Starting from:

$45

Home

Komatsu 930e-2 Dump Truck Operation & Maintenance Manual A30098, A30100, A30128 Series Engine - PDF

Komatsu 930e-2 Dump Truck Operation & Maintenance Manual A30098, A30100, A30128 Series Engine - PDF

Komatsu 930e-2 Dump Truck Operation & Maintenance Manual A30098, A30100, A30128 thru A30155/W/000/4000 Series Engine

Description:

Komatsu 930e-2 Dump Truck Operation & Maintenance Manual A30098, A30100, A30128 thru A30155/W/000/4000 Series Engine

- This Manual is written for use by the operator and/or the service technician and is designed to help these persons to become fully knowledgeable of the truck and all its systems in order to keep it operating safely and efficiently.

- All operators and maintenance personnel should read and understand the materials in this manual before operating the truck or performing maintenance and/or operational checks on the truck. All safety notices, warnings and cautions should be understood and followed when operating or accomplishing repairs on the truck.

- The first section is an Introduction to the manual and contains a Table of Contents to locate specific areas of interest. Other sections include Safety, Operation, Maintenance, Specifications, and Optional Equipment.

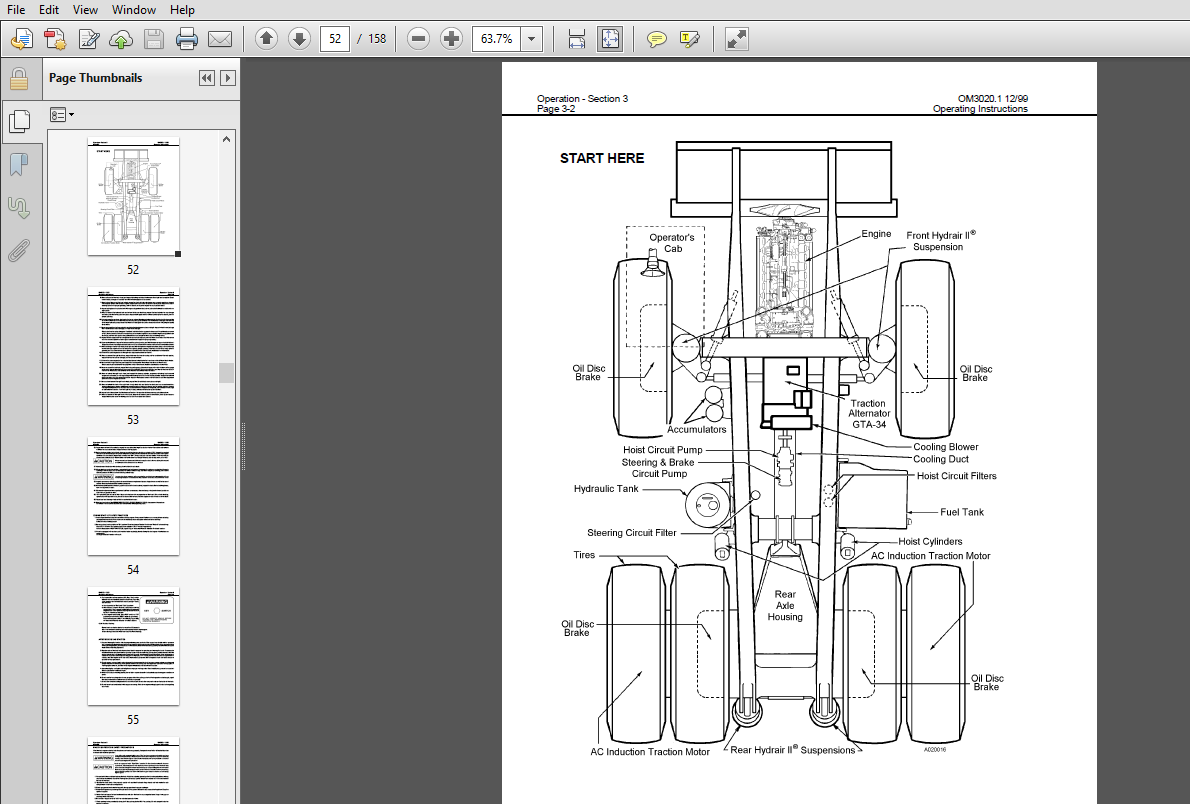

- The illustrations used in this manual are TYPICAL of the component shown and may not be an exact reproduction of what is found on the truck.

- A product identification plate is located on the frame in front of the right side front wheel and designates the Truck Model Number, Product Identification Number (vehicle serial number), and Maximum G.V.W. (Gross Vehicle Weight) rating.

