$38

Komatsu 8V170-1 Series Engine Shop Manual SEBE61700104 – PDF DOWNLOAD

Komatsu 8V170-1 Series Engine Shop Manual SEBE61700104 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 8V170-1 Series Engine Shop Manual SEBE61700104 – PDF DOWNLOAD

Language : English

Pages : 346

Downloadable : Yes

File Type : PDF

Size: 46 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 8V170-1 Series Engine Shop Manual SEBE61700104 – PDF DOWNLOAD

GENERAL PRECAUTIONS:

Mistakes in operation are extremely dangerous. Read the Operation and Maintenance Manual carefully BEFORE operating the machine.1 .Before carrying out any greasing or repairs, read all the precautions given on the decals which are fixed to the machine.

2.When carrying out any operation, always wear safety shoes and helmet. Do not wear loose work clothes, or clothes with buttons missing.

- Always wear safety glasses when hitting parts with a hammer.

- Always wear safety glasses when grinding parts with a grinder, etc.

3. If welding repairs are needed, always have a trained, experienced welder carry out the work. When carrying out welding work, always wear welding gloves, apron, glasses, cap and other clothes suited for welding work.4.When carrying out any operation with two or more workers, always agree on the op- erating procedure before starting. Always inform your fellow workers before starting any step of the operation. Before starting work, hang UNDER REPAIR signs on the controls in the operator’s compartment.5. Keep all tools in good condition and learn the correct way to use them.

6. Decide a place in the repair workshop to keep tools and removed parts. Always keep the tools and parts in their correct places. Always keep the work area clean and make sure that there is no dirt or oil on the floor. Smoke only in the areas provided for smoking. Never smoke while working.PREPARATIONS FOR WORK:

7. Before adding or making any repairs, park the machine on hard, level ground, and block the wheels to

prevent the machine from moving.

8. Before starting work, lower outrigger, bucket or any other work equipment to the ground. If this is not possible,

use blocks to prevent the work equipment from falling down. In addition, be sure to lock all the control levers and hang warning sign on them.

9. When disassembling or assembling, support the machine with blocks, jacks or stands before starting

work.

10. Remove all mud and oil from the steps or other places used to get on and off the machine. Always use the handrails, ladders or steps when getting on or off the machine.Never jump on or off the machine. If it is impossible to use the handrails, ladders or steps, use a stand to provide safe footing.

TABLE OF CONTENTS:

Komatsu 8V170-1 Series Engine Shop Manual SEBE61700104 – PDF DOWNLOAD

MAIN MENU………………………………………………………………………… 0

CONTENTS…………………………………………………………………………. 2

01 GENERAL……………………………………………………………………….. 13

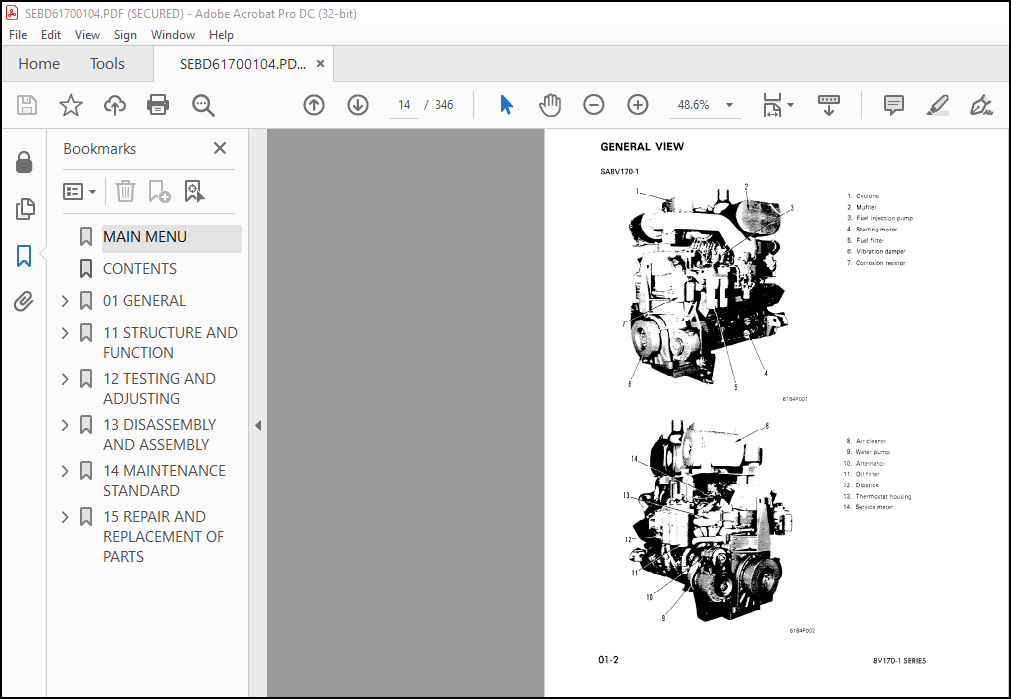

GENERAL VIEW …………………………………………………………………. 14

SPECIFICATIONS ……………………………………………………………….. 15

GENERAL ASSEMBLY DRAWING ………………………………………………………. 16

WEIGHT TABLE …………………………………………………………………. 28

ENGINE PERFORMANCE CURVE ………………………………………………………. 29

11 STRUCTURE AND FUNCTION………………………………………………………….. 33

GENERAL STRUCTURE……………………………………………………………… 34

INTAKE AND EXHAUST SYSTEM………………………………………………………. 36

INTAKE SYSTEM …………………………………………………………….. 36

EXHAUST SYSTEM ……………………………………………………………. 37

TURBOCHARGER ……………………………………………………………… 38

ENGINE BODY…………………………………………………………………… 40

CYLINDER HEAD …………………………………………………………….. 40

VALVE SYSTEM ……………………………………………………………… 42

CYLINDER BLOCK ……………………………………………………………. 44

MAIN REVOLVING SYSTEM ……………………………………………………… 45

TIMING GEAR ………………………………………………………………. 46

FLYWHEEL AND FLYWHEEL HOUSING ………………………………………………. 48

LUBRICATION SYSTEM…………………………………………………………….. 49

LUBRICATION SYSTEM CHART …………………………………………………… 49

OIL PUMP …………………………………………………………………. 50

OIL FILTER AND SAFETY VALVE ………………………………………………… 51

OIL COOLER ……………………………………………………………….. 52

OIL COOLER BYPASS VALVE ……………………………………………………. 53

PISTON COOLING VALVE……………………………………………………….. 53

MECHANICAL PUMP……………………………………………………………. 54

FUEL SYSTEM…………………………………………………………………… 55

FUEL SYSTEM CHART …………………………………………………………. 55

FUEL INJECTION PUMP ……………………………………………………….. 56

FUEL INJECTION NOZZLE ……………………………………………………… 71

FEED PUMP ………………………………………………………………… 72

FUEL INJECTION PUMP DRIVE ………………………………………………….. 75

TIMER…………………………………………………………………….. 76

FUEL FILTER ………………………………………………………………. 79

STARTING AID………………………………………………………………. 80

ENGINE STOP MOTOR …………………………………………………………. 81

COOLING SYSTEM………………………………………………………………… 87

COOLING SYSTEM CHART ………………………………………………………. 87

WATER PUMP ……………………………………………………………….. 88

WATER PUMP DRIVE ………………………………………………………….. 89

FAN DRIVE AND TENSION PULLEY ……………………………………………….. 90

CORROSION RESISTOR ………………………………………………………… 91

THERMOSTAT ……………………………………………………………….. 92

ACCESSORY…………………………………………………………………….. 93

AIR COMPRESSOR MOUNTING ……………………………………………………. 93

AIR COMPRESSOR ……………………………………………………………. 94

ALTERNATOR WITH REGULATOR ………………………………………………….. 95

STARTING MOTOR ……………………………………………………………. 96

12 TESTING AND ADJUSTING…………………………………………………………… 97

COOLING SYSTEM………………………………………………………………… 98

CHECKING AND ADJUSTING ALTERNATOR BELT TENSION ……………………………….. 98

ENGINE BODY……………………………………………………………………100

ADJUSTING VALVE CLEARANCE …………………………………………………..100

FUEL SYSTEM …………………………………………………………………..101

TESTING AND ADJUSTING FUEL INJECTION TIMING …………………………………..101

ADJUSTING FUEL INJECTION TIMING BY DELIVERY CHECK ……………………………..102

ADJUSTING FUEL INJECTION NOZZLE CRACKING PRESSURE ……………………………..103

ADJUSTING ENGINE STOP MOTOR CABLE ……………………………………………105

FUEL INJECTION PUMP CALIBRATION DATA …………………………………………107

PERFORMANCE TEST ……………………………………………………………..111

RUN-IN STANDARD ……………………………………………………………111

PERFORMANCE TEST CRITERIA …………………………………………………..112

TESTING AND ADJUSTING TOOL LIST ……………………………………………..114

TESTING AND ADJUSTING DATA ………………………………………………….116

TROUBLESHOOTING…………………………………………………………….119

POINTS TO REMEMBER WHEN TROUBLESHOOTING …………………………………..121

METHOD OF USING TROUBLESHOOTING CHART …………………………………….122

S-1 Starting performance is poor (Starting always takes time)………………..126

S-2 Engine does not start ……………………………………………….127

1. Engine does not turn ……………………………………………..127

2. Engine turns but no exhaust comes out (Fuel is not being injected) ……128

3. Exhaust gas comes out but engine does not start (Fuel is ……………..129

