizes – Voltage Drop 286

Conversion of AWG to European Standards 287

TROUBLESHOOTING 289

FAILURE CODE (DTC) GENERAL DESCRIPTION 291

Failure code (DTC) list 297

Description 304

Sensor related 305

Crank speed sensor 305

#B0336: Crank Signal Error 305

#B0337: No Crank Signal 307

Cam speed sensor 309

#B0341: Cam Signal Error 309

#B0342: No Cam Signal 311

#B1341: Cam Angle Offset Error 313

#B0008: No Signal on Both Crank and Cam Speed Sensor 315

Accelerator sensor 316

#B0123: Accelerator Sensor 1 (High voltage) 316

#B0122: Accelerator Sensor 1 (Low voltage) 318

#B0223: — 320

#B0222: — 322

#B1646: — 324

#B1647: — 326

#B0228: Accelerrator sensor 3 (Excessive sensor output) 328

#B0227: Accelerrator sensor 3 (Insufficient sensor output) 330

#B1227: — 332

#B1126: Accelerrator sensor 3 failure (Foot pedal in open position) 333

#B1125: Accelerrator sensor 3 failure (Foot pedal in closed position) 335

Intake throttle opening sensor 336

#B02E9: Intake Throttle Open Position Sens Error (High V) 336

#B02E8: Intake Throttle Open Position Sens Error (Low V) 338

EGR low pressure side sensor 340

#B0238: EGR Low Pressure Side Sensor Error (High Voltage) 340

#B0237: EGR Low Pressure Side Sensor Error (Low Voltage) 342

#B0236: EGR Low Pres Side Sens Error (Abnorm Learn Value) 344

EGR high pressure side sensor 346

#B0473: EGR High Pressure Side Sensor Error (High Voltage) 346

#B0472: EGR High Pressure Side Sensor Error (Low Voltage) 348

#B0471: EGR High Pres Side Sens Error (Abnorm Learn Value) 350

Cooling water temperature sensor 352

#B0118: Cooling Water Temperature Sens Error (High Volt) 352

#B0117: Cooling Water Temperature Sensor Error (Low Volt) 354

#B0217: — 356

New air temperature sensor 358

#B0113: New Air Temperature Sensor Error (High Voltage) 358

#B0112: New Air Temperature Sensor Error (Low Voltage) 360

Fuel temperature sensor 362

#B0183: Fuel Temperature Sensor Error (High Voltage) 362

#B0182: Fuel Temperature Sensor Error (Low Voltage) 364

#B0168: Fuel Temperature Sensor Temperature Abnormal High 366

Rail pressure sensor 368

#B0193: Rail Pressure Sensor Error (High Voltage) 368

#B0192: Rail Pressure Sensor Error (Low Voltage) 370

KDPF differential pressure sensor 372

#B2455: KDPF Differential Pressure Sens Error (High Volt) 372

#B2454: KDPF Differential Pressure Sens Error (Low Volt) 374

#B2452: KDPF Differential Pressure High Error 376

#B2453: KDPF Different Press Sens (Abnormal Learn Value) 378