- The KOMATSU Truck Model designation consists of three numbers and one letter (i.e. 930E). The three numbers represent the basic truck model. The letter “M”, when present, designates a Mechanical drive system; The letter “E”, when present, designates an Electrical wheelmotor drive system.

- The Product Identification Number (vehicle serial number) contains information which will identify the original manufacturing bill of material for this unit. This complete number will be necessary for proper ordering of many service parts and/or warranty consideration.

- The Gross Vehicle Weight (GVW) is what determines the load on the drive train, frame, tires, and other components. The vehicle design and application guidelines are sensitive to the total maximum Gross Vehicle Weight (GVW) and this means the TOTAL WEIGHT: the Empty Vehicle Weight + the fuel & lubricants + the payload.

Table Of Contents:

Komatsu 930e-2 Dump Truck Operation & Maintenance Manual A30098, A30100, A30128 thru A30155/W/000/4000 Series Engine

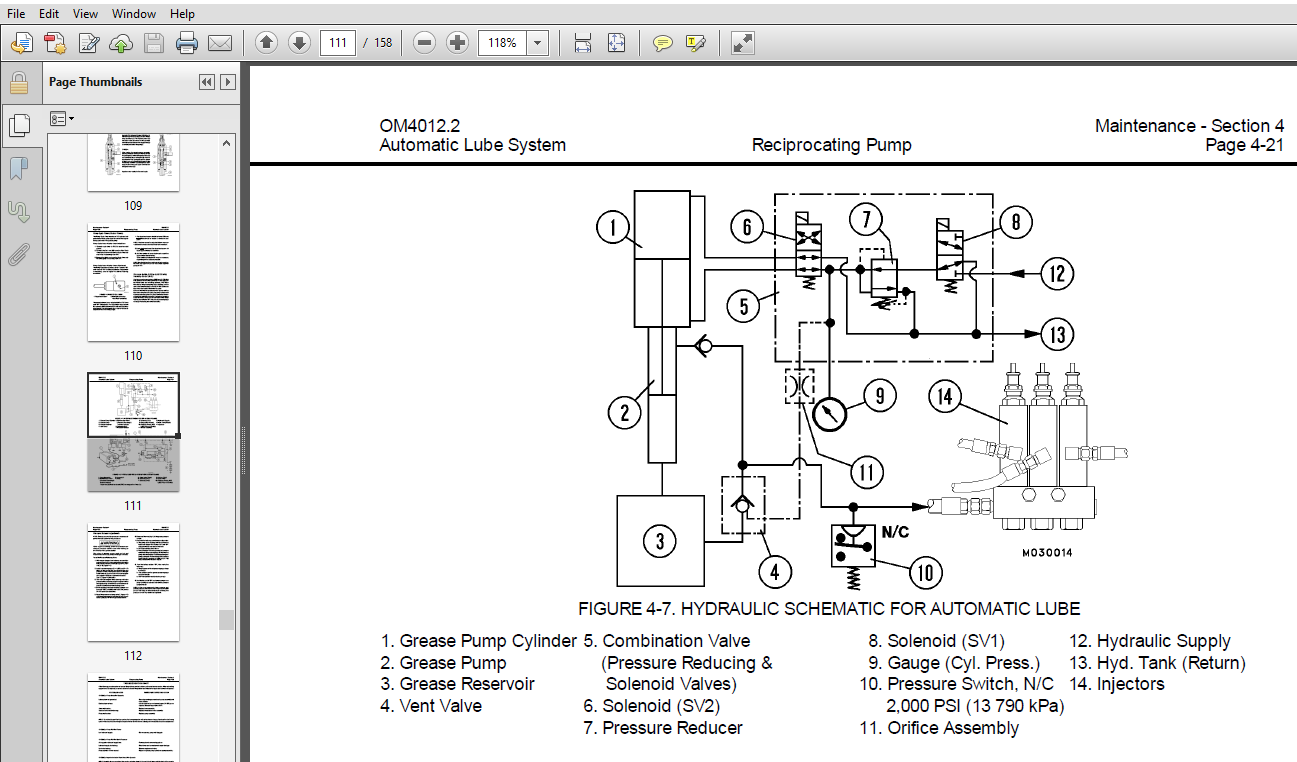

MAIN MENU............................................................................. 0 COVER................................................................................. 1 INTRODUCTION.......................................................................... 7 FOREWARD.......................................................................... 7 ALERTS............................................................................ 8 CONTENTS.......................................................................... 9 TRUCK MODEL ILLUSTRATION.......................................................... 12 ABOUT THIS MANUAL................................................................. 13 STANDARD CHARTS AND TABLES........................................................ 15 SAFETY................................................................................ 21 GENERAL SAFETY.................................................................... 21 PRECAUTIONS DURING OPERATION...................................................... 25 OPERATING MACHINE............................................................. 26 TOWING........................................................................ 29 BATTERY....................................................................... 30 PRECAUTIONS FOR MAINTENANCE....................................................... 31 BEFORE CARRYING OUT MAINTENANCE............................................... 31 DURING MAINTENANCE............................................................ 32 TIRES......................................................................... 35 ADDITIONAL JOB SITE RULES..................................................... 36 WHEN REPAIRS ARE NECESSARY........................................................ 37 SPECIAL PRECAUTIONS FOR WORKING ON A 930E TRUCK............................... 38 WARNING, CAUTION, AND INSTRUCTION PLATES/DECALS................................... 41 OPERATION............................................................................. 51 OPERATING INSTRUCTIONS............................................................ 51 PREPARING FOR OPERATION....................................................... 51 SAFETY IS THINKING AHEAD...................................................... 51 AT THE TRUCK - GROUND LEVEL WALK - AROUND INSPECTION.......................... 51 ENGINE START-UP SAFETY PRACTICES.................................................. 54 AFTER ENGINE HAS STARTED.......................................................... 55 MACHINE OPERATION SAFETY PRECAUTIONS.............................................. 56 MACHINE OPERATION ON THE HAUL ROAD................................................ 56 STARTING ON A GRADE WITH A LOADED TRUCK........................................... 57 PASSING........................................................................... 57 LOADING........................................................................... 57 DUMPING........................................................................... 58 TOWING............................................................................ 59 SAFE PARKING PROCEDURES........................................................... 60 NORMAL ENGINE SHUTDOWN PROCEDURE.................................................. 60 DELAYED ENGINE SHUTDOWN PROCEDURE................................................ 61 OPERATOR CAB AND CONTROLS......................................................... 63 STEERING WHEEL AND CONTROLS................................................... 64 DYNAMIC RETARDER/SERVER BRAKE PEDAL........................................... 65 ACCELERATOR (THROTTLE) PEDAL.................................................. 