S-3 Engine does not pick up smoothly (Follow-up is poor) ……………………130

S-4 Engine stops during operations ……………………………………….131

S-5 Engine does not rotate smoothly (hunting) ……………………………..132

S-6 Engine lacks output (no power) ……………………………………….133

S-7 Exhaust gas is black (incomplete combustion) …………………………..134

S-8 Oil consumption is excessive (or exhaust gas is blue) …………………..135

S-9 Oil becomes contaminated quickly ……………………………………..136

S-10 Fuel consumption is excessive ……………………………………….137

S-11 Oil is in cooling water, or water spurts back, or water level goes down ….138

S-12 Oil pressure lamp lights up (drop in oil pressure) …………………….139

S-13 Oil level rises …………………………………………………..140

S-14 Water temperature becomes too high (overheating) ………………………141

S-15 Abnormal noise is made ……………………………………………..142

S-16 Vibration is excessive ……………………………………………..143

13 DISASSEMBLY AND ASSEMBLY…………………………………………………………145

GENERAL……………………………………………………………………….148

DISASSEMBLY………………………………………………………………..148

WASHING……………………………………………………………………187

WASHING CYLINDER BLOCK…………………………………………………..189

WASHING CRANKSHAFT………………………………………………………190

MEASURING AND INSPECTING PARTS……………………………………………….191

MEASURING PARTS…………………………………………………………192

MEASURING CURVATURE OF CRANKSHAFT…………………………………………192

MEASURING OUTSIDE DIAMETER OF JOURNAL……………………………………..192

MEASURING DEPTH OF CYLINDER LINER COUNTERBORE………………………………193

MEASURING MAIN BEARING BORE………………………………………………193

MEASURING CURVATURE OF CAMSHAFT…………………………………………..194

MEASURING OUTSIDE DIAMETER OF JOURNAL……………………………………..194

MEASURING HEIGHT OF CAM………………………………………………….194

MEASURING PISTON RING GROOVE……………………………………………..195

MEASURING PISTON RING END GAP…………………………………………….195

ASSEMBLY…………………………………………………………………..199

14 MAINTENANCE STANDARD…………………………………………………………….275

INTAKE AND EXHAUST SYSTEM ………………………………………………………276

TURBOCHARGER ………………………………………………………………276

ENGINE BODY……………………………………………………………………277

CYLINDER HEAD ……………………………………………………………..277

VALVE AND VALVE GUIDE ………………………………………………………278

ROCKER ARM SHAFT …………………………………………………………..279

CROSSHEAD …………………………………………………………………280

CAM FOLLOWER AND PUSH ROD …………………………………………………..281

CYLINDER BLOCK …………………………………………………………….282

CYLINDER LINER …………………………………………………………….284

CAMSHAFT…………………………………………………………………..285

CRANKSHAFT ………………………………………………………………..286

PISTON ……………………………………………………………………288

CONNECTING ROD …………………………………………………………….289

TIMING GEAR ……………………………………………………………….290

FLYWHEEL AND FLYWHEEL HOUSING ……………………………………………….292

LUBRICATION SYSTEM……………………………………………………………..293

OIL PUMP ………………………………………………………………….293

MAIN RELIEF VALVE, PISTON COOLING VALVE AND OIL COOLER BYPASS VALVE ……………294

COOLING SYSTEM ………………………………………………………………..295

WATER PUMP ………………………………………………………………..295

15 REPAIR AND REPLACEMENT OF PARTS ………………………………………………….297

CYLINDER HEAD …………………………………………………………………298

TESTING AND INSPECTING …………………………………………………………299

REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING ………………………………301

REPLACING VALVE SEAT INSERTS ……………………………………………………302

REPLACING NOZZLE HOLDER SLEEVE ………………………………………………….307

REPLACING VALVE GUIDE ………………………………………………………….311

REPLACING CROSS HEAD GUIDE ……………………………………………………..312

GRINDING THE VALVE …………………………………………………………….313

CYLINDER BLOCK ………………………………………………………………..314

TESTING AND INSPECTING …………………………………………………………315

GRINDING THE TOP SURFACE OF CYLINDER BLOCK ……………………………………….317

REPLACING MAIN METAL CAP ……………………………………………………….322

REPLACING CAM BUSHING ………………………………………………………….324

CRANKSHAFT ……………………………………………………………………325

REPAIRING THE CRANKSHAFT ……………………………………………………….332

CONNECTING ROD ………………………………………………………………..340

REPLACING CAM GEAR……………………………………………………………..344

REPLACING FLYWHEEL RING GEAR ……………………………………………………344