$23

Komatsu 95-2 Series Diesel Engine Service Manual – PDF DOWNLOAD

Komatsu 95-2 Series Diesel Engine Service Manual

FILE DETAILS:

Komatsu 95-2 Series Diesel Engine Service Manual

Brands: Komatsu

Equipment Type: Diesel Engine

Manuals Type: Shop Manual

Machine Model: 95-2 Series Diesel Engine

Book Code: SEBM018803

Language: English

Pages: 180

File Format: Portable Document Format (PDF)

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 95-2 Series Diesel Engine Service Manual

FOREWORD:

GENERAL:

- This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity.

- This shop manual mainly contains the necessary technical information for operations performed in a service workshop. For ease of understanding, the manual is divided into the following chapters; these chapters are further divided into the each main group of components.

STRUCTURE AND FUNCTION:

This section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting. In addition, this section may contain hydraulic circuit diagrams, electric circuit diagrams, and maintenance standards.

TESTING AND ADJUSTING:

This section explains checks to be made before and after performing repairs, as well as adjustments to be made at completion of the checks and repairs. Troubleshooting charts correlating “Problems” with “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY:

This section explains the procedures for removing, installing, disassembling and assembling each component, as well as precautions for them.

MAINTENANCE STANDARD:

This section gives the judgment standards for inspection of disassembled parts. The contents of this section may be described in STRUCTURE AND FUNCTION.

OTHERS:

This section mainly gives hydraulic circuit diagrams and electric circuit diagrams. In addition, this section may give the specifications of attachments and options together.

TABLE OF CONTENTS:

Komatsu 95-2 Series Diesel Engine Service Manual

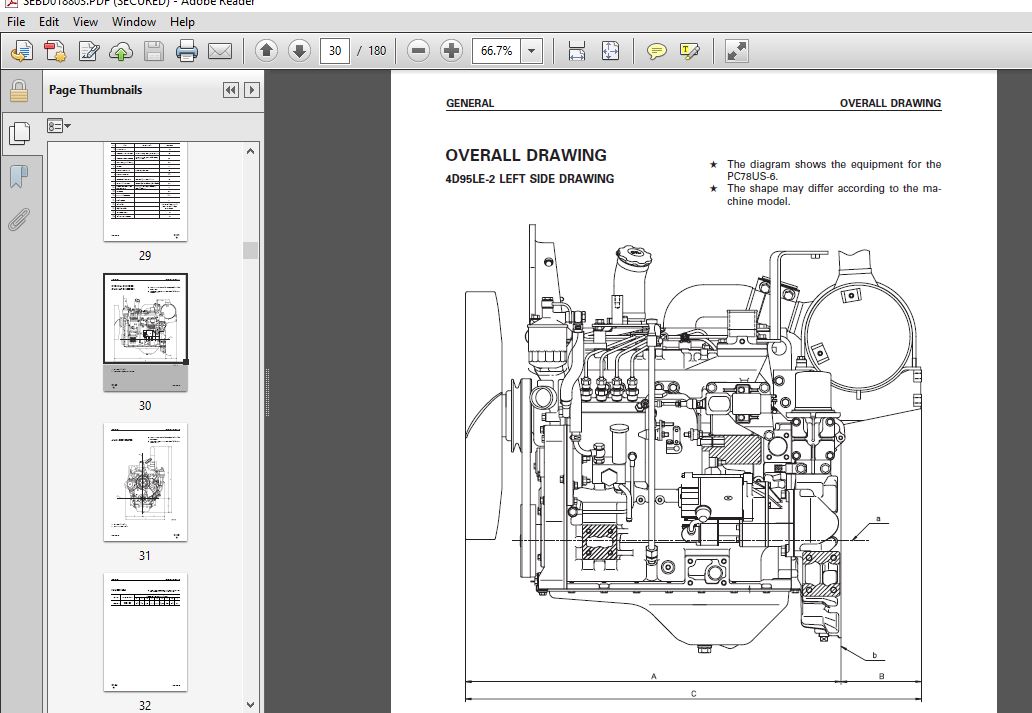

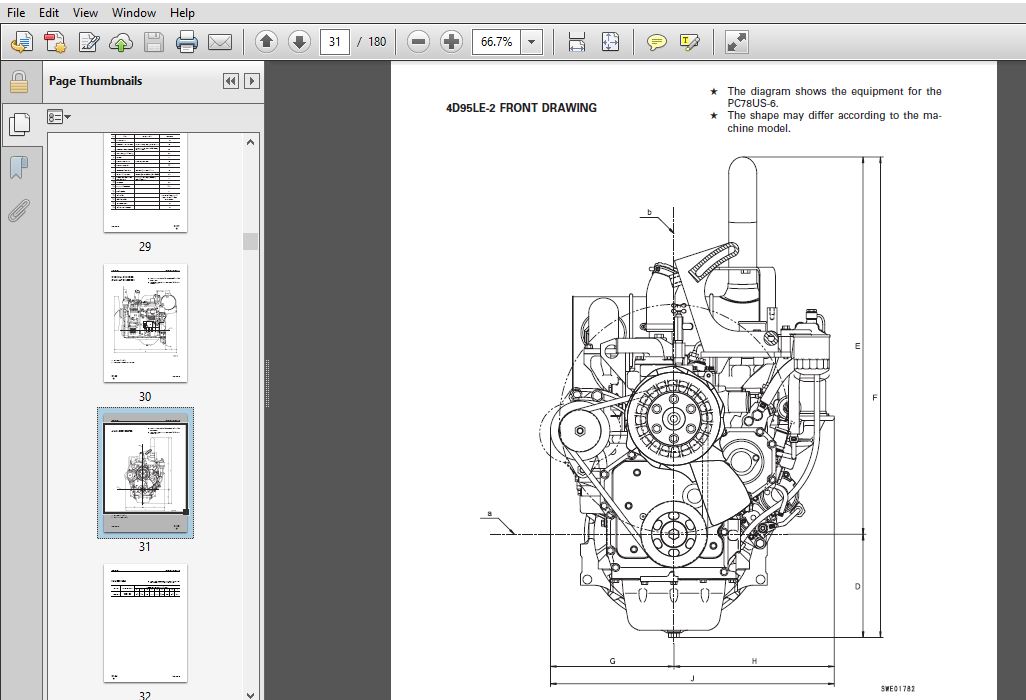

MAIN MENU.......................................................................................... 0 COVER.............................................................................................. 1 CONTENTS........................................................................................... 2 SAFETY............................................................................................. 5 SAFETY NOTICE.................................................................................. 5 FOREWORD........................................................................................... 7 GENERAL........................................................................................ 7 HOW TO READ THE SHOP MANUAL.................................................................... 8 HOISTING INSTRUCTIONS.......................................................................... 9 METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER..................................... 10 COATING MATERIALS.............................................................................. 12 STANDARD TIGHTENING TORQUE..................................................................... 14 ELECTRIC WIRE CODE............................................................................. 17 CONVERSION TABLE............................................................................... 18 UNITS.......................................................................................... 24 01 GENERAL......................................................................................... 25 APPLICABLE MACHINE............................................................................. 26 SPECIFICATIONS................................................................................. 27 WEIGHT TABLE................................................................................... 29 OVERALL DRAWING ............................................................................... 30 ENGINE PERFORMANCE CURVE....................................................................... 33 11 STRUCTURE AND FUNCTION.......................................................................... 36 GENERAL STRUCTURE.............................................................................. 37 GENERAL STRUCTURE.......................................................................... 37 INTAKE AND EXHAUST SYSTEM ..................................................................... 39 INTAKE AND EXHAUST SYSTEM ................................................................. 39 AIR CLEANER................................................................................ 41 ENGINE BODY.................................................................................... 43 CYLINDER HEAD.............................................................................. 43 CYLINDER BLOCK............................................................................. 45 MAIN CIRCULATION SYSTEM.................................................................... 47 TIMING GEAR................................................................................ 49 VALVE SYSTEM .............................................................................. 51 FLYWHEEL AND FLYWHEEL HOUSING.............................................................. 53 LUBRICATION SYSTEM ............................................................................ 55 LUBRICATION SYSTEM CHART................................................................... 55 OIL PUMP................................................................................... 56 OIL FILTER ................................................................................ 57 OIL FILTER MOUNT........................................................................... 58 FUEL SYSTEM ................................................................................... 60 FUEL SYSTEM CHART.......................................................................... 60 FUEL INJECTION PUMP........................................................................ 61 FUEL INJECTION NOZZLE...................................................................... 63 FUEL FILTER................................................................................ 64 ENGINE CUT SOLENOID........................................................................ 65 COOLING SYSTEM................................................................................. 66 COOLING SYSTEM CHART....................................................................... 66 WATER PUMP................................................................................. 67 FAN DRIVE AND THERMOSTAT................................................................... 68 ELECTRICAL SYSTEM ............................................................................. 71 STARTING AND CHARGING SYSTEM ELECTRICAL CIRCUIT DIAGRAM.................................... 71 ALTERNATOR................................................................................. 72 STARTING MOTOR............................................................................. 73 ENGINE STARTING DEVICE..................................................................... 74 12 TESTING AND ADJUSTING........................................................................... 75 TESTING AND ADJUSTING.......................................................................... 76 ADJUSTING VALVLE CLEARANCE................................................................. 76 MEASURING COMPRESSION PRESSURE............................................................. 