65 HEATER/AIR CONDITIONER VENTS.................................................. 65 HEATER/AIR CONDITIONER COMPARTMENT AND CONTROLS............................... 66 OVERHEAD PANEL AND DISPLAYS................................................... 67 CENTER CONSOLE CONTROLS AND FEATURES.......................................... 69 HOIST CONTROL LEVER....................................................... 70 OPERATOR SEAT................................................................. 73 INSTRUMENT PANEL AND INDICATOR LIGHTS............................................. 75 CONTROL SYMBOLS............................................................... 75 INSTRUMENT PANEL (FIGURE 3-6)..................................................... 76 PANEL GAUGES, INDICATORS, AND CONTROLS (DISCUSSION OF ITEMS 1-29, FIGURE 3-6)..... 77 OVERHEAD STATUS/WARNING INDICATOR LIGHT PANEL (FIGURE 3-7)........................ 83 INDICATOR LIGHT SYMBOLS - REFER TO FIGURE 3-7 BY ROWS (A-E) AND COLUMNS (1-6).... 84 HAZARD WARNING LIGHTS (7)..................................................... 90 LAMP TEST SWITCH (8).......................................................... 90 LINK-ON WARNINGS LIGHT............................................................ 90 MAINTENANCE........................................................................... 91 LUBRICATION AND SERVICE........................................................... 91 SERVICE CAPACITIES............................................................ 91 HYDRAULIC TANK SERVICE........................................................ 91 COOLANT LEVEL CHECK........................................................... 92 RADIATOR FILLING PROCEDURE.................................................... 92 COOLING SYSTEM RECOMMENDATIONS................................................ 92 LUBRICATION CHART............................................................. 93 10 HOUR (SHIFT) LUBRICATION AND MAINTENANCE CHECKS............................ 94 50 HOUR LUBRICATION AND MAINTENANCE CHECKS.................................... 96 100 HOUR LUBRICATION AND MAINTENANCE CHECKS................................... 97 250 HOUR LUBRICATION AND MAINTENANCE CHECKS................................... 98 500 HOUR LUBRICATION AND MAINTENANCE CHECKS...................................100 1000 HOUR LUBRICATION AND MAINTENANCE CHECKS..................................101 2500 HOUR LUBRICATION AND MAINTENANCE CHECKS..................................102 5000 HOUR LUBRICATION AND MAINTENANCE CHECKS..................................102 LINCOLN AUTOMATIC LUBRICATION SYSTEM (ROTARY PUMP)................................103 SYSTEM COMPONENTS.............................................................103 SYSTEM OPERATION..............................................................105 GENERAL INSTRUCTIONS..........................................................106 LUBRICANT REQUIRED........................................................106 SYSTEM PRIMING............................................................106 SYSTEM CHECK-OUT..............................................................106 24 VDC SOLID STATE TIMER CHECK................................................107 INJECTORS.....................................................................108 PUMP CYCLE TIMER (FLASHER TIMER)..............................................110 PRESSURE SWITCH...............................................................110 PRESSURE REDUCER ADJUSTMENT...................................................112 TROUBLESHOOTING CHART.........................................................113 PREVENTATIVE MAINTENANCE PROCEDURES...........................................116 SPECIFICATIONS........................................................................117 MAJOR COMPONENT DESCRIPTIONS......................................................117 SPECIFICATIONS....................................................................119 OPTIONAL EQUIPMENT....................................................................121 PAYLOAD METER II (ON BOARD WEIGHING SYSTEM (OBWS) INDEX)..........................121 GENERAL INFORMATION...........................................................123 LIGHTS, SWITHES, AND COMPONENTS...............................................124 TIPS FOR OPERATION............................................................125 EXTERNAL DISPLAY LIGHTS.......................................................125 THEORY OF OPERATION...........................................................126 BASIC DESCRIPTION.........................................................126 LINKAGE FACTOR............................................................126 BRAKE LOCK................................................................127 