$38

Komatsu 95 Series Diesel Engine Shop Manual SEBE61460114 – PDF DOWNLOAD

Komatsu 95 Series Diesel Engine Shop Manual SEBE61460114 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 95 Series Diesel Engine Shop Manual SEBE61460114 – PDF DOWNLOAD

Language : English

Pages : 820

Downloadable : Yes

File Type : PDF

Size: 55.8 MB

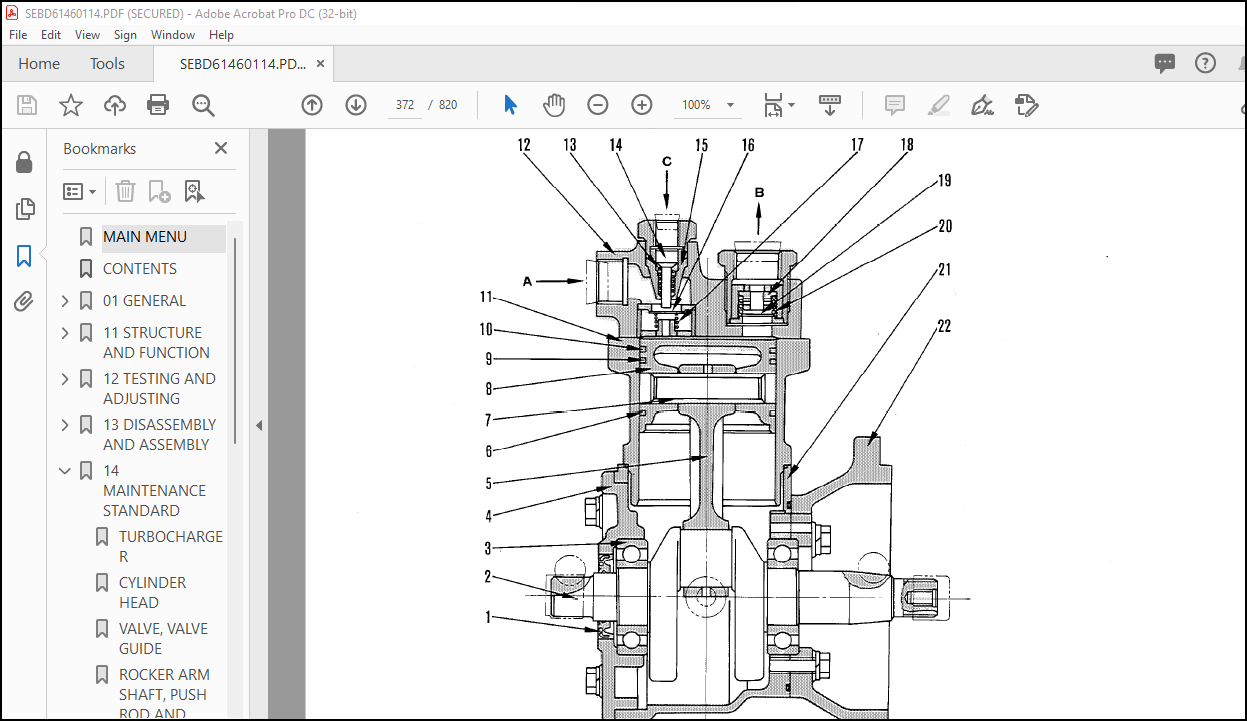

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 95 Series Diesel Engine Shop Manual SEBE61460114 – PDF DOWNLOAD

FOREWORD:

GENERAL:

- This shop manual has been prepared as an aid to improve the quality of repairs by giving the

serviceman an accurate understanding of the product and by showing him the correct way to perform

repairs and make judgements. Make sure you understand the contents of this manual and use it to full

effect at every opportunity. - This shop manual mainly contains the necessary technical information for operations performed in a

service workshop. For ease of understanding, the manual is divided into the following chapters; these

chapters are further divided into the each main group of components.

STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give

an understanding of the structure, but also serves as reference material for troubleshooting.

TESTING AND ADJUSTING

This section explains checks to be made before and after performing repairs, as well as

adjustments to be made at completion of the checks and repairs.

Troubleshooting charts correlating “Problems” to “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY

This section explains the order to be followed when removing, installing, disassembling or

assembling each component, as well as precautions to be taken for these operations.