78 ADJUSTING FUEL INJECTION PRESSURE.......................................................... 79 TESTING AND ADJUSTING FUEL INJECTION TIMING................................................ 80 ADJUSTING FUEL CUT SOLENOID................................................................ 84 FUEL INJECTION PUMP CALIBRATION DATA........................................................... 87 PERFORMANCE TEST .............................................................................. 90 RUN-IN STANDARD............................................................................ 90 PERFORMANCE TEST CRITERIA ................................................................. 91 TROUBLESHOOTING................................................................................ 93 METHOD OF USING TROUBLESHOOTING CHARTS..................................................... 94 POINTS TO REMEMBER WHEN TROUBLESHOOTING.................................................... 98 S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME).............................. 99 S-2 ENGINE DOES NOT START..................................................................100 (1) ENGINE DOES NOT TURN...............................................................100 (2) ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT (FUEL IS NOT BEING INJECTED)...........101 (3) EXHAUST SMOKE COMES OUT, BUT ENGINE DOES NOT START (FUEL IS NOT BEING INJECTED)....102 S-3 ENGINE DOES NOT PICK UP SMOOTHLY.......................................................103 S-4 ENGINE STOPS DURING OPERATIONS.........................................................104 S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)..............................................105 S-6 ENGINE LACK OUTPUT (NO POWER)..........................................................106 S-7 EXHAUST GAS IS BLACK...................................................................107 S-8 OIL CONSUMPTION IS EXCESSIVE, OR EXHAUST GAS IS BLUE...................................108 S-9 OIL BECOMES CONTAMINATED QUICKLY.......................................................109 S-10 FUEL CONSUMPTION IS EXCESSIVE.........................................................110 S-11 OIL IS IN COOLING WATER ..............................................................111 S-12 OIL PRESSURE CAUTION LAMP LIGHTS UPS (DROP IN OIL PRESSURE)...........................112 S-13 OIL LEVEL RISES (WATER, FUEL IN OIL ).................................................113 S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)......................................114 S-15 ABNORMAL NOISE IS MADE................................................................115 S-16 VIBRATION IS EXCESSIVE................................................................116 TESTING AND ADJUSTING TOOL LIST................................................................117 TESTING AND ADJUSTING DATA.....................................................................118 13 DISASSEMBLY AND ASSEMBLY........................................................................120 SPECIAL TOOL LIST..............................................................................121 OVERALL DISASSEMBLY OF 4D95LC-2................................................................122 PREPARATORY WORK...........................................................................123 1. ALTERNATOR, FAN PULLEY..................................................................123 2. STARTING MOTOR, ENGINE STOP SOLENOID, FUEL AND OIL FILTERS, DIPSTICK....................124 3. WATER PUMP..............................................................................124 4. FUEL INJECTION TUBE, GLOW PLUG..........................................................124 5. INJECTION NOZZLE........................................................................124 6. FUEL INJECTION PUMP.....................................................................125 7. INTAKE MANIFOLD.........................................................................125 8. EXHAUST MANIFOLD........................................................................125 9. HEAD COVER..............................................................................125 10. ROCKER ARM.............................................................................126 11. PUSH ROD, CYLINDER HEAD MOUNTING BOLT..................................................126 12. CYLINDER HEAD COVER....................................................................126 13. PTO SHAFT..............................................................................127 14. OIL PAN................................................................................128 15. OIL SUCTION PIPE.......................................................................128 16. CRANKSHAFT PULLEY......................................................................128 17. GEAR CASE COVER........................................................................128 18. OIL PUMP, IDLER GEAR...................................................................129 19. CAMSHAFT ASSEMBLY......................................................................129 20. FLYWHEEL...............................................................................129 21. FLYWHEEL HOUSING.......................................................................130 22. PISTION, CONNECTING ROD ASSEMBLY.......................................................130 23. MAIN CAP...............................................................................132 24. CRANKSHAFT.............................................................................133 