$34

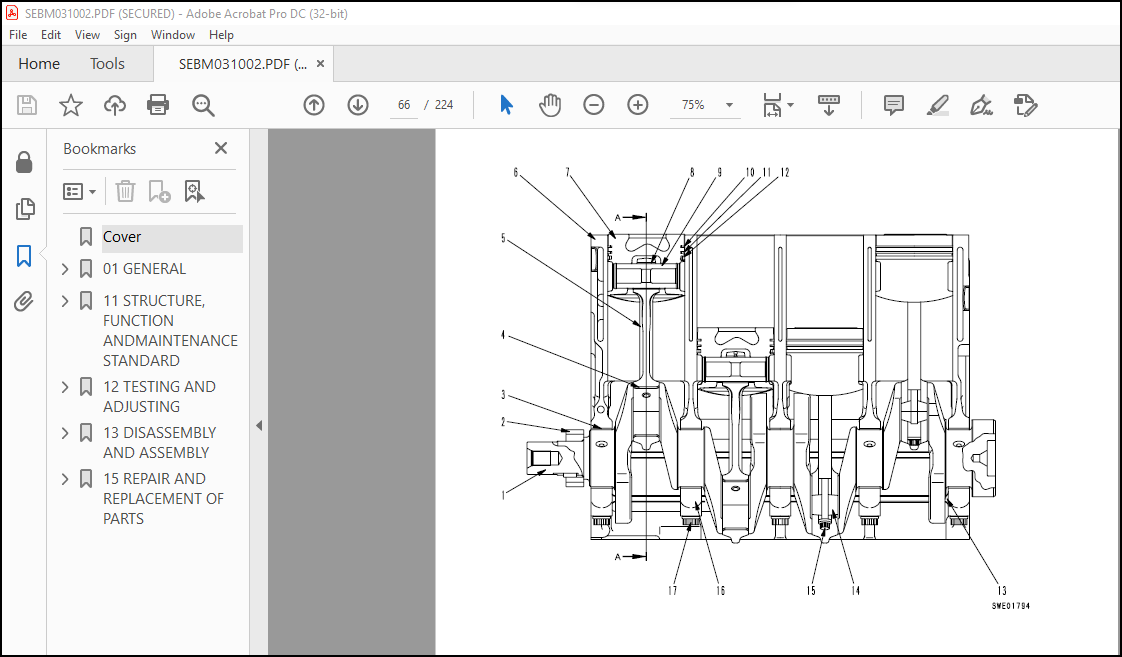

Komatsu 95-3 Series Diesel Engine Shop Manual SEBM031002 – PDF DOWNLOAD

Komatsu 95-3 Series Diesel Engine Shop Manual SEBM031002 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 95-3 Series Diesel Engine Shop Manual SEBM031002 – PDF DOWNLOAD

Language : English

Pages : 224

Downloadable : Yes

File Type : PDF

Size: 6.22 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 95-3 Series Diesel Engine Shop Manual SEBM031002 – PDF DOWNLOAD

The Komatsu 95-3 Series Diesel Engine Shop Manual SEBM031002 is a comprehensive technical reference guide that provides detailed information on the maintenance, repair, and overhaul of the Komatsu 95-3 Series diesel engine. This engine series is commonly used in heavy-duty applications such as construction equipment, mining vehicles, and marine vessels. The shop manual is an essential resource for mechanics, technicians, and service personnel who are responsible for servicing and maintaining these engines.

The Komatsu 95-3 Series Diesel Engine Shop Manual is organized into several sections, each of which covers a specific aspect of the engine. These sections include:

- General Information: This section provides an overview of the engine, including specifications, operating guidelines, and maintenance intervals.

- Inspection and Adjustment: This section provides detailed instructions for inspecting and adjusting engine components, including the fuel injection system, valves, and timing belt.

- Engine Assembly: This section covers the removal and installation of major engine components, such as the cylinder head, crankshaft, and pistons. The manual includes detailed illustrations and specifications to help technicians perform these tasks safely and efficiently.

- Lubrication System: This section provides information on the engine’s lubrication system, including oil pump removal and installation, oil filter replacement, and oil pressure testing.

- Cooling System: This section provides information on the engine’s cooling system, including water pump removal and installation, radiator removal and installation, and thermostat replacement.

- Fuel System: This section covers the engine’s fuel system, including fuel pump removal and installation, fuel injector replacement, and fuel system troubleshooting.

- Air Intake and Exhaust System: This section provides information on the engine’s air intake and exhaust system, including air filter replacement, turbocharger removal and installation, and exhaust manifold removal and installation.

- Electrical System: This section provides information on the engine’s electrical system, including alternator and starter motor removal and installation, as well as troubleshooting procedures for electrical faults.

- Special Tools: This section lists the special tools required for servicing the engine, including part numbers and illustrations.

The Komatsu 95-3 Series Diesel Engine Shop Manual SEBM031002 is an essential resource for maintaining and repairing these engines. It provides a comprehensive guide to servicing the engine and includes detailed instructions, specifications, and illustrations to help technicians perform tasks accurately and safely. The manual is a valuable tool for ensuring that the Komatsu 95-3 Series diesel engine continues to operate at peak performance, with maximum efficiency and reliability over its long service life.