SOURCES OF ERROR..........................................................127 TYPICAL DATA FROM SERVICE CHECK MODE......................................127 EXAMPLE CALCULATION OF PAYLOAD............................................128 CALCULATION OF THE CALIBRATION LOAD.......................................128 TYPES OF DATA STORED..........................................................129 CYCLE DATA................................................................129 ENGINE ON/OFF DATA........................................................130 FAULT CODES AND WARNING DATA..............................................130 ENGINE OPERATION..........................................................131 TOTAL PAYLOAD AND TOTAL NUMBER OF CYCLES..................................131 OTHER DATA................................................................131 OPERATOR FUNCTIONS............................................................132 USING THE OPERATOR LOAD COUNTER...........................................132 DESCRIPTION...........................................................132 VIEWING THE OPERATOR LOAD COUNTER.....................................132 CLEARING THE OPERATOR LOAD COUNTER....................................132 DIMMING THE LIGHTS ONTHE DISPLAY..........................................132 INITIAL SETUP OF PAYLOAD METER................................................133 SWITCH SETTINGS...........................................................133 CHECKING THE OPERATOR CHECK MODE..........................................133 CHECKING THE SERVICE CHECK MODE...........................................134 SETTING "UP:00".......................................................134 SETTING "PL:00".......................................................134 CHECKING THE Gt SETTING...................................................134 CHECKING THE INCLINOMETER SETTINGS........................................134 CALIBRATING A TRUCK.......................................................135 DISPLAYS AT START-UP..........................................................136 SETUP AND MAINTENANCE.........................................................137 SETTING THE SPEED LIMIT...................................................137 SETTINGS THE OPTION CODE..................................................137 SETTING THE MACHINE I.D...................................................137 SETTING THE OPERATOR I.D..................................................138 SETTING THE TIME AND DATE.................................................138 DOWNLOAD OF PAYLOAD FAULT CODES...............................................138 DISPLAY OF FAULT CODES........................................................139 CHARTS OF ERROR CODES AND OTHER INFORMATION...................................140 SERVICE CHECK MODE............................................................142 MONITORING INPUT SIGNALS .....................................................142 UP FACTOR - PAYLOAD CALCULATION GAIN..........................................143 PL MODE - LOAD CALCULATION....................................................143 FINAL GEAR RATIO SELECTION....................................................144 BATTERY REPLACEMENT PROCEDURE.................................................145 REPLACING THE BATTERY.....................................................145 AFTER REPLACING THE BATTERY...............................................146 SUSPENSION PRESSURE SENSOR....................................................146 REMOVAL...................................................................146 INSTALLATION..............................................................147 INCLINOMETER..................................................................147 REMOVAL...................................................................147 INSTALLATION..............................................................147 SCOREBOARD....................................................................148 DESCRIPTION...............................................................148 MAKING CONNECTIONS........................................................148 WIRING DIAGRAM............................................................149 NORMAL OPERATION OF THE SCOREBOARD........................................150 PAYLOAD METER BACK PANEL......................................................150 CONNECTIONS (AMP PIN IDENTIFICATION)......................................151 PAYLOAD CIRCUIT NUMBERS.......................................................152 PAYLOAD METER II RE-INITIALIZATION PROCEDURE..................................153 RADIO, AM/FM STERO CASSETTE.......................................................155

Screenshot Of The Manual:

1 file (1.9MB)