MAINTENANCE STANDARD

This section gives the judgement standards when inspecting disassembled parts

TABLE OF CONTENTS:

Komatsu 95 Series Diesel Engine Shop Manual SEBE61460114 – PDF DOWNLOAD

MAIN MENU……………………………………………………………………………………….. 0

CONTENTS………………………………………………………………………………………… 2

01 GENERAL ……………………………………………………………………………………… 27

GENERAL VIEW ………………………………………………………………………………… 28

SPECIFICATIONS ………………………………………………………………………………. 30

GENERAL ASSEMBLY DRAWING ……………………………………………………………………… 52

ENGINE PERFORMANCE CURVE ……………………………………………………………………… 94

WEIGHT TABLE………………………………………………………………………………….154

11 STRUCTURE AND FUNCTION …………………………………………………………………………157

GENERAL STRUCTURE …………………………………………………………………………….158

INTAKE AND EXHAUST SYSTEM ……………………………………………………………………..169

INTAKE AND EXHAUST SYSTEM…………………………………………………………………..169

FTG AIR CLEANER……………………………………………………………………………185

TURBOCHARGER………………………………………………………………………………189

AFTER-COOLER………………………………………………………………………………196

ENGINE BODY…………………………………………………………………………………..198

CYLINDER HEAD……………………………………………………………………………..198

VALVE SYSTEM………………………………………………………………………………218

CYLINDER BLOCK…………………………………………………………………………….226

CYLINDER LINER…………………………………………………………………………….232

MAIN CIRCULATION SYSTEM…………………………………………………………………….234

TIMING GEAR……………………………………………………………………………….252

FLYWHEEL AND FLYWHEEL HOUSING……………………………………………………………….258

LUBRICATION SYSTEM…………………………………………………………………………….263

LUBRICATION SYSTEM CHART……………………………………………………………………263

OIL PUMP …………………………………………………………………………………269

OIL FILTER ……………………………………………………………………………….270

OIL COOLER ……………………………………………………………………………….272

FUEL SYSTEM ………………………………………………………………………………….274

FUEL SYSTEM CHART …………………………………………………………………………274

FUEL INJECTION PUMP ……………………………………………………………………….286

GOVERNOR………………………………………………………………………………….316

FEED PUMP…………………………………………………………………………………320

FUEL INJECTION NOZZLE ……………………………………………………………………..322

FUEL CUT SOLENOID …………………………………………………………………………325

ENGINE STOP MOTOR …………………………………………………………………………328

FUEL FILTER ………………………………………………………………………………333

WATER SEPARATOR …………………………………………………………………………..334

COOLING SYSTEM ……………………………………………………………………………….335

COOLING SYSTEM CHART ………………………………………………………………………335

WATER PUMP ……………………………………………………………………………….338

CORROSION RESISTOR (OPTION) ………………………………………………………………..341

THERMOSTAT AND FAN DRIVE ………………………………………………………………….342

ELECTRICAL SYSTEM……………………………………………………………………………..352

ALTERNATOR………………………………………………………………………………..352

STARTING MOTOR ……………………………………………………………………………361

ELECTRICAL INTAKE AIR HEATER ……………………………………………………………….367

ACCESSORY…………………………………………………………………………………….372

AIR COMPRESSOR…………………………………………………………………………….372

12 TESTING AND ADJUSTING…………………………………………………………………………..375

INTAKE AND EXHAUST SYSTEM………………………………………………………………………376

ADJUSTING VALVE CLEARANCE…………………………………………………………………..376

MEASURING EXHAUST GAS COLOR…………………………………………………………………378

ENGINE BODY…………………………………………………………………………………..379

MEASURING COMPRESSION PRESSURE………………………………………………………………379

MEASURING BLOW-BY PRESSURE………………………………………………………………….380

ADJUSTING ENGINE SPEED SENSOR……………………………………………………………….381

FUEL SYSTEM…………………………………………………………………………………..382

CHECKING AND ADJUSTING FUEL INJECTION TIMING………………………………………………….382

ADJUSTING GOVERNOR…………………………………………………………………………392

TESTING AND ADJUSTING FUEL CUT SOLENOID………………………………………………………395

PROCEDURE FOR ADJUSTING ENGINE STOP MOTOR CABLE……………………………………………….400

ADJUSTING FUEL INJECTION PRESSURE……………………………………………………………402

LUBRICATION SYSTEM…………………………………………………………………………….405

MEASURING OIL PRESSURE……………………………………………………………………..405

MEASURING OIL TEMPERATURE…………………………………………………………………..406

COOLING SYSTEM………………………………………………………………………………..407

MEASURING WATER TEMPERATURE…………………………………………………………………407

TESTING AND ADJUSTING FAN BELT TENSION……………………………………………………….408

FUEL INJECTION PUMP CALIBRATION DATA…………………………………………………………….409

PERFORMANCE TEST………………………………………………………………………………528

RUN-IN STANDARD……………………………………………………………………………528

PERFORMANCE TEST CRITERIA…………………………………………………………………..537

TESTING AND ADJUSTING TOOL LIST……………………………………………………………..558

TESTING AND ADJUSTING DATA………………………………………………………………….559

TROUBLESHOOTING……………………………………………………………………………….582

METHOD OF USING TROUBLESHOOTING TABLE………………………………………………………..583

POINTS TO REMEMBER WHEN TROUBLESHOOTING………………………………………………………587

S-1 Starting performance is poor (Starting always takes time) ………………………………….588

S-2 Engine does not start…………………………………………………………………..589

(1) Engine does not turn………………………………………………………………..589

(2) Engine turns but no exhaust gas comes out (Fuel is not being injected)……………………590