KDPF high pressure side sensor 380

#B1455: KDPF High Pressure Side Sens Error (High Volt) 380

#B1454: KDPF High Pressure Side Sensor Error (Low Voltage) 382

KDPF inlet temperature sensor 384

#B1428: KDPF Inlet Temperature Sensor Error (High Voltage) 384

#B1427: KDPF Inlet Temperature Sensor Error (Low Voltage) 386

#B1436: KDPF Inlet Temperature High Error 388

KDPF intermediate temperature sensor 389

#B1434: KDPF Intermediate Temperature Sens Error (HighVolt) 389

#B1435: KDPF Intermediate Temperature Sens Error (LowVolt) 391

#B0420: KDPF Inter Temperature Low Error 393

#B1426: KDPF InterTemperature High Error (Post-injection) 394

Atmospheric pressure sensor 395

#B2229: Ambient Pressure Sensor Error (High Voltage) 395

#B2228: Ambient Pressure Sensor Error (Low Voltage) 396

#B1231: Ambient Pressure Sensor Characteristic Error 397

EGR gas temperature sensor 399

#B041D: EGR Gas Temperature Sensor Error (High Voltage) 399

#B041C: EGR Gas Temperature Sensor Error (Low Voltage) 401

Intake manifold temperature sensor 403

#B040D: Intake Manifold Temperature Sens Error (High Volt) 403

#B040C: Intake Manifold Temperature Sens Error (Low Volt) 405

Exhaust manifold temperature sensor 407

#B0546: Exhaust Manifold Temperature Sens Error (HighVolt) 407

#B0545: Exhaust Manifold Temperature Sens Error (Low Volt) 409

Contact output related 411

Main relay 411

#B068B: Main Relay Contact Stuck 411

#B068A: Main Relay Early Opening 413

Startup assist relay 415

#B0543: Startup Assist Relay Open Circuit 415

#B0541: Startup Assist Relay GND Short Circuit 417

CRS (common rail system) related 419

Injector 4 419

#B0204 (4-cylinder engine): Injector of 4th Cylinder OpenC (Inherent Location) #B0203 (3-cylinder engine): — 419

#B0271 (4-cylinder engine): Injector of 4th Cylinder Coil Short Circuit #B0268 (3-cylinder engine): — 421

#B1271 (4-cylinder engine): Injector of 4th Cylinder Short Circuit #B1268 (3-cylinder engine): — 423

Injector 2 425

#B0202: Injector of 2nd Cylinder OpenC (Inherent Location) 425

#B0265: Injector of 2nd Cylinder Coil Short Circuit 427

#B1265: Injector of 2nd Cylinder Short Circuit 429

Injector 1 431

#B0201: Injector of 1st Cylinder OpenC (Inherent Location) 431

#B0262: Injector of 1st Cylinder Coil Short Circuit 433

#B1262: Injector of 1st Cylinder Short Circuit 435

Injector 3 437

#B0203 (4-cylinder engine): Injector of 3rd Cylinder OpenC (Inherent Location) 437