TABLE OF CONTENTS:

Komatsu 95-3 Series Diesel Engine Shop Manual SEBM031002 – PDF DOWNLOAD

Cover……………………………………………………………………….. 1

01 GENERAL…………………………………………………………………… 25

GENERAL………………………………………………………………….. 26

SPECIFICATIONS……………………………………………………………. 30

WEIGHT TABLE……………………………………………………………… 35

OVERALL DRAWING…………………………………………………………… 36

ENGINE PERFORMANCE CURVE…………………………………………………… 42

11 STRUCTURE, FUNCTION ANDMAINTENANCE STANDARD…………………………………… 45

GENERAL STRUCTURE…………………………………………………………. 46

INTAKE AND EXHAUST SYSTEM………………………………………………….. 48

AIR CLEANER………………………………………………………………. 52

TURBOCHARGER……………………………………………………………… 54

CYLINDER HEAD…………………………………………………………….. 58

CYLINDER BLOCK……………………………………………………………. 62

CYLINDER…………………………………………………………………. 65

MAIN CIRCULATION SYSTEM……………………………………………………. 66

CRANKSHAFT……………………………………………………………….. 70

PISTON, PISTON RING AND PISTON PIN………………………………………….. 71

CONNECTING ROD……………………………………………………………. 74

FLYWHEEL AND FLYWHEEL HOUSING………………………………………………. 76

TIMING GEAR………………………………………………………………. 80

VALVE SYSTEM……………………………………………………………… 84

CAMSHAFT…………………………………………………………………. 86

ROCKER ARM SHAFT, PUSH ROD AND TAPPET……………………………………….. 87

VALVE, VALVE GUIDE………………………………………………………… 88

LUBRICATION SYSTEM CHART…………………………………………………… 89

OIL PUMP…………………………………………………………………. 90

REGULATOR VALVE…………………………………………………………… 94

OIL FILTER MOUNT………………………………………………………….. 96

OIL FILTER……………………………………………………………….. 97

FUEL SYSTEM CHART…………………………………………………………. 99

FUEL INJECTION PUMP………………………………………………………..102

BOOST COMPENSATOR………………………………………………………….106

FUEL INJECTION NOZZLE………………………………………………………108

FUEL FILTER……………………………………………………………….109

FUEL CUT SOLENOID………………………………………………………….112

COOLING SYSTEM CHART……………………………………………………….113

WATER PUMP………………………………………………………………..114

FAN DRIVE AND THERMOSTAT……………………………………………………116

STARTING AND CHARGING SYSTEM ELECTRICAL CIRCUIT DIAGRAM………………………..120

ALTERNATOR………………………………………………………………..123

STARTING MOTOR…………………………………………………………….124

ENGINE STARTING DEVICE……………………………………………………..125

12 TESTING AND ADJUSTING……………………………………………………….127

ADJUSTING VALVE CLEARANCE…………………………………………………..128

MEASURING COMPRESSION PRESSURE………………………………………………130

ADJUSTING FUEL INJECTION PRESSURE (CRACKING PRESSURE)………………………….131

TESTING AND ADJUSTING FUEL INJECTION TIMING…………………………………..132

ADJUSTING FUEL CUT SOLENOID…………………………………………………136

FUEL INJECTION PUMP CALIBRATION DATA…………………………………………140

PERFORMANCE TEST…………………………………………………………..144

PERFORMANCE TEST CRITERIA…………………………………………………..146

TROUBLESHOOTING……………………………………………………………149

METHOD OF USING TROUBLESHOOTING CHARTS……………………………………150

POINTS TO REMEMBER WHEN TROUBLESHOOTING…………………………………..154

S-1 Starting performance is poor (starting always takes time)……………….155

S-2 Engine does not start……………………………………………….156

S-3 Engine does not pick up smoothly (follow-up is poor)……………………159

S-4 Engine stops during operations……………………………………….160

S-5 Engine does not rotate smoothly (hunting)……………………………..161

S-6 Engine lacks output (no power)……………………………………….162

S-7 Exhaust smoke is black (incomplete combustion)…………………………163

S-8 Oil consumption is excessive or exhaust smoke is blue…………………..164

S-9 Oil becomes contaminated quickly……………………………………..165

S-10 Fuel consumption is excessive……………………………………….166

S-11 Oil is in cooling water, or water spurts back, or water level goes down….167

S-12 Oil pressure caution lamp lights up (drop in oil pressure)……………..168

S-13 Oil level rises (water, fuel in oil)…………………………………169

S-14 Water temperature becomes too high (overheating)………………………170

S-15 Abnormal noise is made……………………………………………..171

S-16 Vibration is excessive……………………………………………..172

TESTING AND ADJUSTING TOOL LIST………………………………………….173

TESTING AND ADJUSTING DATA………………………………………………174

13 DISASSEMBLY AND ASSEMBLY…………………………………………………….177

SPECIAL TOOL LIST………………………………………………………….178

OVERALL DISASSEMBLY, ASSEMBLY……………………………………………….179

DISASSEMBLY……………………………………………………………….180

ASSEMBLY………………………………………………………………….192

15 REPAIR AND REPLACEMENT OF PARTS………………………………………………209

GRINDING CYLINDER HEAD MOUNTING SURFACE………………………………………210

REPLACING VALVE GUIDE………………………………………………………211

GRINDING VALVE…………………………………………………………….212

REPLACING CAMSHAFT BUSHING………………………………………………….213

REPLACING CRANKSHAFT GEAR…………………………………………………..215

REPLACING CAM GEAR…………………………………………………………216

REPLACING FLYWHEEL RING GEAR………………………………………………..217

PROCEDURE FOR PRESSURE TEST…………………………………………………218

CYLINDER LINER (SPECIAL RESTORATION PART)…………………………………….219

MACHINING DRAWING FOR CYLINDER BLOCK BORE…………………………………….220

ADDITIONAL MACHINING OF CAM JOURNAL………………………………………….221

GRINDING CRANKSHAFT………………………………………………………..222

REPLACING CONNECTING ROD SMALL END BUSHING……………………………………223