(3) Exhaust gas comes out but engine does not start (Fuel is being injected)………………….591

S-3 Engine does not pick up smoothly (Follow-up is poor) ………………………………………592

S-4 Engine stops during operations ………………………………………………………….593

S-5 Engine does not rotate smoothly …………………………………………………………594

S-6 Engine lacks output (no power) ………………………………………………………….595

S-7 Exhaust gas is black (incomplete combustion) ……………………………………………..596

S-8 Oil consumption is excessive (or exhaust gas is blue)………………………………………597

S-9 Oil becomes contaminated quickly ………………………………………………………..598

S-10 Fuel consumption is excessive ………………………………………………………….599

S-11 Oil is in cooling water, or water spurts back, or water level ……………………………..600

S-12 Oil pressure lamp lights up (drop in oil pressure) ……………………………………….601

S-13 Oil level rises……………………………………………………………………….602

S-14 Water temperature becomes too high (overheating) …………………………………………603

S-15 Abnormal noise is made…………………………………………………………………604

S-16 Vibration is excessive…………………………………………………………………605

S-17 Diagnosis of electronical governor by diagnosis display (electronical governor made by ZEXEL)….606

13 DISASSEMBLY AND ASSEMBLY………………………………………………………………………..622

3D95S-W-1…………………………………………………………………………………….623

GENERAL DISASSEMBLY………………………………………………………………………..624

GENERAL ASSEMBLY ………………………………………………………………………….631

4D95S-1………………………………………………………………………………………644

GENERAL DISASSEMBLY………………………………………………………………………..645

GENERAL ASSEMBLY ………………………………………………………………………….655

4D95L SERIES………………………………………………………………………………….671

GENERAL DISASSEMBLY………………………………………………………………………..671

GENERAL ASSEMBLY…………………………………………………………………………..685

6D95L SERIES………………………………………………………………………………….707

GENERAL DISASSEMBLY………………………………………………………………………..707

GENERAL ASSEMBLY…………………………………………………………………………..721

DISASSEMBLY AND ASSEMBLY OF AIR COMPRESSOR……………………………………………………….745

14 MAINTENANCE STANDARD …………………………………………………………………………..752

TURBOCHARGER …………………………………………………………………………………753

CYLINDER HEAD ………………………………………………………………………………..756

VALVE, VALVE GUIDE…………………………………………………………………………….761

ROCKER ARM SHAFT, PUSH ROD AND TAPPET……………………………………………………………764

CYLINDER BLOCK ……………………………………………………………………………….765

CRANKSHAFT …………………………………………………………………………………..767

CAMSHAFT …………………………………………………………………………………….771

TIMING GEAR (HELICAL GEAR) …………………………………………………………………….777

FLYWHEEL AND FLYWHEEL HOUSING ………………………………………………………………….782

PISTON, PISTON RING AND PISTON PIN………………………………………………………………783

CONNECTING ROD ……………………………………………………………………………….792

OIL PUMP …………………………………………………………………………………….793

REGULATOR VALVE ………………………………………………………………………………795

WATER PUMP, THERMOSTAT ………………………………………………………………………..796

FUEL SYSTEM ………………………………………………………………………………….799

15 REPAIR AND REPLACEMENT …………………………………………………………………………802

CYLINDER HEAD SECTION………………………………………………………………………….804

GRINDING CYLINDER HEAD MOUNTING SURFACE ……………………………………………………804

REPLACING VALVE SEAT INSERT…………………………………………………………………805

REPLACING VALVE GUIDE ……………………………………………………………………..809

GRINDING VALVE ……………………………………………………………………………810

CYLINDER BLOCK SECTION…………………………………………………………………………811

REPLACING CAM BUSHING ……………………………………………………………………..811

REPLACING GEARS……………………………………………………………………………813

PROCEDURE FOR PRESSURE TEST ………………………………………………………………..815

CYLINDER LINER (SPECIAL RESTORATION PART) ……………………………………………………816

MACHINING DRAWING FOR CYLINDER BLOCK BORE ……………………………………………………817

ADDITIONAL MACHINING OF CAM JOURNAL …………………………………………………………818

GRINDING CRANKSHAFT ……………………………………………………………………….819