#B0268 (4-cylinder engine): Injector of 3rd Cylinder Coil Short Circuit 439

#B1268 (4-cylinder engine): Injector of 3rd Cylinder Short Circuit 441

Injector (common) 443

#B0611: Injector Drive IC Error 443

#B1146: Injector Drive Circuit (Bank1) Short Circuit 444

#B1149: Injector Drive Circuit (Bank2) Short Circuit 446

#B1648: Injector of 1st Cylinder Compensation Value Error 448

#B1649: Injector of 2nd Cylinder Compensation Value Error 449

#B1650: Injector of 3rd Cylinder Compensation Value Error 450

#B1651: Injector of 4th Cylinder Compensation Value Error 451

SCV (MPROP) 452

#B1641: SCV (MPROP) (Low Side VB Short) 452

#B1643: SCV (MPROP) (Low Side GND Short) 453

#B0629: SCV (MPROP) (High Side VB Short) 455

#B1642: SCV (MPROP) (High Side GND Short) 457

#B0627: SCV (MPROP) (Open Circuit) 458

#B062A: SCV (MPROP) (Drive Current High Error) 459

#B1645: SCV (MPROP) (Pump Overload Error) 461

Abnormal rail pressure 463

#B0088: Actual Rail Pressure Rise Error 463

#B0094: Rail Press Deviation Error in Act Rail Press Drop 465

#B0093: Rail Press Deviation Error in Act Rail Press Rise 467

PLV (Common rail pressure limit valve) 469

#B000F: PLV Open Valve 469

#B1666: PLV (Number of times of PLV Valve Opening Error) 471

#B1667: PLV (Time of PLV Valve Opening Error) 473

#B1668: PLV (Non-Performance) 475

#B1665: PLV (Malfunction) 477

Rail pressure control 479

#B1669: Rail Press Control (Fuel Temp High in PLV V Open) 479

#B1670: Rail Press Control (Pump or Fuel Temp Error) 481

Actuator 482

Intake throttle drive circuit 482

#B0660: No-load of Throttle Valve Drive H Bridge Circuit 482

#B1658: Power Short of Throttle Valve Drive H Bridge Out 1 483

#B1659: GND Short of Throttle Valve Drive H Bridge Out 1 484

#B1660: O-load on the Drive H Bridge Cir of Throttle Valve 485

#B1661: VB P Short of Throttle Valve Drive H Bridge Out 2 486

#B1662: GND Short of Throttle Valve Drive H Bridge Out 2 487

EGR 488

#B0404: EGR Voltage High Error 488

#B1404: EGR Voltage Low Error 489

#B1409: EGR Feedback Error 490

#BG401: EGR ECM Data Error 491

#B0403: Open Circuit Between the EGR Motor Coils 492

#B1405: Short Circuit Between the EGR Motor Coils 493

#B0488: EGR Position Sensor Error 494

#B148A: EGR Stuck Open Valve Error 495

#B049D: EGR Initialization Error 496

#BH401: EGR Target Value Out of Range 497

#B1410: EGR High Temperature Thermistor Error 498

#B1411: EGR Low Temperature Thermistor Error 499

Exhaust throttle 500

#B1438: Exhaust throttle (Voltage fault) 500

#B1439: Exhaust throttle (Motor fault) 501

#B1440: Exhaust throttle (Sensor system fault) 502

#B1441: Exhaust throttle (MPU fault) 503

#B1442: Exhaust throttle (PCB fault) 504

#B1443: Exhaust throttle (CAN fault) 505

Communication related 506

CAN1 506

#BG10B: CAN1 (for EGR): Reception Time Out 506

#BH107: Exhaust throttle (CAN message from the exhaust throttle time out) 507

CAN2 508

#BG292: TSC1 (CAN Message) Reception Time Out (SA1) 508

#BH301: TSC1 (CAN Message) Reception Time Out (SA2) 510

#BH292: Y_ECR1 (CAN Message) Reception Time Out 512

#BH293: Y_EC (CAN Message) Reception Time Out 514

#BH294: — 516

#BH296: — 518

#BH298: — 520

#BG168: — 522

#BK002: — 524

#BH300: — 526

#BH302: — 528

#BH303: Y_DPFIF (CAN Message) Reception Time Out 530

ECU related 532

EEPROM 532

#B0601: EEPROM Memory Deletion Error 532

#B160E: EEPROM Memory Read Error 533

#B160F: EEPROM Memory Writing Error 534

ECU internal fault 535

#B1613: CY146 SPI Communication Error 535

#B1608: Excessive Voltage of Supply 1 536

#B1617: Insufficient Voltage of Supply 1 537

#B1609: Sensor Supply Voltage Error 1 538

#B1618: Sensor Supply Voltage Error 2 539

#B1619: Sensor Supply Voltage Error 3 540

#B1626: Actuator Drive Circuit 1 Short to Ground 541

#B1633: Actuator Drive Circuit 2 Short to Ground 542

#B1467: Actuator Drive Circuit 3 Short to Ground 543

#B1469: AD Converter Error 1 544

#B1470: AD Converter Error 2 545

#B1471: External Monitoring IC and CPU Error 1 546

#B1472: External Monitoring IC and CPU Error 2 547

#B1473: ROM Error 548

#B1474: Shutoff Path Error 1 549

#B1475: Shutoff Path Error 2 550

#B1476: Shutoff Path Error 3 551

#B1477: Shutoff Path Error 4 552

#B1478: Shutoff Path Error 5 553

#B1479: Shutoff Path Error 6 554