25. TAPPET.................................................................................133 26.CYLINDER BLOCK ASSEMBLY.................................................................133 OVERALL ASSEMBLY...............................................................................134 1. CYLINDER BLOCK ASSEMBLY.................................................................134 2. TAPPET..................................................................................134 3. CRANKSHAFT..............................................................................134 4. MAIN CAP................................................................................135 5. FLYWHEEL HOUSING........................................................................138 6. FLYWHEEL................................................................................139 7. CAMSHAFT ASSEMBLY.......................................................................139 8. OIL PUMP, IDLER GEAR....................................................................140 9. GEAR CASE COVER.........................................................................141 10. CRANKSHAFT PULLEY......................................................................141 11. OIL SUCTION PIPE.......................................................................141 12. OIL PAN................................................................................142 13. PTO SHAFT..............................................................................142 14. FUEL INJECTION PUMP....................................................................142 15. CYLINDER HEAD ASSEMBLY.................................................................143 16. ADJUSTMENT OF VALVE CLEARANCE..........................................................145 17. HEAD COVER.............................................................................146 18. EXHAUST MANIFOLD.......................................................................146 19. INTAKE MANIFOLD........................................................................146 20. INJECTION NOZZLE.......................................................................146 21. FUEL INJECTION TUBE, GLOW PLUG.........................................................147 22. WATER PUMP.............................................................................147 23. STARTING MOTOR. ENGINE STOP SOLENOID, FUEL AND OIL FILTERS, DIPSTICK...................147 24. ALTERNATOR, FAN PULLEY.................................................................148 25. ENGINE ASSEMBLY........................................................................148 26. FAN, EXHAUST PIPE, MUFFLER, ENGINE OIL TUBES, BLOCK, COVER.............................149 14 MAINTENANCE STANDARD............................................................................150 CYLINDER HEAD..................................................................................151 VALVE AND VALVE GUIDE..........................................................................152 ROCKER ARM SHAFT, PUSH ROD AND TAPPET..........................................................153 CYLINDER BLOCK.................................................................................154 CYLINDER.......................................................................................155 CRANKSHAFT.....................................................................................156 CAMSHAFT.......................................................................................157 TIMING GEAR....................................................................................158 PISTION, PISTON RING AND PISTION PIN...........................................................159 CONNECTING ROD.................................................................................160 FLYWHEEL AND FLYWHEEL HOUSING..................................................................161 OIL PUMP.......................................................................................162 REGULATOR VALVE................................................................................163 WATER PUMP AND THERMOSTAT......................................................................164 15 REPAIR AND REPLACEMENT OF PARTS.................................................................165 CYLINDER HEAD SECTION..........................................................................166 GRINDING CYLINDER HEAD MOUNTING SURFACE....................................................166 REPLACING VALVE GUIDE......................................................................167 GRINDING VALVE.............................................................................168 CYLINDER BLOCK SECTION.........................................................................169 REPLACING CAMSHAFT BUSHING.................................................................169 REPLACING CRANKSHAFT GEAR..................................................................171 REPLACING CAM GEAR.........................................................................172 REPLACING FLYWHEEL RING GEAR...............................................................173 PROCEDURE FOR PRESSURE TEST ...............................................................174 CYLINDER LINER (SPECIAL RESTORATION PART)..................................................175 MACHINING DRAWING FOR CYLINDER BLOCK BORE..................................................176 ADDITIONAL MACHINING OF CAM JOURNAL........................................................177 GRINDING CRANKSHAFT........................................................................178 REPLACING CONNECTING ROD SMALL END BUSHING.................................................179