#B1480: Shutoff Path Error 7 555

#B1481: Shutoff Path Error 8 556

#B1482: Shutoff Path Error 9 557

#B1483: Shutoff Path Error 10 558

#B1484: Recognition Error of Engine Speed 559

Contact input related 560

Air cleaner switch 560

#B1101: — 560

Oil/water separator switch 562

#B1151: — 562

Charge switch 564

#B1562: Charge Switch Open Circuit 564

#B1568: Charge Alarm 566

Oil pressure switch 568

#B1192: Oil Pressure Switch Open Circuit 568

#B1198: Oil Pressure Low Error Alarm 570

Post treatment control 572

KDPF 572

#B2463: Overaccumulation (Method C) 572

#B1463: Overaccumulation (Method P) 573

#B2458: Defective Regeneration (StationaryRegene Failure) 574

#B2459: Defective Regeneration (StationaryR Not Performed) 575

KDPF OP interface 576

#B242F: Ash Cleaning Request 1 576

#B1420: Ash Cleaning Request 2 577

#B1421: Stationary Regeneration Standby 578

#B1424: Backup Mode 579

#B1425: — 580

#B1445: — 581

#B1446: — 582

Others 583

Overspeed 583

#B0219: Overspeed 583

Immobilizer 584

#BG167: Immobilizer CAN Communication Error 584

#BG426: Immobilizer System Error 586

METHOD AND PROCEDURE OF FAILURE DIAGNOSIS 587

Description 589

E-ECU pin layout diagram 590

How to use the Tier 4 checker harness 592

Sensor related 593

Crank speed sensor 593

Cam speed sensor 596

Accelerator sensor 600

Intake throttle position sensor 604

EGR low pressure side sensor 607

EGR high pressure side sensor 610

Cooling water temperature sensor 613

New air temperature sensor 617

Fuel temperature sensor 621

Rail pressure sensor 625

KDPF differential pressure sensor 628

KDPF inlet temperature sensor 632

KDPF intermediate temperature sensor 636

EGR gas temperature sensor 640

Intake manifold temperature sensor 644

Exhaust manifold temperature sensor 648

Contact output related 652

Main relay 652

Startup assist relay (Glow relay) 656

Contact input related 660

Contact input related 1 660

Contact input related 2 664

CRS (common rail system) related 667

Injector 667

Injector open circuit and coil short circuit 667

Injector short circuit 671

High-pressure pump (MPROP) 673

Actuator 676

Intake throttle drive circuit 676

EGR valve 681

EGR valve 685

Communication related 687

CAN1 687

CAN2 690

ECU related 693

Others 696

Overspeed 696

Immobilizer 698

MECHANICAL SYSTEM FAILURE DIAGNOSIS 701

Special Service Tools 703

Tier 4 (BOSCH) Compression Inspection Procedures 704

Standard compression pressure (reference value) 705

Engine speed and compression pressure (use for reference) 705

Measured Value and Troubleshooting 706

Quick Reference Table for Troubleshooting 706

Failure Diagnostic List 707

DESCRIPTION:

Komatsu 86E-7 – 98E-7 Series Engine (With common rail injection system) Shop Manual SEN06575-02 – PDF DOWNLOAD

INTRODUCTION:

How to read the shop manual:

• Some of the attachments and options described in this shop manual may not be available in some areas.

If they are required, consult your Komatsu distributor.

• The materials and specifications are subject to change without notice.

• Shop Manuals are available for “machine part” and “engine part”. For the engine unit, see the shop

manual for the machine which has the same engine model.

• Actual machine may differ from the images which are contained in this manual. A typical model is shown

in the illustrations of this shop manual.

Composition of the shop manual:

This shop manual contains technical information necessary to perform services in workshops. It is divided

into “Structure and Function, Testing and Adjusting, Disassembly and Assembly, and Maintenance

Standard” and “Troubleshooting” section for the ease of use.

Basic informaton:

This Shop Manual describes the service procedures for 86E – 98E-7 series engines have common rail

injection system.

Please use this manual for accurate, quick and safe servicing of the engine. Since the directions in this

manual are for a typical engine, some specifications and components may be different from your engine.

For the replacement of some parts and troubleshooting for this series engines, the Diagnostics Tool called

SMARTASSIST-Direct is required. In addition, please read both “Troubleshooting” Section and

SMARTASSIST-Direct Operation Manual.

IMAGES PREVIEW OF THE MANUAL: